2509

As I using 3d-scanner forged key, holding a skull, heart and gun

Hi Habr!

Once again, looked at the guests to the professionals in the field of 3d-3d-printing and scanning.

- Do you have something interesting?

- That's what we have!

Manual

- Wow, what else?

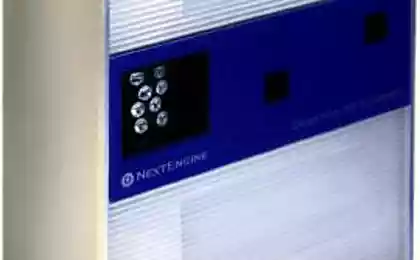

High-precision industrial optical scanner

I decided potestit stationary 3d-scanner, as with a manual, I have already played dealt .

- And they basically scan?

- Teeth and jewelry. There? Go on.

- Um ... and easier? Something closer to hacking the practical tasks required in everyday life?

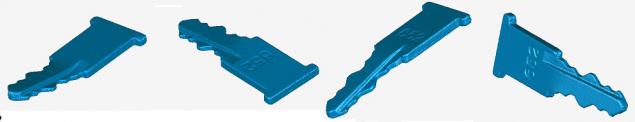

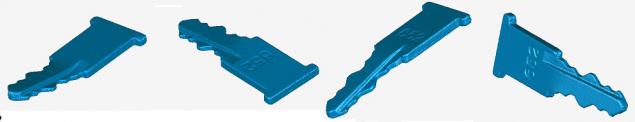

- Well, you bent the key to scan in the 3d-editor, straighten, and then either print the form for casting, either directly on the metal 3d-printer recreate.

- OK, if you just show how the process of scanning and editing, as well as metallic 3d-printer works I know, and form casting also already done.

(Warning, lots of photos)

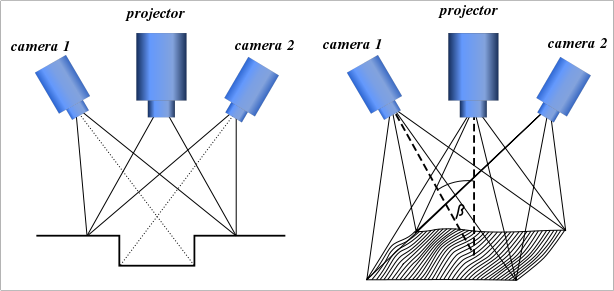

TTX scanner h4> Scanning method - phase shift optical triangulation (Phase shifting optical triangulation)

Number of cameras - 2

Volume Scanning - 80x60x60 mm

Camera resolution - 1.4 megapixel

Accuracy ± 0.01 mm

The format of the output data - STL

googled price

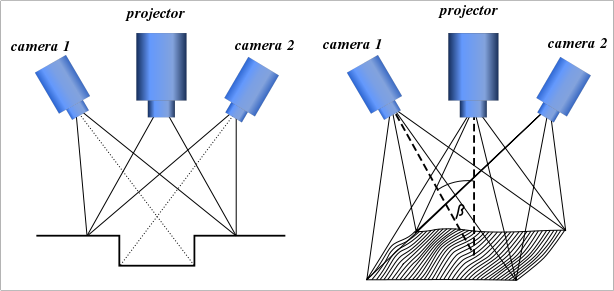

Scanning Technology h4> Patent «Phase shifting optical triangulation»

en.wikipedia.org/wiki/Structured_light

en.wikipedia.org/wiki/Structured-light_3D_scanner

The principle of creating 3d-image surface of the interference picture used in the 3d-scanner on structured light.

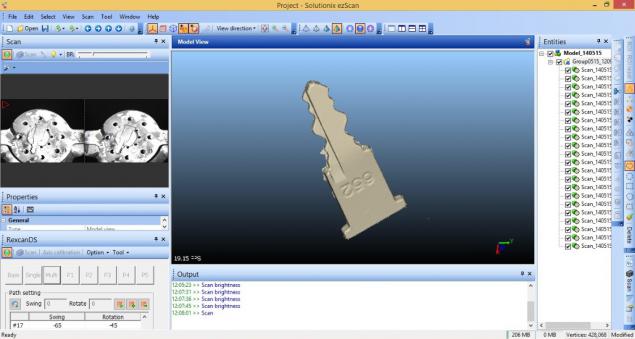

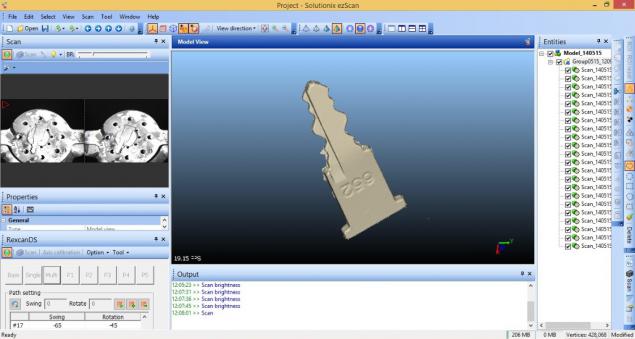

The scanning process h4>

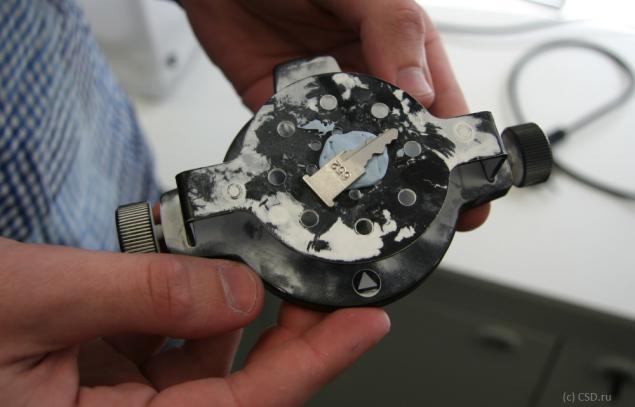

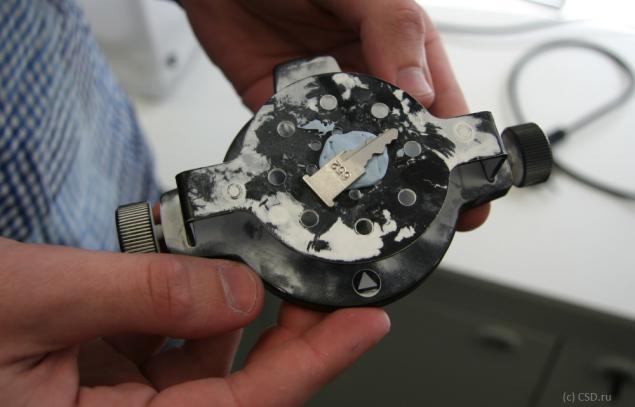

The key is attached to the platform, thanks to a special "cud».

The key is too shiny. First, it is necessary to cover the matte film.

Spray talc

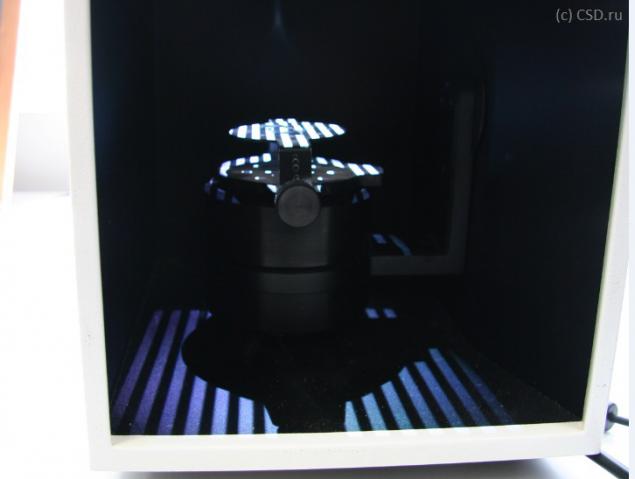

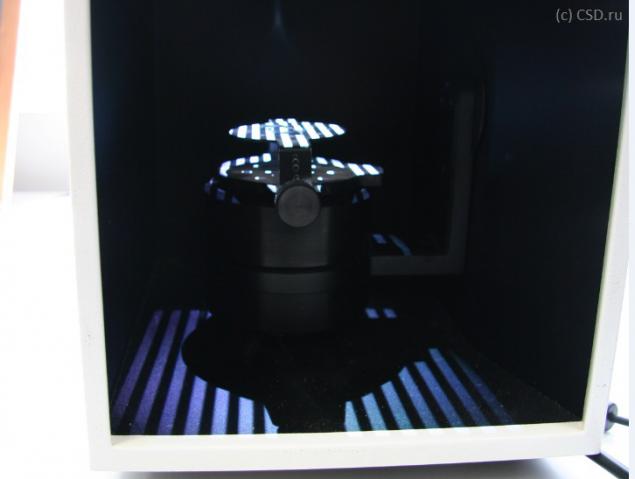

Placed in the chamber to scan where it will twist-spins and photograph

Scanned object can be moved along two axes (oscillation and rotation).

Video of the scanning process.

Scanning takes about 10 minutes, and parallel 3d-model is shown in the program

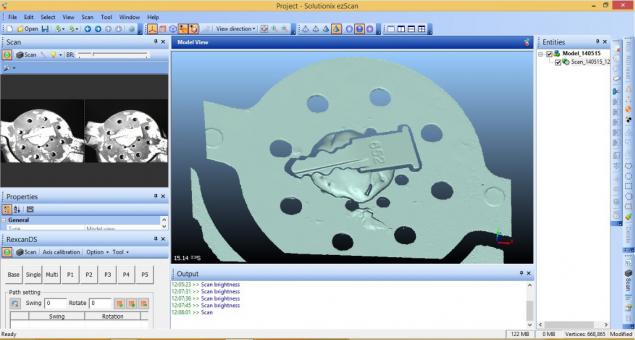

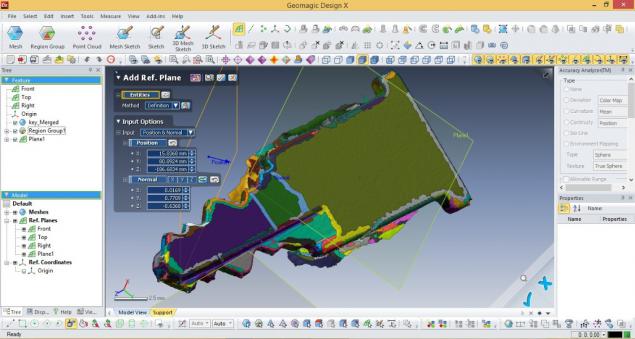

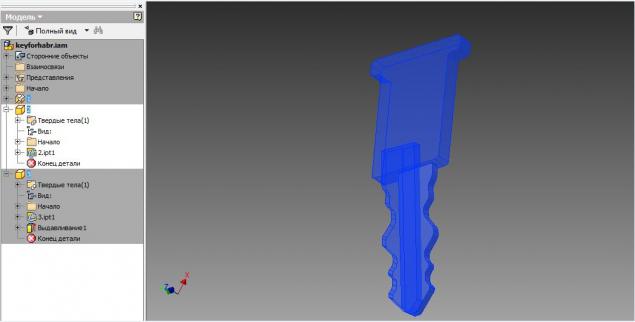

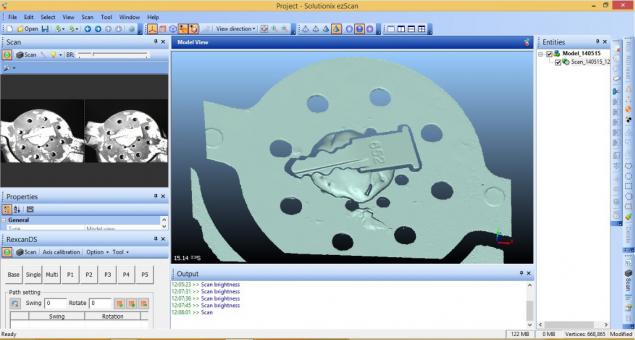

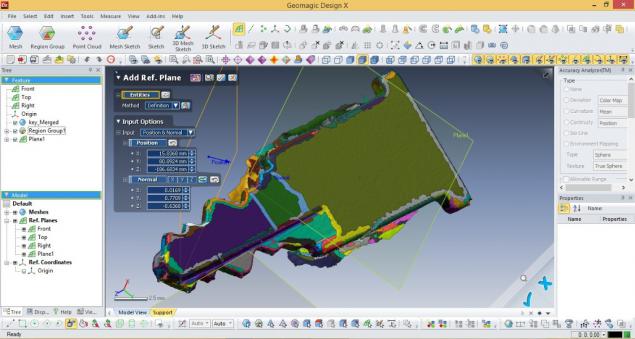

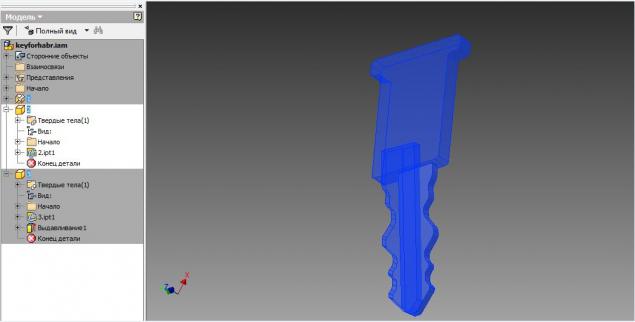

Processing in the 3d-editor

Removed platform (but the "cud" remained)

More serious editor. Allows you to group area. Clear the model of "cud».

Almost ready to modify 3d-model.

While specialist machining model in 3d-editor, I looked around and found something curious

What I noticed more h4>

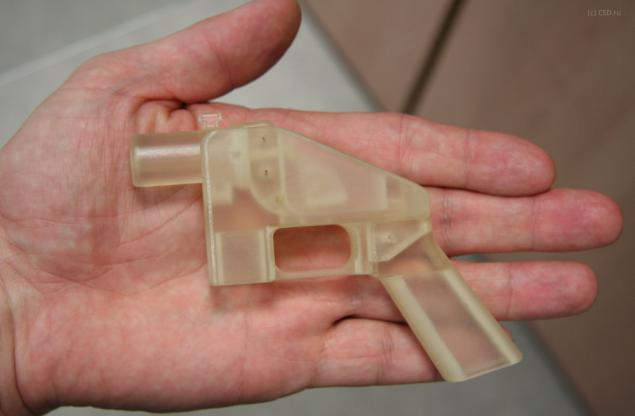

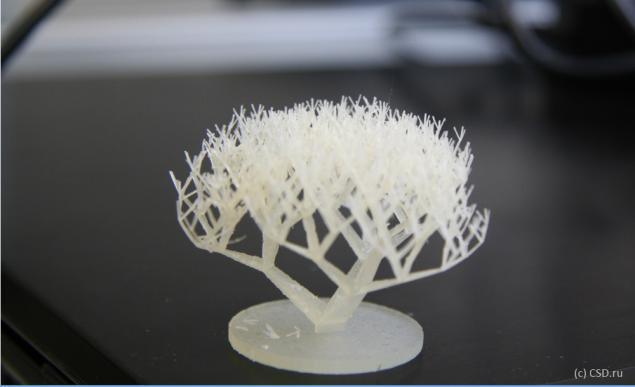

Printing on the basis of light-curing acrylate, one of the most accurate technologies

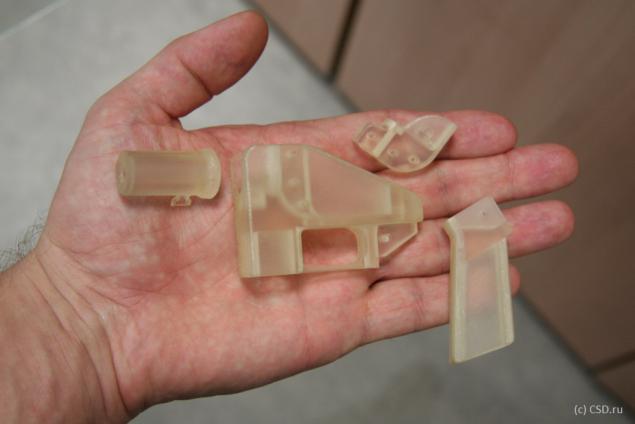

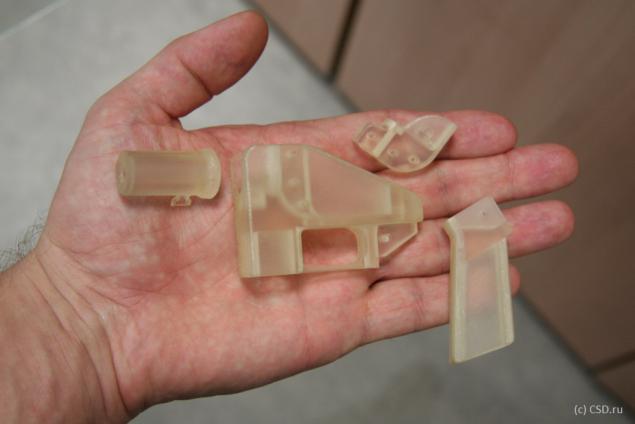

Liberator exploded

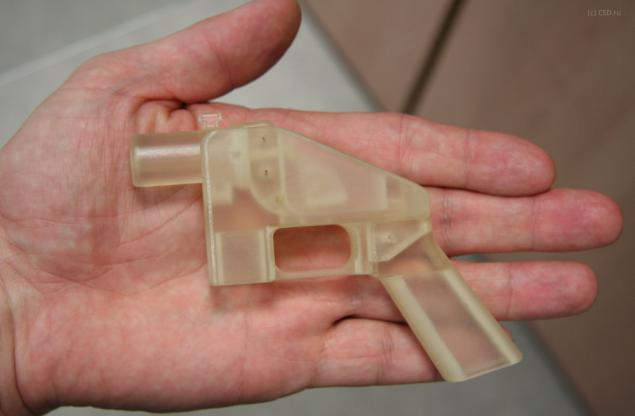

Liberator assembled (75% of the original size)

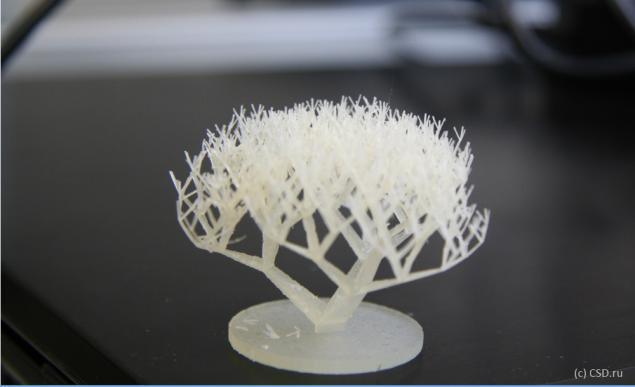

detail is striking (tree height 2 cm)

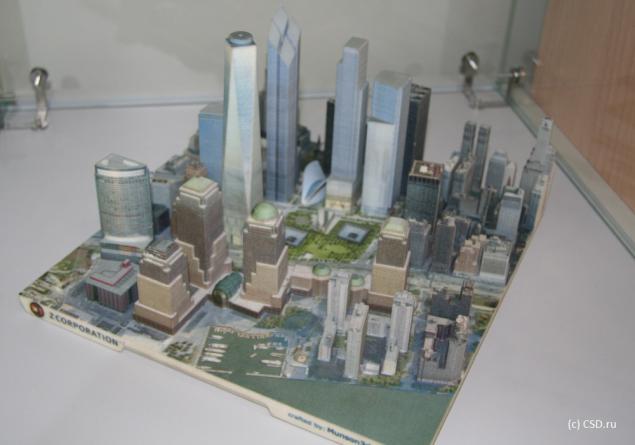

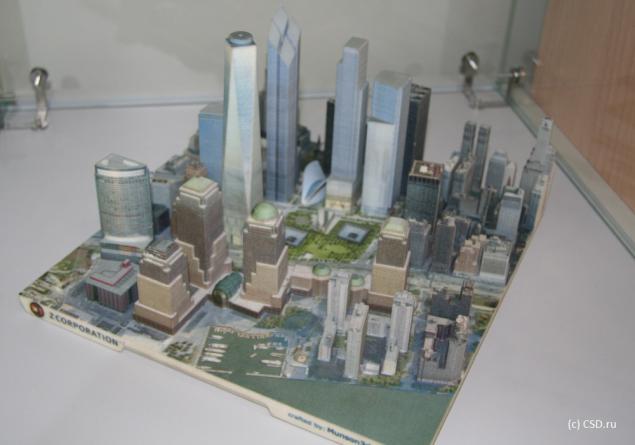

The layout of the city

Gypsum

Bus to treat a hand injury

They say that much easier adaptations of classic because it is easy and personalized

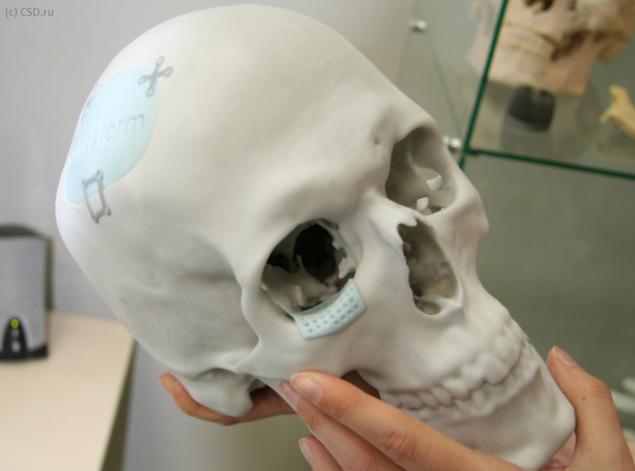

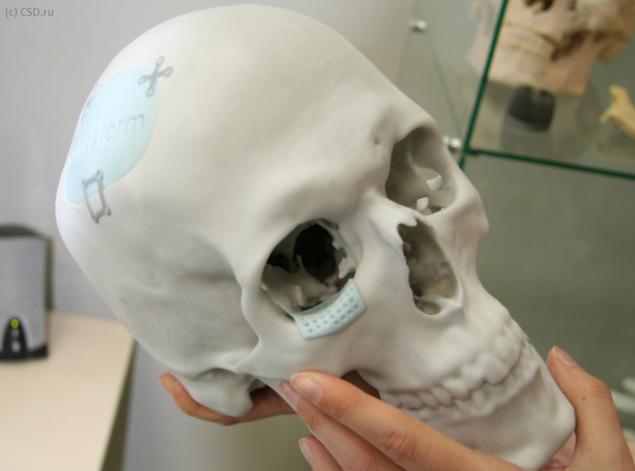

Skull 1

layout used in real neurosurgery

Skull 2

3d-models are based on X-ray images

Serdtse1

Serdtse2

It is not such as school textbooks on anatomy

Teeth

Dental use of 3d-3d-printers and scanners growing

Micro

3d-metal printers can work with incredible detail

"See you soon»

PS

Thank you to all the staff of the company, for what patiently answered all my questions and give me the time to share their experience of using modern devices steep. What else would you like the equipment to meet?

3d-hand scanners 3d-stationary scanners 3d-printers streolitograficheskie < / 3d-printer prints wax 3d-printer prints metal Only registered users can vote in polls. Sign , please. 106 people have voted. 17 people abstained. Source: habrahabr.ru/post/228697/