1038

First printed in the Philippine suite hotel will soon take a rest

Luxury Hotel Lewis Grand Hotel in Angelese the Philippines got the world's first 3D-printed hotel room suites, with a total area of 130 square meters. With the problem, according to Lewis Yakicha - the owner of the hotel, a giant 3D-printer performed admirably for 100 hours, while attaining a fairly complex design concept. Number printed concrete at the Lewis Grand Hotel - is the first in the history of mankind suitable for a comfortable stay at the apartment, built in a similar way.

The owner of the hotel - Lewis Yakich from California, a civil engineer by profession so far has accumulated considerable experience in the construction of homes in the United States. But the number built in the Lewis Grand Hotel, most likely, was not destined to go down in history, if not the idea of Lewis bring to the construction of Andrey Rudenko from Minnesota, is widely known as the creator of a unique concrete of 3D-printers and the world's first printing 3D-lock of concrete.

Little concrete about the author of 3D-printers and invention

A few words for those who are not familiar with the invention Andrei Rudenko - concrete of 3D-printers for building large-scale construction of structures and whole buildings. The first mention of the concrete of 3D-printers Rudenko and the author of the invention relate to Minnesota, where the experiment was built mini-castle of concrete, became the first experience for Andrew.

Construction of the castle by 3D-printing

Successful projects of the castle, Rudenko has returned to the idea of 3D-printing house. Initially, their first house he planned to build in Minnesota, but due to the harsh climatic conditions and harsh winters platform for future, larger scale experiments have been chosen and the Philippines Lewis Grand Hotel.

Certain difficulties were related to the transportation of large-sized 3D printer from Minnesota. Fortunately, one of the most important issues - the ingredients for the production of mortar found in the region in excess. The main components of the composition used as a filler was sand and volcanic ash. From them, and built all the structural elements of the building of the hotel. Another factor in the successful implementation of the plan conceived by the Philippines has become a climate conducive to rapid drying of the mortar.

The dimensions allow a printer Rudenko not elementwise and monolithic seal elements design that eliminates the need for subsequent Build to form joints.

Apartment size 10, 5 x 12 m, 5 m and a height of 3 m is located in a separate annexe to the main building and the hotel has everything necessary for comfortable rest - utilities, including water and electricity, a set of modern sanitary ware, jacuzzi, elements of heat systems -, waterproofing and & quot; Smart House & quot ;. Strength erected structure is increased due to the reinforcement steel bars.

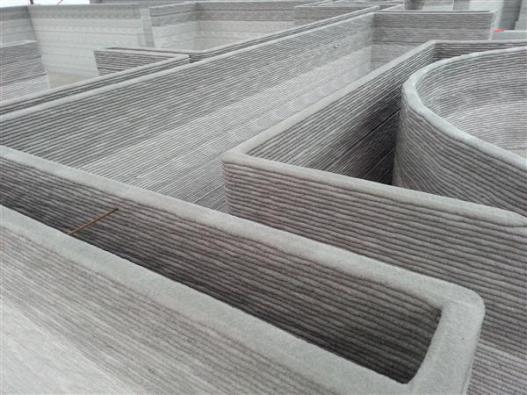

Perhaps the use of 3D-printing with the current level of technology - not the fastest way to the construction of building designs with a predominance of straight-line geometry, but where the concept of the architect and the designer goes beyond the usual geometric shapes and involves the use of sophisticated straight-elements, an alternative 3D-technology is not. With the 3D-printer Rudenko cement layers can be applied up to 10 mm and a thickness of 30 mm. The main advantages of the model - speed, precision and accuracy of the operations.

Serious help optimize the operation of the printer inventor had the project participants' self-copying 3D-printer » RepRap .

By implementing a large-scale 3D-construction projects with the support of professional construction companies today we are very close to China, where the question of affordable housing is most acute. Basic research in the field of building 3D-printing are carried out in Europe and the US.

Projects WinSun

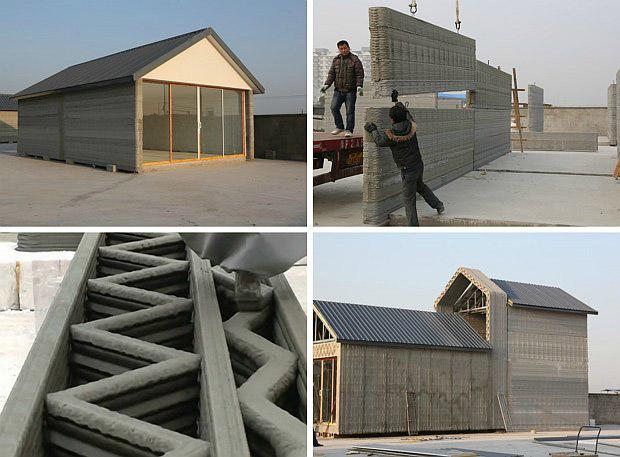

In April last year the Chinese company WinSun announced the successful completion of the construction of 10 homes of 200 square meters. meters by 3D-printing during the day! The cost of each house of the processing of industrial waste and construction waste is estimated at only 30,000 yuan = $ 4 800. For piecemeal printing was used printer is 32 meters long, 10 meters wide and 6 meters high 6. Printed separately walls and frame the final stage of going into a single structure. Of course, talk about any architectural value of houses, printed in one area of Shanghai Qingpu, as is the case with the number of the hotel Rudenko, in this case is inappropriate, but the foundation for solving the problem of affordable housing the Chinese were able to clearly lay.

In order to ensure the pace of printing company planned to create at least 100 plants for recycling of construction waste in the construction of ultra ink of 3D-printers.

Less than six months

Another record in the construction of large-scale structures using 3D-printing company WinSun delivered six months after the completion of the project of 10 houses. At this time in the pilot project specialists built 5-storey complex and quite a respectable two-storey mansion in the area of Suzhou Industrial Park.

The area of the building 1100 square meters. m. i>

After becoming acquainted with the projects implemented WinSun, achieving Rudenko no longer looks something incredible. However, one of the main obstacles to the large-scale introduction of technology 3D-construction - a complete lack of unified national legislative and regulatory regulations. Much easier it is now the implementation is as solid and prefabricated low-rise building structures that brilliantly managed to confirm Andrei Rudenko, typing posh room at the Lewis Grand Hotel in just 100 hours.

Successful completion of the construction of suites in the Grand Hotel in Lewis deadlines - the best advertisement Lewis Yakichu already signed a contract for the joint construction of another 20 such apartments by November 2015. According to estimates of Rudenko, the use of improved models of its 3D-printer allows to print on a similar technology to 6 low-rise buildings per week, and that is important, with the reduction of up to 60 percent of the material and physical costs. Well, until someone develops enthusiasm 3D-печать toy houses with the use of small printers, ABS and PLA-plastic, for someone to individual 3D-reality measured by the number of printed square meters.

However, it is better to see once:

Dear readers, we are always happy to meet and wait for you in the pages of the blog iCover ! We will continue to delight you with their publications and will do everything possible to ensure that the time spent with us will bring pleasure to you.

Source: geektimes.ru/company/icover/blog/262838/