Introductions will not. I just think that the technology developed by people, not companies. Similarly, non-commercial companies. The most interesting among enthusiasts and geeks.

Once upon a time, when I got my first publication

«What happens when you're about to collect a 3D printer with your hands» , to me at once a flurry of emails by creating a printer and so forth. Since then I have never ceased to assemble and disassemble the printer, follow the news and try themselves in many ways. To date on my account for more than 12 projects from scratch, but only one disappointed me and pleased at the same time.

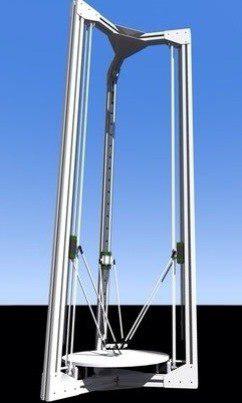

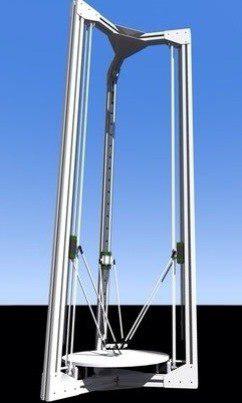

In August of 2014 in the glorious city of St. Petersburg hosted the notorious exhibition GeekPicnic, in which I participated for the second time. She modestly in the suburbs and was the highest Russian 3D printer PRISM PRO (I'm still not impressed with this title, but what to do):

About him something and will be discussed. I want to tell you how to create such machines as they are in fact, you need to do what is required of you, where to find all the details and present all the drawings and concepts, in general, to give you this printer.

I have to say. The car is more expensive home printers, whale sets and other things. But the real price still fits in a wooden 30.000.

How it all began h4> It all started as usual on the knee. Long time I look at the delta printers, they are painfully unusual, and that I should try something. That tasted. From the first time and everything was as it should.

Details printed on the printer, bought in the market square aluminum profile, on the balcony found pieces of plywood. Delov a couple of days, it is wise nothing. The machine turned out fun, great (a little more than a meter tall), but stupid.

That summer, I worked part time in the same office that dealt with the three-dimensional printing, the benefit of which in Moscow a dime a dozen. Word for word, but decided to commercialize my printer. Well, I-what? I happily agreed on, and sat down to design. And then it all started. One - to do for yourself, the other - for the consumer. A consumer is a not very burdened mind, and fears of a complicated mechanism.

In general, at the very least the project moved. Decided to be reached heights of up to five feet and increase the workspace to 40h40h100sm. The basis was taken printer Delta Tower.

The nuances of design and highlights This is more for those who have already started similar projects, but threw out of ignorance of some moments.

1. delta printers have one bad moment, they need extra space on top for height + printhead carriage;

2. The length of the "hands" (6 sticks that are connected to the printhead carriage) is equal to the diameter of the printing area;

3. bouden- tube extruder (at which the plastic is supplied) should be as short as possible (within the high friction), but does not extend into the printing area;

4. Do not use the model ball joints, they have a large backlash, use a ring magnet + steel ball;

5. Aluminum heating table when heated inevitably deformed and forms a kind of lens;

6. Do not use paired with hot surfaces inductive position sensor, it is very sensitive to temperature and will not give repeatable results.

Well, how was the foundation of ... Full lapped frame design and mechanics. The frame is assembled from aluminum machining profile 40x40mm. Used rails with carriages:

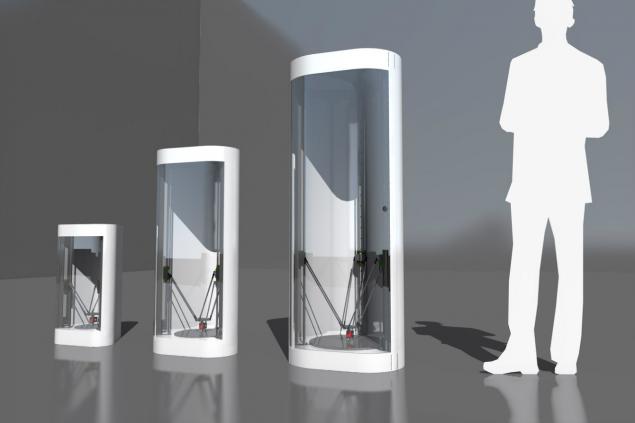

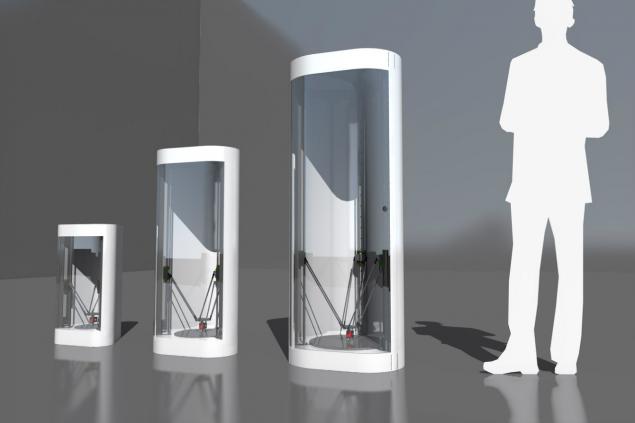

Is it that he decided to add body to close everything. The same range of several sizes, and of beauty brought.

Project part this seemed to be over. Began the painful part. Namely - search for people and organizations that can translate some parts in life. As it turned out, such a beautiful body nobody do not undertake (meaning, for the right price and terms) and had to urgently seek a solution. And it was found.

* Here I want to start to speak about concrete things and prices of these things, but I have to go back a little.

In the beginning I wrote that this printer can collect 30 thousand rubles. That's right. Someone will immediately start to brainwash about commerce, production flow, VAT and other nonsense. If you need to feed 3-4 extra mouth that just as we know, waving their hands, and one plow, then, of course, the price soars. If you want to organize the production of these machines, you give up the office, refuse advertisers, from the manager, from the boss and from the courier. There is garbage seller. Not a lot of work, you are interchangeable and do not spend too much. Not that it's a business. By the way, in the same company where I worked part time, had a lot of extra mouths to feed, which, as it turned out, I must be fed, in connection with which I finished working with them. They use my drawings and developments, engaged in the production of unfinished cars, but that's another story.

I want to warn you right away: you do not need a printer. He does not need anyone. B> A lot of smaller printers + glue will do the job faster and better (faster in proportion to the number of printers, and better, because the item the more sausage than he above).

So you threw her doubts and common sense and firmly decided that you just need such a machine (for whole printing children in full growth?).

At the root of all is a basic set of any printerostroitelya: electronics, motors, extruder.

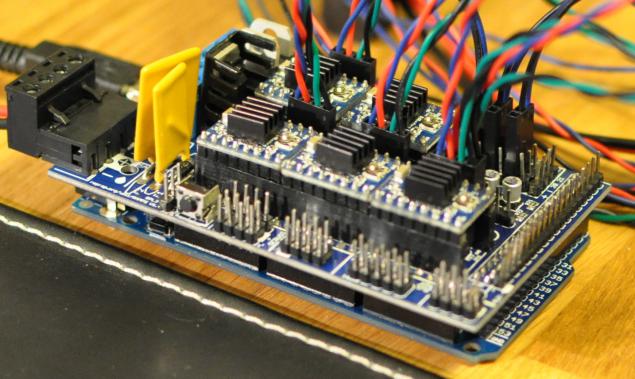

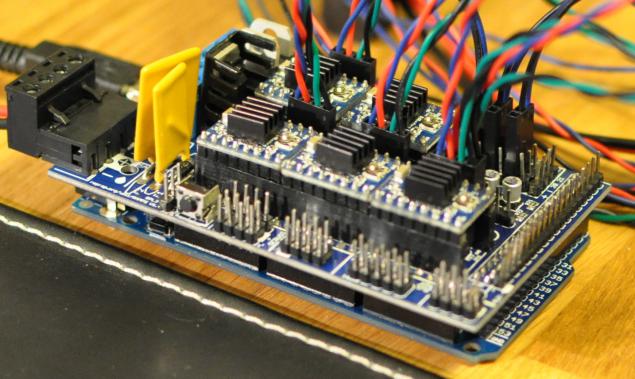

1. Electronics h4>

Everything is simple: take a cheaper price, namely RAMPS 1.4, Ali sets the screen are from 1200 rubles. We choose the cheaper. Check the packaging, there must be a Arduino Mega, he RAMPS, stepper motor driver in the number of 4-5 pieces and screen.

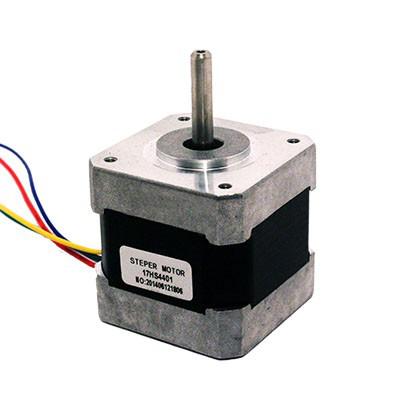

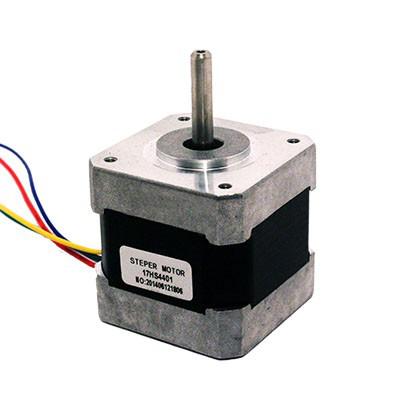

2. Motors h4>

Or rather, stepper motors. The parameters of the engine depends on many things, but there are universal options: nema 17 size, code 17HS8401. One of the most powerful in its size, but can be any other, but there is a chance not to fall in voltage in the resistance, current, and so on and so forth. For five of these engines you will be charged 2200-2600 rubles, depending on luck. (We need only 4, but if you take one, you will more than 5 pieces at once.)

3. Extruder h4>

Consists of the extruder, which pushes the plastic and heater nozzle (hotend). Motor for it already has, so look for the feed gear (and write in pioiske - extruder gear), spring-loaded for clamping rod (Chinese already being found out what and who is looking for, because of problems with the search will not be looking for springs clumsy request extruder spring ). Next, we need a tube that passes plastic fittings and collet (bowden extruder tube or something like togas in the search). For all this little thing you lay 600-700 rubles (more than a party, the cheaper way, cooperate). Next, we will find hotend. Prices are flying down and valid version can be found for 600 rubles (a couple of months ago 1500 r) or less (request e3d hotend). It is important to carefully read the description to the product. You need a 1.75 plastic, Bowden and nozzle on request (take 0.3 and 0.5 for example).

That's the whole base set with whom you are no longer lost. It cost you 4,500 rubles. And it is about the same for all printer manufacturers. Few developing its electronics and extruders, usually on the print quality is not affected, and the impact on the final price of the product.

Then we take you for special components, namely:

4. Pulleys and belts h4>

All the same, in China, we will find them. Pulleys need 3 pieces, I like T2.5 16 teeth and a suitable belt of the same size T2.5, 10 meters (actually about 7, but will not be superfluous). It has approximately 1000-1500 wood.

Now is the time to decide what to like and what you do. If you want a universal machine that will eat all kinds of plastic, you will have to fork out. I will describe this variant because it I'm going, but if you want to restrict printing PLA plastic parts that are not subject to strong (greater than 70 degrees) heat, you can save time and money. In secret , will tell you that such big cars will be given adequate print quality only PLA plastic and nothing else.

5. Heating table h4>

An important element to print all but pla plastics. My printer it 40 cm in diameter and you need the appropriate heater under it. Look silicone round heater. You need a 24 volt 400 mm in diameter and this will cost you stray 2500+ rubles.

6. Power supplies h4>

Remember, in the preceding paragraph, you have decided that you need a huge heated surface? Time to pay. Separate power supply for such a machine will cost you extra 5-6 thousand rubles, for need is none other than the power supply to 24 volts issuing 450-500 watts. Search torment from China expensive. + Relay to him (50 rubles, will go from zhiguley 12 volt). Another power supply for the rest of the electronics. 12 volts, 100 watts is enough. (Estimated 67 watts eats, but you can hang another extruder, etc.). Cost you a ridiculous 500 rubles.

7. Every little thing h4> Limit switches, wires. 500 rubles, not more.

Electrical and electro-mechanical components sorted out. Our empty pocket to 14,000 RR (or 6500, depending on the choice). It was the turn of the mechanical part. By the way, here we say goodbye to China and orient our search queries on the host country (in my case, Moscow, Russia).

8. Frame h4>

Big and strong. What else is required of her. As I said earlier, this part I totally stole constructors Delta Tower. Machine profile 40x40 + + milled corners connecting plate for connecting the converging rays. It is important to find where it is cheaper. A profile for 2000P / meter, and have over 435 (I took the soberizavod). All together will cost you 4-5 thousand (you can save on Reza, but then there are issues with accuracy).

9. Carriages and rails h4>

We need the track length of 1200 mm 3 pieces and 3 carriage under these rails. I advise to look rails for miniature devices (IMPORTANT: the width of the rail exceed the amount of the groove profile and then simply fails). You can try to search in China, we can at dealers. I took HIWIN 15HG, but it's loaded with rails for parts and they are not very easy to begin to move + heavier ones. This position is the most expensive of all. It all depends on your ability to search. The price for all of 8000.

10. Moving parts h4>

I do not know what to call it all together. In general, there is a carriage (the ones that go on the rails does not count), there is a "hands" (connect and print head carriage) and the central carriage on which is fixed hotend. Sami carriage with fastening hand strap can be printed or milled. The hands are made of durable and lightweight sticks and two ball joints (can be magnetic). Stick - carbon fiber with a diameter of 6-7mm and the price of 200p / m. It is necessary to 3 meters. Hinges I took Traxxas 12 pieces in a pack of 350 rubles, but will have to somehow compensate for their play (you can carve new balls for them or pull your hands with rubber bands / springs). Central carriage also printed or milled (depending on features). All in total will cost you 1000-3000 rubles, depending on the chosen path.

11. Holders of the motor and bearing h4>

The carriage is driven by a pulley and belt motor. It would be necessary to fix the engine. Print or milled, no difference. Same with the bearing (belt stretched between the pulley and bearing), the holder can be printed. Price 0+ p.

12. Platform for printing h4>

Good role performs aluminum sheet thickness 5+ mm. Top can be glass, for the convenience of removal. Again, keep looking. Price material is not more than 800 rubles. Heater is better to take thicker, less strain is when heated.

14. Fasteners h4>

All sorts of screws, bolts. Change in general. If the balcony is not overlooked, it is possible to allocate 200 rubles.

15. Body h4>

Important part. Determined by the needs. Selected heating table? Already spent on the powerful PSU? Will have to be spent on housing that protects against drafts and allow warm air inside, which, in theory, improves print quality ABS- plastic. In fact, large figures still will crack the layers. Housing material picked up a long time. From Plexiglas refuse immediately, aluminum road. Good choice - aluminum composite. Approximately 4000r per sheet, different colors. It's hard to find where it is not only cutting, but also vyfrezeruyut holes. Just needed him the door (there is suitable acrylic) plus cover the top, bottom and Wizard table. All together with the milling is possible to get 5-10 thousand, depending on the availability of the familiar.

Total we get 35,000 rubles for lazy scenario (if all goes well, with wholesale orders and good relations with a milling machine and other price drops to 30,000 rubles). And if you include the head and refused to universality, it is even less - 22 thousand.

What does that mean? The printer is worth a penny, and vparivayut for hundreds of thousands of rubles. Yes, yes. Production, advertising, website and more. But you forget that now the demand for such products is virtually nonexistent. You will not, and 10 orders per month. This printer is ready to collect at all during the day. But he did not need a

I read all these articles from the manufacturers, about which printer is all good, better innovation. I looked at the price estimate, how many have wound and I understand that in Russia this mess with printers for a couple of years. No innovation, no development, no reduction in price or the use of local resources. China, twist the screwdriver and - bang, "Russian product."

Everyone can create the highest printer in Russia. I just want to features were among those who are really interested , and not the sellers of windows that suddenly want to sell technology and think it's the same thing.

If you crave answers to questions, drawings, source, developments or cooperation, so please: vk.com/maxmoroz

Source: geektimes.ru/post/241848/