Print plastic - boring? Me - too, so today I will tell you my idea how to make silicone products on a standard 3D printer.

Now I'm involved in a project

interior things - we are experimenting with a variety of technologies for the production of items. Almost all originally designed in 3D, so the key technology is 3D printing.

But by itself 3D printing has limitations. When we print technology FDM (conventional 3D printers) that, accordingly, find ourselves limited in choice of materials, surface quality, time of printing.

Therefore, for a long time brewing task: to circumvent some of the limitations of FDM 3D printing with minimal effort.

idea h4>

The essence of my idea is this: to get the product from the injection of silicone, but pour it right in printed form!

What is the innovation here? And that this usually creates silicone mold, and it is removed from the master model. That is, if you pour the silicone directly into printed form, we will rid themselves of the cost of casting forms, and in fact on the form requires sometimes several times larger than the silicone on the product itself. Let us begin to implement.

The implementation of the idea of casting in printed form h4>

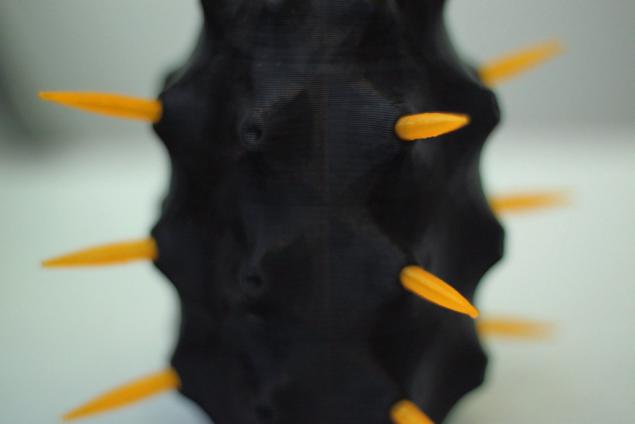

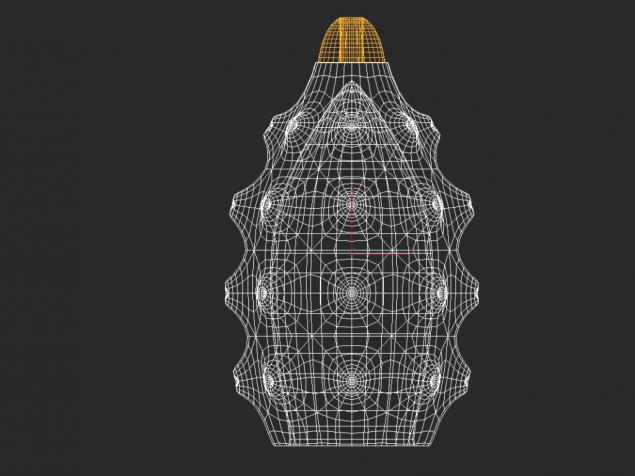

I forgot to say - now we are experimenting with the manufacture of lamps. Therefore, the first step is to think about how our product should function and how it will be filled silicone. As a result, taking into account all the nuances of printing and casting, the designer has created just such a 3D model of the luminaire:

This model is also the same model for printing forms, here is such a trick. Clearly visible inside the cavity and which will fill material

The object turned out medium size - 23 cm in height and 11 cm in diameter. Let's have finally print.

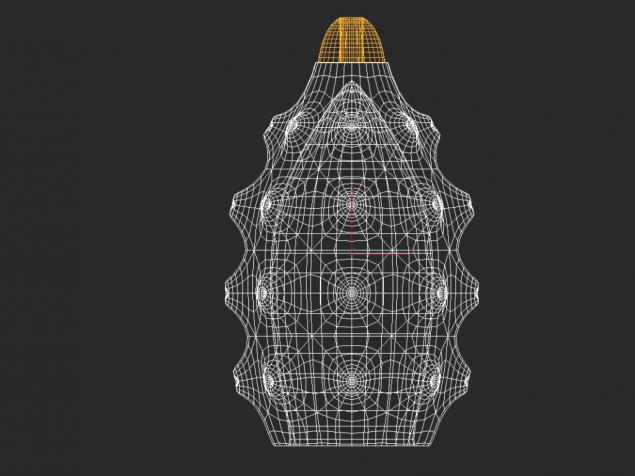

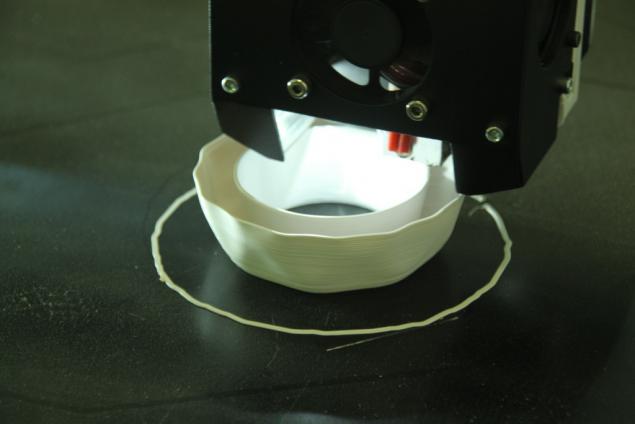

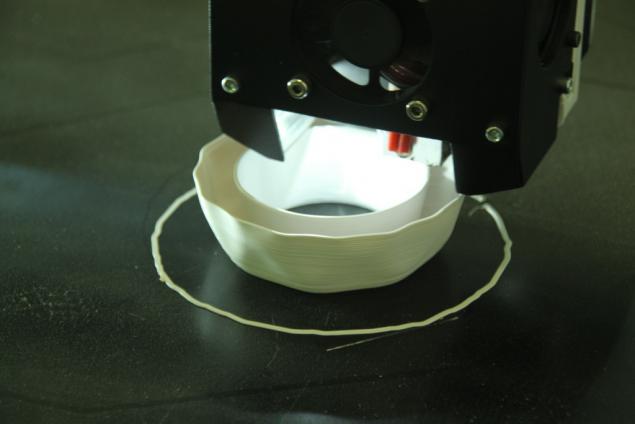

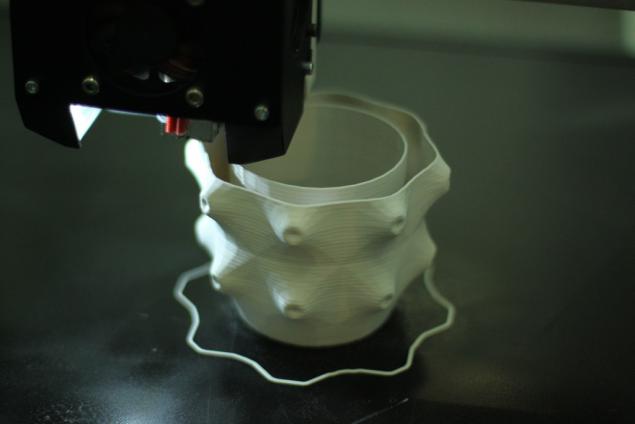

Print decided on our large 3D printer, because he stood nozzle 1, 0 mm - so the press was quick, and the form has turned out strong, though, and a thickness of only 1 wall. Material - ABS. Naturally, print only the wall - no filling.

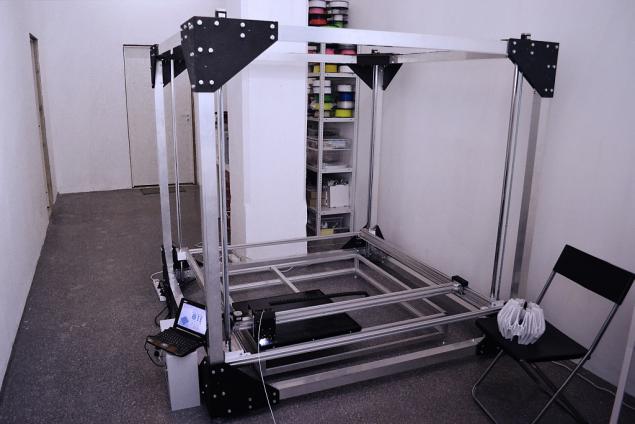

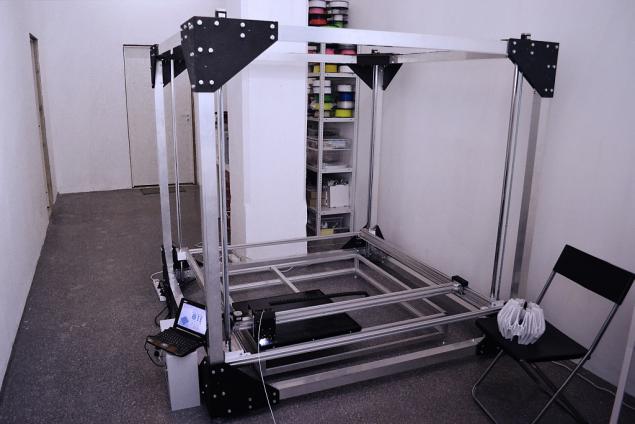

By the way, here's a photo of this King the Printer:

His areas of print - 1, 2 x 1 m, 2 m, so print such a small piece of course a bit ridiculous. If someone is interested, I will write an article about him, he is almost finished and has a very interesting feature.

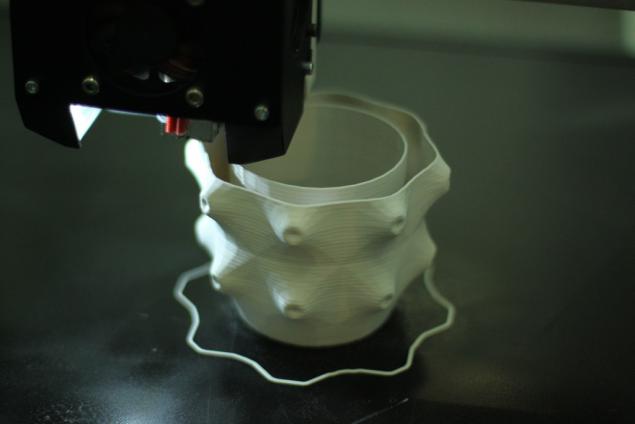

Thus, the form is received:

Below you can see how thick the line width. Spout at the top of a specially extended, to be able to exactly cut it then.

In general, turned smartly on the first try. Now you have to pour into the silicone. Do not forget to seal form by covering all the small holes, such as hot melt.

Unfortunately, the molding process could not be removed, because Silicone much spoiled, and especially delay was impossible.

Further silicone cured in a day and we break the mold, taking silicone products.

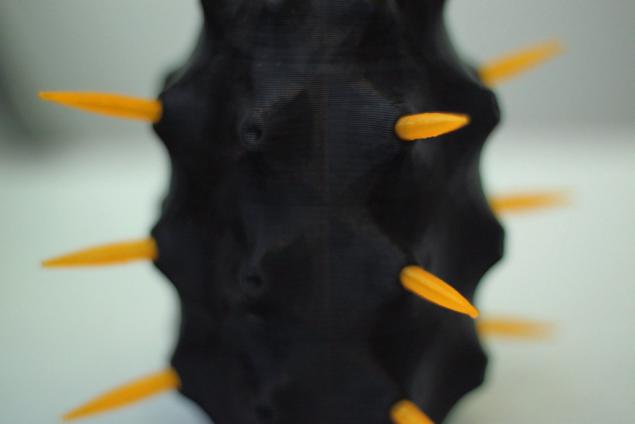

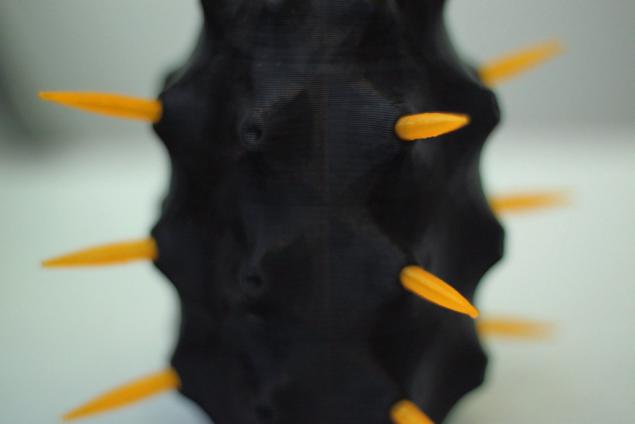

According to the idea of the designer is to be a lamp with translucent spines. But shed spikes we did not and decided to just print. To insert the spikes did in silicon holes.

Next, insert the bulb and can now evaluate how it happened.

Result h4>

It turned out the lamp, for example, for the bar. As planned, he is not alone and is in a similar interior.

The surface texture is completely repeated layering of 3D printing, but, since the layer was thick - about 0.6 mm, then it is different and interesting eye shimmers. At the touch of a very unusual - it is soft, but it seems printed in black plastic.

As a result, a design idea has been implemented. Cost of time and money has turned quite economical, but the most important thing that tried another way of using 3D printing, which means that more ideas can be realized.

Off-Topic h4> About printing of plastic - we also have a lamp that is completely printed. Very long printed, probably weighs a kilogram. Here it is:

Its height - 30 cm, so that a sufficiently large. Shine well and on the walls draws an interesting pattern.

Other fixtures can look at the project site.

P.S. It would be interesting to hear your ideas on the subject of production in this way. Next time I hope to tell you about printing directly by the silicone.

Source: geektimes.ru/post/242274/