1280

How to operate 3D printers and 3D scanners.

Phenomena and things described in science fiction stories and novels Verne, Clarke and Asimov have firmly taken their place in our world. We are used to cell phones, talking on Skype across continents, electric vehicles, and other seemingly weird things recently. Now the little that can surprise us in the present. However, a list of the ideas embodied in the fiction is expanding day by day and sometimes something can still break the patterns of our perception.

One of these phenomena have invaded our reality are the 3D printers and 3D scanners. I was curious to know how they work, and recently I was able to get into a company that is engaged in the sale of such vehicles and manufacturing of prototypes of a 3D printer.

a lot of photos and video, as the finish will tell, please do not break

he first 3D printer was born almost 30 years ago, in 1984. It was invented by Chuck Hull, founder of the world's largest company «3D Systems» - the leader in the field of 3D printers. Since then, the technology in this area has leaped forward, and the possibility of such devices greatly enhanced. Now 3D printers can print almost anything from anything. The size of created things is limited only by the working area of printers, however, and this problem is solved - there is a special superglue, which are glued part of the future product.

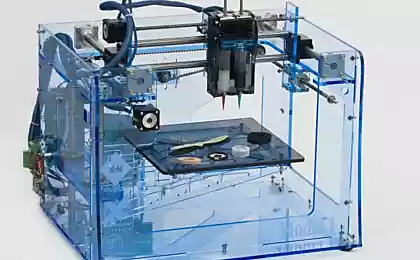

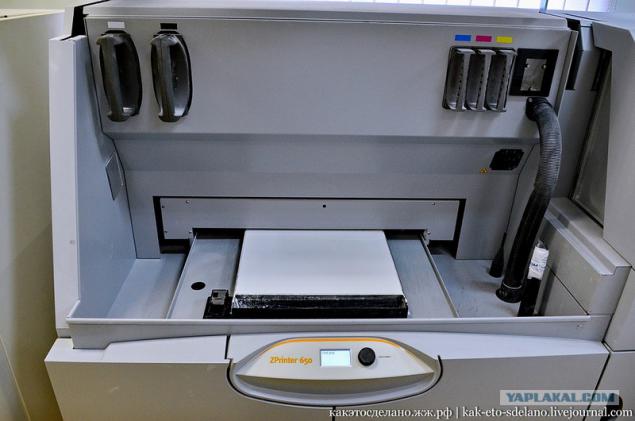

But first things first. The printer is connected to a computer that sets him the task to print with a special program prepared 3D models of the future product. This 3D printer uses to print composite material based on plaster, which allows you to print high-resolution, virtually reproducing the full palette of colors.

The principle of operation is as follows - the printer has the capacity in which a thin layer of fine powder is poured, leveled at him from the cartridge carriage rides and sprays a curing agent of different color on the desired areas. Again, a layer of powder is filled, leveled, sprayed hardener, and so many times. The layers are so thin that it can be seen under the previous ones.

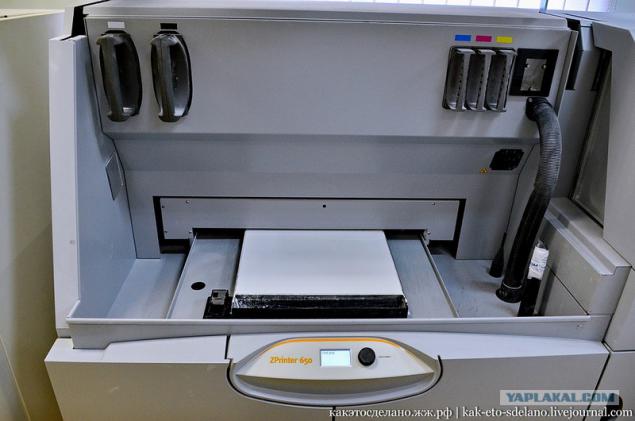

Layer by layer, the operation is repeated, and the bottom of the tank gradually goes down. To print a 3D model requires up to several hours, depending on the complexity of the product. Note: the right upper corner of the arm with color-coded, it cartridges. The three basic colors mingling get the desired color printing.

After the process, the finished model is carefully removed from the composite and placed in the booth, where with the help of air from the compressor and soft brushes are cleaned from powder.

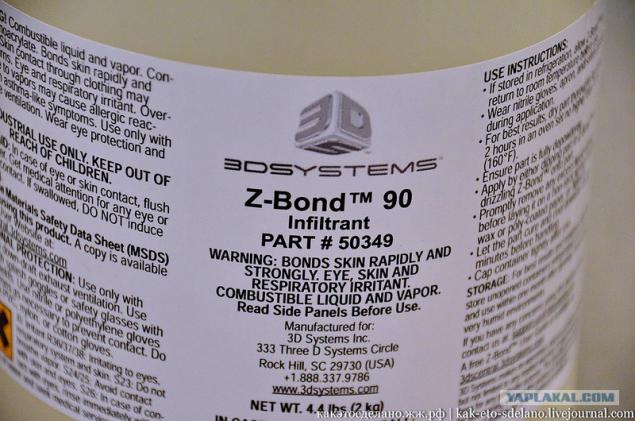

Pay attention to the bottom, all of the powder, which shook off the model is back in production, that is, it virtually waste-free. Then, immediately ready model is impregnated with special superglue because it is still fragile, and since it will still be possible to do forms, etc.

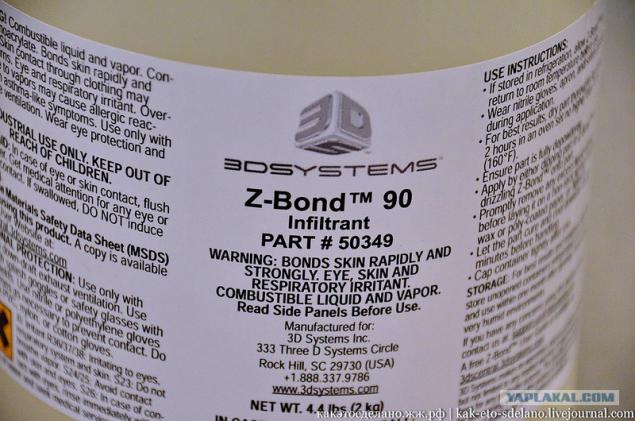

That is the very glue.

Producer is the same as that of the printer.

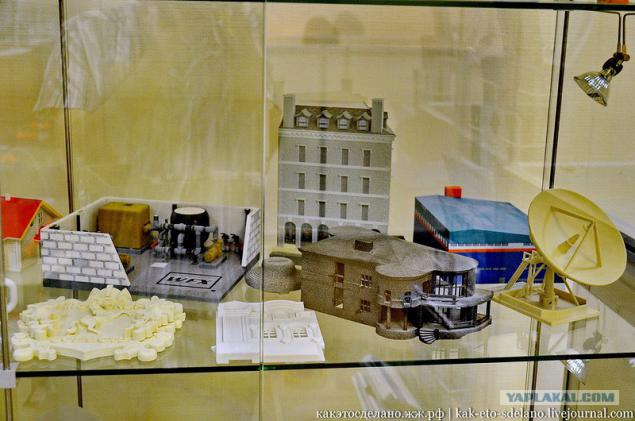

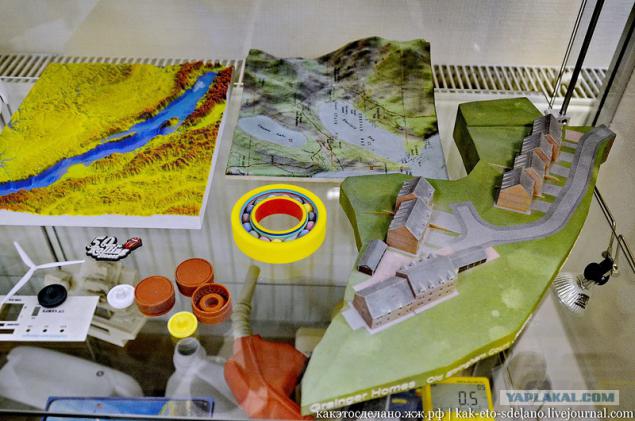

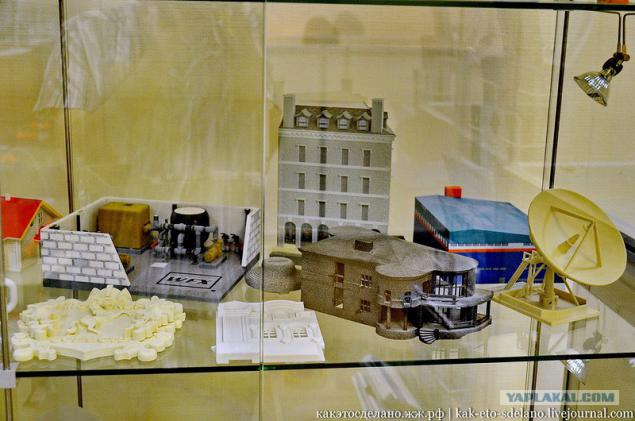

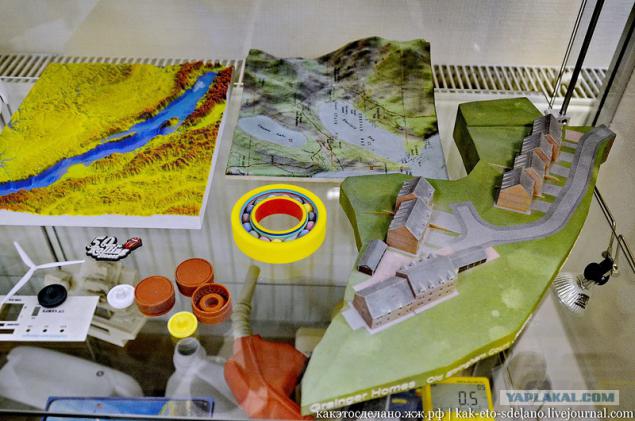

This ready-made products, the layout of the future premises of the office, made to order by a single firm.

Look at the details, but it's flowers, then we will see more small gizmos.

A little about the machine: the 3D printer was released by Z Corporation, which is now a part engulfed her company 3D Systems.

New instances are no different from this, except that the body color and a new name.

Posted in [mergetime] 1385180073 [/ mergetime]

We strongly recommend to view these videos, which shows in detail the process of printing on this machine.

Further, our story is about a different type of printer. The printer is on the left - ProJet HD 3000, works on technology MJM. It light cure resin is due to the ultraviolet flash. Molten hot acrylic photopolymer (plastic) is supplied to the printhead which causes it to print platform, where it illuminates a halogen UV lamp, after which it hardens, then the next layer, and so on.

As you probably guessed, when printing of virtually all models, there is a need to support performers, often grown hanging models and for this purpose uses a simple wax, which is applied simultaneously with the polymer, it is removed by simply heating in an oven, leaving little trace.

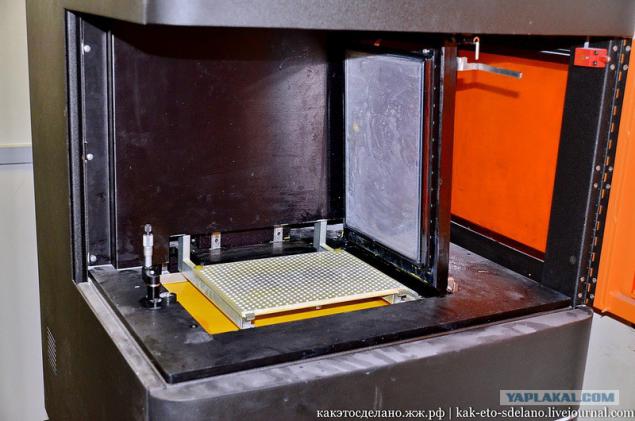

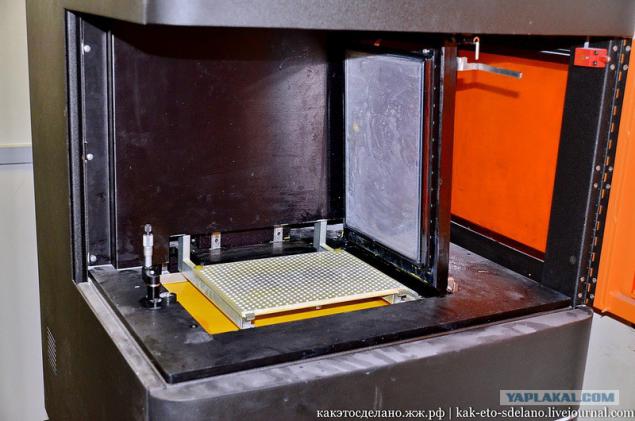

Next model printer - Ultra works on technology DLP.

If I am not mistaken in this picture, you can see the DLP projector.

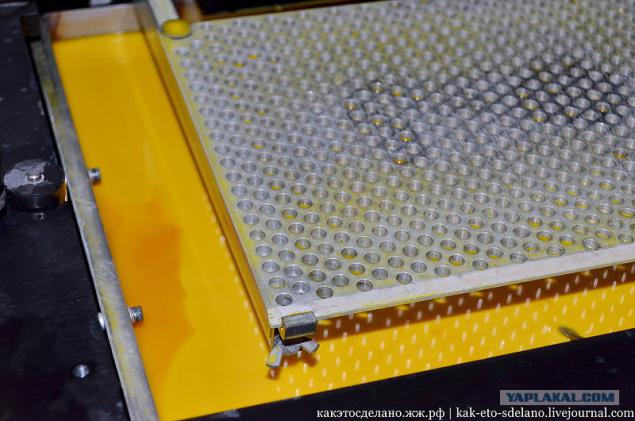

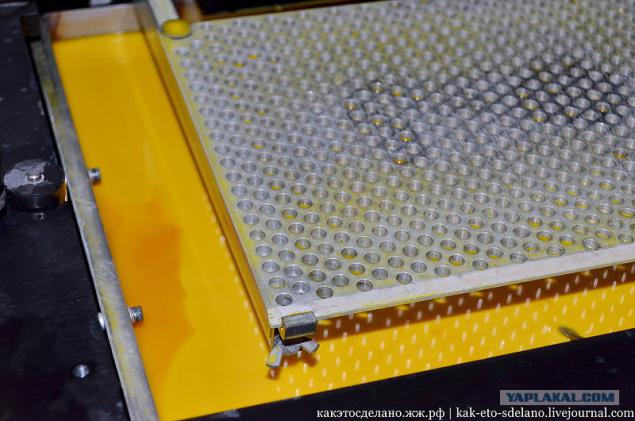

This printer has a container with a photopolymer, which is closed glass cover. On a top of the projector projects the image. The program switches the image on the projector (sections of the object) and as hardening the porous metal model platform is gradually going down. As the consumption of photopolymer is filled in a cell. During the printing process, the machine is closed in order to avoid exposure.

If the printer ProJet HD 3000 model is cured UV flash, the Ultra are making DLP projector ordinary light.

Posted in [mergetime] 1385180280 [/ mergetime]

This video explains it this printer.

In this video you can see the printer, which works on the same principle, but the illumination comes from the bottom of the polymer.

This oven, which melts the wax, which served as additional material for printing. The temperature may be visible on the display.

We'll get the tray

Finished products.

Notice how fine print.

The opaque material - wax.

From these detalek will collect car.

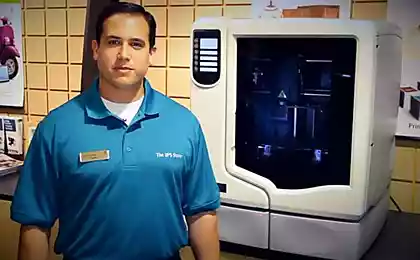

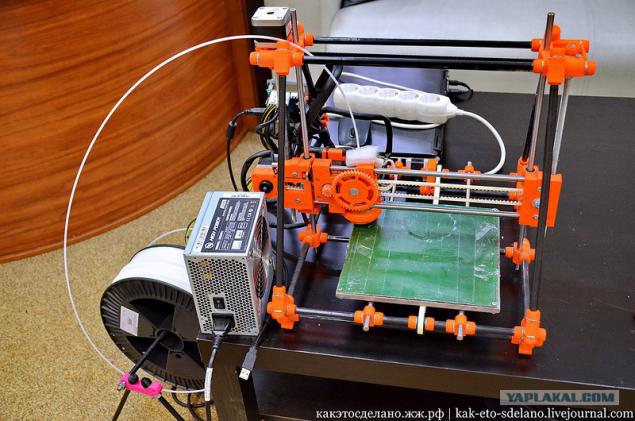

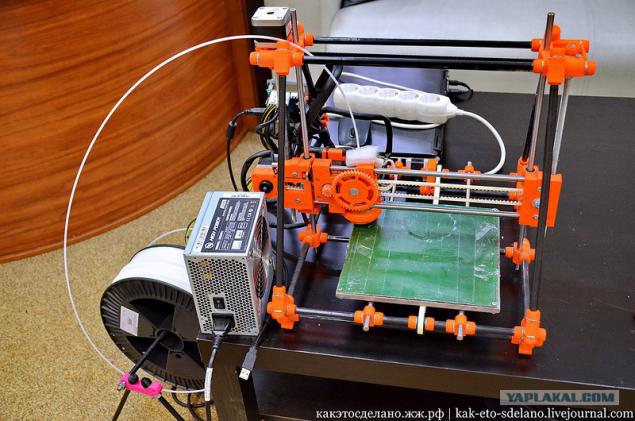

I almost forgot to tell you about the most common and affordable 3D printers, from which you can say the era of machines of the future. This printer uses plastic. Technology FDM (Fused Deposition Modeling) - layering of hot polymer thread its different types. The most popular plastic - is ABS and PLA.

ABS plastic - neproznachny shockproof thermoplastic material, is used to print most common plastic prototypes. The three-dimensional printing systems became popular thanks to its glass transition temperature - low enough for safe extrusion using standard tools, but high enough to print model is not afraid of a little heat, which may be subject to the conditions of life.

The printer does not operate on the cartridge, and from conventional plastic coils, connected to it in the form in which they are sold. Plastic thread tucked into the extruder, heated up and there printhead pushes the material on a moving platform.

This printer is known for a long time and had been replaced by other devices that can print just three types of plastic.

The next unit is a new generation of 3D printers that print on rolls of plastic. There are three variants:

- Monochrome printer CubeX

- CubeX Duo - prints two colors

- CubeX Trio with three extruders,

Here are examples of such products. They are strong enough, just do not break your hands.

In this video you can see in detail how it works this printer.

As I was told, 3D printing technology has advanced so much in recent years that suschestvut printers that can print anything from chocolate, ending with metal and sand!

Some industrial printers can use several different types of photopolymers in a single product. In fact, this is a great inkjet printer, with tens of printhead reservoir connection with different materials. During the printing process the polymer is applied to the product and immediately lights up.

In this video for example, it is seen that the printer prints as plastic and rubber.

And this video shows a unique printer works independently from the solar panels. Author of the project as a material used sand, which gained here in the desert. Instead, he used the laser beams large Fresnel lens, which is concentrating the sun to the point and melt the sand. As it poured, and the alignment device performed by the author of the project. The coordinate system of the printer and the computer, as I said earlier, powered by solar batteries. Within a few hours in the desert he did incomprehensible and damn cup.

And this printer is made of metal chips. The powder particles are sintered to each other by laser, then even during the day the tray is cooling down. However, the product brittle, sintering the metal particles gives the strength of the product, it is sufficiently porous and may break in the hands, because it again treated in a special oven, placing another tray with the other metal powder which fills the pores and make it sufficiently durable.

The next part of our story is about 3D scanners - Tools without which it would be impossible to print many products. They help to make the virtual model, which will be implemented 3D printer.

There are close-range scanners, (like this one in the photo below), medium and long range. By the way, long-range scanners are often installed on military aircraft and drones to scan the area from the air.

This 3D scanner domestic production, as I said, pretty good.

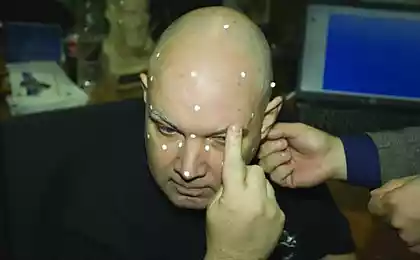

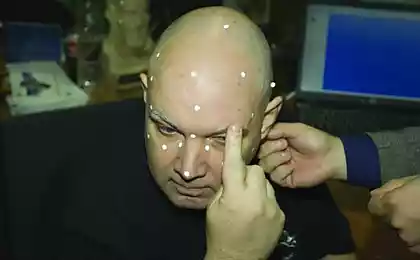

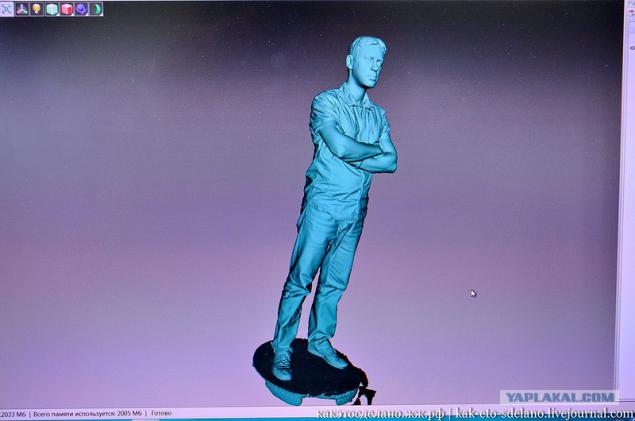

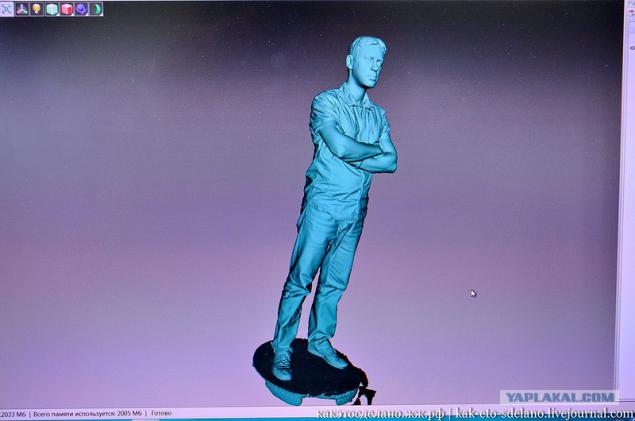

And now, as an experiment, we make a virtual model of one of the company's specialists. Connecting the scanner to your computer, turn on the software and go.

We provide a scanner over the entire height of the figures at a distance of no more than one meter away.

The podium on which stands a man at this time slowly rotate.

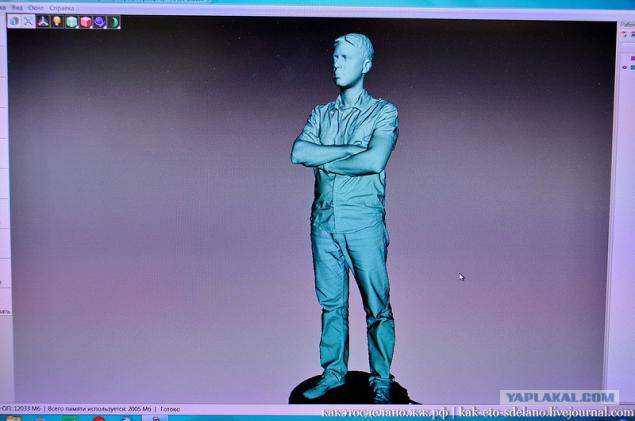

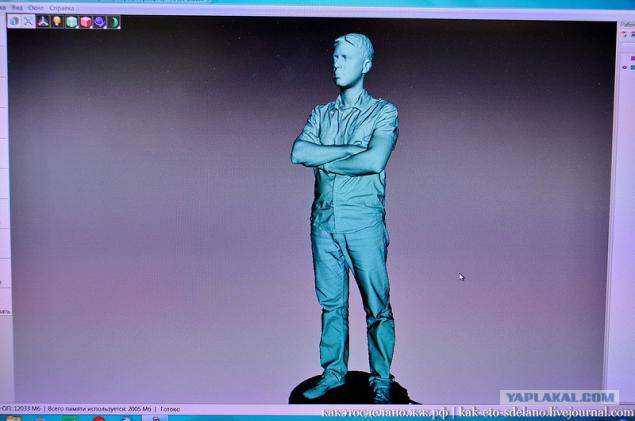

Voila and this figure of a man appeared in the computer. Almost like in the science fiction film "The Lawnmower Man."

Unnecessary items will be removed, adjusted roughness.

This is another similar scanner.

To scan an object, you must turn off the room light.

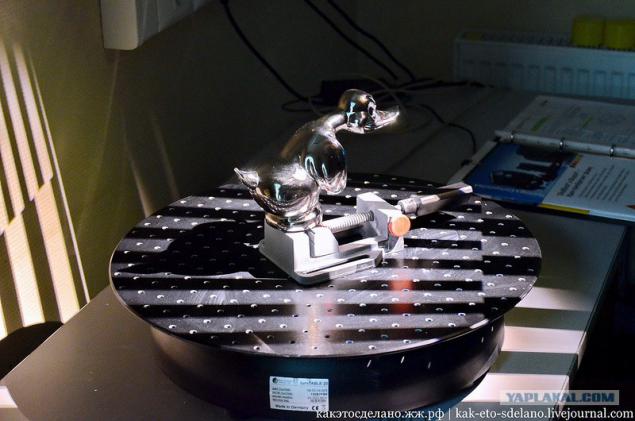

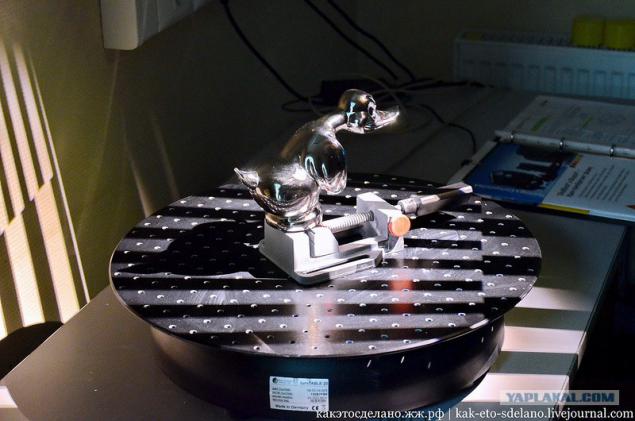

By the way, the future model should not be glossy, otherwise it will be difficult to scan. This duck has already been scanned, before she had a matte surface.

Note the multiple lenses.

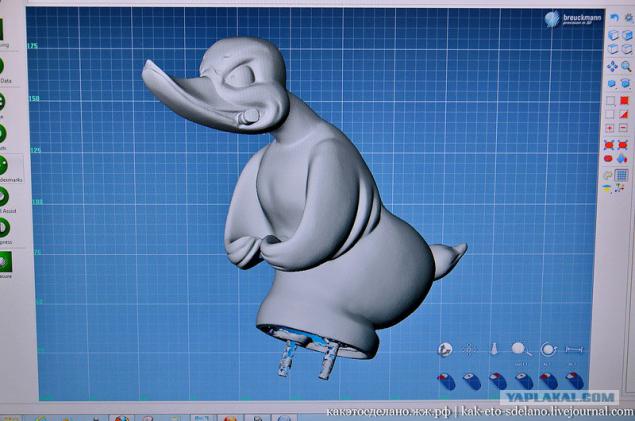

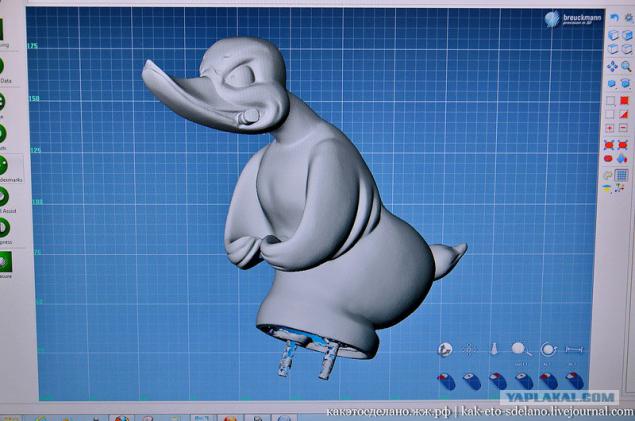

That's what happens in the end.

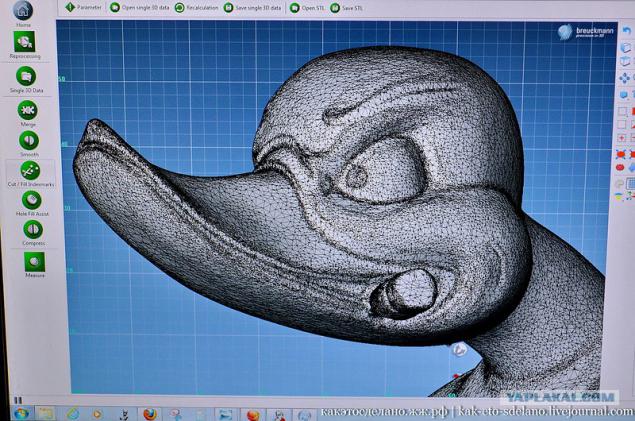

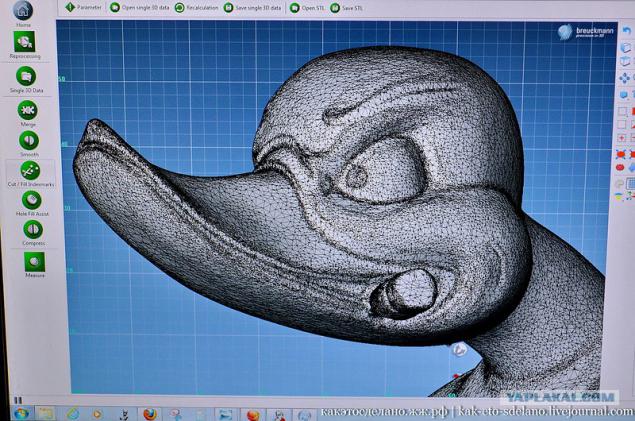

Another kind. The surface model is dotted triangles.

This 3D models of various parts of machines, made by order of tuning studio.

Atelier receive its 3D model, Doris fancy bumper or something else, then your customer will please the new bodywork.

This is our story about the technical part of the machines of the future came to an end, but not in a hurry to close the window now, you will see all the product samples, printed on different printers 3D.

That's the human figure is obtained by printing on a printer that uses the gypsum composite.

Detailing detail. I saw the figure of a man, which could see his tattoos.

The figure of the Hindu god Ganesha. Plastic.

The polymer of another type.

And the end result is that the customer made of printed prototypes.

Technical details with complex interior.

Various plastic rings. 3D printers will greatly facilitate the work of jewelers in the future.

Christ the Savior Cathedral. Model printed approximately 10 hours, the gypsum composite wall thickness is about a centimeter.

Another temple, can someone tell me the name?

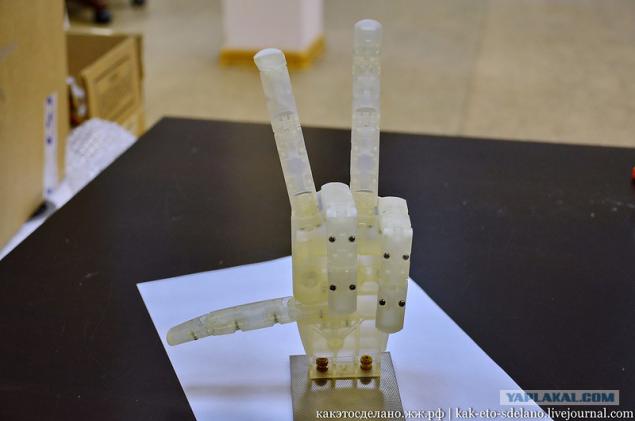

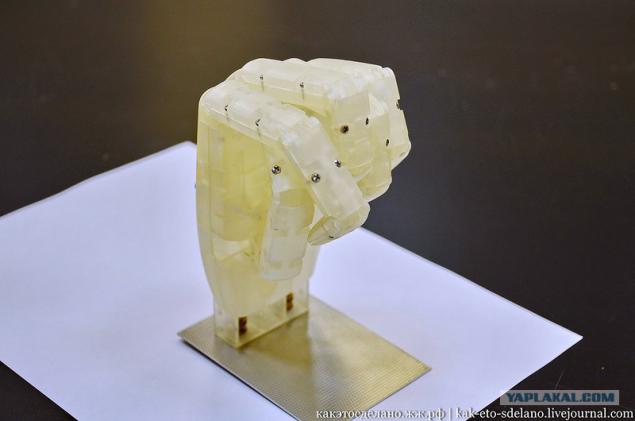

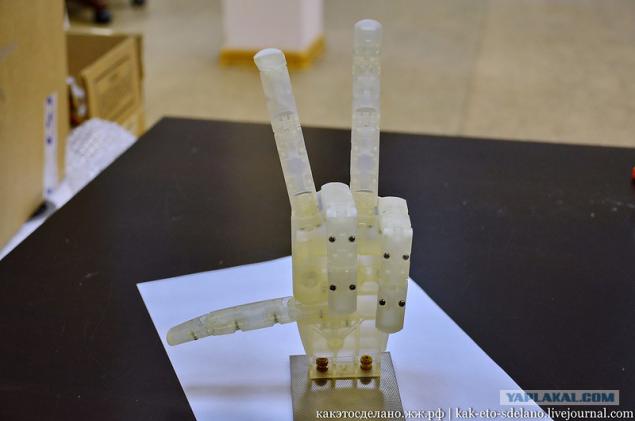

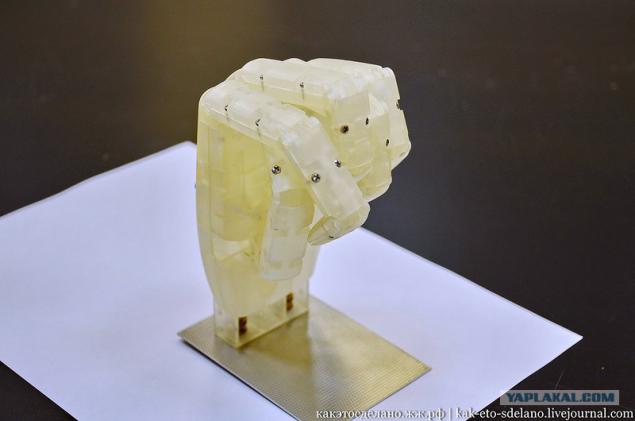

Hand cyborg plastic model.

We print all parts affixed cogs and all!

The sample was fairly active, not brittle.

In the windows of a variety of patterns printed here.

Some products can be galvanized and used in this form.

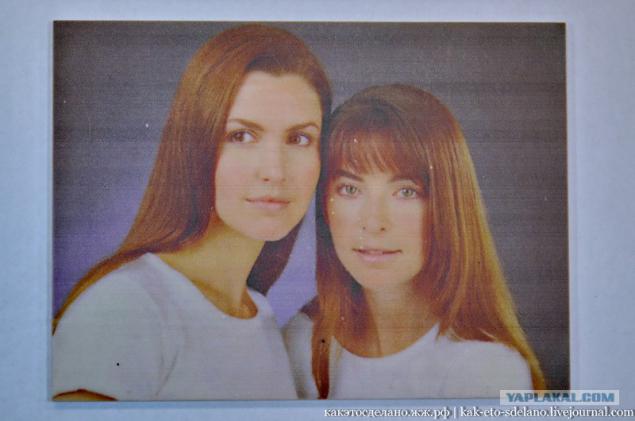

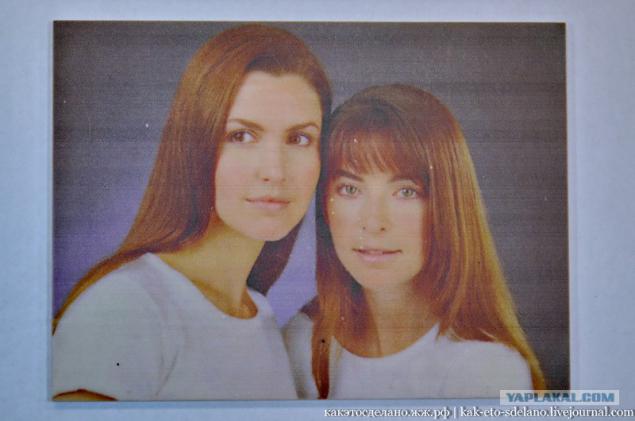

This photo is of course printed in the printer, and it is possible.

The thickness of the gypsum photos about 3-5 mm.

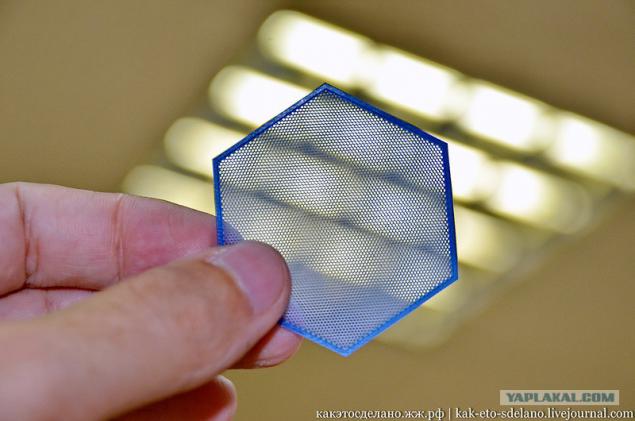

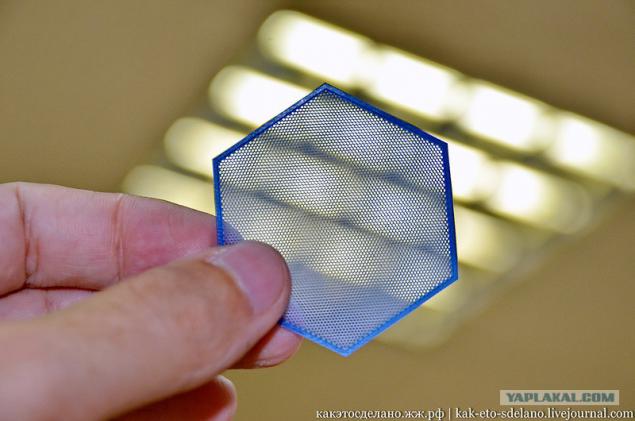

However, the thing that struck me the most here is the strainer. Look how fine a thing, just amazing.

Once again - all that is on display - made on a 3D printer

,,,

,,,

,,,

Finally, you can soon forget about the potter's wheel, with such technologies)

this vse_))

Source escogido7.livejournal.com

Source:

One of these phenomena have invaded our reality are the 3D printers and 3D scanners. I was curious to know how they work, and recently I was able to get into a company that is engaged in the sale of such vehicles and manufacturing of prototypes of a 3D printer.

a lot of photos and video, as the finish will tell, please do not break

he first 3D printer was born almost 30 years ago, in 1984. It was invented by Chuck Hull, founder of the world's largest company «3D Systems» - the leader in the field of 3D printers. Since then, the technology in this area has leaped forward, and the possibility of such devices greatly enhanced. Now 3D printers can print almost anything from anything. The size of created things is limited only by the working area of printers, however, and this problem is solved - there is a special superglue, which are glued part of the future product.

But first things first. The printer is connected to a computer that sets him the task to print with a special program prepared 3D models of the future product. This 3D printer uses to print composite material based on plaster, which allows you to print high-resolution, virtually reproducing the full palette of colors.

The principle of operation is as follows - the printer has the capacity in which a thin layer of fine powder is poured, leveled at him from the cartridge carriage rides and sprays a curing agent of different color on the desired areas. Again, a layer of powder is filled, leveled, sprayed hardener, and so many times. The layers are so thin that it can be seen under the previous ones.

Layer by layer, the operation is repeated, and the bottom of the tank gradually goes down. To print a 3D model requires up to several hours, depending on the complexity of the product. Note: the right upper corner of the arm with color-coded, it cartridges. The three basic colors mingling get the desired color printing.

After the process, the finished model is carefully removed from the composite and placed in the booth, where with the help of air from the compressor and soft brushes are cleaned from powder.

Pay attention to the bottom, all of the powder, which shook off the model is back in production, that is, it virtually waste-free. Then, immediately ready model is impregnated with special superglue because it is still fragile, and since it will still be possible to do forms, etc.

That is the very glue.

Producer is the same as that of the printer.

This ready-made products, the layout of the future premises of the office, made to order by a single firm.

Look at the details, but it's flowers, then we will see more small gizmos.

A little about the machine: the 3D printer was released by Z Corporation, which is now a part engulfed her company 3D Systems.

New instances are no different from this, except that the body color and a new name.

Posted in [mergetime] 1385180073 [/ mergetime]

We strongly recommend to view these videos, which shows in detail the process of printing on this machine.

Further, our story is about a different type of printer. The printer is on the left - ProJet HD 3000, works on technology MJM. It light cure resin is due to the ultraviolet flash. Molten hot acrylic photopolymer (plastic) is supplied to the printhead which causes it to print platform, where it illuminates a halogen UV lamp, after which it hardens, then the next layer, and so on.

As you probably guessed, when printing of virtually all models, there is a need to support performers, often grown hanging models and for this purpose uses a simple wax, which is applied simultaneously with the polymer, it is removed by simply heating in an oven, leaving little trace.

Next model printer - Ultra works on technology DLP.

If I am not mistaken in this picture, you can see the DLP projector.

This printer has a container with a photopolymer, which is closed glass cover. On a top of the projector projects the image. The program switches the image on the projector (sections of the object) and as hardening the porous metal model platform is gradually going down. As the consumption of photopolymer is filled in a cell. During the printing process, the machine is closed in order to avoid exposure.

If the printer ProJet HD 3000 model is cured UV flash, the Ultra are making DLP projector ordinary light.

Posted in [mergetime] 1385180280 [/ mergetime]

This video explains it this printer.

In this video you can see the printer, which works on the same principle, but the illumination comes from the bottom of the polymer.

This oven, which melts the wax, which served as additional material for printing. The temperature may be visible on the display.

We'll get the tray

Finished products.

Notice how fine print.

The opaque material - wax.

From these detalek will collect car.

I almost forgot to tell you about the most common and affordable 3D printers, from which you can say the era of machines of the future. This printer uses plastic. Technology FDM (Fused Deposition Modeling) - layering of hot polymer thread its different types. The most popular plastic - is ABS and PLA.

ABS plastic - neproznachny shockproof thermoplastic material, is used to print most common plastic prototypes. The three-dimensional printing systems became popular thanks to its glass transition temperature - low enough for safe extrusion using standard tools, but high enough to print model is not afraid of a little heat, which may be subject to the conditions of life.

The printer does not operate on the cartridge, and from conventional plastic coils, connected to it in the form in which they are sold. Plastic thread tucked into the extruder, heated up and there printhead pushes the material on a moving platform.

This printer is known for a long time and had been replaced by other devices that can print just three types of plastic.

The next unit is a new generation of 3D printers that print on rolls of plastic. There are three variants:

- Monochrome printer CubeX

- CubeX Duo - prints two colors

- CubeX Trio with three extruders,

Here are examples of such products. They are strong enough, just do not break your hands.

In this video you can see in detail how it works this printer.

As I was told, 3D printing technology has advanced so much in recent years that suschestvut printers that can print anything from chocolate, ending with metal and sand!

Some industrial printers can use several different types of photopolymers in a single product. In fact, this is a great inkjet printer, with tens of printhead reservoir connection with different materials. During the printing process the polymer is applied to the product and immediately lights up.

In this video for example, it is seen that the printer prints as plastic and rubber.

And this video shows a unique printer works independently from the solar panels. Author of the project as a material used sand, which gained here in the desert. Instead, he used the laser beams large Fresnel lens, which is concentrating the sun to the point and melt the sand. As it poured, and the alignment device performed by the author of the project. The coordinate system of the printer and the computer, as I said earlier, powered by solar batteries. Within a few hours in the desert he did incomprehensible and damn cup.

And this printer is made of metal chips. The powder particles are sintered to each other by laser, then even during the day the tray is cooling down. However, the product brittle, sintering the metal particles gives the strength of the product, it is sufficiently porous and may break in the hands, because it again treated in a special oven, placing another tray with the other metal powder which fills the pores and make it sufficiently durable.

The next part of our story is about 3D scanners - Tools without which it would be impossible to print many products. They help to make the virtual model, which will be implemented 3D printer.

There are close-range scanners, (like this one in the photo below), medium and long range. By the way, long-range scanners are often installed on military aircraft and drones to scan the area from the air.

This 3D scanner domestic production, as I said, pretty good.

And now, as an experiment, we make a virtual model of one of the company's specialists. Connecting the scanner to your computer, turn on the software and go.

We provide a scanner over the entire height of the figures at a distance of no more than one meter away.

The podium on which stands a man at this time slowly rotate.

Voila and this figure of a man appeared in the computer. Almost like in the science fiction film "The Lawnmower Man."

Unnecessary items will be removed, adjusted roughness.

This is another similar scanner.

To scan an object, you must turn off the room light.

By the way, the future model should not be glossy, otherwise it will be difficult to scan. This duck has already been scanned, before she had a matte surface.

Note the multiple lenses.

That's what happens in the end.

Another kind. The surface model is dotted triangles.

This 3D models of various parts of machines, made by order of tuning studio.

Atelier receive its 3D model, Doris fancy bumper or something else, then your customer will please the new bodywork.

This is our story about the technical part of the machines of the future came to an end, but not in a hurry to close the window now, you will see all the product samples, printed on different printers 3D.

That's the human figure is obtained by printing on a printer that uses the gypsum composite.

Detailing detail. I saw the figure of a man, which could see his tattoos.

The figure of the Hindu god Ganesha. Plastic.

The polymer of another type.

And the end result is that the customer made of printed prototypes.

Technical details with complex interior.

Various plastic rings. 3D printers will greatly facilitate the work of jewelers in the future.

Christ the Savior Cathedral. Model printed approximately 10 hours, the gypsum composite wall thickness is about a centimeter.

Another temple, can someone tell me the name?

Hand cyborg plastic model.

We print all parts affixed cogs and all!

The sample was fairly active, not brittle.

In the windows of a variety of patterns printed here.

Some products can be galvanized and used in this form.

This photo is of course printed in the printer, and it is possible.

The thickness of the gypsum photos about 3-5 mm.

However, the thing that struck me the most here is the strainer. Look how fine a thing, just amazing.

Once again - all that is on display - made on a 3D printer

,,,

,,,

,,,

Finally, you can soon forget about the potter's wheel, with such technologies)

this vse_))

Source escogido7.livejournal.com

Source: