676

Printing serious printer

I propose to take a short tour of the workshop, in which the UV printing (UV printing) on a serious machine.

First, briefly about the very essence of UV printing:

UV printing different brightness and saturation of colors, as well as high-definition images, which makes possible to apply any image in compliance with the color. Moreover, UV printing enables to apply to the material of white color, which makes possible to apply the image on the surface of a variety of colors - from transparent to black. Option printing white ink creates the effect of the backlight and makes whites to the fore, giving the image accuracy and brightness.

35 photo.

The printer itself

It is no secret that the image applied solvent printing, eventually losing color. UV-curable inks, on the contrary, do not fade or dissolve in water and solvents withstand temperature variations from -40 to + 180 ° C. Moreover, under the influence of sunlight, paint adhesion becomes even stronger. Therefore, if you need temporary advertising structure, which has to be updated every six months, the solvent printing - an acceptable option. But the image applied by UV printing, will serve as much as will serve as the product itself.

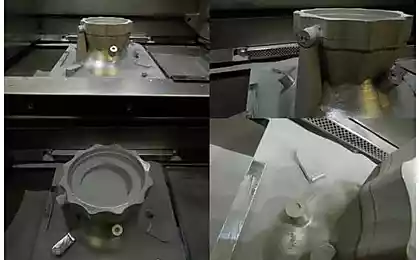

2) Type the printer back and "receiving" the table for printing on rigid substrates

UV printing is completely safe for the environment. When printing does not emit harmful substances that ensures absolute ecological compatibility of the finished product. Through the image article, UV printing, can be used not only in manufacturing, but also in dwellings, including nurseries. For comparison, when printing with solvent into the atmosphere falls to 80% of the ink, and the evaporation is continued in the operation of the product.

3) The table of "exit" of the material. The line, which it is - 1m.

The obvious advantage of UV printing - direct printing of high resolution on hard surfaces. Other solutions to this problem involve the use of self-adhesive film. However, in addition to the above "weak" solvent printing, in this case the quality of products is poor due to the fragility of the film itself.

4) The same table with different perspective to transfer production scale

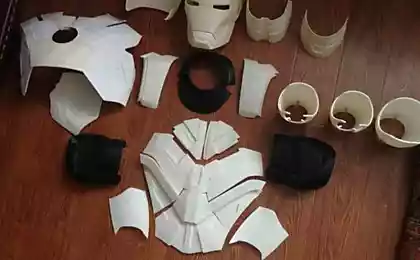

The possibility of formation of bulk, texture images when printed elements of the "rise" above the surface, is another unique advantage of UV printing, widely used for the production of stained-glass windows. Get a similar effect is possible only with the use of 3D-printers - for solvent printing it just is not available.

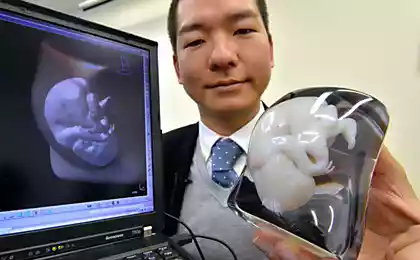

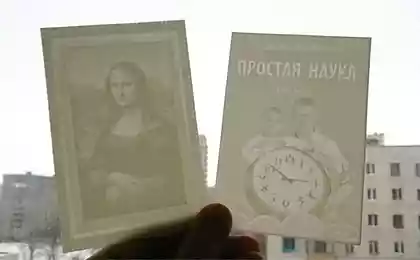

5) Product samples

Maximum workpiece dimensions: width - 2500 mm, thickness - 130 mm in length for hard materials - 3000 mm.

6) Once the sample

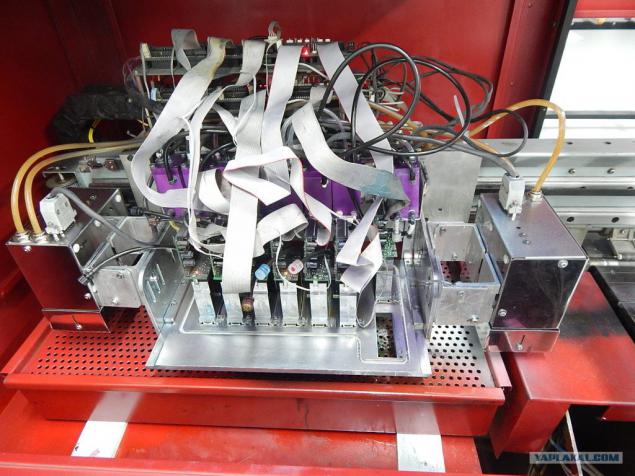

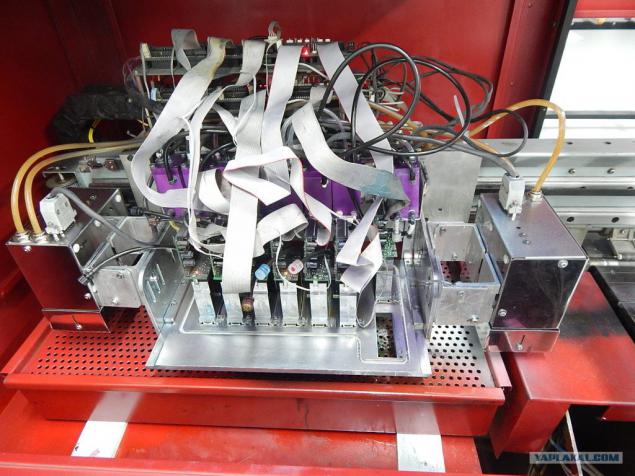

7) parked carriage with printheads

8) pumps ink, air and vacuum

9) Sami ink - in these bubbles

10) of the carriage with printheads larger. Along the edges are clearly visible UV lamp

11) Remote control carriage with ink level indicator heads

12) Operator

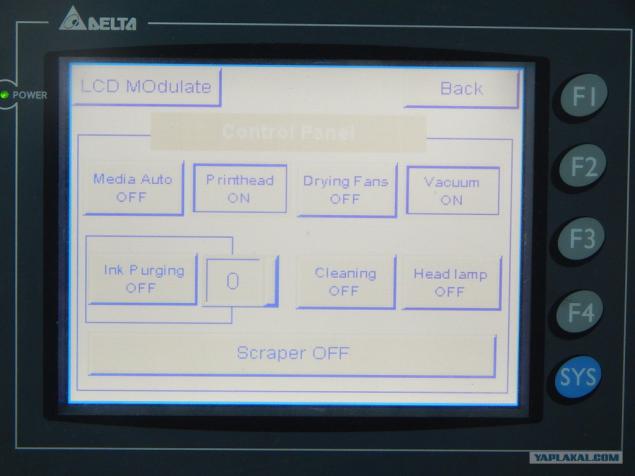

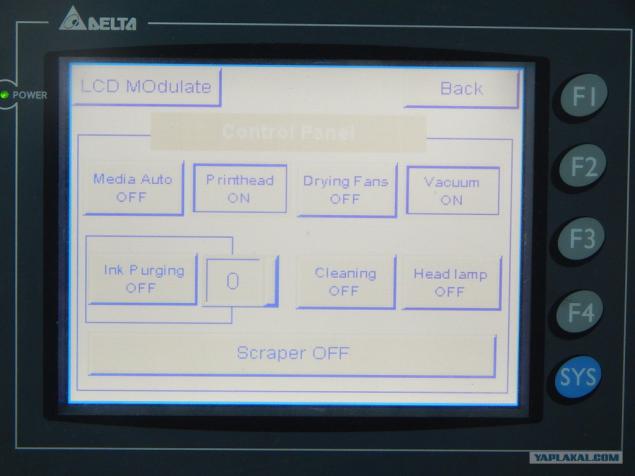

13) Monitor printer large

14) emblem. The serial number 140. In the history of the manufacturer produced about 300 cars, of which UV printers - less than 100. This is just one of these.

15) The stabilizer and UPS 3 kW. All grown-up)

16) In the event of a power failure - emergency GASOLINE 6, 5 kW entire production drags without problems.

First, briefly about the very essence of UV printing:

UV printing different brightness and saturation of colors, as well as high-definition images, which makes possible to apply any image in compliance with the color. Moreover, UV printing enables to apply to the material of white color, which makes possible to apply the image on the surface of a variety of colors - from transparent to black. Option printing white ink creates the effect of the backlight and makes whites to the fore, giving the image accuracy and brightness.

35 photo.

The printer itself

It is no secret that the image applied solvent printing, eventually losing color. UV-curable inks, on the contrary, do not fade or dissolve in water and solvents withstand temperature variations from -40 to + 180 ° C. Moreover, under the influence of sunlight, paint adhesion becomes even stronger. Therefore, if you need temporary advertising structure, which has to be updated every six months, the solvent printing - an acceptable option. But the image applied by UV printing, will serve as much as will serve as the product itself.

2) Type the printer back and "receiving" the table for printing on rigid substrates

UV printing is completely safe for the environment. When printing does not emit harmful substances that ensures absolute ecological compatibility of the finished product. Through the image article, UV printing, can be used not only in manufacturing, but also in dwellings, including nurseries. For comparison, when printing with solvent into the atmosphere falls to 80% of the ink, and the evaporation is continued in the operation of the product.

3) The table of "exit" of the material. The line, which it is - 1m.

The obvious advantage of UV printing - direct printing of high resolution on hard surfaces. Other solutions to this problem involve the use of self-adhesive film. However, in addition to the above "weak" solvent printing, in this case the quality of products is poor due to the fragility of the film itself.

4) The same table with different perspective to transfer production scale

The possibility of formation of bulk, texture images when printed elements of the "rise" above the surface, is another unique advantage of UV printing, widely used for the production of stained-glass windows. Get a similar effect is possible only with the use of 3D-printers - for solvent printing it just is not available.

5) Product samples

Maximum workpiece dimensions: width - 2500 mm, thickness - 130 mm in length for hard materials - 3000 mm.

6) Once the sample

7) parked carriage with printheads

8) pumps ink, air and vacuum

9) Sami ink - in these bubbles

10) of the carriage with printheads larger. Along the edges are clearly visible UV lamp

11) Remote control carriage with ink level indicator heads

12) Operator

13) Monitor printer large

14) emblem. The serial number 140. In the history of the manufacturer produced about 300 cars, of which UV printers - less than 100. This is just one of these.

15) The stabilizer and UPS 3 kW. All grown-up)

16) In the event of a power failure - emergency GASOLINE 6, 5 kW entire production drags without problems.