831

10 technologies that should be remembered in 2015

Technology is perhaps the biggest cause of change in the modern world. And although, like every coin, they have a reverse side, technological breakthroughs promise of solving the most pressing global issues of our time. From cars with zero emissions at the expense of hydrogen to the computer chip, created in the image and likeness of the human brain, this year we are expecting a very, very much. Before you ten technologies that will help to improve life, transform the industry and save our planet.

The items in this list were presented at the annual meeting of the World economic forum (WEF), whose goal was to identify important technology trends.

Alternative avtomobilestroiteli with zero emissions running on hydrogen.

For a long time, from year to year, automotive engineers promise to transfer the machine to the electricity or hydrocarbons instead of gasoline. Only now these technologies have begun to reach the stage where automotive companies are planning to launch such vehicles to consumers. The starting price likely to be between 70 000 dollars, but will fall significantly in the next few years.

Unlike batteries that must be charged from external sources for five to twelve hours, depending on the car and chargers, fuel cells can produce electricity directly by using hydrogen or natural gas. In practice, fuel cells and batteries are combined, with fuel cells generating electricity and the batteries storing this energy until needed by a motor. The fuel cell vehicles will be hybrids, as well as to use regenerative braking, which allows to extract energy from the excess heat, maximizing efficiency and range.

In contrast to transport batteries, transportation fuel cells offers greater range up to 650 miles on a single tank (the fuel is usually compressed hydrogen); the hydrogen fuel is refilled in three minutes. Hydrogen does not form a dirty waste combustion, producing only water vapor as emissions, which is an extremely important factor in the fight against air pollution.

There are several ways of producing hydrogen without generating carbon emissions. The most obvious is the use of renewable energy sources (wind and solar power) for the electrolysis of water, although the overall efficiency of this process is extremely low. Hydrogen is also released from the water in high temperature nuclear reactors, or produced from fossil fuels like coal or natural gas, if the resulting carbon dioxide is captured and absorbed instead of being released into the atmosphere.

Along with producing cheap hydrogen on a large scale, a significant problem remains the lack of infrastructure of hydrogen distribution, which ultimately must replace gas and diesel gas stations. Long distance transport of hydrogen, even compressed, is not considered economically feasible today. Innovative technology for hydrogen storage media such as organic liquids, which do not require compressed storage, may soon reduce the cost of transportation of distant following, and also to reduce the risks associated with storage and possible gas leak.

Mass-market fuel-cell cars are attractive because they are just as comfortable, modern diesel and gas vehicles, while having advantages in personal transportation. But to achieve these benefits you will need to find a way reliable and economical production of hydrogen from low-carbon sources, and the distribution of the vehicle fleet based on it.

Robotics new pokoleniyami leave the conveyor

The popular imagination has long anticipated a world in which robots take over all manner of everyday tasks. However, such a future with robots stubbornly refused to materialize, because the robots remains limited to factory Assembly lines and perform other controlled tasks. Being widely used (in the automotive industry, for example), these robots are large and dangerous for the workers; they have to be separated by safety cages.

Advances in robotic technology has gradually embody in the reality of everyday human interaction with the machine. Better and cheaper sensors make robots more able to understand and respond to its environment. Robot bodies become more adaptive and flexible, with designers taking inspiration from the incredible flexibility and dexterity of complex biological structures like the human hand. Robots are becoming more connected, benefiting from cloud computing, with instant access to remote data and constantly updated.

A new era of robotics needs to take these machines away from the production lines and assign new work. Using GPS technology, like smartphones, robots will be used in precision agriculture for monitoring crops, weed and harvest. In Japan, robots are already trying themselves in the role of nurses. They help patients get out of bed, assisting victims of stroke regain control over their limbs. Smaller and more nimble robots like Dexter Bot, Baxter and the LBR iiwa is designed so that they are easily programmed and configured to perform the precise tasks that are time consuming or inconvenient from the point of view of the person.

Robots are ideal for tasks that are too monotonous or dangerous for humans, and they can operate 24 hours a day without wages. A new generation of robotic machines are likely to work with people rather than replace them. Even with the advances in design and artificial intelligence, human involvement and oversight will remain essential.

There is a risk that robots will displace people from jobs, but as history has shown, previous waves of automation, as a rule, led to increased productivity and growth throughout the economy. The old fears that robots connected to the Network, out of control, eroding, people are gradually getting used to home robots. Although, of course, the next generation of robots will raise new questions about the human relationship with machines.

Recycling of thermosetting plastmassovyh a kind of plastic that won't fill landfills

Plastics are divided into thermoplastics and thermosetting plastics. First, you can heat and change their shape many times, and they are widely distributed in the modern world, including everything from toys to toilets. Because they can be melted down and changed in form, thermoplastics are recyclable. Thermosetting plastics can be heated and formed once, after which they "harden", while maintaining its shape and strength even when exposed to intense heat and pressure.

In connection with such strength, thermosetting plastics have become a vital part of our modern world. They are used in everything from mobile phones and chips to the aerospace industry. But the same characteristics that have made them essential in modern production, lead to the fact that they cannot be disposed of. As a result, most thermosetting polymers are sent to landfill. For a long time, there is an urgent need for re-processing of thermosetting plastics.

In 2014, Science published a major article, heralding an epochal shift in this area: the discovery of new classes of thermosetting polymers which are suitable for recycling. They are called polyesterurethane, or PGT, and can be dissolved in strong acid, breaking apart the polymer chains into their component monomers, which can then be reassembled into new products. As traditional non-recyclable thermosetting materials, these new structures are rigid, resistant to heat and durable, with the same potential applications as their predecessors.

Although no recycling is 100% efficient, this innovation — if widespread — will accelerate the transition to a circular economy and a big reduction in landfill plastic waste. We expect that recyclable thermoset polymers to replace non-recyclable thermoset for five years and come into wide use by 2025.

The exact technique genetic Ingenieria in this area will provide the best yields

Traditional genetic engineering has long caused controversy. Now there are new methods that allow us to directly "edit" the genetic code of plants, making them, for example, more nutritious or able to cope with climate change. We believe that the advantages and the accuracy of the "edit", can dispel fears associated with genetic modification, and lead to their wide spread.

Currently, the genetic engineering of crops relies on the bacterium Agrobacterium tumefaciens to transfer the desired DNA into the target genome. This technique proved to be reliable and proven, and despite widespread public fears in the scientific community there is a consensus that the use of such a method is not more risky than traditional breeding. The bacteria benefit, but gradually developed a more accurate and common methods for genome editing.

They include the ZFN, TALEN, and a newly developed CRISPR-Cas9 system, which evolved in bacteria as a defense mechanism against viruses. CRISPR-Cas9 uses the RNA molecule to the target DNA, shortening configured to a known sequence in the target genome. This ability can disable an unwanted gene or modify it in a way that is functionally indistinguishable from natural mutations. Using "homologous recombination", CRISPR can also be used to introduce new DNA sequences or even whole genes into the genome in a precise way.

Another aspect of genetic engineering that appears poised for a major advance is the use of RNA interference (RNAi) in cultures. RNAi is effective against viruses and pathogenic fungi, and can also protect plants from insect pests, reducing the need for chemical pesticides. Viral genes have been successfully used to protect papaya plants against the virus RPSV, also known as the virus circular spots, which developed in Hawaii for ten years, without encountering any resistance. RNAi may also protect wheat from stem rust, rice blast, potato late blight and the banana against Fusarium wilt.

Many of these innovations will be particularly useful for small farms in developing countries. Thus, genetic engineering may become less controversial as people recognize its effectiveness in raising the incomes and improving the diets of millions of people. Together, these techniques promise to develop sustainable agriculture by reducing input threshold from water to fertilizers, in a variety of areas, as well as contribute to the adaptation of crops to climate change.

Additive proizvodstvennoye of production, from print to smart clothing

As the name implies, additive manufacturing is the opposite of subtractive manufacturing. The latter is a traditional production: a large piece of material (wood, metal, stone, etc.) layers are removed, leaving the desired shape. Additive manufacturing, by contrast, starts with a material, liquid or powder and creates a three-dimensional form using a digital template.

Three-dimensional products can be precisely customized to the end user, unlike mass-produced goods. An example is the company Invisalign, which uses computer imaging teeth customers to make near-invisible braces are ideal for their mouths. Other medical applications using 3D-printers in a biological direction: directly print human cells to create living tissue that can be used not only for treatment and transplant, but also for the creation of a new organ for transplantation. For example, Organovo has printed living cells of the liver and now uses them to test drugs, hoping to soon start creating a liver for transplantation. The same results for bioprinting has already been used for the production of bone and skin, cardiovascular tissue, which has a strong potential for personalized medicine.

An important next step in additive manufacturing is the 3D printing of integrated electronic components such as circuit boards. Nanoscale computer parts, processors, difficult to produce thus because of the challenges of combining electronic components with components of other materials. In other areas of 4D printing promises to bring into our world a new generation of products that can change itself depending on the environmental change under the action of heat and humidity. This will be useful in the field of clothing or shoes, for example, and health care, manufacturing implants designed for accurate delivery.

As distributed manufacturing, additive manufacturing is potentially damaging to conventional supply chains. But it remains a niche, it applications are developed mostly in the automotive, aerospace and medical applications. In the next decade it is expected a rapid development of this technology.

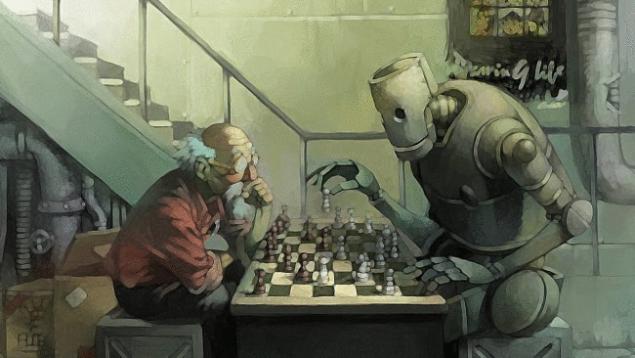

The development of artificial intellectance happens when a computer learns in the process?

Artificial intelligence (AI) is, in simple words, the science of how to make the computer do things that can make people. In recent years, AI has advanced significantly: many of us use smartphones that can recognize human speech, or pass through the airport terminal, using the technology of facial recognition. Now in the testing phase are self-driving cars and automated flying drones. In some areas of the car for a long time and certainly outnumber the people. Watson, the artificial intelligence system, faster than any human in the world finds answers to the questions.

Artificial intelligence, unlike a conventional hardware and software, allows the machine to perceive and react in accordance with changes in the environment. Emergent AI takes this a step further, with the ability to automatically learn by absorbing large amounts of information. An example of this intelligence was given in a recent article on the topic.

As next-generation robotics, advanced AI will lead to significant progress, when machines will take over — and even perform better in this task people. All evidence suggests that self-driving cars will reduce the frequency of collisions on the roads and prevent deaths and injuries from road transport, because the machines do not commit human error, always focus and see much more, not to mention other shortcomings. Intelligent machines, having quick access to the vast volumes of human information, will work better than medical professionals in the diagnosis of diseases. Watson is currently being implemented in Oncology to assist in the diagnosis and personalized treatment of cancer patients.

In any science fiction nightmare coming AI is always fraught with risks — the most obvious being that machine superintelligence will one day to rise up and enslave people. This risk, however, is not expected in the near future, and when it begins to loom on the horizon — will have a serious Institute for the study of AI safety. In January 2015, scientists, and entrepreneurs around the world have signed an open letter urging people to pay attention to the growing risks of the development of AI. There are more prosaic fears: for example, automated drones could replace most of the drivers, self-driving cars can completely obliterate a taxi as a class.

On the other hand, emergent AI can do the attributes still were uniquely human — creativity, emotions, interpersonal relations, is more valuable to us. As soon as the car will grow from the point of view of human intelligence, this technology will gradually erode our point of view and very understanding person.

Distributed proizvodstvenniy the future is online — and on your doorstep

Distributed manufacturing fully applies to the way we produce and deliver products. In traditional manufacturing, the raw materials collected and produced in large centralized plants in identical finished products, and then sent to the consumer. In distributed manufacturing, raw materials and production methods decentralized, and the final product is produced in the vicinity of the final consumer.

The idea is to replace the maximum part of the material supply chain of digital information. To make a chair, for example, instead of looking for wood and assemble it into chairs at the Central factory, you can distribute among the local manufacturers of digital plans on cutting parts of the chair using computerised cutting tools, known as CNC machines. Then the parts can be assembled by the consumer or the local production workshops, which will then turn them into finished products. In the United States already operates a furniture company AtFAB.

The modern application of distributed generation rely heavily on the DIY "Maker movement", which enthusiasts use their own 3D printers to manufacture products from local materials. In this scheme, there are elements of open-source thinking: consumers can customize the products to suit your needs and preferences. Instead of creating products centrally, creative design can involve more people. Crowdsourcing has already shown a good side, and here, too, it will be used.

Distributed manufacturing is expected to allow more efficient use of resources and centralized factories with less power. It also lowers the barriers to entry into the market by reducing the amount of capital required to build the first prototypes and products. Importantly, it also reduces the overall environmental impact of production: the digital information will be transmitted over the Internet rather than in physical products by road, sea or air; and raw materials will be used on site, reducing the need for excessive transportation.

If distributed manufacturing will be widespread, it would seriously weaken the traditional labour markets and the Economics of traditional manufacturing. It is a risk; it may be more difficult to regulate and control distributed manufacturing remotely, for example in terms of illegal or dangerous products — weapons. Not all products can be made using distributed generation, and will have to maintain traditional production and supply chains that produce the most important and complex consumer goods.

Distributed manufacturing may encourage a wider variety of objects, which are now standardized, such as smartphones and cars. The focus will shift to the production of individual objects using 3D printers; this will take into account all the wishes of the user.

Sensitive дроны

Flying robots (unmanned aerial vehicles, or drones) to check power lines or deliver first aid have become an extremely important and controversial part of the military potential in recent years. They are also used in agriculture, filming and many other applications that require cheap and extensive aerial surveillance. While all of these drones require of the operator; the difference is that the operator stands on the ground and controls the drone, while the drones fly in the sky.

The next step in drone technology is to develop machines that fly by themselves, that opens a whole new range of applications. For this to happen, the drones should be able to feel and respond to the local environment, change the height and trajectory, avoiding collisions with other objects in its path. In nature, birds, fish and insects can gather in a swarm, flock or shoal, where each animal almost instantly responds to its neighbor and the whole group flies as one. Drones can learn from the animals.

With reliable autonomy and ability to avoid hitting the drones can take on tasks that are too dangerous or difficult for people: check the power lines, delivery of medications, but your own. Drones delivery machines will be able to find the best path to the goal and ignore the other aircraft and obstacles on your way. In agriculture, Autonomous drones can gather and process huge amounts of visual data from the air, allowing precise and effective use of fertilizers and irrigation.

In January 2014, Intel and Ascending Technologies has demonstrated a prototype drones-multicopters, which can move around the scene with obstacles and automatically avoid people on your way. These machines use module Intel's RealSense camera, which weighs only eight grams and has a thickness of less than four millimeters. This level of collision avoidance will soon allow drones to fly close to people. Drones are essentially robots that can operate in three, not in two dimensions; advances in next-generation robotics technology will accelerate the development of unmanned drones.

Aircraft always will represent some risk, regardless of, operated by humans or intelligent machines. For wide dissemination, the sense of space and the opportunity to avoid the collision, drones should work as a watch and in the most difficult weather conditions: night, Blizzard, dust storm. Unlike our modern digital mobile devices (which are not movable, because we were wearing them from place to place), drones will be mobile and will be able to fly in a three dimensional world that is beyond our direct involvement and our reach.

Technologycomputer neuromorphic chips that mimic human brain

Even the best supercomputers of today can't compete with a clever human brain. Computers are linear, moving data back and forth between the memory chips and the CPU over a high speed network. The brain, on the other hand, is fully lined paths of neurons which form billions of links with densities billions of times greater than the density of modern computers. Neuromorphic chips are designed to process information in a fundamentally different from traditional hardware method, mimicking the architecture of the brain with speed and response of your computer.

Miniaturization of conventional computing power continues for years, but a narrow bottleneck, which is trying to squeeze the data coming and going between the drive and the CPU, consumes large amounts of energy and produces a lot of heat, limiting further improvement. In contrast, neuromorphic chips can be more energy efficient and powerful, combining data-storage and data-processing components in the same interconnected modules. From this position, the system copies the neuromorphic chip network of neurons in the human brain.

Neuromorphic technology will be the next stage in the development of powerful computing hardware will be faster to process the data and have large storage capacity for machine learning. A chip of one million neurons North was introduced by IBM as a prototype in August of 2014, and some of the tasks it already performs at speeds hundreds of times greater than the speed of a regular CPU. Neuromorphic chips increased power will enable machines in the nanoscale and the development of artificial intelligence.

Potential applications include the following: drones can better process the visual cues and react to them; cameras and smartphones will become smarter; processing large volumes of data will enable an analysis of the financial market or to predict the climate. Computers will be able to anticipate and to learn, not just respond to pre-programmed steps.

Digital genomatica medicine, when your genetic code is to be written to the flash drive

Since the first sequencing of the 3.2 billion DNA base pairs that make up human genome, was for many years, and the procedure is worth millions of dollars. Today, your genome can be sequenced and digitized within a few minutes and it will cost you only a couple hundred dollars. Results can be saved on a memory stick and shared via the Internet. This ability to rapidly and cheaply determine our individual and unique genetic make-up promises a revolution in personalised and effective healthcare.

Many of our most intractable health problems, from heart disease to cancer, have a genetic basis. Cancer is best described as a disease of the genome. With digitization, doctors will be able to make decisions about the patient's cancer treatment based on the genetic nature of the tumor. New knowledge will also enable the development of highly targeted therapies that offer the potential of improving quality of care, especially for patients with cancer.

As with any personal information, digital human genome needs to be carefully protected for privacy reasons. Otherwise, it could use employers or insurance companies, getting access to it. The advantages, however, outweigh the risks, because personalized treatments and targeted therapies can be developed with the potential to cure many diseases that are beyond treatment to date. published

Source: hi-news.ru

"Winter" children in school should go to 6.5 years

Chocolate cakes in the Mandarin — elegant and very simple