595

St. Petersburg scientists have created a safe analogue of Li-ion batteries

St. Petersburg scientists have developed a new technology to produce batteries that do not have the disadvantages of lithium-ion batteries. New energy sources are environmentally friendly, do not explode under any loads are charged per minute and not lose capacity after 10 thousand cycles of recharge. This was reported by TASS, one of the developers of the Alexander Tarasenko, Advisor to the rector on scientific work of ITMO University.

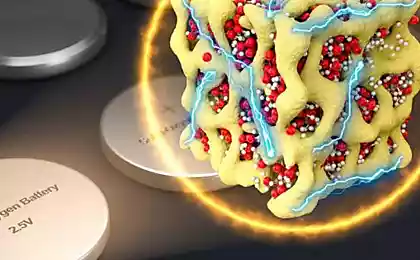

"We have created a new electrode material with a record performance in energy capacity, and also replaced the active metal, lithium, in the solid electrolyte. It is possible to increase the charging speed of the new supercapacitor (energy storage battery) up to one minute, the number of cycles of charge-discharge without losing its capacity to over 10 thousand cycles and to ensure the safety during use and disposal", — he said.

Director of the Institute of telecommunications Sergei Prisyazhnyuk said that the search for a new material for supercapacitors — a "very actual scientific task." "It tried to solve scientists of Physical-technical Institute. A. F. Ioffe their American counterparts, exploring the properties of nanotubes, but so far to create a more effective battery lithium-ion battery, none of the groups did not work", — he said, expressing hope that the new attempt will be successful.

Why replace lithium

According to Tarasenko, the activity of lithium leads to the fact that the battery of the mobile phone, discarded together with household waste and trapped in a landfill, pollutes up to 15 cubic meters of soil. In addition, the production of lithium-ion batteries reached the limit of technical solutions. "It means even more to reduce the occupied volume of the battery while maintaining the parameters of operation of the device is not obtained", — said Tarasenko.

He illustrated this thesis with the experience of Samsung, forced to withdraw a series of phones, as reducing the thickness of the batteries reduced their structural strength and "the batteries began to crumble with a small shock load, for example in the fall".

Lithium-ion batteries, as shown, and laboratory and field tests, after 1 thousand charge cycles and retain only 70% of its original capacity, and this restrains the development of many technical devices, which use batteries — electrotransport, drones. In addition, lithium-ion batteries work well only in a limited temperature range. "At minus 10 degrees Celsius start quickly discharged (the optimal work temperature is — 20 degrees), and at minus 50, as in Yakutia, are not working at all", — said the Agency interlocutor.

Physics instead of chemistry

"In our development of a chemical process when impact energy is available, as it is a supercapacitor. And it eliminates the "whims" of the device under shock and thermal loads," said Tarasenko. He said that on the basis of the Physico-technical Institute. A. F. Ioffe RAS, the developers conducted a series of tests.

The results showed that the battery is created based on the new technology, withstand more than 10 thousand cycles of charge-discharge without loss of capacity, works at temperatures from 50 to minus 50 degrees, withstand the electric current is 20 times more operational and does not explode and does not burn in the destruction. "Electrode material based on a carbon, so it is safe for the environment," said the developer.

The thing to work

However, right now, to bring down the market of lithium-ion batteries Petersburg scientists can't. They have not yet reached the higher capacity super capacitor than lithium-ion batteries. "We have reached the capacity of the battery 140-170 WH/kg, while the best lithium-ion batteries, it up to 250 W*h/kg. to reach and slightly exceed this limit, we need at least another six months of work," said Tarasenko.

Prysiazhniuk noted that the important question of the cost of materials, the ability to continuously hold a charge. "It is particularly important for manufacturers of unmanned aerial vehicles, and all devices operating on batteries, mass-dimensional characteristics. Drone is a narrow place," — said Prisyajnyuk. He headed the Institute in cooperation with the ITMO University is preparing to expand the production of drones in the science city Innopolis (a satellite town South of St. Petersburg).

To complete technology development necessary to create a pilot production.

"We do not seek to embody their development into the construction of the plant. We want to become the holders of the technology and sell it either many companies or any one with the full redemption of intellectual property. Then, on the money, and they in the second option will be much more planning to begin development of a new technology in another region," — shared his plans for the developer, adding that the pilot production will need to invest from $2.5 million to $5 million.

The main advantage of technology, Tarasenko considers the minimum number of changes that will have to make in their production lines, potential buyers of the technology. "Capital costs are always pushing the plants when the issue of changing production technologies, as the purchase of new equipment, and settings — a lot of money. In our case, you will have to change much less than usual", — he explained.

Interest industry

"Now we establish relationships with the industrial partner — the EuroSibEnergo, which is interested in using technology somewhat different angle, to adjust the pulse fluctuations in power grids, and also plan to bring the technology to the form suitable for the acquisition of major production," he added, Atroshenko. Among potential interested parties, he cited the company Tesla, which produces electric cars or Apple. "These companies repeatedly stated publicly that they are looking for and ready to buy new technology. And we have something to offer," he said.

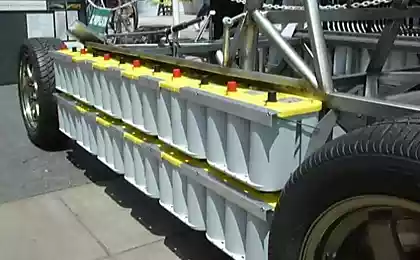

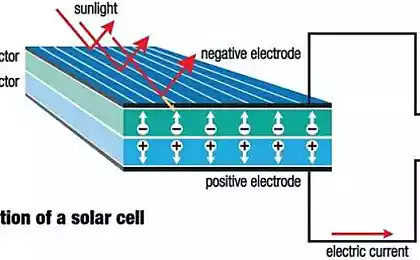

Head of the Department of scientific and technical activity of JSC "EuroSibEnergo" Anna Korotcenkov told TASS that "for "the EuroSibEnergo", the supercapacitor is a potential interest for application in several directions: to stabilize the pulse fluctuations in electricity as the drive energy generated by the solar panels and wind turbines, as well as high performance frame battery electric vehicle".

"The EuroSibEnergo", the largest private Russian energy company, which includes enterprises engaged in the full production cycle — from resource extraction and energy generation to its transmission and distribution to consumers. "The company is actively investing in modernization of production and new developments, aimed not only at increasing the performance and reliability of energy supply, but also on the development of alternative energy sources, converters and drives," said Korotchenkove.

History of the project

The search for new technology batteries for mobile phones, drones, electric transport is already half a dozen years. Two years ago, for it took colleagues, Tarasenko himself. "Initially, we invested in research your money, then received the funds "Fund of assistance to innovations" — 2 million rubles. are Now in the active phase of search of venture capital investments of up to $500 thousand.

The developers also went through the largest startup accelerator in Russia and Eastern Europe GenerationS, which said its market orientation.

"We strive to develop in the markets of the future, I want to trade in iron and technology. Russia is still little doing in the West, these tools are used actively. However, the national technology initiative (NTI) directs us precisely that," he said Tarasenko, adding that the development of technology is completely suitable for road map Energinet STI.

Startup accelerators GenerationS held in 2013, JSC "Russian venture company". Industrial partners GenerationS each year, more than 20 Russian corporations, in whose interests the selection and acceleration of startups. In 2016 to participate in GenerationS 4237 submitted applications from 30 countries. The prize Fund of GenerationS-2016 will amount to RUB 15 million total value of prizes from partners will exceed 100 million rubles. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.energy-fresh.ru/news/?id=14151

"We have created a new electrode material with a record performance in energy capacity, and also replaced the active metal, lithium, in the solid electrolyte. It is possible to increase the charging speed of the new supercapacitor (energy storage battery) up to one minute, the number of cycles of charge-discharge without losing its capacity to over 10 thousand cycles and to ensure the safety during use and disposal", — he said.

Director of the Institute of telecommunications Sergei Prisyazhnyuk said that the search for a new material for supercapacitors — a "very actual scientific task." "It tried to solve scientists of Physical-technical Institute. A. F. Ioffe their American counterparts, exploring the properties of nanotubes, but so far to create a more effective battery lithium-ion battery, none of the groups did not work", — he said, expressing hope that the new attempt will be successful.

Why replace lithium

According to Tarasenko, the activity of lithium leads to the fact that the battery of the mobile phone, discarded together with household waste and trapped in a landfill, pollutes up to 15 cubic meters of soil. In addition, the production of lithium-ion batteries reached the limit of technical solutions. "It means even more to reduce the occupied volume of the battery while maintaining the parameters of operation of the device is not obtained", — said Tarasenko.

He illustrated this thesis with the experience of Samsung, forced to withdraw a series of phones, as reducing the thickness of the batteries reduced their structural strength and "the batteries began to crumble with a small shock load, for example in the fall".

Lithium-ion batteries, as shown, and laboratory and field tests, after 1 thousand charge cycles and retain only 70% of its original capacity, and this restrains the development of many technical devices, which use batteries — electrotransport, drones. In addition, lithium-ion batteries work well only in a limited temperature range. "At minus 10 degrees Celsius start quickly discharged (the optimal work temperature is — 20 degrees), and at minus 50, as in Yakutia, are not working at all", — said the Agency interlocutor.

Physics instead of chemistry

"In our development of a chemical process when impact energy is available, as it is a supercapacitor. And it eliminates the "whims" of the device under shock and thermal loads," said Tarasenko. He said that on the basis of the Physico-technical Institute. A. F. Ioffe RAS, the developers conducted a series of tests.

The results showed that the battery is created based on the new technology, withstand more than 10 thousand cycles of charge-discharge without loss of capacity, works at temperatures from 50 to minus 50 degrees, withstand the electric current is 20 times more operational and does not explode and does not burn in the destruction. "Electrode material based on a carbon, so it is safe for the environment," said the developer.

The thing to work

However, right now, to bring down the market of lithium-ion batteries Petersburg scientists can't. They have not yet reached the higher capacity super capacitor than lithium-ion batteries. "We have reached the capacity of the battery 140-170 WH/kg, while the best lithium-ion batteries, it up to 250 W*h/kg. to reach and slightly exceed this limit, we need at least another six months of work," said Tarasenko.

Prysiazhniuk noted that the important question of the cost of materials, the ability to continuously hold a charge. "It is particularly important for manufacturers of unmanned aerial vehicles, and all devices operating on batteries, mass-dimensional characteristics. Drone is a narrow place," — said Prisyajnyuk. He headed the Institute in cooperation with the ITMO University is preparing to expand the production of drones in the science city Innopolis (a satellite town South of St. Petersburg).

To complete technology development necessary to create a pilot production.

"We do not seek to embody their development into the construction of the plant. We want to become the holders of the technology and sell it either many companies or any one with the full redemption of intellectual property. Then, on the money, and they in the second option will be much more planning to begin development of a new technology in another region," — shared his plans for the developer, adding that the pilot production will need to invest from $2.5 million to $5 million.

The main advantage of technology, Tarasenko considers the minimum number of changes that will have to make in their production lines, potential buyers of the technology. "Capital costs are always pushing the plants when the issue of changing production technologies, as the purchase of new equipment, and settings — a lot of money. In our case, you will have to change much less than usual", — he explained.

Interest industry

"Now we establish relationships with the industrial partner — the EuroSibEnergo, which is interested in using technology somewhat different angle, to adjust the pulse fluctuations in power grids, and also plan to bring the technology to the form suitable for the acquisition of major production," he added, Atroshenko. Among potential interested parties, he cited the company Tesla, which produces electric cars or Apple. "These companies repeatedly stated publicly that they are looking for and ready to buy new technology. And we have something to offer," he said.

Head of the Department of scientific and technical activity of JSC "EuroSibEnergo" Anna Korotcenkov told TASS that "for "the EuroSibEnergo", the supercapacitor is a potential interest for application in several directions: to stabilize the pulse fluctuations in electricity as the drive energy generated by the solar panels and wind turbines, as well as high performance frame battery electric vehicle".

"The EuroSibEnergo", the largest private Russian energy company, which includes enterprises engaged in the full production cycle — from resource extraction and energy generation to its transmission and distribution to consumers. "The company is actively investing in modernization of production and new developments, aimed not only at increasing the performance and reliability of energy supply, but also on the development of alternative energy sources, converters and drives," said Korotchenkove.

History of the project

The search for new technology batteries for mobile phones, drones, electric transport is already half a dozen years. Two years ago, for it took colleagues, Tarasenko himself. "Initially, we invested in research your money, then received the funds "Fund of assistance to innovations" — 2 million rubles. are Now in the active phase of search of venture capital investments of up to $500 thousand.

The developers also went through the largest startup accelerator in Russia and Eastern Europe GenerationS, which said its market orientation.

"We strive to develop in the markets of the future, I want to trade in iron and technology. Russia is still little doing in the West, these tools are used actively. However, the national technology initiative (NTI) directs us precisely that," he said Tarasenko, adding that the development of technology is completely suitable for road map Energinet STI.

Startup accelerators GenerationS held in 2013, JSC "Russian venture company". Industrial partners GenerationS each year, more than 20 Russian corporations, in whose interests the selection and acceleration of startups. In 2016 to participate in GenerationS 4237 submitted applications from 30 countries. The prize Fund of GenerationS-2016 will amount to RUB 15 million total value of prizes from partners will exceed 100 million rubles. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.energy-fresh.ru/news/?id=14151

Nissan Leaf the 2018 model year will be shown in September in Frankurt

The first Volvo electric car will travel without recharging for 400 kilometers