Browse UP! 3D Printer Mini

This model caught my attention and I want to share with the public, for the reason that it is ready, finished, tuned (you can get it out of the box and print) printer for the price set for self-assembly. (45 000 rubles, the price of stock in Moscow, that is already given "Customs»).

This printer simple (If you want to know what a "difficult" - read here , here or here . And also you can find the lucky one who has the printer Solidoodle) .

This printer cheap In comparison with the Up! Plus 2 for 83 thousand rubles, Picaso, Ultimaker 2, Printbox3d, Replicatort 2 (that is, in Moscow) - more than 99 thousand rubles.

This printer work You need only download software from the site, download 3d model, enter the platform level and send to print.

This is a printer for those who need to quickly and easily get ready prototype / toy. Since it is closed, it provides additional security (children, pets).

Saucy slogan on the box

How did the US military 90,347,287

Under the cut a few photos of the printer and the contents are short comments.

TTX The material used for printing models

ABS plastic filament diameter is 1.75mm, white / color

The size of the workspace

120mm (width) x 120mm (depth) x 120mm (height)

Layer thickness

0.25 / 0.30 / 0.35mm

Compatibility with software

Windows: Windows XP, Windows Vista, Windows 7; MAC.

Dimensions and weight

240mm (width) x 340mm (depth) x 355mm (height); Weight - 6kg

Power requirements

100-240 V, 50-60 Hz, 220W

The printer prints plastic ABS, PLA, Crystal Flex

Since one of the most common situations - strain model due to "temperature gradient" (read - if you blew a draft, on the one hand Circuits cooled and the whole structure is deformed by 2-3 mm), one of the ways to solve - to do this enclosure.

This printer has a closed housing.

(However, actually not so simple, since motors that move the platform and the printhead located inside the housing, and they begin to fail at a temperature above 80 degrees).

Closed body does not solve all problems, but at least he decides that's the problem (garbage bag on 3D printer).

Appearance h4>

Side view:

Rear view:

Stylish button:

Kompklektuyuschie:

The coil of the original ABS plastic vacuum packed. (700 g)

2 more platforms, power cord, data cable, hexagon pin for suspension coil tube for feeding plastic.

Power supply:

As usual for printers Up - PSU is huge. 20V and 10A

opens the door h4>

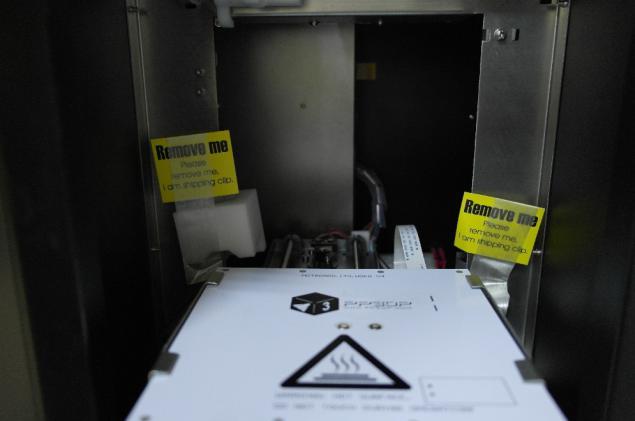

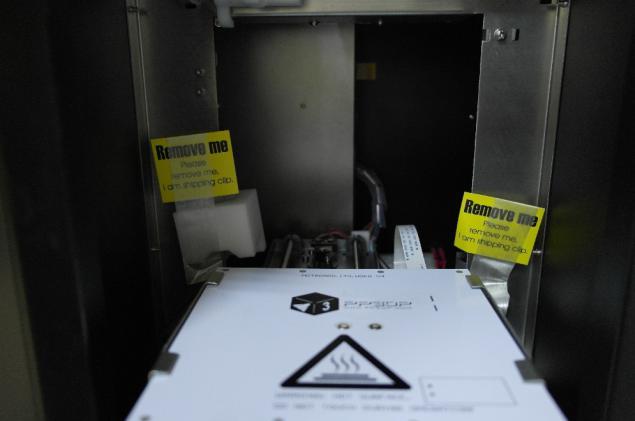

On this photo seen "reminders" - that is necessary to remove the transport securing, and some left them inside, and then complained that the printer is "knocking».

Just seen that there is a design feature of the platform - it is on a spring - and on each side mounting.

(By the way, for the calibration has only 1 bolt, the developers decided that this is enough.)

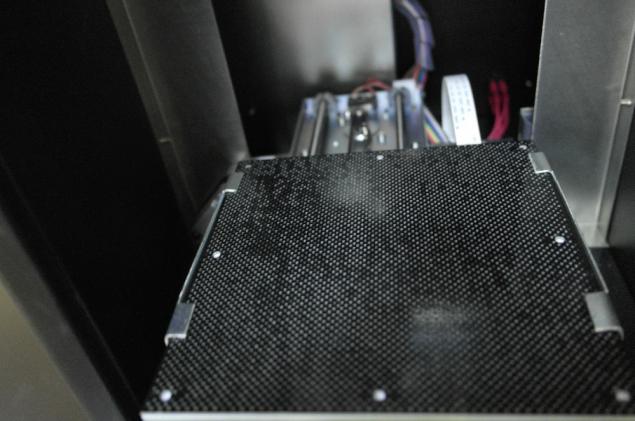

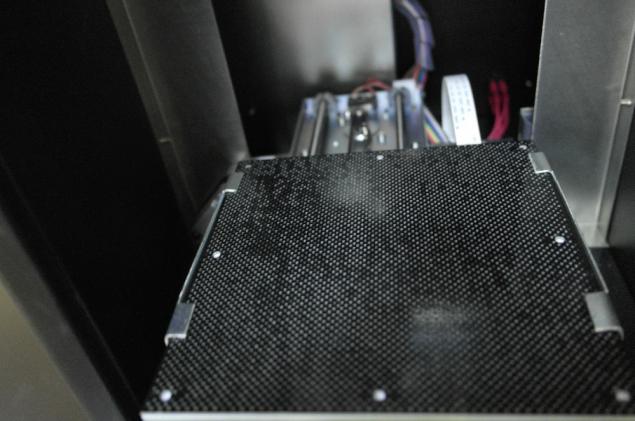

The platform is installed:

The platform does not fall with a clang, and gently lowered.

On this photo you can see how the platform and inserted as the grooves hold her.

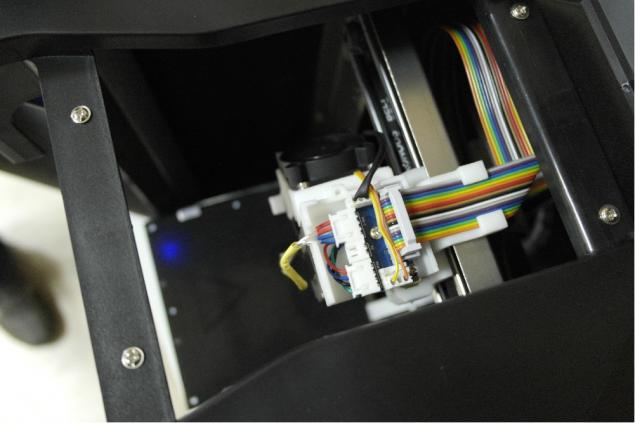

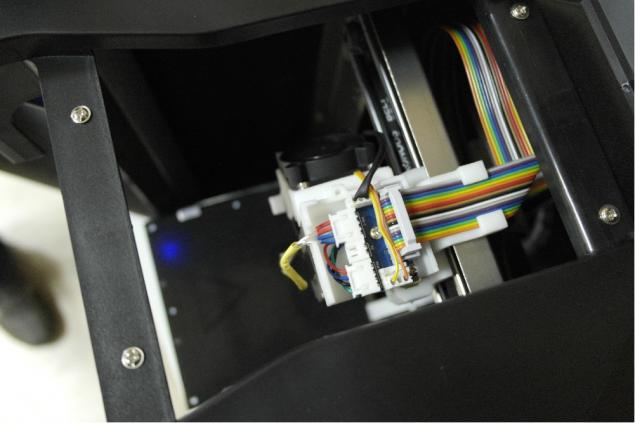

Printhead:

2-pin printhead (light and fan). With cheerful colored wires.

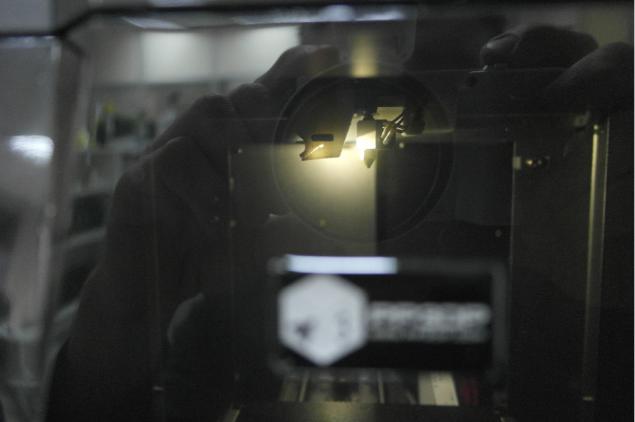

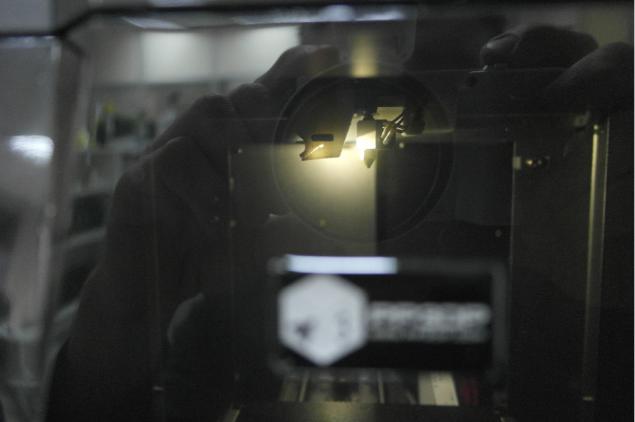

Illumination:

Lights - that it was possible to observe the process without opening the door.

unscrew and look insides h4>

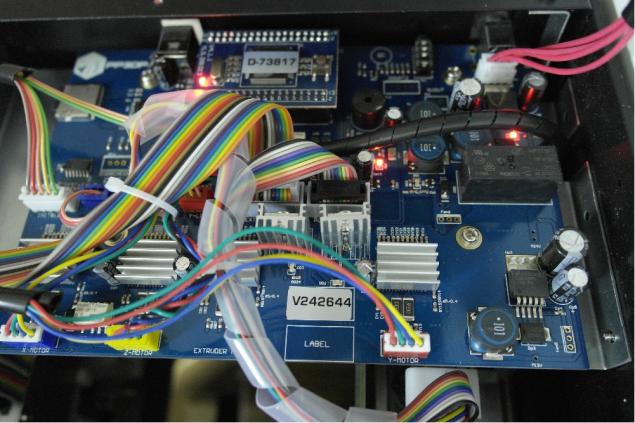

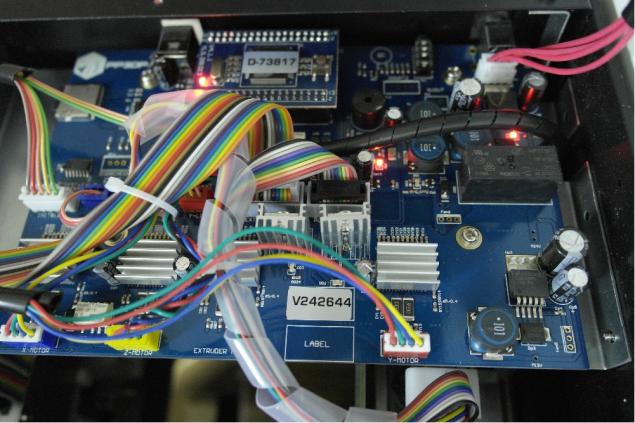

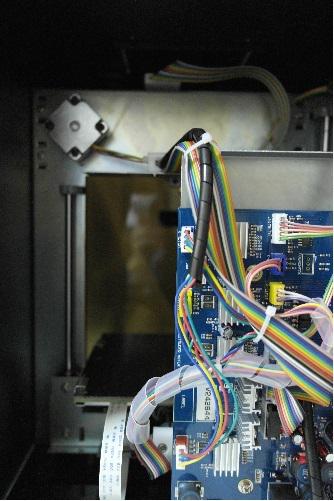

Electronics:

Pay with ominous "Terminator" LEDs (very similar to Up! Plus 2 in quality, unlike старой Version ).

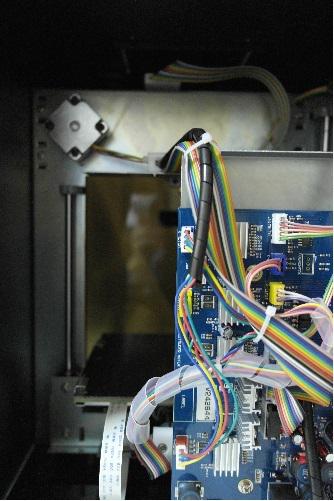

Frame:

Steel construction. Shafts double. You can operate 24/7.

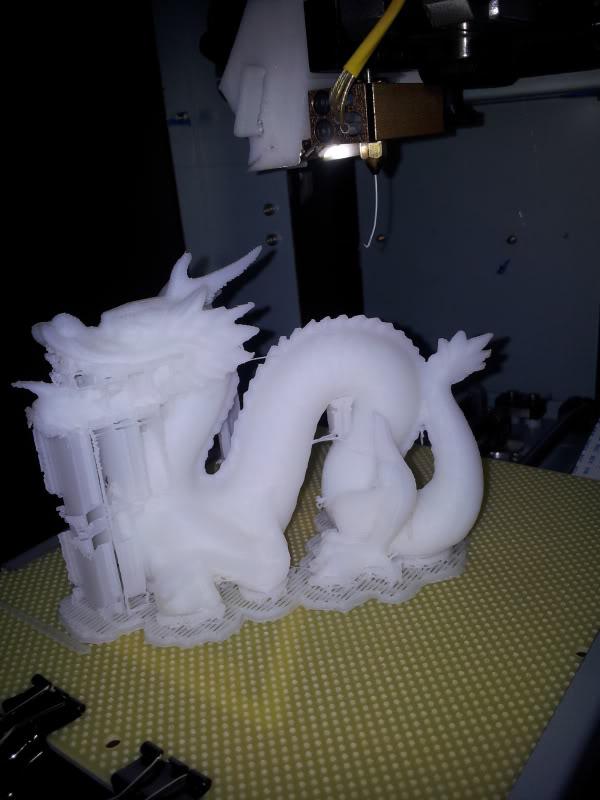

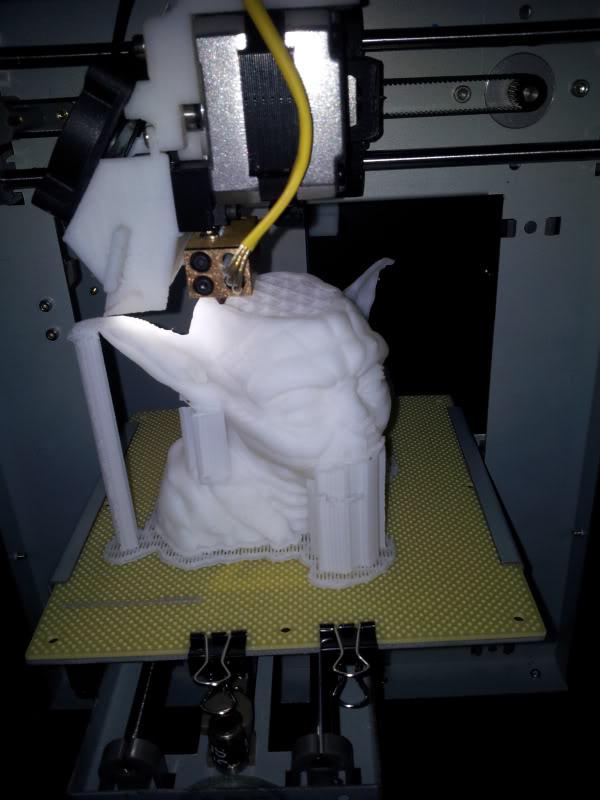

The first print h4>

First you need to set the height of the platform. It takes 1 minute.

Next, load the 3d model and send to print.

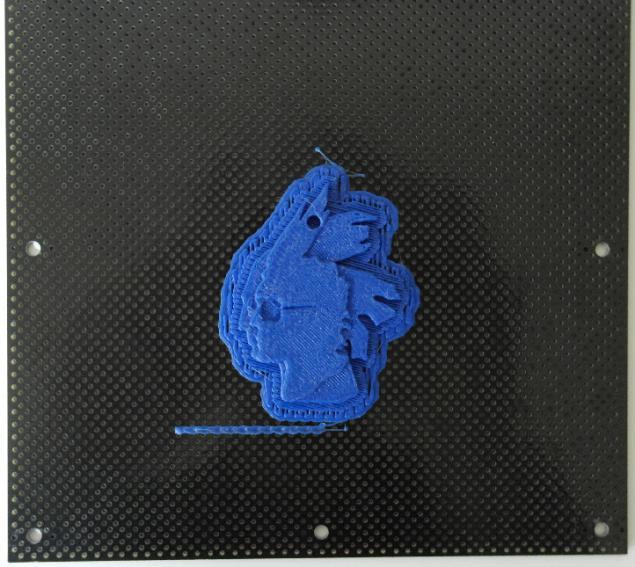

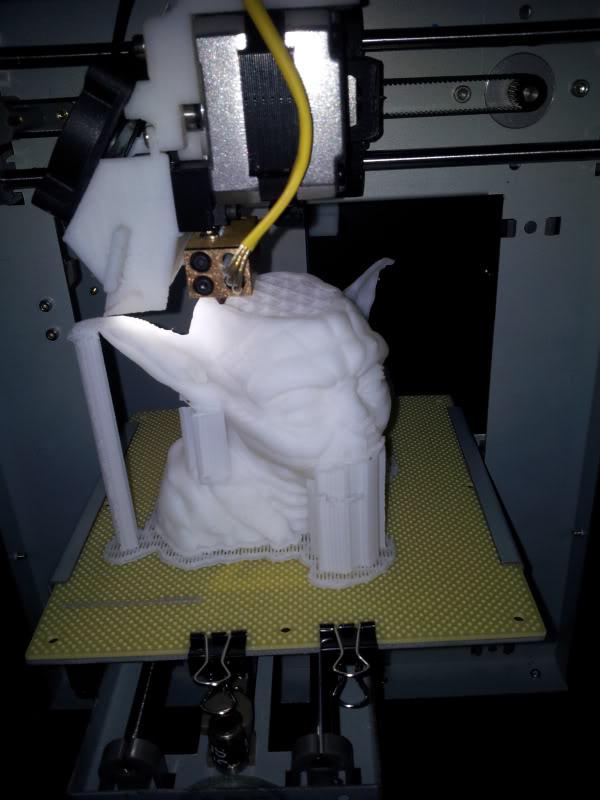

This time I chose "plemenngo Indians", and set the maximum printing speed.

The program prints the expected time of printing 8 minutes.

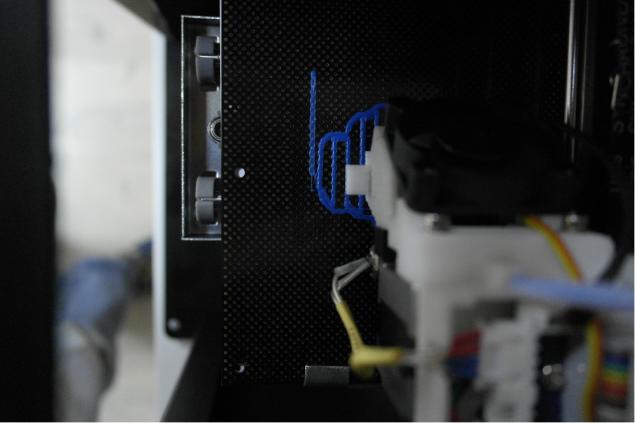

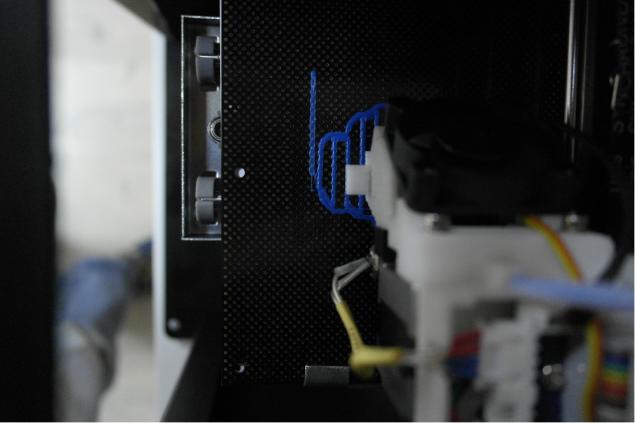

Start printing:

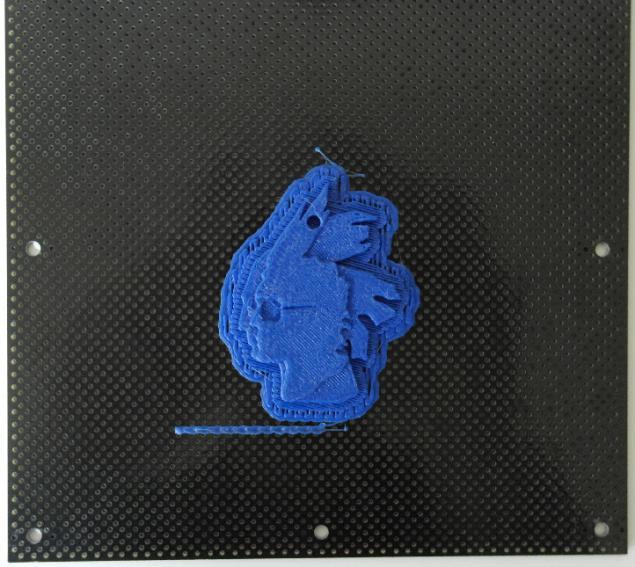

The End of Print:

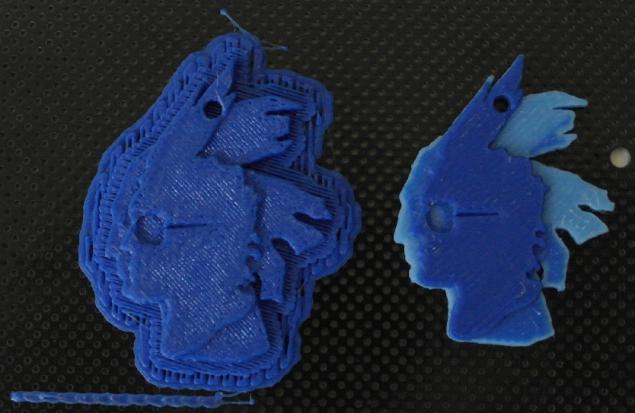

"Bicolor" Print:

Software h4>

The software is downloaded from the printer manufacturer from the site (PP3DP.com), similar to UP! Plus 2

There are 2 types of printers: those who use the "open software" and those who use their own software.

And those and others have their own advantages.

Free Software claims to universality, the ability to improve the code and the ability to customize the "9000" parameter. Open software gives full freedom (in conjunction - full responsibility) to the user. If you're a fan settings to within microns and to a degree - it's a godsend for you. But you can insert the plastic from any manufacturer and for a while for him to get the optimum temperature printing.

Net software from the manufacturer 100% satisfaction guarantee "hardware" and software. Just own software from the manufacturer suggests that 95% of "9000" has already tweaked parameters technicians, professionals, and the company is responsible for it (somehow). Software from the manufacturer to avoid any additional software, several (tens, hundreds) of hours settings, and allows «unpack and print» i> Developing their own software can afford only large companies (3d systems, Makerbot, PP3DP etc.) or some startups that make the software on a special rate. Blockquote>

Cons h4>

1. The thickness of only 200 microns

(Up! Plus 2 - 150 microns, Replicator 2 - 100 microns)

2. The small print surface

120mm (width) x 120mm (depth) x 120mm (height) UP! 3D Printer Mini (44,900 rubles)

140mm (width) x 140mm (depth) x 135mm (height) Up! plus 2 (82 900 rubles)

285mm (width) x 153mm (depth) x 155mm (height) MakerBot Replicator 2 (115 000 rubles)

250mm (width) x 200mm (depth) x 200mm (height) ShareBot NG (129,000 rubles)

3. No automatic calibration

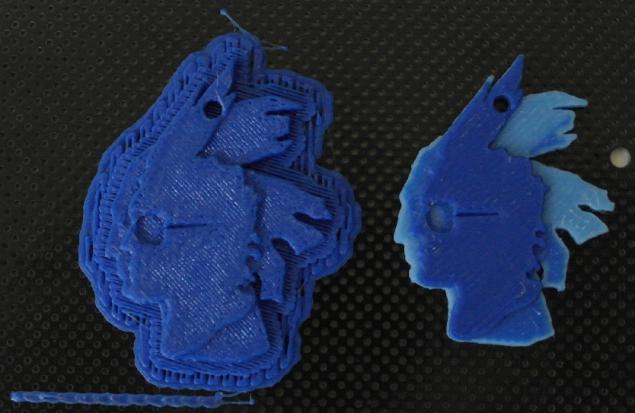

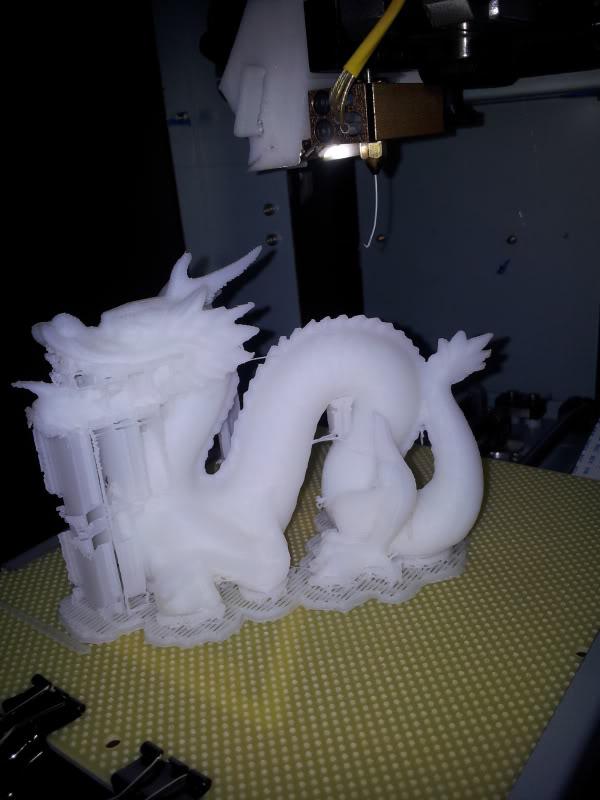

But these disadvantages do not interfere Minicoy print such things here:

Examples of work

PS h4>

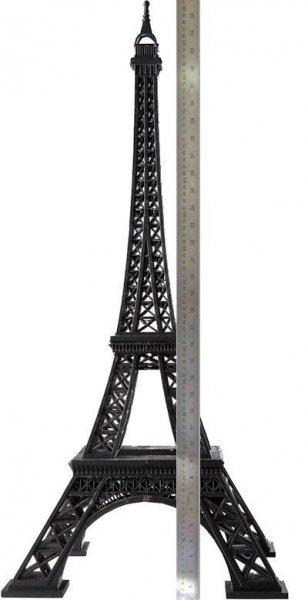

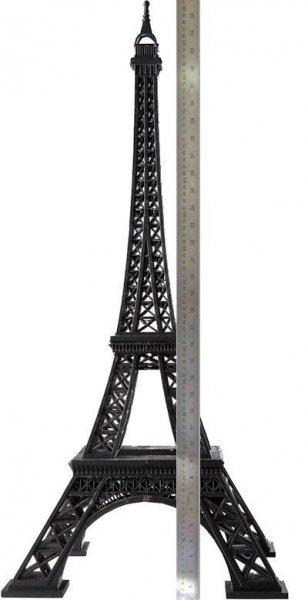

Meter Eiffel Tower printed on the UP! 3D Printer Mini (consisting of 13 parts)

PPS h4>

Videos in Russian about the "mini»:

Cheerful video from foreign comrades:

Source: habrahabr.ru/post/218827/