632

Ceiling panel cooling

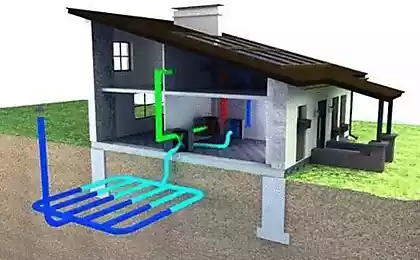

Attention and interest in the"cooling" ceilings are rising, especially in Northern Europe where they are considered as interesting alternatives to traditional systems used in rooms with low ceilings and in reconstructed buildings. The relatively high temperature of the water supplied to the ceiling panel, allows for its preparation of a system of free cooling (free cooling) in the off-season.

The benefits of using "cooling" ceiling lie in their quiet operation, no unpleasant drafts and extremely low maintenance cost. "Cooling" ceilings can carry a decent load, it does not take up valuable space and due to the fact that they lower the average radiant temperature in the room, their use makes it possible to increase the air temperature beyond the limits allowed by the organization of cooling of the room.

For example, to create comfort, feel equal at a temperature of 24°C using conventional systems, the use of "cooling" ceiling allows you to heat the air in the room to 25-26°C dry bulb, depending on the intensity of heat radiation, for example solar radiation.

Cooling radiant flux on the heads of people gives them a special feeling of freshness.

The ability to operate at higher temperatures allows the use of the water rather high temperature (15°C), which leads to substantial savings in the electricity bills.

In recent years we have tested many systems prefabricated ceiling cooling.

These include panels with built-in overlap of cooling coils pipes and a variety of suspended panels, the top of which was zapressovyvat, welded or fastened clips tubes, through which was passed cold water.

One of the first patents in this field included even lay water pipe directly in the ceiling construction.

Compared with suspended panels, advantage panels with integrated cold coil that their use gives greater installation flexibility, though the works themselves are objectively more complex, because you require constant quality control and logistic coordination of actions between members of the project (construction and erection organization and the firm-installer).

As to guarantee optimal insulation over the pipe is almost impossible, the system is in any case leads to losses of up cold at an average of 20 % of the total flow of radiant energy.

Association ASHRAE has defined a procedure for calculating "cooling" ceiling with built-in coil and the corresponding data for exposure. Most of the "cooling" of the ceilings established in the last thirty years, is classified as suspended panels, usually aluminum.

Sometimes this panel gives the properties of sound absorption by stacking in the upper part of perforated panel sound-absorbing sheets or mounting the panel itself at some distance from the ceiling and filling the layers with sound-absorbing insulation.

In the latter case, the cooling produced by upward from the panel plays an important role for the overall characteristics of the radiating ceiling, where the heat transfer is divided equally between the radiation and Convention. By the way, you can minimize if you extend the upper insulating layer.

The step of laying of the pipes in the panels is usually from 90 to 800 mm.

Using such systems can also provide space heating if piping some hot water panels so that you can have in the system and hot and cold water, and/or completely switch panel with refrigerant coolant.

Partial switching panels in the off-season combined with a full switching periods, when colder weather, it seems appropriate in buildings where there is a clear differentiation of the load.

An example of such differentiation could serve as perimeter and internal zones of the building. Need for perimeter heating or cooling season, and for internal cooling during the year. Noise in the panels of the water should have a temperature above the dew point for the surrounding air. Association ASHRAE recommends that the temperature of the water at the entrance to the bar was at least 1.5°C above dew point to prevent it from possible temperature fluctuations caused by the control units.

This precaution is particularly necessary to prevent damage that may cause condensation on the surface of the panels.

Note that the heat transfer resistance of smooth pipes, missing panels, significantly lower than that of finned tubes, which are equipped, for example, heaters. As a result, the surface temperature of very close to the temperature circulating through the pipes of water.

The task of maintaining the humidity of internal air, as in the traditional system rests with the system of ventilation.

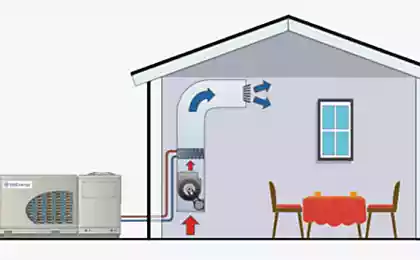

The unit can operate entirely on outside air, or mixed with recirculated, depending on whether there is enough mass of outside air to provide the required load. Usually panels are calculated by size and are organized in a system in accordance with the data on variations in load due to changes in the occupancy of the premises and/or the intensity of solar radiation. But the temperature of the primary air may vary depending on the ambient temperature when applied to perimeter plots (Fig. 2) or be maintained at a constant level in the distribution in the internal parts.

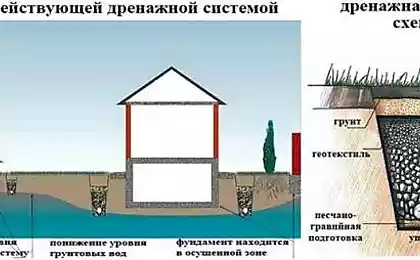

Scheme of water distribution in the system of ceiling cooling

specifying system management and zone protection from condensation

In determining the curve of temperature change of the supplied primary air is necessary, so that the dew point of room air did not exceed the surface temperature of the panels. One way of damping the perimeter loads is to install the heaters (which, for example, it is possible to supply heat recovered in the condensers of refrigeration equipment) in air ducts of primary air directed to the areas with homogeneous solar radiation. Such heaters may be arranged by means of a solar sensor.

The primary air (the consumption of which, as a rule, is two-fold air exchange of premises per hour) should be distributed evenly around the room so that evenly to assimilate the pollutants accumulating in the air (tobacco smoke, various odors, etc.).

The primary air is charged with the task of regulating the relative humidity of the air in the room. Thus, when a minor is involved the air flow is no risk of noise generation and education drafts. The primary air diffusers and lighting equipment, as a rule, can be easily installed in most standard modules "cooling" panels, although I must admit that the heat of a light bulb affects the characteristics of the "cooling" ceiling. A suspended ceiling cannot be used as an air duct from which air is drawn for cooling of lighting equipment, as this seriously degrades the performance of radiating panels.

These panels can be used in combination with any engineering systems maintain the microclimate, provided that they are able to guarantee the normal regulation of the relative humidity of the air in the room. For this purpose, do not fit system with an adjustable flow rate primary air system receives air from the Autonomous air conditioners, or such, where the unit cooler direct boiling of freon is regulated by switching on and off of the compressor.

In the Nordic countries, cooling ceiling panels are used in combination with systems which supply primary air to spread from the bottom in order to optimize users ' comfort.

The movement of air and temperature gradients is quite complicated. However, accumulated in the Nordic countries, experience shows that the optimum for exhaust devices is the placement at approximately 500 mm from the ceiling, then the diversion load due to lighting equipment, does not occur. Otherwise, generated by the increase in convective loads in accordance with the size of the lighting panel, which in turn reduces the amount of cold that can be used in order to cool the served room.

The design, functioning and commissioning

Although the temperature (dry-bulb), which can be higher than the temperature obtained in traditional systems, the relative humidity should not be above 45% below the dew point remained above 11-12°C. This means that the temperature of the cooling water flowing through the panel, should not be lower than 12+1,5=13,5°C. the working temperature of the water inside the panels should not exceed 2-4°C to maintain at an acceptable level uniform surface temperature of the panel. Taking in the design of small temperature difference can be compensated with the same distribution network subsequent expansion of the space load increases to 80 % by simply adding panels and increased to the required level of temperature difference between water (of course, provided that the refrigeration unit has a sufficient power reserve).

The rate of passage of water through the panels must be high enough to increase to the required level of heat transfer coefficient, but not to create noise so people in the room heard the roar of the water. Optimum can be considered the speed of the order of 0.3-0.6 m/s.

To ensure that the linkage between the hydraulic circuits, requires the extensive use of measurement sensors. The use of threaded couplings should be restricted in order to minimize the risk of loss of load. Instead of the threaded couplings it is recommended to use welded joints. For this reason, it is recommended not to install the automatic air vent, and the longest horizontal sections of piping must be installed by all possible means of compensation of thermal expansion. Each station should be equipped with a separate coil, which will be regulated by means of temperature sensor room air (Fig. 2). The response speed depends mainly on the length of the pipeline, but in any case will be low and insufficient to effectively compensate for sudden load fluctuations. Proportional control with a wide range can ensure the maximum stability even with large jumps of the heat load. When using two-way valves with zonal adjustment for efficient compensation of power fluctuations it is necessary to observe some precautions. Such, for example, is to install valves on the bypass to limit the static pressure or (even better) use pump with adjustable drive, controlled by inverter, which in turn activates regulatory pressostato.

The water supplied on the panel is the water from the coolers of the treatment unit primary air. For this reason, should be carefully monitored and a proportional-integral manner to regulate its flow and temperature. In particular, each unexpected raising of the dew point of the air in the room should be removed and used to change the temperature of water supplied to the panel. Sensors dew points should be placed with caution: if the number of premises served by a little, you can probably install one such sensor where it is assumed that relative humidity is the highest, or one sensor in the General exhaust duct. In systems serving a large number of areas, or when to define a space with the highest relative humidity is impossible, just need a few sensors, and a selector signal actuation it is possible to control the regulator, which will change the water temperature sensor, removing higher at the time the relative humidity.

The primary air diffusers should be selected and set so as to ensure optimal conditions for mixing incoming air with room air, and to efficiently assimilate the contaminants accumulating in the premises.

The use of cooling ceiling makes it possible to significantly save on operating costs and to free up significant space for other use. In addition, such systems provide good opportunities regulation average radiation temperature, to minimize the risk of formation of cold air flows and is virtually silent. Despite this, they still have not received wide enough distribution due to the existing architectural requirements on the appearance of the ceilings and the well-known fear of (mainly users), suggestible a water mass flowing along the ceiling.

The latter circumstance is perhaps most relevant because of the high density of electronic devices installed in modern administrative buildings. The use of cooling panels appear to be interesting in the reconstruction of old buildings: before a contractor is always a number of limitations in terms of space, and space for the organization of the system of microclimate maintenance of the building, often when the investor does not agree to the reduction of useful area.

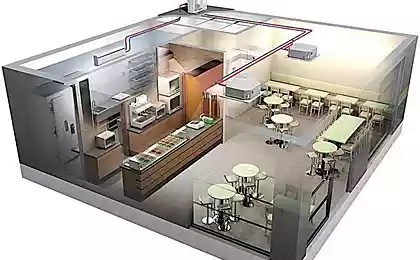

Such systems can be considered ideal in all cases when there are narrowly localized latent loads, for example in restaurants.

The possibility of using cold water at a relatively high temperature for cooling and hot water of moderate temperature for heating creates excellent conditions for the application of systems of heating provision in systems with heat recovery. In the off-season can be effective flow to the water panel from the "dry cooling towers", i.e. the use of free cooling (free cooling). The only thing you should pay attention in these cases is the presence of "dry cooling tower" with a closed circuit, since the use of water from an open cooling tower increases significantly the risk of contamination of the pipelines, laid in panels.

From experience

One of the most recent examples of the use of air-conditioning systems based on the "cooling" ceilings — engineered building systems company Courage Brewers (one of the best known UK manufacturers of beer), located in the centre of Stein, in the County of middlesex (UK). The building has four floors. To embed elements of the air conditioning system in a suspended ceiling is required for air systems 600 mm has allocated a total of 200 mm.

In addition, it supplied the demand is no clutter (air ducts or fan coils) perimeter walls, where the heating was provided by a pipeline under the floor.

The problem was solved by installation of cooling ceilings Flakt, who ensured the assimilation of the significant cooling load in administrative buildings, offices of leadership and transit stations. The distribution of primary air via the air ducts of oval cross section with the flow using ceiling diffusers. Were used the aluminum panels are equipped with copper tubing, sealed factory method directly in the panel. The pressing was carried out at the factory in order to maximize the ease of connecting panels to the existing building distribution system chilled water. The majority of panels installed at a distance of 20 mm from each other, have a width of 180 mm and are Monotube or twin-tube. Along with the radiant panels were installed false panels without pipes, performs a decorative function. Panels without pipes are surface, slightly different from the active panels, this is done in order to identify areas of possible installation of interior partitions.

Each independent section separately connected to two-pipe distribution system, where in turn the flow is regulated through three-way valve deviator, ceiling controlled by a thermostat. The panels have a matte surface for the purpose of intensifying the radiant flux.

Provided the cooling load constitute 70-90 W/m2, including some dissipation due to the work of office equipment. The main facades of the buildings have large glazed surfaces on the axis North-South, while the South facade is equipped with external sun protection devices such as shutters.

Inside, the building is divided into three perimeter and internal zones, divided according to needs and forming separate rooms and administrative offices open space. The temperature of the water supplied to the panel is 15°C, which allows to avoid the formation of condensate when the air temperature in the room below 24°C dry bulb temperature at 60% relative humidity. The use of cooling panels allows, furthermore, to provide effective direct cooling of people in transit areas inside the atrium, preventing heating caused by solar radiation, and temperature stratification, characteristic of areas with extensive glazing.

The supply temperature primary air varies depending on the difference of external and internal temperatures.

In conclusion, it can be noted that on the Scandinavian Peninsula systems of this type are spreading mainly in areas with low ceilings where significant excess heat is generated and high demands on the noise level. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: www.gazanet.com.ua/potolochnoe-panelnoe-ochlazhdenie-pomescheniy

The benefits of using "cooling" ceiling lie in their quiet operation, no unpleasant drafts and extremely low maintenance cost. "Cooling" ceilings can carry a decent load, it does not take up valuable space and due to the fact that they lower the average radiant temperature in the room, their use makes it possible to increase the air temperature beyond the limits allowed by the organization of cooling of the room.

For example, to create comfort, feel equal at a temperature of 24°C using conventional systems, the use of "cooling" ceiling allows you to heat the air in the room to 25-26°C dry bulb, depending on the intensity of heat radiation, for example solar radiation.

Cooling radiant flux on the heads of people gives them a special feeling of freshness.

The ability to operate at higher temperatures allows the use of the water rather high temperature (15°C), which leads to substantial savings in the electricity bills.

In recent years we have tested many systems prefabricated ceiling cooling.

These include panels with built-in overlap of cooling coils pipes and a variety of suspended panels, the top of which was zapressovyvat, welded or fastened clips tubes, through which was passed cold water.

One of the first patents in this field included even lay water pipe directly in the ceiling construction.

Compared with suspended panels, advantage panels with integrated cold coil that their use gives greater installation flexibility, though the works themselves are objectively more complex, because you require constant quality control and logistic coordination of actions between members of the project (construction and erection organization and the firm-installer).

As to guarantee optimal insulation over the pipe is almost impossible, the system is in any case leads to losses of up cold at an average of 20 % of the total flow of radiant energy.

Association ASHRAE has defined a procedure for calculating "cooling" ceiling with built-in coil and the corresponding data for exposure. Most of the "cooling" of the ceilings established in the last thirty years, is classified as suspended panels, usually aluminum.

Sometimes this panel gives the properties of sound absorption by stacking in the upper part of perforated panel sound-absorbing sheets or mounting the panel itself at some distance from the ceiling and filling the layers with sound-absorbing insulation.

In the latter case, the cooling produced by upward from the panel plays an important role for the overall characteristics of the radiating ceiling, where the heat transfer is divided equally between the radiation and Convention. By the way, you can minimize if you extend the upper insulating layer.

The step of laying of the pipes in the panels is usually from 90 to 800 mm.

Using such systems can also provide space heating if piping some hot water panels so that you can have in the system and hot and cold water, and/or completely switch panel with refrigerant coolant.

Partial switching panels in the off-season combined with a full switching periods, when colder weather, it seems appropriate in buildings where there is a clear differentiation of the load.

An example of such differentiation could serve as perimeter and internal zones of the building. Need for perimeter heating or cooling season, and for internal cooling during the year. Noise in the panels of the water should have a temperature above the dew point for the surrounding air. Association ASHRAE recommends that the temperature of the water at the entrance to the bar was at least 1.5°C above dew point to prevent it from possible temperature fluctuations caused by the control units.

This precaution is particularly necessary to prevent damage that may cause condensation on the surface of the panels.

Note that the heat transfer resistance of smooth pipes, missing panels, significantly lower than that of finned tubes, which are equipped, for example, heaters. As a result, the surface temperature of very close to the temperature circulating through the pipes of water.

The task of maintaining the humidity of internal air, as in the traditional system rests with the system of ventilation.

The unit can operate entirely on outside air, or mixed with recirculated, depending on whether there is enough mass of outside air to provide the required load. Usually panels are calculated by size and are organized in a system in accordance with the data on variations in load due to changes in the occupancy of the premises and/or the intensity of solar radiation. But the temperature of the primary air may vary depending on the ambient temperature when applied to perimeter plots (Fig. 2) or be maintained at a constant level in the distribution in the internal parts.

Scheme of water distribution in the system of ceiling cooling

specifying system management and zone protection from condensation

In determining the curve of temperature change of the supplied primary air is necessary, so that the dew point of room air did not exceed the surface temperature of the panels. One way of damping the perimeter loads is to install the heaters (which, for example, it is possible to supply heat recovered in the condensers of refrigeration equipment) in air ducts of primary air directed to the areas with homogeneous solar radiation. Such heaters may be arranged by means of a solar sensor.

The primary air (the consumption of which, as a rule, is two-fold air exchange of premises per hour) should be distributed evenly around the room so that evenly to assimilate the pollutants accumulating in the air (tobacco smoke, various odors, etc.).

The primary air is charged with the task of regulating the relative humidity of the air in the room. Thus, when a minor is involved the air flow is no risk of noise generation and education drafts. The primary air diffusers and lighting equipment, as a rule, can be easily installed in most standard modules "cooling" panels, although I must admit that the heat of a light bulb affects the characteristics of the "cooling" ceiling. A suspended ceiling cannot be used as an air duct from which air is drawn for cooling of lighting equipment, as this seriously degrades the performance of radiating panels.

These panels can be used in combination with any engineering systems maintain the microclimate, provided that they are able to guarantee the normal regulation of the relative humidity of the air in the room. For this purpose, do not fit system with an adjustable flow rate primary air system receives air from the Autonomous air conditioners, or such, where the unit cooler direct boiling of freon is regulated by switching on and off of the compressor.

In the Nordic countries, cooling ceiling panels are used in combination with systems which supply primary air to spread from the bottom in order to optimize users ' comfort.

The movement of air and temperature gradients is quite complicated. However, accumulated in the Nordic countries, experience shows that the optimum for exhaust devices is the placement at approximately 500 mm from the ceiling, then the diversion load due to lighting equipment, does not occur. Otherwise, generated by the increase in convective loads in accordance with the size of the lighting panel, which in turn reduces the amount of cold that can be used in order to cool the served room.

The design, functioning and commissioning

Although the temperature (dry-bulb), which can be higher than the temperature obtained in traditional systems, the relative humidity should not be above 45% below the dew point remained above 11-12°C. This means that the temperature of the cooling water flowing through the panel, should not be lower than 12+1,5=13,5°C. the working temperature of the water inside the panels should not exceed 2-4°C to maintain at an acceptable level uniform surface temperature of the panel. Taking in the design of small temperature difference can be compensated with the same distribution network subsequent expansion of the space load increases to 80 % by simply adding panels and increased to the required level of temperature difference between water (of course, provided that the refrigeration unit has a sufficient power reserve).

The rate of passage of water through the panels must be high enough to increase to the required level of heat transfer coefficient, but not to create noise so people in the room heard the roar of the water. Optimum can be considered the speed of the order of 0.3-0.6 m/s.

To ensure that the linkage between the hydraulic circuits, requires the extensive use of measurement sensors. The use of threaded couplings should be restricted in order to minimize the risk of loss of load. Instead of the threaded couplings it is recommended to use welded joints. For this reason, it is recommended not to install the automatic air vent, and the longest horizontal sections of piping must be installed by all possible means of compensation of thermal expansion. Each station should be equipped with a separate coil, which will be regulated by means of temperature sensor room air (Fig. 2). The response speed depends mainly on the length of the pipeline, but in any case will be low and insufficient to effectively compensate for sudden load fluctuations. Proportional control with a wide range can ensure the maximum stability even with large jumps of the heat load. When using two-way valves with zonal adjustment for efficient compensation of power fluctuations it is necessary to observe some precautions. Such, for example, is to install valves on the bypass to limit the static pressure or (even better) use pump with adjustable drive, controlled by inverter, which in turn activates regulatory pressostato.

The water supplied on the panel is the water from the coolers of the treatment unit primary air. For this reason, should be carefully monitored and a proportional-integral manner to regulate its flow and temperature. In particular, each unexpected raising of the dew point of the air in the room should be removed and used to change the temperature of water supplied to the panel. Sensors dew points should be placed with caution: if the number of premises served by a little, you can probably install one such sensor where it is assumed that relative humidity is the highest, or one sensor in the General exhaust duct. In systems serving a large number of areas, or when to define a space with the highest relative humidity is impossible, just need a few sensors, and a selector signal actuation it is possible to control the regulator, which will change the water temperature sensor, removing higher at the time the relative humidity.

The primary air diffusers should be selected and set so as to ensure optimal conditions for mixing incoming air with room air, and to efficiently assimilate the contaminants accumulating in the premises.

The use of cooling ceiling makes it possible to significantly save on operating costs and to free up significant space for other use. In addition, such systems provide good opportunities regulation average radiation temperature, to minimize the risk of formation of cold air flows and is virtually silent. Despite this, they still have not received wide enough distribution due to the existing architectural requirements on the appearance of the ceilings and the well-known fear of (mainly users), suggestible a water mass flowing along the ceiling.

The latter circumstance is perhaps most relevant because of the high density of electronic devices installed in modern administrative buildings. The use of cooling panels appear to be interesting in the reconstruction of old buildings: before a contractor is always a number of limitations in terms of space, and space for the organization of the system of microclimate maintenance of the building, often when the investor does not agree to the reduction of useful area.

Such systems can be considered ideal in all cases when there are narrowly localized latent loads, for example in restaurants.

The possibility of using cold water at a relatively high temperature for cooling and hot water of moderate temperature for heating creates excellent conditions for the application of systems of heating provision in systems with heat recovery. In the off-season can be effective flow to the water panel from the "dry cooling towers", i.e. the use of free cooling (free cooling). The only thing you should pay attention in these cases is the presence of "dry cooling tower" with a closed circuit, since the use of water from an open cooling tower increases significantly the risk of contamination of the pipelines, laid in panels.

From experience

One of the most recent examples of the use of air-conditioning systems based on the "cooling" ceilings — engineered building systems company Courage Brewers (one of the best known UK manufacturers of beer), located in the centre of Stein, in the County of middlesex (UK). The building has four floors. To embed elements of the air conditioning system in a suspended ceiling is required for air systems 600 mm has allocated a total of 200 mm.

In addition, it supplied the demand is no clutter (air ducts or fan coils) perimeter walls, where the heating was provided by a pipeline under the floor.

The problem was solved by installation of cooling ceilings Flakt, who ensured the assimilation of the significant cooling load in administrative buildings, offices of leadership and transit stations. The distribution of primary air via the air ducts of oval cross section with the flow using ceiling diffusers. Were used the aluminum panels are equipped with copper tubing, sealed factory method directly in the panel. The pressing was carried out at the factory in order to maximize the ease of connecting panels to the existing building distribution system chilled water. The majority of panels installed at a distance of 20 mm from each other, have a width of 180 mm and are Monotube or twin-tube. Along with the radiant panels were installed false panels without pipes, performs a decorative function. Panels without pipes are surface, slightly different from the active panels, this is done in order to identify areas of possible installation of interior partitions.

Each independent section separately connected to two-pipe distribution system, where in turn the flow is regulated through three-way valve deviator, ceiling controlled by a thermostat. The panels have a matte surface for the purpose of intensifying the radiant flux.

Provided the cooling load constitute 70-90 W/m2, including some dissipation due to the work of office equipment. The main facades of the buildings have large glazed surfaces on the axis North-South, while the South facade is equipped with external sun protection devices such as shutters.

Inside, the building is divided into three perimeter and internal zones, divided according to needs and forming separate rooms and administrative offices open space. The temperature of the water supplied to the panel is 15°C, which allows to avoid the formation of condensate when the air temperature in the room below 24°C dry bulb temperature at 60% relative humidity. The use of cooling panels allows, furthermore, to provide effective direct cooling of people in transit areas inside the atrium, preventing heating caused by solar radiation, and temperature stratification, characteristic of areas with extensive glazing.

The supply temperature primary air varies depending on the difference of external and internal temperatures.

In conclusion, it can be noted that on the Scandinavian Peninsula systems of this type are spreading mainly in areas with low ceilings where significant excess heat is generated and high demands on the noise level. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: www.gazanet.com.ua/potolochnoe-panelnoe-ochlazhdenie-pomescheniy

BMW will show the future car Vision Car at CES 2016

Horoscope for the sign Aquarius. Find out what to expect in 2016