Case 3d-printing from metal (DMLS): microreactor for refining

«Come military, ask to print some gizmo the size of a matchbox, just buy the printer and disappear» from a conversation with suppliers 3d-printer i> blockquote>

The photograph on the right - Elon Musk tweet about what they printed piece of rocket engine heat-resistant nickel-chromium alloy (Inconel) on 3d-printer EOS.

Later, at presentation has information that SuperDraco - completely i> printed on the 3D-printer landing engines each of which has a thrust of about eight tons.

( impressive video i> A rocket engine is fully printed on the 3d-printer to create a "flick of the wrist» i> < / a>)

About how things are in the world with 3d-printing services I already wrote , since I was interested in what they are capable 3d the Printer on metal. First I tried to find a place in Moscow where you can touch / pofotat this device but encountered difficulties, they say 200,000 €, and you with unwashed hands or these printers are in the territory of military / space objects that can not go there without tolerance.

But there were St. Petersburg colleagues who shared information, as they created a microreactor on 3d-printer (from the same company as at Elon Musk).

Case of the St. Petersburg service by 3d-printing:

Customer Order Requirements

Learn more about the technology DMLS,

about printer EOS M290

and about the microreactor

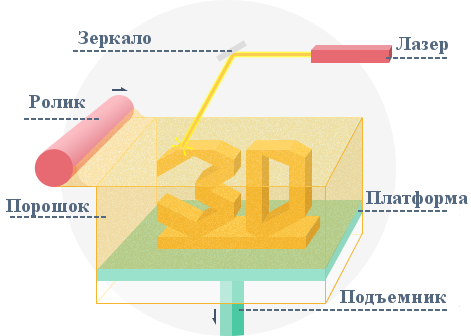

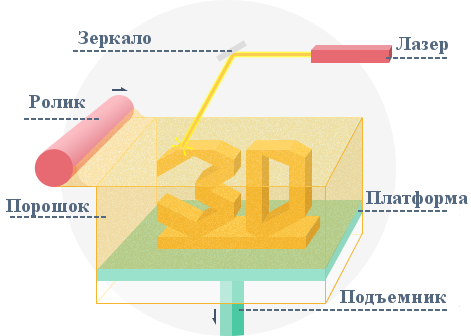

About the technology h4> Open The article on Wikipedia about < br />

Selective laser melting (SLM) is an additive manufacturing process that uses CAD data files as a digital source of information and energy in the form of a laser beam of high power (usually fiber laser) to create a three-dimensional metal parts by fusing fine metal powder particles together.

Printing Technology DMLS is as follows: the fine metal powder is distributed by means of a thin layer of coating or roller mechanism on a platform that is lowered vertically.

The modeling process is performed laser melts the powder layer by layer, thus forming a finished object. The procedure takes place in the chamber of the closed type, at the end of the print model cools down and cleaned of powder residue.

mikroveschi

About the printer h4> Open EOS (Electro Optical Systems, Germany)

EOS M290

Machines Series «M» are used for mold making general-purpose, special tools, parts made of special alloys for the aircraft and aerospace industries.

The dimensions of the zone of construction 250h250h215 mm.

Depending on the material used, the speed of construction part 7, 2-72, 0 cm3 / hr, the thickness construction of 20 - 100 microns, the laser power of 400 W,

laser spot diameter of 100-500 microns.

Consumers are offered new metal-powder composition:

- An alloy of cobalt-chromium (CoCr);

- Titanium alloys;

- Stainless steel;

- Alloy Inconel (superalloy based on nickel),

- Tool steel.

Preparing data

PC with Windows

WebBuilder Software: EOS RP Tools; EOSTATE; Magics RP (Materialise)

Format: STL (optional - Converter from all standard formats)

Network: Ethernet

Certification: CE, NFPA

video service history

About 3d-printing service h4>

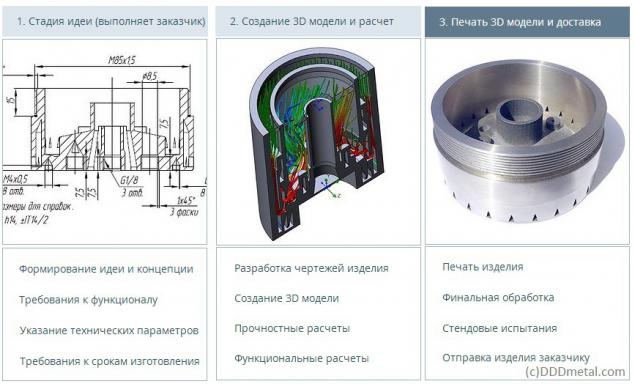

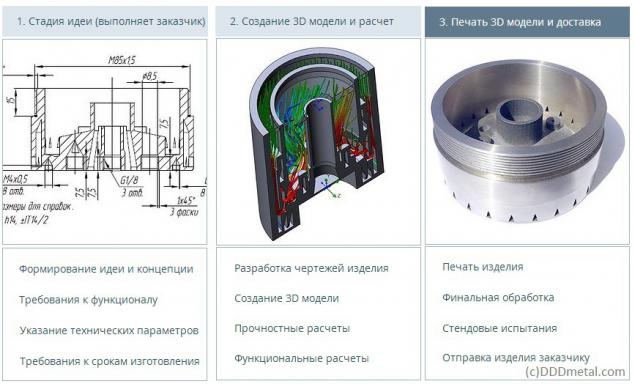

How it looks in theory

As it was in reality

Experts on the basis of drawings was developed 3D model of the microreactor.

Then the model was printed stainless steel.

After printing outside the reactor is finally processed (polished), and screw the threaded fitting hydrogen supply at the side.

For example (at the request of the customer) printed product in the "cut", the customer was able to assess the quality of the print.

The size of the microreactor: height 150 mm, outer diameter of about 50 mm.

The item was printed about 16 hours (if you print immediately 10 parts - it also took 16 hours)

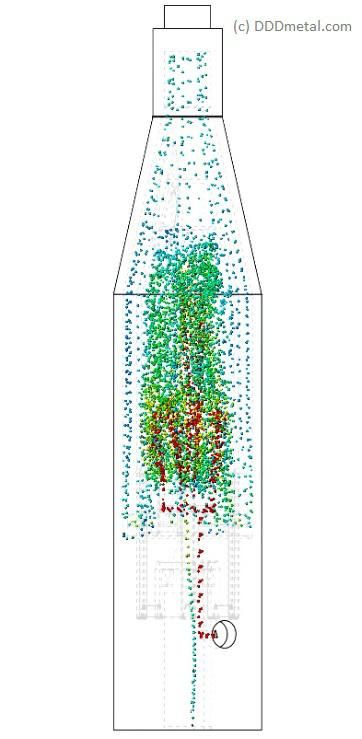

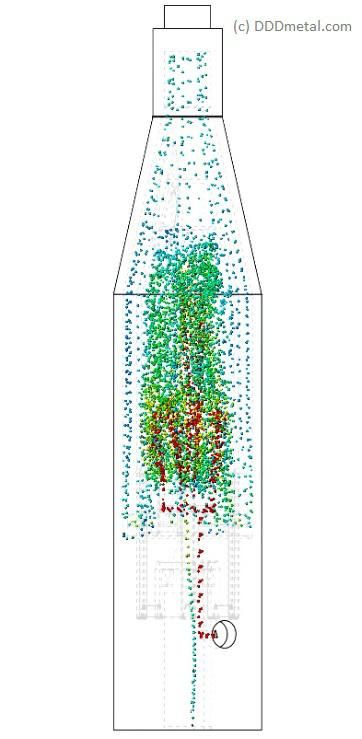

Service representatives 3d-printing invited to participate in testing on standard microreactor reactor facility (within the orange frame specified placement microreactor - he's under the insulation).

A series of tests was carried out in a few months. Continuous operation mode setting (24 hours). Pressure in the reactor was from 30 to 50 atmospheres (depending on the experimental design), the temperature from 150 to 500 degrees Celsius.

process testing

In the reactor a high-octane components of gasoline (required for the production of gasoline Euro 5)

the distribution of hydrogen in the reactor chamber. Color gradations displayed speed of hydrogen.

After successful testing the customer decided to order one party microreactors printed on a 3D printer.

The cost of the microreactor was about $ 500, that for similar microreactors (manufactured by traditional methods) about 10-15 times cheaper.

Traditional manufacturing process - a welding tokarka, prefabricated structures. (Cost $ 5000-7500 per piece)

Finally a few more articles published in Petersburg 3d-service:

Manifold for refining

product with an internal cooling system (integrated heat exchanger)

"The tube bundle" - part of the distribution system flows (liquid and gas)

Source: