763

Alternative energy for the home with their hands: a review of the best eco-technologies

Each inhabitant of the planet is well-known that the reserves of natural fuel are limited, while energy prices are constantly rising. To replace the usual sources of supply capable alternative energy: your hands can make a very efficient installation. "Green technology" will greatly reduce household expenses through the use of almost free sources.

Popular sources of renewable energysince ancient times people used in the daily life of the mechanisms and devices, which was aimed at transformation of mechanical energy forces of nature. A striking example of this are watermills and windmills. With the advent of electricity, the presence of the generator let the mechanical energy transform into electricity.

Water mill — the predecessor of the pump is automatic, not requiring human presence to perform work. The wheel spontaneously rotate under the pressure of the water and independently draws water Today, a significant amount of energy is produced by wind systems and hydro power plants. In addition to wind and water people available sources such as biofuel, energy of the earth, the sunlight, the energy of geysers and volcanoes, the power of the tides.

In the home for renewable energy is widely used the following devices:

When choosing an alternative energy source must rely on its availability, then maximum power will be achieved with minimum investmentSolar panels are handwritten the manufactureof the Finished solar panel costs a lot of money, so buying it and installation is not affordable for everyone. When the independent panel manufacturing costs can be reduced by 3-4 times. Before the solar panel needs to understand how it all works.

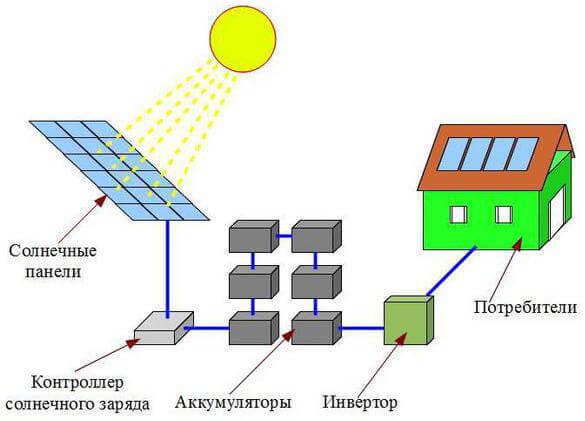

System solar power: the principle ofUnderstanding the purpose of each of the system elements will help to present its work as a whole. The main components of any solar system:

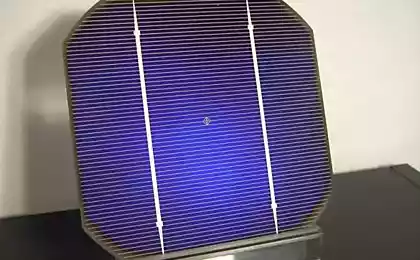

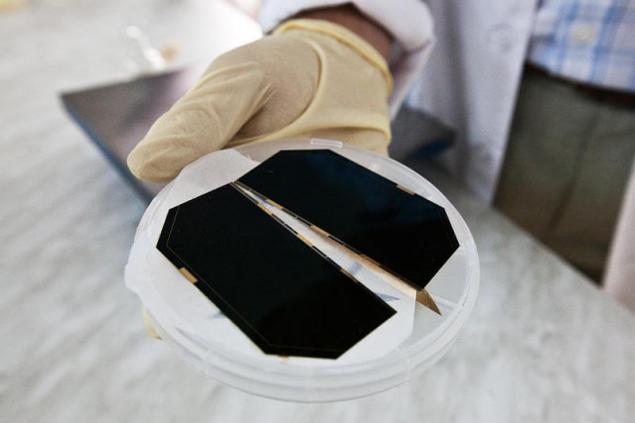

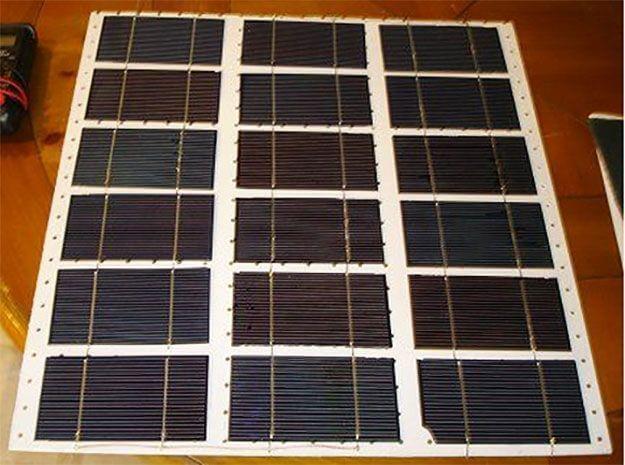

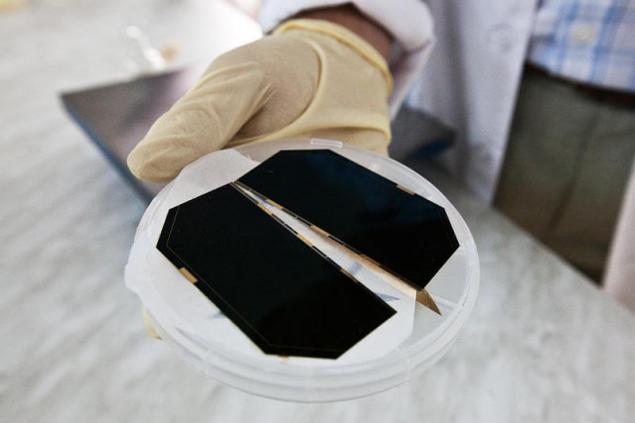

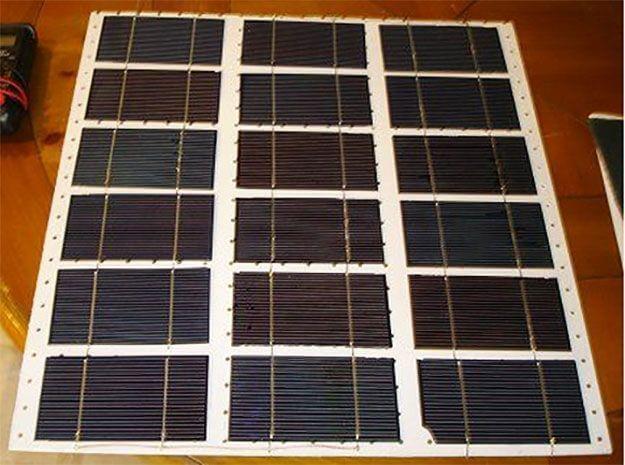

Quality controller and proper connection will help as much as possible to maintain efficiency of batteries and the entire Autonomous solar stations in General, the manufacture of solar panelsFor the manufacture of batteries, you must purchase solar cells on mono - or polycrystals. It should be noted that the lifetime of the polycrystals is much smaller than that of single crystals. In addition, the efficiency of polycrystals does not exceed 12%, whereas the figure for single crystals of up to 25%. In order to make one solar panel you need to buy at least 36 of these elements.

Solar battery assembled from modules. Each module is for household use includes 30, 36 or 72 PCs cells connected in series with the power supply with a maximum voltage of about 50 V Housing solar panelswork Begins with the construction of the hull you will need the following materials:

The properly made holes with a pitch of 0.15 to 0.20 m will protect against overheating of the solar panel and will provide stable work of the system solar panelthe size of the case you must use the utility knife to cut out the fiberboard backing for solar cells. When it is also necessary to provide venting, arranged at intervals of 5 cm square-cluster method. Ready housing is double-dyed and dried.

Solar cells should be upside down to spread on a substrate of hardboard and run the wiring. If the finished product has not been fitted with soldered conductors, the job is greatly simplified. However, the process of desoldering to be done in any case.

You need to remember that the connection elements must be consistent. Initially, the elements should be connected in rows, and then the finished rows to combine into a complex by joining the current-carrying tires. Upon completion of the elements you need to turn to put properly and to lock in their seats with the help of silicone.

Each of the elements must be securely fixed on the substrate with tape or silicone, in the future it will allow to avoid unwanted damage (+) After which it is necessary to check the output voltage. Roughly it should be between 18-20 V. Now the battery should be break in several days, test the ability to charge the batteries. Only after health is made by sealing joints.

Convinced of the irreproachable functionality, you can build the supply system. The input and output contact wire must output for subsequent connection of the device. Plexiglas should be cut the cover and secure it with screws to the sides of the casing through the pre-drilled holes.

Instead of solar cells for the manufacture of battery you can use a diode circuit with the diodes Д223Б. A panel of 36 series-connected diodes capable of delivering a voltage of 12 V.

The diodes need to be soaked in acetone to remove paint. In a plastic panel to drill the holes, insert the diodes and their solder. The panel must be placed in a transparent housing and sealing.

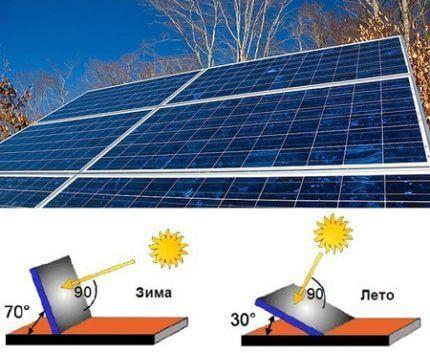

Correctly oriented and installed solar panels provide maximum efficiency of receiving solar energy and lightness and ease of maintenance of the system Basic rules for the installation of solar panelson the correct installation of the solar battery depends largely on the efficiency of the entire system. When installing, consider the following important parameters:

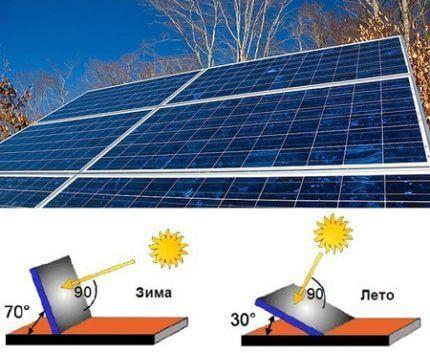

Shading. If the battery will be in the shade of the trees or higher buildings, it will not only function normally, but can fail. Orientation. For maximum sunlight on the solar cells, the battery must be directed towards the sun. If You live in the Northern hemisphere, the panel should be facing South if in the southern, on the contrary. Tilt. This parameter is determined by geographical location. Experts recommend installing the panel at an angle equal to the geographical latitude. Accessibility. You need to constantly monitor the cleanliness of the front side and the time to remove the layer of dust and dirt. And in the winter the bar is periodically necessary to clear snow from sticking. It is desirable that during operation the solar panel tilt angle was not constant. The device will work to the maximum only in the case directly to the cover sunlight. In the summer it is better to have a steep incline of 30º to the horizon. In the winter time it is recommended to lift and set at 70º.

In a number of industrial options solar provides tracking devices for the movement of the sun. For household use you can think and to provide a stand that allows you to change the angle of the panel Heat pumps for heatingHeat pumps are one of the most advanced technological solutions in production of alternative energy for your home. They are not only more convenient, but also environmentally safe. Their operation will significantly reduce the costs associated with paying for cooling and heating the room.

Classification of heat pumpsHeat pumps classify on the number of circuits, power source and method of its receipt. Depending on the final requirements heat pumps can be:

On the correct choice of a heat pump largely depends on the efficiency of the system and the cost of the device working Principle of the heat pumpthe Principle of operation of heat pumps based on the Carnot cycle, which is due to a compression of the fluid provides a temperature increase. On the same principle, but with the opposite effect, running most climatic devices with the compressor units (refrigerator, freezer, air conditioning).

The main cycle is implemented in the cells of these plants, says the opposite effect – as a result of sudden expansion there is a narrowing of the refrigerant.

That is why one of the most accessible methods of production of the heat pump based on the use of separate functional components used in HVAC equipment.

So, for the manufacture of heat pump can be used in a household refrigerator. Its evaporator and condenser will play the role of heat exchangers taking heat from the environment and direct it directly onto the heating fluid, which circulates in the heating system.

Low-grade heat from the ground, air or water together with the coolant enters the evaporator where it is converted into gas, and further still more compressed, whereby the temperature is even higher (+) Heat pump with units from home appliancesWork starts with the preparation of the compressor of the pump, the functions of which will be allocated to the relevant node of the air conditioner or refrigerator. This node must be consolidated with the soft suspension on one of the walls of the working space where it will be convenient.

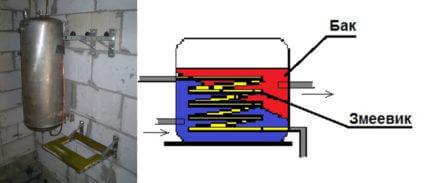

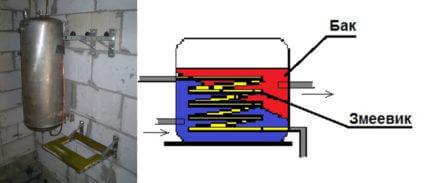

After this you need to make a capacitor. For this ideal stainless steel tank with a volume of 100 L. it is necessary to mount the coil (you can get copper tube from the old air conditioner or refrigerator. Prepared tank you need using the grinder cut lengthwise into two equal parts is needed for installation and fixation of the coil in the body of the future capacitor.

After installation of the coil in one of both halves of the tank need to connect and weld together in such a way to make a closed tank. Note that when welding you need to use special electrodes, and even better to use argon welding, only it can ensure the maximum quality of the weld.

For the manufacture of condenser used stainless steel tank with a volume of 100 l, using the grinder he was cut in half, mounted the coil and are produced in opposite welding For the manufacture of the evaporator will require a sealed plastic tank with a capacity of 75-80 litres, which will need to place a coil of pipe with a diameter of ¾ inch.

For the manufacture of the coil is sufficient to wrap a copper pipe around the steel pipe with a diameter of 300-400 mm with subsequent fixation of turns of the perforated area At the ends of the pipe must be tapped to further ensure the connection with the pipeline. After Assembly and check the sealing of the evaporator should be mounted on the wall of the working space by means of the brackets of appropriate size.

Completion is best left to a specialist. If the part of the Assembly can be performed independently, with soldering copper pipes and the pumping of refrigerant must work professional. Build the main part of the pump connecting ends of the heating panels and heat exchanger. It should be noted that this system is low-power. Therefore, it would be better if the heat pump will be an additional part of the existing heating system.

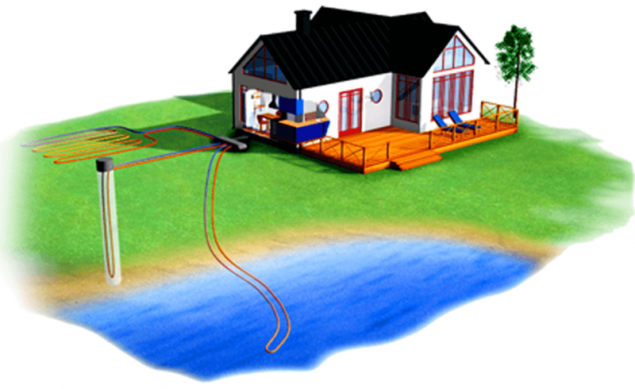

The arrangement and connection of the external deviceas the heat source best suited water from a well or wells. It never freezes even in winter the temperature rarely drops below 12 degrees. You will need two of these wells. One well will be a water extraction and then fed into the evaporator. Next, the wastewater will be discharged into the second hole. All that remains is to connect the evaporator inlet to the exit and sealing.

In principle, the system is ready for operation, but for full autonomy will require the automation system that controls the temperature of a moving heat carrier in the heating circuits and the pressure of the freon. At first, you can do an ordinary starter, but keep in mind that the start-up of system after shutdown of the compressor can be run in 8-10 minutes – this time is necessary to equalize the pressure of the freon in the system.

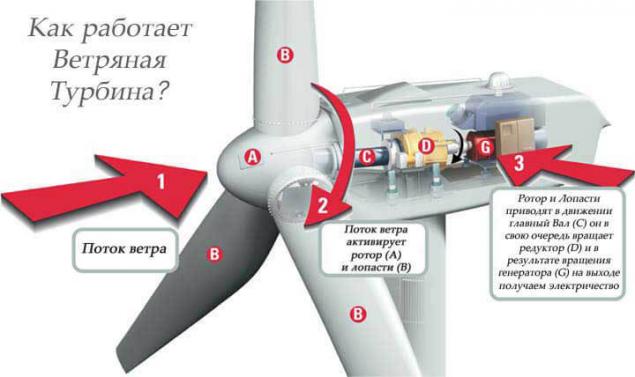

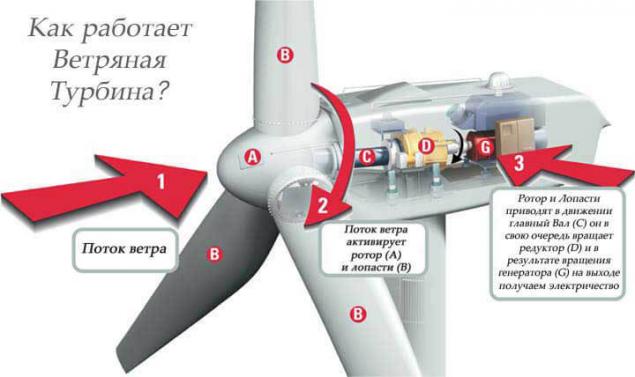

Wind turbines provide kilowatts of electricity iswind Energy used by our ancestors. Since ancient times, in principle, nothing has changed. The only difference is that the millstone of the mill replaced the alternator and drive, which convert the mechanical energy of the blades into electrical energy.

The installation of the wind turbine is considered economically viable if the average annual wind speed exceeds 6 m/s. Installation is best done in the hills and the plains, the ideal places are the coast, rivers and large bodies of water away from various utilities.

To convert the energy of air masses in the applied electric wind turbines, the most productive in the coastal regions and the Classification of wind turbinesClassification of wind generators depends on the following main parameters:

The wind turbines almost do not need the classic sources of energy. The use of the installation capacity of about 1MW will allow you to save some 92,000 barrels of oil, or 29 000 t of coal over 20 years the Device of wind turbine generatorAt any wind turbine has the following main elements:

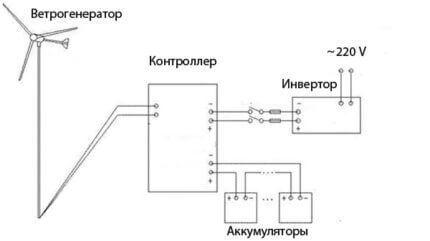

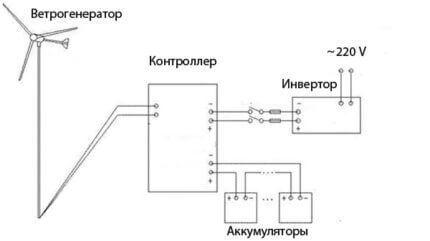

In the scheme of any, even the most simple wind turbine generator shall include the inverter, charge controller and battery low-speed wind generator from the oscillator, it is Considered that this design is the easiest and most accessible for self-production. It may be as an independent source of energy, and take on the part of the capacity of the existing supply system. If you have an automobile alternator, and battery all other parts can be made from scrap materials.

The manufacturer of the wind wheelBlade is considered one of the most important parts of the wind turbine, as their design is determined by the operation of other nodes. For the manufacture of blades can be used in a variety of materials – fabric, plastic, metal and even wood. We manufacture blades from sewer of plastic pipe. The main advantages of this material – low cost, high moisture resistance, ease of processing. Work is performed in the following order:

Calculates the length of the blade, the diameter of plastic pipe should be 1/5 of the required footage; using a jigsaw, the tube should be cut lengthwise into 4 pieces; One piece will become the template for making all subsequent blades; After cutting of the pipe burrs on the edges is necessary to process an emery paper; Cut the blades must be fixed on a prepared aluminum disk with a specified fastening; Also to this disk after alterations need to tie the generator. Note that the PVC pipe does not have sufficient strength and can not withstand strong gusts of wind. For the manufacture of the blades is best to use the PVC pipe with a minimum thickness of 4 cm a significant role on the magnitude of the load exerted by the size of the blade. Therefore it is useful to consider the option of reducing the size of the blade due to the increase in their number.

Of wind turbine blades manufactured on the pattern of ¼ PVC sewer pipe with a diameter of 200 mm, cut along the axis into 4 parts After Assembly should proceed with the balancing of the wind wheel. This requires it to be mounted horizontally on a tripod indoors. The result of the correct Assembly of the immobility of the wheels. If it happens, the rotation of the blades, it is necessary to do their gun nose abrasive milking trim design.

The installation of masts and wind turbinesFor production of a mast you can use steel pipe with a diameter of 150-200 mm. the Minimum length of the mast shall be 7 m. If the area is obstacle for moving air masses, the wheel of the wind turbine need to be lifted to a height that exceeds the obstacle is not less than 1 m.

Pegs to secure the stretch marks and the mast itself needs to be concreted. As stretch marks you can use steel or galvanized cable with a thickness of 6-8 mm.

Conversion of automotiveAlteration is only in the winding wire of the stator and also in the manufacture of a rotor with neodymium magnets. First you need to drill the holes necessary for fixing the magnets in the poles of the rotor. Installation of the magnets is performed with alternating poles. Upon completion of the work meimagine emptiness you need to fill with epoxy, and the rotor wrapping paper.

When rewinding you have to consider that the efficiency of the generator will depend on the number of turns. The coil must shake at the three-phase scheme in one direction. Generator ready need to test, the result of a properly done job will be a measure of 30 To 300 rpm of the generator.

Converted the generator is ready for testing and issued the rated voltage before the final installation of the entire system low-speed wind turbine Completion of a low-speed wind turbineRotary axis of the generator is performed from the pipe fitted with the two bearings and the tail part is cut out of galvanized iron of a thickness of 1.2 mm. Before mounting the generator to the mast it is necessary to manufacture the frame, it is best suitable for this profile pipe. When you run mount, you need to consider that the minimum distance from the mast to the blades should be greater than 0.25 m.

Under the action of wind flow is the movement of the blades and rotor, the result is the rotation of the reducer and the result is electric energy (+) For the system after the turbine you want to install the charge controller, batteries and inverter. Battery capacity is determined by the power turbines. This figure depends on the size of the wind wheel, the number of blades and wind speed.

The distinctive feature of alternative energy sources is their ecological cleanness and safety. Pretty low power settings and bind to specific terrain conditions allow to effectively use only the combined system of traditional and alternative sources. published

Source: sovet-ingenera.com/eco-energy/eko-dom/alternativnaya-energiya-svoimi-rukami.html

Popular sources of renewable energysince ancient times people used in the daily life of the mechanisms and devices, which was aimed at transformation of mechanical energy forces of nature. A striking example of this are watermills and windmills. With the advent of electricity, the presence of the generator let the mechanical energy transform into electricity.

Water mill — the predecessor of the pump is automatic, not requiring human presence to perform work. The wheel spontaneously rotate under the pressure of the water and independently draws water Today, a significant amount of energy is produced by wind systems and hydro power plants. In addition to wind and water people available sources such as biofuel, energy of the earth, the sunlight, the energy of geysers and volcanoes, the power of the tides.

In the home for renewable energy is widely used the following devices:

- Solar panels.

- Heat pumps.

- Wind turbines.

When choosing an alternative energy source must rely on its availability, then maximum power will be achieved with minimum investmentSolar panels are handwritten the manufactureof the Finished solar panel costs a lot of money, so buying it and installation is not affordable for everyone. When the independent panel manufacturing costs can be reduced by 3-4 times. Before the solar panel needs to understand how it all works.

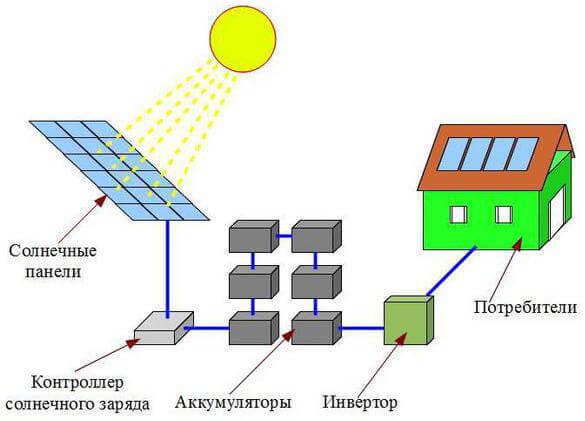

System solar power: the principle ofUnderstanding the purpose of each of the system elements will help to present its work as a whole. The main components of any solar system:

- Solar panel. It is a complex of United into a single whole elements that converts sunlight into a flow of electrons. Their main feature is that they are unable to produce a current of high voltage. Single element of the system is capable of producing a voltage of 0.5-0.55 V. Accordingly, a solar battery capable of producing voltage of 18-21 V, which is sufficient for charging a 12-volt battery.

- Batteries. One battery will not last long, so the system can count up to a dozen such devices. The number of batteries is determined by the power of electricity consumed. The number of batteries can be increased in the future by adding to the system the required number of solar panels;

- The solar charge controller. This device is necessary to ensure normal battery charging. Its main purpose is to prevent repeated overcharging of the battery.

- Inverter. The device is required to convert the current. Batteries give low voltage, and the inverter converts the current required for a functional high-voltage – power output. For home, it will be enough inverter with a handout with a capacity of 3-5 kW.

Quality controller and proper connection will help as much as possible to maintain efficiency of batteries and the entire Autonomous solar stations in General, the manufacture of solar panelsFor the manufacture of batteries, you must purchase solar cells on mono - or polycrystals. It should be noted that the lifetime of the polycrystals is much smaller than that of single crystals. In addition, the efficiency of polycrystals does not exceed 12%, whereas the figure for single crystals of up to 25%. In order to make one solar panel you need to buy at least 36 of these elements.

Solar battery assembled from modules. Each module is for household use includes 30, 36 or 72 PCs cells connected in series with the power supply with a maximum voltage of about 50 V Housing solar panelswork Begins with the construction of the hull you will need the following materials:

- Wooden bars

- Plywood

- Plexiglass

- Fiberboard

The properly made holes with a pitch of 0.15 to 0.20 m will protect against overheating of the solar panel and will provide stable work of the system solar panelthe size of the case you must use the utility knife to cut out the fiberboard backing for solar cells. When it is also necessary to provide venting, arranged at intervals of 5 cm square-cluster method. Ready housing is double-dyed and dried.

Solar cells should be upside down to spread on a substrate of hardboard and run the wiring. If the finished product has not been fitted with soldered conductors, the job is greatly simplified. However, the process of desoldering to be done in any case.

You need to remember that the connection elements must be consistent. Initially, the elements should be connected in rows, and then the finished rows to combine into a complex by joining the current-carrying tires. Upon completion of the elements you need to turn to put properly and to lock in their seats with the help of silicone.

Each of the elements must be securely fixed on the substrate with tape or silicone, in the future it will allow to avoid unwanted damage (+) After which it is necessary to check the output voltage. Roughly it should be between 18-20 V. Now the battery should be break in several days, test the ability to charge the batteries. Only after health is made by sealing joints.

Convinced of the irreproachable functionality, you can build the supply system. The input and output contact wire must output for subsequent connection of the device. Plexiglas should be cut the cover and secure it with screws to the sides of the casing through the pre-drilled holes.

Instead of solar cells for the manufacture of battery you can use a diode circuit with the diodes Д223Б. A panel of 36 series-connected diodes capable of delivering a voltage of 12 V.

The diodes need to be soaked in acetone to remove paint. In a plastic panel to drill the holes, insert the diodes and their solder. The panel must be placed in a transparent housing and sealing.

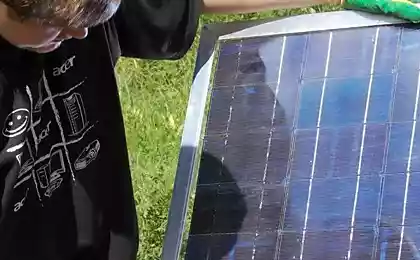

Correctly oriented and installed solar panels provide maximum efficiency of receiving solar energy and lightness and ease of maintenance of the system Basic rules for the installation of solar panelson the correct installation of the solar battery depends largely on the efficiency of the entire system. When installing, consider the following important parameters:

Shading. If the battery will be in the shade of the trees or higher buildings, it will not only function normally, but can fail. Orientation. For maximum sunlight on the solar cells, the battery must be directed towards the sun. If You live in the Northern hemisphere, the panel should be facing South if in the southern, on the contrary. Tilt. This parameter is determined by geographical location. Experts recommend installing the panel at an angle equal to the geographical latitude. Accessibility. You need to constantly monitor the cleanliness of the front side and the time to remove the layer of dust and dirt. And in the winter the bar is periodically necessary to clear snow from sticking. It is desirable that during operation the solar panel tilt angle was not constant. The device will work to the maximum only in the case directly to the cover sunlight. In the summer it is better to have a steep incline of 30º to the horizon. In the winter time it is recommended to lift and set at 70º.

In a number of industrial options solar provides tracking devices for the movement of the sun. For household use you can think and to provide a stand that allows you to change the angle of the panel Heat pumps for heatingHeat pumps are one of the most advanced technological solutions in production of alternative energy for your home. They are not only more convenient, but also environmentally safe. Their operation will significantly reduce the costs associated with paying for cooling and heating the room.

Classification of heat pumpsHeat pumps classify on the number of circuits, power source and method of its receipt. Depending on the final requirements heat pumps can be:

- One, two or three loops;

- One or dvukhkoridornye;

- With the possibility of heating or heating and cooling.

- Soil – water. Apply in a temperate climatic zone with a uniform warming of the earth regardless of the time of year. For mounting, use the manifold or the probe depending on the soil type. For drilling of shallow wells is not required to obtain permits.

- Air to water. Heat is accumulated from the air and goes into heating the water. The installation will be appropriate in climates with winter temperatures below -15 degrees.

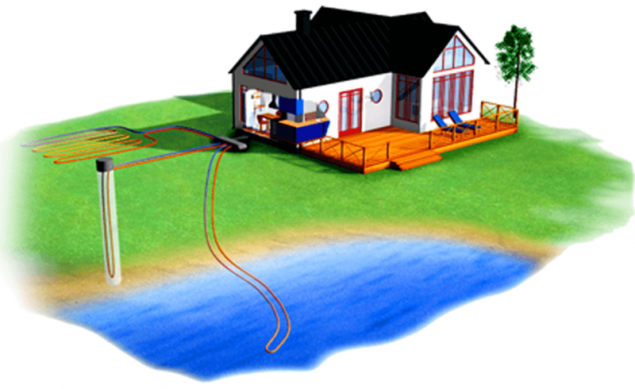

- Water – water. Installation due to the presence of water bodies (lakes, rivers, ground water, wells, sumps). The efficiency of this heat pump is very impressive, due to the high source temperature in the cold season.

- Water – to-air. In this mapping the role of heat source are the same reservoirs, but heat through a compressor is directly transferred to the air used for space heating. In this case, the water acts as the coolant.

- Ground – to-air. In this system, the heat conductor is a ground. Heat from the ground through the compressor air is passed. The role of energy carrier used antifreeze. This system is considered the most versatile.

- Air – to-air. The operation of this system is similar to the operation of the air conditioner that can heat and cool the room. This system is the cheapest as it does not require excavation works and laying of pipelines.

On the correct choice of a heat pump largely depends on the efficiency of the system and the cost of the device working Principle of the heat pumpthe Principle of operation of heat pumps based on the Carnot cycle, which is due to a compression of the fluid provides a temperature increase. On the same principle, but with the opposite effect, running most climatic devices with the compressor units (refrigerator, freezer, air conditioning).

The main cycle is implemented in the cells of these plants, says the opposite effect – as a result of sudden expansion there is a narrowing of the refrigerant.

That is why one of the most accessible methods of production of the heat pump based on the use of separate functional components used in HVAC equipment.

So, for the manufacture of heat pump can be used in a household refrigerator. Its evaporator and condenser will play the role of heat exchangers taking heat from the environment and direct it directly onto the heating fluid, which circulates in the heating system.

Low-grade heat from the ground, air or water together with the coolant enters the evaporator where it is converted into gas, and further still more compressed, whereby the temperature is even higher (+) Heat pump with units from home appliancesWork starts with the preparation of the compressor of the pump, the functions of which will be allocated to the relevant node of the air conditioner or refrigerator. This node must be consolidated with the soft suspension on one of the walls of the working space where it will be convenient.

After this you need to make a capacitor. For this ideal stainless steel tank with a volume of 100 L. it is necessary to mount the coil (you can get copper tube from the old air conditioner or refrigerator. Prepared tank you need using the grinder cut lengthwise into two equal parts is needed for installation and fixation of the coil in the body of the future capacitor.

After installation of the coil in one of both halves of the tank need to connect and weld together in such a way to make a closed tank. Note that when welding you need to use special electrodes, and even better to use argon welding, only it can ensure the maximum quality of the weld.

For the manufacture of condenser used stainless steel tank with a volume of 100 l, using the grinder he was cut in half, mounted the coil and are produced in opposite welding For the manufacture of the evaporator will require a sealed plastic tank with a capacity of 75-80 litres, which will need to place a coil of pipe with a diameter of ¾ inch.

For the manufacture of the coil is sufficient to wrap a copper pipe around the steel pipe with a diameter of 300-400 mm with subsequent fixation of turns of the perforated area At the ends of the pipe must be tapped to further ensure the connection with the pipeline. After Assembly and check the sealing of the evaporator should be mounted on the wall of the working space by means of the brackets of appropriate size.

Completion is best left to a specialist. If the part of the Assembly can be performed independently, with soldering copper pipes and the pumping of refrigerant must work professional. Build the main part of the pump connecting ends of the heating panels and heat exchanger. It should be noted that this system is low-power. Therefore, it would be better if the heat pump will be an additional part of the existing heating system.

The arrangement and connection of the external deviceas the heat source best suited water from a well or wells. It never freezes even in winter the temperature rarely drops below 12 degrees. You will need two of these wells. One well will be a water extraction and then fed into the evaporator. Next, the wastewater will be discharged into the second hole. All that remains is to connect the evaporator inlet to the exit and sealing.

In principle, the system is ready for operation, but for full autonomy will require the automation system that controls the temperature of a moving heat carrier in the heating circuits and the pressure of the freon. At first, you can do an ordinary starter, but keep in mind that the start-up of system after shutdown of the compressor can be run in 8-10 minutes – this time is necessary to equalize the pressure of the freon in the system.

Wind turbines provide kilowatts of electricity iswind Energy used by our ancestors. Since ancient times, in principle, nothing has changed. The only difference is that the millstone of the mill replaced the alternator and drive, which convert the mechanical energy of the blades into electrical energy.

The installation of the wind turbine is considered economically viable if the average annual wind speed exceeds 6 m/s. Installation is best done in the hills and the plains, the ideal places are the coast, rivers and large bodies of water away from various utilities.

To convert the energy of air masses in the applied electric wind turbines, the most productive in the coastal regions and the Classification of wind turbinesClassification of wind generators depends on the following main parameters:

- Depending on the placement of the axis can be vertical and horizontal. A horizontal design provides the ability to AutoRotate the main part of the search for wind. The main equipment of vertical wind turbine is located on the ground, so it is easier to maintain, while the efficiency of vertically arranged blades below.

- Depending on the number of blades distinguish one-, two-, three - and multi-blade wind generators. Multiblade wind turbines are used for low speed air flow, are rarely used due to the installation of the reducer.

- Depending on the material used for the manufacture of the blades, the blades can be sailing and hard. Blades type of sailing is easy to manufacture and installation, but require frequent replacement as quickly fail under the influence of sudden gusts of wind.

- Depending on the pitch, distinguish between variable and fixed steps. When using a variable pitch to achieve a significant increase in the working speed range of the wind turbine, but it will lead to the inevitable complexity of design and increase its mass.

The wind turbines almost do not need the classic sources of energy. The use of the installation capacity of about 1MW will allow you to save some 92,000 barrels of oil, or 29 000 t of coal over 20 years the Device of wind turbine generatorAt any wind turbine has the following main elements:

- The blades, rotating under the action of the wind and provide movement of the rotor;

- A generator that produces alternating current;

- The controller of the blades, responsible for the formation of AC to DC, which is required for charging the battery;

- Batteries needed for the accumulation and alignment of electrical energy;

- The inverter performs a reverse conversion of DC to AC, which operate all household appliances;

- The mast is required to raise the blades above the ground to reach the height of the movement of air masses.

In the scheme of any, even the most simple wind turbine generator shall include the inverter, charge controller and battery low-speed wind generator from the oscillator, it is Considered that this design is the easiest and most accessible for self-production. It may be as an independent source of energy, and take on the part of the capacity of the existing supply system. If you have an automobile alternator, and battery all other parts can be made from scrap materials.

The manufacturer of the wind wheelBlade is considered one of the most important parts of the wind turbine, as their design is determined by the operation of other nodes. For the manufacture of blades can be used in a variety of materials – fabric, plastic, metal and even wood. We manufacture blades from sewer of plastic pipe. The main advantages of this material – low cost, high moisture resistance, ease of processing. Work is performed in the following order:

Calculates the length of the blade, the diameter of plastic pipe should be 1/5 of the required footage; using a jigsaw, the tube should be cut lengthwise into 4 pieces; One piece will become the template for making all subsequent blades; After cutting of the pipe burrs on the edges is necessary to process an emery paper; Cut the blades must be fixed on a prepared aluminum disk with a specified fastening; Also to this disk after alterations need to tie the generator. Note that the PVC pipe does not have sufficient strength and can not withstand strong gusts of wind. For the manufacture of the blades is best to use the PVC pipe with a minimum thickness of 4 cm a significant role on the magnitude of the load exerted by the size of the blade. Therefore it is useful to consider the option of reducing the size of the blade due to the increase in their number.

Of wind turbine blades manufactured on the pattern of ¼ PVC sewer pipe with a diameter of 200 mm, cut along the axis into 4 parts After Assembly should proceed with the balancing of the wind wheel. This requires it to be mounted horizontally on a tripod indoors. The result of the correct Assembly of the immobility of the wheels. If it happens, the rotation of the blades, it is necessary to do their gun nose abrasive milking trim design.

The installation of masts and wind turbinesFor production of a mast you can use steel pipe with a diameter of 150-200 mm. the Minimum length of the mast shall be 7 m. If the area is obstacle for moving air masses, the wheel of the wind turbine need to be lifted to a height that exceeds the obstacle is not less than 1 m.

Pegs to secure the stretch marks and the mast itself needs to be concreted. As stretch marks you can use steel or galvanized cable with a thickness of 6-8 mm.

Conversion of automotiveAlteration is only in the winding wire of the stator and also in the manufacture of a rotor with neodymium magnets. First you need to drill the holes necessary for fixing the magnets in the poles of the rotor. Installation of the magnets is performed with alternating poles. Upon completion of the work meimagine emptiness you need to fill with epoxy, and the rotor wrapping paper.

When rewinding you have to consider that the efficiency of the generator will depend on the number of turns. The coil must shake at the three-phase scheme in one direction. Generator ready need to test, the result of a properly done job will be a measure of 30 To 300 rpm of the generator.

Converted the generator is ready for testing and issued the rated voltage before the final installation of the entire system low-speed wind turbine Completion of a low-speed wind turbineRotary axis of the generator is performed from the pipe fitted with the two bearings and the tail part is cut out of galvanized iron of a thickness of 1.2 mm. Before mounting the generator to the mast it is necessary to manufacture the frame, it is best suitable for this profile pipe. When you run mount, you need to consider that the minimum distance from the mast to the blades should be greater than 0.25 m.

Under the action of wind flow is the movement of the blades and rotor, the result is the rotation of the reducer and the result is electric energy (+) For the system after the turbine you want to install the charge controller, batteries and inverter. Battery capacity is determined by the power turbines. This figure depends on the size of the wind wheel, the number of blades and wind speed.

The distinctive feature of alternative energy sources is their ecological cleanness and safety. Pretty low power settings and bind to specific terrain conditions allow to effectively use only the combined system of traditional and alternative sources. published

Source: sovet-ingenera.com/eco-energy/eko-dom/alternativnaya-energiya-svoimi-rukami.html

HOW to understand each other: 10 phrases that are worth avoiding

Leo Babauta: WHAT to DO When the irritation begins to command