1218

3D-printing in the service of prosthetists

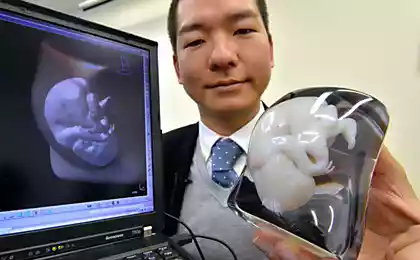

It's amazing how quickly fantasy turns into reality. Semifinalists GenerationS - Moscow company "Express Prosthetics" - presented the project to create electromechanical upper-limb prostheses with myo-management system (removal of electrical impulses to the muscles). At the stage of development of prostheses used 3D-printing technology, which significantly reduces the cost of R & D and prototyping accelerates. If successful, the project will solve the problem of availability of cheap functional upper limb prostheses both in the domestic and foreign markets. But the main thing is that the development will return people to full life and will endure misfortune.

The project started in August 2013, the commercial implementation is planned for the IV quarter of 2014. The essence of a startup is to develop an electromechanical prosthetic hands and arms in general management system by reading the twitch. Key partners of the project were MPO "Metalist" (Rostec), Institute of Prosthetics them. GA Albrecht (St. Petersburg), a business incubator "Ingria" Autodess, Social Insurance Fund, the Agency for Strategic Initiatives and others.

Manufacturing technology of prosthetic parts using 3D-printing has been tested - set 3 mechanical prosthetic fingers. Prosthesis maximum repeats functional real hands, and visual perception is not in doubt. Prosthesis previously collected and checked all the connections work, and final assembly occurs at the patient's arm. Under the prosthesis sleeve is made from medical thermoplastic material which, when heated in hot water becomes flexible and it is easy to make shape. After a few minutes, the material solidifies and acts as a rigid frame, which is attached to the prosthesis. Mass prototype is from 150 to 300 g, the force of the gripper - from 0, 5 to 4 N, which is more than enough for the normal life.

Now the project is at the zero stage, involving the certification of mechanical (traction) prosthetic fingers. Further planned development of electromechanical prosthetic hand, forearm prosthesis and prosthetic hands. The final stage will be developed prosthetic control system using brain neyrointerfeys. Necessary investments at zero phase is estimated at 5 million rubles in the first stage - 20 million rubles.

The final cost of the electromechanical prosthetic hand will start from 120 thousand. Rubles. Price will depend on the functionality of the prosthesis. Provided from 6 to 20 species of tongs and gestures assumes the possibility of remote control system over a wireless connection, the ability to install (or the presence of a basic version) of various functional modifications.

According to the authors of a startup, in Russia this project is the only real tried and proven feasibility and effectiveness. The most advanced prostheses now manufactured using carbon fiber or expensive polymers that provides them with the lightness and strength, but it guarantees a very high cost. Application of 3D-printing will allow to make more ergonomic, and most importantly cheap dentures by reducing costs in the development stage. "Now 3D-printing technology for these purposes only beginning to be applied and not yet widespread and commercial realization in prosthetic and orthopedic industry. But the potential is high enough technology including due to the presence of the remote control myo "- says the ideological and technological mastermind of" EXPRESS Prosthetics "Ilya Cech.

Moreover, according to co-founder of the company Vasily Khlebnikov, a Russian mechanical and electromechanical prostheses practically developed, and those that are still manufactured, are overpriced and hardly improved. "That's why we created the product will be in demand, because of the low price, speed of manufacturing, functionality and ergonomics, as well as the wide availability" - sure Khlebnikov.

The annual volume of the world market of prostheses is about 600 billion rubles, Russia - 1, 7 bln. Rubles. The overall dynamics of the global market upper-limb prostheses estimated 4-5% per year. In 2013, the availability of markets for products stood at 60% worldwide and 15% in Russia. By 2019, the company plans to set up 5,000 prostheses and exceed the annual turnover of 150 million rubles. Developers plan to take up to 20% of the world market and 70% of the Russian market in 2020. Now patients have already been received from the first 30 applications.

Today, there are prospects of a full import of existing upper-limb prostheses available on the market, due to the poor quality and very limited functionality analogues. Feature developed prostheses is the possibility of quick modification optional removable functional modules (different types of fixing devices for phones and tablets, removable or embedded tools for engineering works and so on.).

As the possible risks to the realization of the project authors identify bureaucratic delays certification of products, market conservatism prosthetics in Russia, limited access to markets the US and Europe because of the political situation and, consequently, an increase in the cost of imported components.

Source: habrahabr.ru/company/generations-2014/blog/239539/

The project started in August 2013, the commercial implementation is planned for the IV quarter of 2014. The essence of a startup is to develop an electromechanical prosthetic hands and arms in general management system by reading the twitch. Key partners of the project were MPO "Metalist" (Rostec), Institute of Prosthetics them. GA Albrecht (St. Petersburg), a business incubator "Ingria" Autodess, Social Insurance Fund, the Agency for Strategic Initiatives and others.

Manufacturing technology of prosthetic parts using 3D-printing has been tested - set 3 mechanical prosthetic fingers. Prosthesis maximum repeats functional real hands, and visual perception is not in doubt. Prosthesis previously collected and checked all the connections work, and final assembly occurs at the patient's arm. Under the prosthesis sleeve is made from medical thermoplastic material which, when heated in hot water becomes flexible and it is easy to make shape. After a few minutes, the material solidifies and acts as a rigid frame, which is attached to the prosthesis. Mass prototype is from 150 to 300 g, the force of the gripper - from 0, 5 to 4 N, which is more than enough for the normal life.

Now the project is at the zero stage, involving the certification of mechanical (traction) prosthetic fingers. Further planned development of electromechanical prosthetic hand, forearm prosthesis and prosthetic hands. The final stage will be developed prosthetic control system using brain neyrointerfeys. Necessary investments at zero phase is estimated at 5 million rubles in the first stage - 20 million rubles.

The final cost of the electromechanical prosthetic hand will start from 120 thousand. Rubles. Price will depend on the functionality of the prosthesis. Provided from 6 to 20 species of tongs and gestures assumes the possibility of remote control system over a wireless connection, the ability to install (or the presence of a basic version) of various functional modifications.

According to the authors of a startup, in Russia this project is the only real tried and proven feasibility and effectiveness. The most advanced prostheses now manufactured using carbon fiber or expensive polymers that provides them with the lightness and strength, but it guarantees a very high cost. Application of 3D-printing will allow to make more ergonomic, and most importantly cheap dentures by reducing costs in the development stage. "Now 3D-printing technology for these purposes only beginning to be applied and not yet widespread and commercial realization in prosthetic and orthopedic industry. But the potential is high enough technology including due to the presence of the remote control myo "- says the ideological and technological mastermind of" EXPRESS Prosthetics "Ilya Cech.

Moreover, according to co-founder of the company Vasily Khlebnikov, a Russian mechanical and electromechanical prostheses practically developed, and those that are still manufactured, are overpriced and hardly improved. "That's why we created the product will be in demand, because of the low price, speed of manufacturing, functionality and ergonomics, as well as the wide availability" - sure Khlebnikov.

The annual volume of the world market of prostheses is about 600 billion rubles, Russia - 1, 7 bln. Rubles. The overall dynamics of the global market upper-limb prostheses estimated 4-5% per year. In 2013, the availability of markets for products stood at 60% worldwide and 15% in Russia. By 2019, the company plans to set up 5,000 prostheses and exceed the annual turnover of 150 million rubles. Developers plan to take up to 20% of the world market and 70% of the Russian market in 2020. Now patients have already been received from the first 30 applications.

Today, there are prospects of a full import of existing upper-limb prostheses available on the market, due to the poor quality and very limited functionality analogues. Feature developed prostheses is the possibility of quick modification optional removable functional modules (different types of fixing devices for phones and tablets, removable or embedded tools for engineering works and so on.).

As the possible risks to the realization of the project authors identify bureaucratic delays certification of products, market conservatism prosthetics in Russia, limited access to markets the US and Europe because of the political situation and, consequently, an increase in the cost of imported components.

Source: habrahabr.ru/company/generations-2014/blog/239539/

The Germans invented a way to print flexible touch screens on a standard printer

On the Moon - dangerous