2105

Russian prosthetic fingers by using 3D-printing

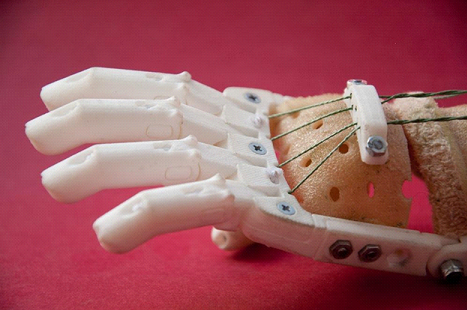

In Russia is very serious problem - the lack of functional prosthetic fingers. There are solutions available dysfunctional and are purely cosmetic. But nearly a year ago, a team of Can-Touch.ru (specialists in the field of industrial 3D-print) inspired the idea of creating a functional prosthesis child. It soon joined the project engineers WEAS Robotics (experts in the field of robotics), and began serious work.

Under the cut story about how to develop the prosthesis. Here is the text written in the first person directly to the members of the project team.

The first patient

Our first patient - Alexander, a resident of the city of Yaroslavl. As a result of the accident he lost the fingers on both hands, but the wrist retain full functionality.

A detailed report is created, this prosthesis, you can read the article Denture brush using 3D-printing: our way from idea to realization . It was difficult, but interesting, and the first time not all turned out, his prosthesis still needs work.

Girl Oksana

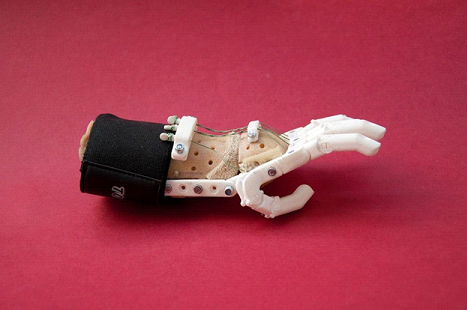

The second patient - little girl Oksana. The basis of the version of the prosthesis for her lying model, fully established designers and project designers.

It is worth noting that the fitting has identified design flaws, but also showed some of the decisions have been successful. Now Oksana already mastered a second, improved modification of the prosthesis.

And here's a video with the installation of our third decade-prosthesis Daniel from Saratov.

How it all went

Here is a video inspired the project team to create a prosthesis. South African cabinetmaker Richard Van Ace developed a mechanical prosthesis with functioning fingers, which can be printed on the 3D-printer. Van Ac free dentures already produced several children.

This theme is very interested in them and wanted to do something good and useful. The children began to look for information about this practice in Russia and unfortunately found nothing. Perhaps we just could not find anything, but maybe we did it no one does.

The design of the prosthesis, and installation technology

Dentures are made using 3D-printing, working on industrial 3D-printers. These printers can print high precision, which guarantees high quality products. Another of the major advantages of 3D-printing is that you can do absolutely individual product size, shape and design, and makes it indispensable in prosthetics.

Denture work (carried tong) due to bending of the wrist joint. It compensates for the absence of the child fingers and allows for a more fulfilling life.

Fabrication and installation of the prosthesis is as follows:

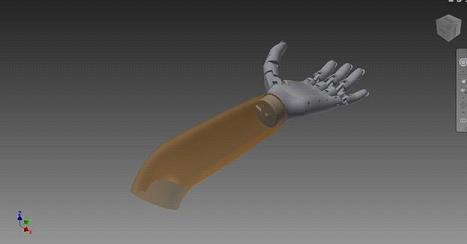

1. First, you must remove the hand size of the child, further refine the model and send to print.

2. Details of the prosthesis are printed on 3D-printer technology from SLS biologically neutral plastics - polyamide (PA2200)

3. Next, the prosthesis is going to a special thermoplastic which softens at a temperature of 80 degrees, cools and forms the framework of the prosthesis on the right hand.

4. After assembly can only adjust the tension of the pull rope and you can begin to familiarization of the prosthesis, which, of course, takes time.

The whole process of installing the prosthesis (from model preparation before training) takes 5-6 days.

We should also mention another feature of the project at the current stage. Development of the construction and design of the prosthesis is done remotely by different team members. In this regard, we have been searching for the possibility of joint project management in the cloud, and after meeting with representatives of Autodesk, they offered a solution. We have partnered with the company on the program CleanTech, and we were provided with multiple licenses software package Product Design Suite . The main advantage of collaboration with Autodesk for us is a very handy remote work all the team members who use a variety of software solutions (Inventor, 3ds Max, AutoCAD, etc.). The integration is carried out with the help of the program Autodesk Vault, which significantly reduces the time for the exchange of information within the team.

Support Project

An important task for the successful implementation of the project is to find serious partners both in Russia and abroad. To date, the partners of the company are: Institute of Prosthetics them. GA Albrecht (St. Petersburg), a business incubator "Ingria" (St. Petersburg), a design agency Organica (Moscow, British Higher School of Design), a network of international centers for social innovation ImpactHub.

Current challenges and look forward

As noted above, we still have some flaws in the design. Here's the basic problem to be solved:

1. Development of a new mechanism to return the brush default position after folding.

2. Finding the optimal position of the thumb for the most convenient and functional gripper.

3. We need to do more convenient mounting and adjustment of the tension of cables.

Next will be printed 5-6 prostheses for testing (each of these prostheses will be set to a single patient), the results of which will be set up pre-market sample, which is to certification (the main requirement - must work prosthesis 1 million. Cycles).

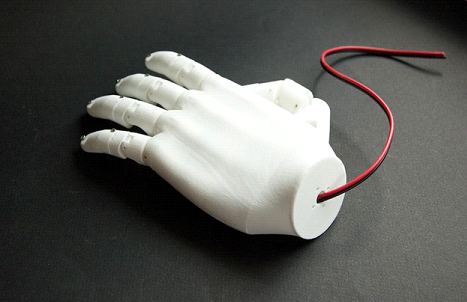

As we started to develop electromechanical prosthesis and have already made the first prototype. Who checks the entire collection on the electromechanical circuit and the first tests in conjunction with myo-datchitkami.

In general, the project development plan for the coming year is as follows:

1. Finalize the design of mechanical prosthetic fingers.

2. Finalization of the electromechanical prosthesis.

3. Certification and market mechanical prosthetic fingers.

4. Certification and marketing of electromechanical prosthesis.

5. Development of a prototype of shoulder exoskeleton for people with the disease arthrogryposis and demonstration prototype at an international conference in Moscow.

We are open to cooperation

We welcome any advice, suggestions, information, the right contacts, as well as the dissemination of the ideas and repost. Joint efforts have managed to produce three samples. Pave a path to the future, where many children and adults can get a similar prosthesis at affordable prices, compared to what we have now. Minded, invite you to dialogue and interaction. Leave your comments to the post, write messages on the mail info@can-touch.ru. We will be glad everyone responded!

Source: habrahabr.ru/company/autodesk/blog/229297/