1755

3D-printer - in every home

Hello, Giktayms! B> There's probably every second already have a 3D-printer, but still ... Today we want to talk a bit about one of the characters of the decade. Today, 3D-printer is no longer a trend and not a fashion, but it is a tools for creating prototypes, finished products, models and all kinds of spare parts, including parts for protein forms of life :) in the news every now and then they say that three-dimensional printer, then print out the prosthesis, the model of the skull, a piece of the beak, the dog paws repaired - the technology develops, and medical laboratories slowly master print living cells to recreate the internal organs.

Educational program

For those who should not be at home 3D-printer (or even two), probably should explain what we have achieved technology in recent years. Themselves ways to generate three-dimensional object in a fully or nearly fully automatic mode is not much. Actually, only two basic approaches: to take any amount of material and to "remove all superfluous" (ie, the material will go to waste, and not the fact that they can be recycled and reused) or take and "ramp up" some "personal "to the point that we need to: mold, glue type layers and immediately make the necessary form the subject of a viscous polymer layers and" learn by heart "it in any way.

Actually, the first method (subtracting material "extra") in the industry known for a long time: the apex of technology in this field is a multi-axis turning and CNC milling machine. Stands as a wing of the aircraft, takes place about the same, requires huge amounts of energy and expensive tools, but in the end allows you to create unique pieces in the form of a monolithic structures:

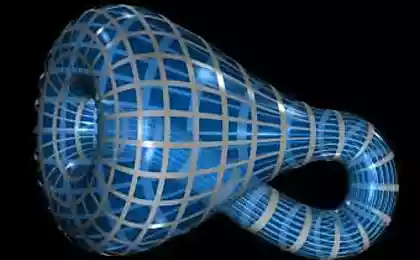

Unfortunately, even though these machines are capable of and very, very many things, they are not omnipotent. Write a hollow sphere, cube or dodecahedron without a seam or hole "subtracting" excess will not work.

It was then, and come to the aid of the second method, or rather - one of its subspecies. Three-dimensional printing.

Methods of 3D-printing

Print material "layers" can be carried out in completely different ways. The most popular and well-known methods: melting powder raw laser in the right places for contour layers (DLS / SLS), the use of photopolymer curing it with a laser or other sources of UV radiation using a photo-mask (LSA), direct printing molten polymer.

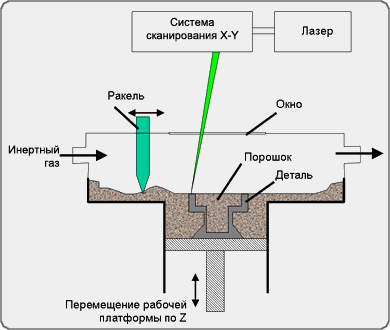

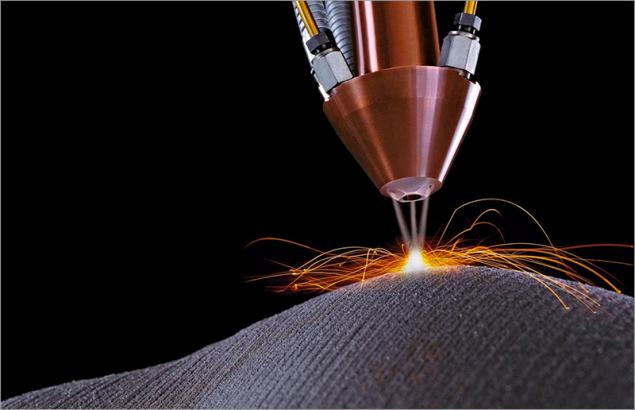

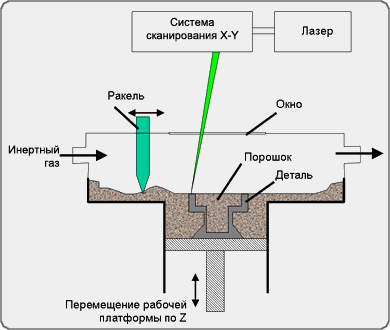

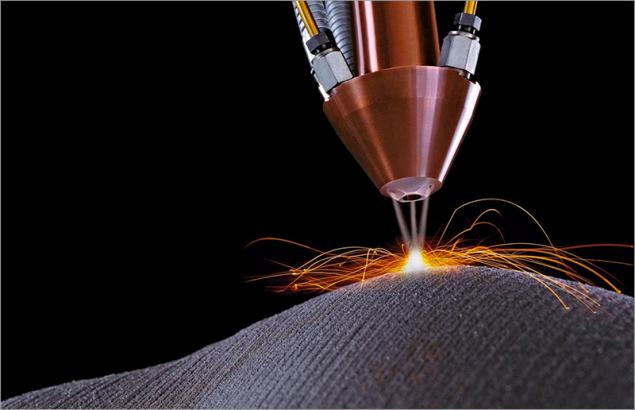

Direct laser sintering

Laser sintering - a great way to get the details of materials which can not be fed in liquid form and rapidly cooled, while spending a reasonable amount of energy. Powdered ceramics, metal, plastic quickly and dot laser heated to a high temperature, and then instantly "stick" to the available layer quickly and give the resulting thermal energy almost immediately back to "the solid one" state.

This technology allows you to make one of the most accurate and durable components, apply advanced space materials and work with an accuracy of ~ coincides with the applied granules. Cons is, where do without them. The price of the printer - one of them. Furthermore, there is an alternative printing system combining powder supply approximately the same manner as in the "classical» 3D-printers and instantaneous "fusing" of particles existing on the model. It has its pluses, minuses but derive directly from the construction of the "Printhead».

Design of complex forms require any printing supports and struts, or cunning positioning model. Theoretically, to save the situation could sliding table with a large number of degrees of freedom and axes, allowing the model to turn to the desired angle and continue printing "vertically", but in practice this has some problems, both financial and overall. In general, the technique is not for the home. Yet.

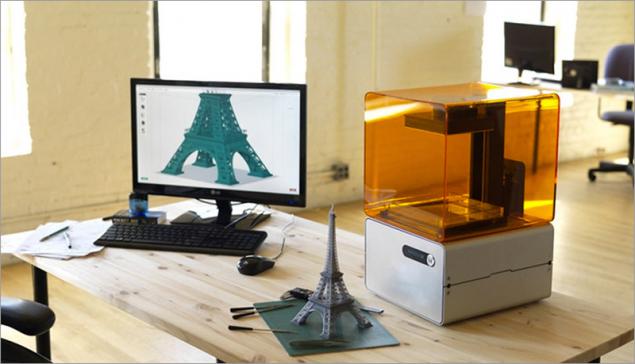

Stereolithography

Stereolithography is also often uses a laser, but it works on a different principle. Some chemical compounds (photopolymer) may be in the liquid or viscous state until they are exposed by light of the desired wavelength. After that, the structure of the polymer occur almost irreversible changes, and the point at which was the "correct" light polymer solidifies. Thus, step by step, the model "appears" in a special bath solution. The process is somewhat similar to crystal growth, that's only for the growth in the right direction or sfokussirovanny meet at one point a laser beam projected through a special mask image of the new layer.

Theoretically, stereolithography is the most accurate method of three-dimensional objects creation: a similar technique is used to create microprocessors, and minimum values obtained are measured in nanometers structure hard. Unfortunately, this accuracy is at home at the moment unattainable (and do not need. By and large), but the tens to hundreds of micrometers are very real.

Everything from stereolithography well, except for one sad fact: in the choice of material you are limited to photopolymer and various resins. They are different in strength characteristics, but almost always inferior to the strength of metals and ceramics. Another unpleasant thing is the price of the printer itself: a powerful laser or UV projector are never cheap. The main application of these printers - print high-precision samples for the jewelry industry for manufacturing them forms and subsequent melting of finished products.

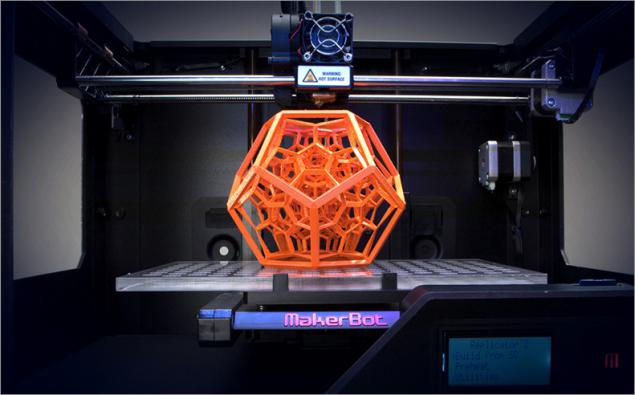

The "classic" three-dimensional printing

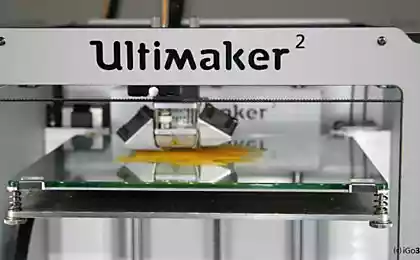

Third, the most popular and well-known method - direct printing layered molten plastic. This format printers - a great variety of different sizes, designs, one, two, three printheads.

Different printers such as accuracy, and capability, but most importantly - they made a big "revolution" in the popularization of the phenomenon of amateur 3D-printing: hardware simplicity, high competition among different projects, the availability of spare parts and consumables led to that prices have fallen from a few thousand dollars to hundreds of 3-5.

Detail paint all possible types of plastics and other design features for the umpteenth time no sense: GT already has an excellent selection of materials that describe the work with fabberami (so called 3D-printer abroad).

Three-dimensional printing a dedicated hub: 3D-printers , which in addition to reviews of various models of printers and technologies are found very interesting publication as a personal experience of users and the experience of Russian production printers. Well, the news industry, of course.

For example, here here user Stas_cake shares his experience to improve the quality of three-dimensional printing. For six months of work with a homemade (or rather samosbornym) printer achieved impressive results!

Here's a little publication user 3Dgeek of raw materials for three-dimensional printing of Russian and Chinese production.

Story user Cyberon about domestic stereolithography 3D-priter.

Another publication of stereolithography, this time from the user Slavik_Kenny - it shares his experience on the use of DLP-projector as a source of UV light for curing the resin.

User MagisterLudi tells a > how to print three-dimensional metal allows you to create unique items and save a lot of money.

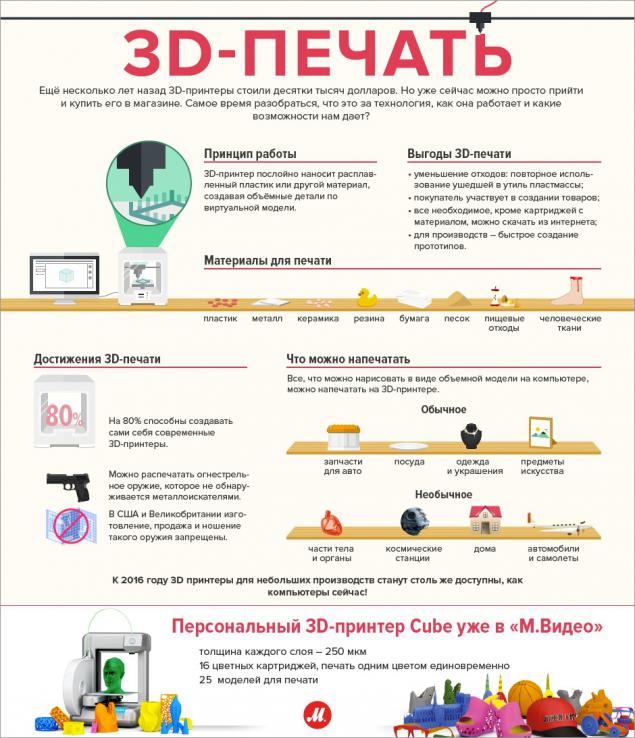

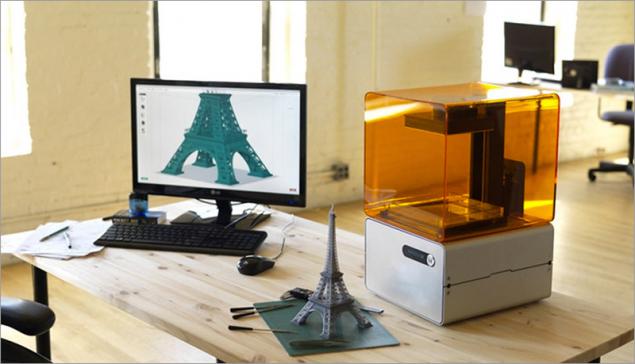

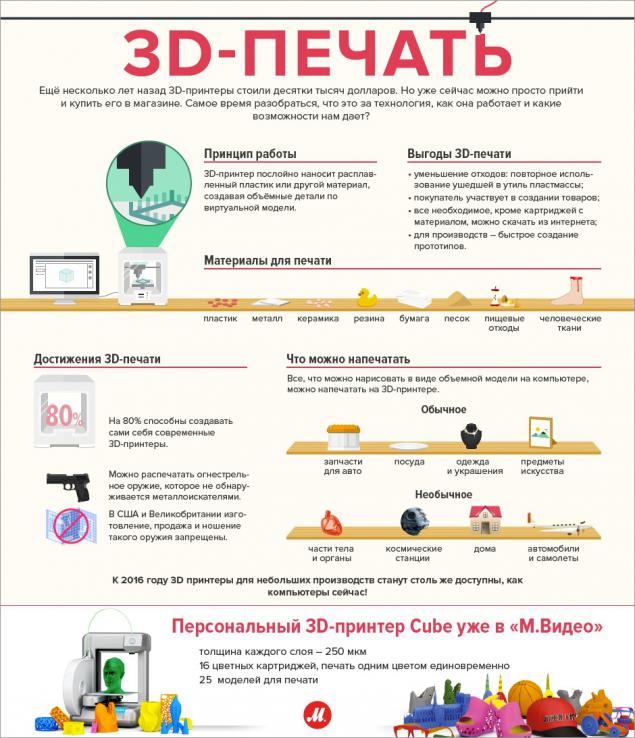

Well, if you still have not managed to convince his wife / family / boss / staff / friends that such a thing as a 3D-printer you exactly come in handy - show them this picture here. Maybe they'll come up with some interesting application fabberu for themselves, and there to buy a stone's throw!

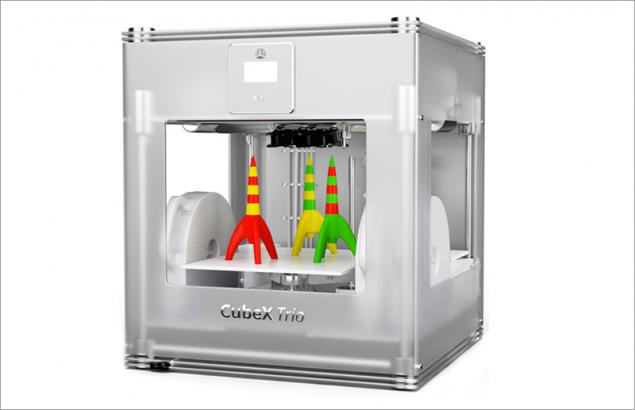

In stores M.Video продаются 3D-printer 3D Systems Cube Silver 381000 , 3D Systems CubeX 401383 and 3D Systems CubeX Trio 401385 - if you're interested, we can do a review of some of them.

Since we're on the GT and here all such advanced - do not consider the difficulty, answer a couple of questions, tell us about your experience in the three-dimensional printing, about his printer, the pros and cons - do a kind of census followers 3D printing.

Thank you for your attention Do you have access to a 3D-printer? Yes, there is a 3D-printer, the house is worth Yes, there is a 3D-printer, stands in a separate room (garage, workshop , in the country) No, but have a printer at work, I can print to it No, but others have / friend There is not at home or at work or with friends Voted 496 people. 35 people abstained. How to print? ABS-plastic PLA-plastic HIPS-plastic (polystyrene) < / Polycarbonate Plexiglass (acrylic) Nylon td > PTFE Other, specify in comments I photolithographic 3D- Printer I DLS / SLS 3D-printer Voted 88 people. Excused 282 people. My printer ... He came prepared, and (almost) directly print He came prepared, and spent a long time with the setup / calibration before printing < / He came as a kit, assembled, included works He came as a kit for assembly, the assembly had to apply for file and such a Mother He came as China for assembly, gather not work Designed and assembled my own / according to the instructions in the network Voted 70 people. Excused 290 people. 3D printer I need ... For For hobby ... and do not need he told me. Played and scored. Other, please specify in the comments Voted 288 people. 151 people abstained. Only registered users can vote in polls. Sign , please.

Source: geektimes.ru/company/mvideo/blog/246458/

Educational program

For those who should not be at home 3D-printer (or even two), probably should explain what we have achieved technology in recent years. Themselves ways to generate three-dimensional object in a fully or nearly fully automatic mode is not much. Actually, only two basic approaches: to take any amount of material and to "remove all superfluous" (ie, the material will go to waste, and not the fact that they can be recycled and reused) or take and "ramp up" some "personal "to the point that we need to: mold, glue type layers and immediately make the necessary form the subject of a viscous polymer layers and" learn by heart "it in any way.

Actually, the first method (subtracting material "extra") in the industry known for a long time: the apex of technology in this field is a multi-axis turning and CNC milling machine. Stands as a wing of the aircraft, takes place about the same, requires huge amounts of energy and expensive tools, but in the end allows you to create unique pieces in the form of a monolithic structures:

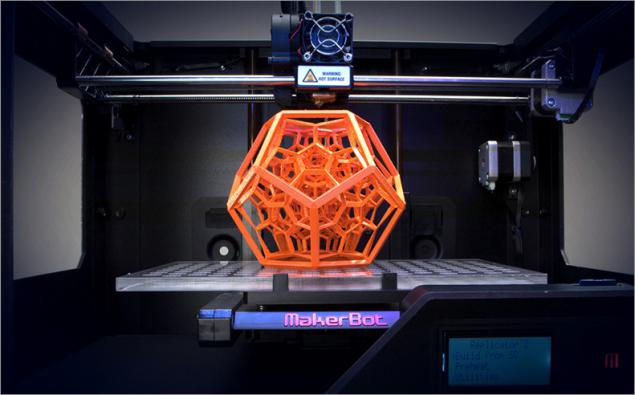

Unfortunately, even though these machines are capable of and very, very many things, they are not omnipotent. Write a hollow sphere, cube or dodecahedron without a seam or hole "subtracting" excess will not work.

It was then, and come to the aid of the second method, or rather - one of its subspecies. Three-dimensional printing.

Methods of 3D-printing

Print material "layers" can be carried out in completely different ways. The most popular and well-known methods: melting powder raw laser in the right places for contour layers (DLS / SLS), the use of photopolymer curing it with a laser or other sources of UV radiation using a photo-mask (LSA), direct printing molten polymer.

Direct laser sintering

Laser sintering - a great way to get the details of materials which can not be fed in liquid form and rapidly cooled, while spending a reasonable amount of energy. Powdered ceramics, metal, plastic quickly and dot laser heated to a high temperature, and then instantly "stick" to the available layer quickly and give the resulting thermal energy almost immediately back to "the solid one" state.

This technology allows you to make one of the most accurate and durable components, apply advanced space materials and work with an accuracy of ~ coincides with the applied granules. Cons is, where do without them. The price of the printer - one of them. Furthermore, there is an alternative printing system combining powder supply approximately the same manner as in the "classical» 3D-printers and instantaneous "fusing" of particles existing on the model. It has its pluses, minuses but derive directly from the construction of the "Printhead».

Design of complex forms require any printing supports and struts, or cunning positioning model. Theoretically, to save the situation could sliding table with a large number of degrees of freedom and axes, allowing the model to turn to the desired angle and continue printing "vertically", but in practice this has some problems, both financial and overall. In general, the technique is not for the home. Yet.

Stereolithography

Stereolithography is also often uses a laser, but it works on a different principle. Some chemical compounds (photopolymer) may be in the liquid or viscous state until they are exposed by light of the desired wavelength. After that, the structure of the polymer occur almost irreversible changes, and the point at which was the "correct" light polymer solidifies. Thus, step by step, the model "appears" in a special bath solution. The process is somewhat similar to crystal growth, that's only for the growth in the right direction or sfokussirovanny meet at one point a laser beam projected through a special mask image of the new layer.

Theoretically, stereolithography is the most accurate method of three-dimensional objects creation: a similar technique is used to create microprocessors, and minimum values obtained are measured in nanometers structure hard. Unfortunately, this accuracy is at home at the moment unattainable (and do not need. By and large), but the tens to hundreds of micrometers are very real.

Everything from stereolithography well, except for one sad fact: in the choice of material you are limited to photopolymer and various resins. They are different in strength characteristics, but almost always inferior to the strength of metals and ceramics. Another unpleasant thing is the price of the printer itself: a powerful laser or UV projector are never cheap. The main application of these printers - print high-precision samples for the jewelry industry for manufacturing them forms and subsequent melting of finished products.

The "classic" three-dimensional printing

Third, the most popular and well-known method - direct printing layered molten plastic. This format printers - a great variety of different sizes, designs, one, two, three printheads.

Different printers such as accuracy, and capability, but most importantly - they made a big "revolution" in the popularization of the phenomenon of amateur 3D-printing: hardware simplicity, high competition among different projects, the availability of spare parts and consumables led to that prices have fallen from a few thousand dollars to hundreds of 3-5.

Detail paint all possible types of plastics and other design features for the umpteenth time no sense: GT already has an excellent selection of materials that describe the work with fabberami (so called 3D-printer abroad).

Three-dimensional printing a dedicated hub: 3D-printers , which in addition to reviews of various models of printers and technologies are found very interesting publication as a personal experience of users and the experience of Russian production printers. Well, the news industry, of course.

For example, here here user Stas_cake shares his experience to improve the quality of three-dimensional printing. For six months of work with a homemade (or rather samosbornym) printer achieved impressive results!

Here's a little publication user 3Dgeek of raw materials for three-dimensional printing of Russian and Chinese production.

Story user Cyberon about domestic stereolithography 3D-priter.

Another publication of stereolithography, this time from the user Slavik_Kenny - it shares his experience on the use of DLP-projector as a source of UV light for curing the resin.

User MagisterLudi tells a > how to print three-dimensional metal allows you to create unique items and save a lot of money.

Well, if you still have not managed to convince his wife / family / boss / staff / friends that such a thing as a 3D-printer you exactly come in handy - show them this picture here. Maybe they'll come up with some interesting application fabberu for themselves, and there to buy a stone's throw!

In stores M.Video продаются 3D-printer 3D Systems Cube Silver 381000 , 3D Systems CubeX 401383 and 3D Systems CubeX Trio 401385 - if you're interested, we can do a review of some of them.

Since we're on the GT and here all such advanced - do not consider the difficulty, answer a couple of questions, tell us about your experience in the three-dimensional printing, about his printer, the pros and cons - do a kind of census followers 3D printing.

Thank you for your attention Do you have access to a 3D-printer? Yes, there is a 3D-printer, the house is worth Yes, there is a 3D-printer, stands in a separate room (garage, workshop , in the country) No, but have a printer at work, I can print to it No, but others have / friend There is not at home or at work or with friends Voted 496 people. 35 people abstained. How to print? ABS-plastic PLA-plastic HIPS-plastic (polystyrene) < / Polycarbonate Plexiglass (acrylic) Nylon td > PTFE Other, specify in comments I photolithographic 3D- Printer I DLS / SLS 3D-printer Voted 88 people. Excused 282 people. My printer ... He came prepared, and (almost) directly print He came prepared, and spent a long time with the setup / calibration before printing < / He came as a kit, assembled, included works He came as a kit for assembly, the assembly had to apply for file and such a Mother He came as China for assembly, gather not work Designed and assembled my own / according to the instructions in the network Voted 70 people. Excused 290 people. 3D printer I need ... For For hobby ... and do not need he told me. Played and scored. Other, please specify in the comments Voted 288 people. 151 people abstained. Only registered users can vote in polls. Sign , please.

Source: geektimes.ru/company/mvideo/blog/246458/

5 most accurate predictions of scientists of the past

Striiv Inc. - 5 years in the market of smart fitness gadgets 5 device in the portfolio