969

3D-printing will be the basis of data centers of the future

Nike uses a 3D-printers for the production of football boots. Doctors - for prosthetics. Ford and GM - Prototyping brake pads, levers and other parts. This new type of industrial equipment can reproduce any material object, at least theoretically could.

No wonder that the world of technology and now tries to apply 3D-press for the construction of data centers. Company IO at its plant in Chandler, Arizona, uses a 3D-printers for prototyping modules DPC - a kind of giant Lego. Almost as easy as GM and Ford, IO can generate, test, and modify the prototype vehicle. "This greatly speeds up the process and make it more flexible," - said vice-president Andreas Soll.

The idea of a modular data center was born at Google about a decade ago. Instead of designing each of its data centers from scratch, the search giant has started to apply the so-called container construction. The basis of their - the usual containers for transportation, including computing, cooling and electrical equipment, customized to work in concert. Using the railway, road and sea transport, Google was able to move them around the world and gather together in one place. It was a way to speed up not only the construction process, but also increase the efficiency of these modules.

A few years later, many have adopted this simple approach to the design of data centers. Microsoft used the modular data center to host your web services, many equipment manufacturers now sell modular solutions, and many businesses, in turn, can use them to build their own data centers. Among manufacturers giants such as Dell and HP, along with IO, whose equipment now enjoys one of the world's largest commercial bank Goldman Sachs.

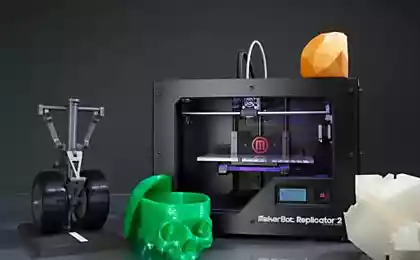

In the past, when the company only develops IO modules had to involve different parts manufacturers to get the desired prototype. For the production of even a tiny lamp bracket at the top of the module the company had to spend hundreds of dollars and wait for two or three weeks, until the prototype will come into place. But recently they have used 3D-printer Makerbot, to expedite the process. Now, as stated by Soll, we can not get more details, say the bracket, the most for a couple of hours, the time is comparable to the lunch break. This product will cost the company 75 cents, of course, not including the cost of the printer, which costs several thousand dollars. "The beauty of this technology is that it can play a potentially complex object without involving specialized organizations, giving this process companies such as us, or even in the hands of certain people" - said Soll.

The company can manufacture the basic design from drawings using computer-aided design CAD. After creating a 3D-model of the printer, and the creation process can be represented as the superposition of a single layer of molten plastic on the other, the possibilities of this technology are becoming more visible. "Instead of studying in detail the graphical editor, we can print it pretty quickly and see it live, it's an amazing opportunity. Create a layout, you can easily answer the questions: where we will place the interface where human access is limited? It's like Lego. We can move elements of the module in the design process - from the beginning to its very end, "- shared his impressions from Soll 3D-design. The created model is certainly not full prototypes. The modules themselves are the size of a room, and would require a huge printer. But even the team produced IO model, with dimensions of just two or three as iPhone, give a new and better opportunities for the design.

In the future, 3D-printing can be used not only for prototyping, but also for the production of its own data center, including motherboards for computers and other schemes, but it is the prospect of the coming decades, it will not happen tomorrow - if ever happens. "You can print the little things and play with them. Architects do it all the time, "- says an expert in the field of 3D-printing Berok Koshnevits, professor of Industrial and Systems Engineering University of Southern California. "It is not possible now to print the whole entire container. Today's reality 3D-printing is that to reproduce all the essential components of the server module will not work, it needs other technologies, other materials. 3D printing may become a drug that will accelerate, improve the methods of design and erection, but it is not a panacea. " Employees IO, however, are just beginning to delve into the 3D-printing technology as a tool for prototyping and where they will lead this way only time will tell.

In the IO say they pioneered the use of 3D-printing technology for the design of commercial data centers, but they also believe that this technology will be widely applied by their competitors. Frank Frankowski, privately confessed that monitors the hardware design Facebook, the company, which in his words, is in the heart of the movement to improve the efficiency of data centers as such, and this company makes extensive use of 3D-printers, which means only one - other companies also take up this technology, it is only a matter of time. The company is renowned for its expertise in the development of data centers, and 3D-printing is undoubtedly a unique technology which could provide for development on the basis of its more advanced, amazing opportunities.

Source: habrahabr.ru/company/ua-hosting/blog/238631/

No wonder that the world of technology and now tries to apply 3D-press for the construction of data centers. Company IO at its plant in Chandler, Arizona, uses a 3D-printers for prototyping modules DPC - a kind of giant Lego. Almost as easy as GM and Ford, IO can generate, test, and modify the prototype vehicle. "This greatly speeds up the process and make it more flexible," - said vice-president Andreas Soll.

The idea of a modular data center was born at Google about a decade ago. Instead of designing each of its data centers from scratch, the search giant has started to apply the so-called container construction. The basis of their - the usual containers for transportation, including computing, cooling and electrical equipment, customized to work in concert. Using the railway, road and sea transport, Google was able to move them around the world and gather together in one place. It was a way to speed up not only the construction process, but also increase the efficiency of these modules.

A few years later, many have adopted this simple approach to the design of data centers. Microsoft used the modular data center to host your web services, many equipment manufacturers now sell modular solutions, and many businesses, in turn, can use them to build their own data centers. Among manufacturers giants such as Dell and HP, along with IO, whose equipment now enjoys one of the world's largest commercial bank Goldman Sachs.

In the past, when the company only develops IO modules had to involve different parts manufacturers to get the desired prototype. For the production of even a tiny lamp bracket at the top of the module the company had to spend hundreds of dollars and wait for two or three weeks, until the prototype will come into place. But recently they have used 3D-printer Makerbot, to expedite the process. Now, as stated by Soll, we can not get more details, say the bracket, the most for a couple of hours, the time is comparable to the lunch break. This product will cost the company 75 cents, of course, not including the cost of the printer, which costs several thousand dollars. "The beauty of this technology is that it can play a potentially complex object without involving specialized organizations, giving this process companies such as us, or even in the hands of certain people" - said Soll.

The company can manufacture the basic design from drawings using computer-aided design CAD. After creating a 3D-model of the printer, and the creation process can be represented as the superposition of a single layer of molten plastic on the other, the possibilities of this technology are becoming more visible. "Instead of studying in detail the graphical editor, we can print it pretty quickly and see it live, it's an amazing opportunity. Create a layout, you can easily answer the questions: where we will place the interface where human access is limited? It's like Lego. We can move elements of the module in the design process - from the beginning to its very end, "- shared his impressions from Soll 3D-design. The created model is certainly not full prototypes. The modules themselves are the size of a room, and would require a huge printer. But even the team produced IO model, with dimensions of just two or three as iPhone, give a new and better opportunities for the design.

In the future, 3D-printing can be used not only for prototyping, but also for the production of its own data center, including motherboards for computers and other schemes, but it is the prospect of the coming decades, it will not happen tomorrow - if ever happens. "You can print the little things and play with them. Architects do it all the time, "- says an expert in the field of 3D-printing Berok Koshnevits, professor of Industrial and Systems Engineering University of Southern California. "It is not possible now to print the whole entire container. Today's reality 3D-printing is that to reproduce all the essential components of the server module will not work, it needs other technologies, other materials. 3D printing may become a drug that will accelerate, improve the methods of design and erection, but it is not a panacea. " Employees IO, however, are just beginning to delve into the 3D-printing technology as a tool for prototyping and where they will lead this way only time will tell.

In the IO say they pioneered the use of 3D-printing technology for the design of commercial data centers, but they also believe that this technology will be widely applied by their competitors. Frank Frankowski, privately confessed that monitors the hardware design Facebook, the company, which in his words, is in the heart of the movement to improve the efficiency of data centers as such, and this company makes extensive use of 3D-printers, which means only one - other companies also take up this technology, it is only a matter of time. The company is renowned for its expertise in the development of data centers, and 3D-printing is undoubtedly a unique technology which could provide for development on the basis of its more advanced, amazing opportunities.

Source: habrahabr.ru/company/ua-hosting/blog/238631/