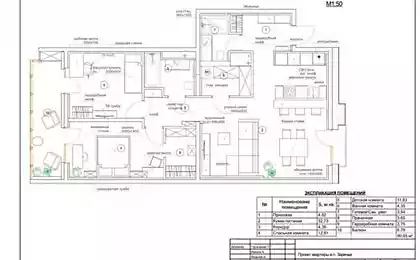

722

Private eco house made from Adobe: an unusual and important

The successful construction of houses of Adobe, perhaps to a greater extent than houses of other materials, depends on the enthusiasm of its owner. You have to understand all of the details of the technology, to experiment, to correct mistakes. If you combine imagination and knowledge, the house will be unique and comfortable.

The choice for the construction of houses of Adobe technology is usually associated with the desire to live in the most ecologically clean environment, the reluctance (or inability) to invest in building significant funds, principled position that housing should be build with their own hands, embodying in it his own ideas about comfort.

Such ideas feasible: of Adobe, a material based on natural components, it is possible to obtain unique architecture, eco-friendly, comfortable, durable home. Save on independent fabrication and erection of walls is an essential attractive feature of the Adobe (the brick and ceramic blocks is also composed of clay, like Adobe, eco-friendly, but the walls of them will cost significantly more).

But to build a cob house is more complicated than it seems some Amateur developers. Therefore, to realize a dream, you should thoroughly examine the features of the material and construction technology, consult with experts, to present the real costs associated with creation of comfortable accommodation and mind - but to determine its size.

Manageable

First of all, the risk of Adobe construction is associated with the lack of information. Government regulations and professional literature according to Adobe there is no construction, the quality of the material not studied by professionals. Enthusiasts who are building out of clay, learning mostly on their own experience and share them on Internet forums and seminars. The guiding and inspiring document for them is the book "the Construction of Adobe. Philosophy and practice" Ianto Evans, Michael George. Smith and Linda Smiley.

Meanwhile, in Russia it is possible to find professionals that will give comprehensive recommendations for Adobe construction. Furthermore, it is always useful will be the assistance of any experienced architect or designer. So Adobe is really to build a solid house at a carefully calculated project.

Another risk is that the properties of the Adobe undefined, depend on the characteristics of production and construction. Different behaves this material in different climatic conditions. All parameters from the compressive strength and Flexural strength to thermal conductivity is estimated. As depends on them the opportunity to load the walls (the frequency of the laying of the floor beams, the erection of a second floor, etc.), thickness design, the need of insulation, size of Windows, the required capacity of the heating equipment. To determine the quality of Adobe can be made by examining samples of bricks in the construction of the laboratory (it is possible for the product of industrial manufacturing). Developers often find themselves exploring the material manufactured, heavily loading the blocks, checking whether they crack upon impact.

The risks are significantly reduced if you build one-storey house using planning techniques that improve energy efficiency, and to provide for the possibility of warming in the future.

How much is the house worth?

The Declaration that the house of Adobe, you can build almost for free, often are the main reason encouraging people to use Adobe technologies. The economy arises due to the self-construction and practically free material for walls, including their finishing.

But in the course of construction you can be sure that this is only a small part of the investments required a full house-all the rest will have to buy.

Usually the cost of a box with a roof is 40-50% of your home's value, and 50-60 % goes to finishing and engineering equipment. The price of the material for the walls is only 20-25 % of the cost of the box and of the total amount -10-15 %.

Adobe homes are not built in large, the most popular square — 60-80 m2. The cost of such a turnkey building of brick at the professional building will be 35-65 y. that is, when the squatter with the purchase and delivery of materials -20-40 thousand. e Value-2 to 4 thousand. E. for self-fabrication of the wall material this amount can be reduced to the cost of delivery of the material. If the clay is on the site and in the construction of walls is not provided the tree, they will cost all free.

Savings on the walls is very important because one of the aspects of the attractiveness of the Adobe house is the opportunity to get a roof over their head, and so on — to settle. But the walls must stand on the Foundation that will cost about 1 thousand. E. Also need a roof, and therefore the acquisition of a minimum of wood for the truss system and roofing material. Economical material, such as metal, will cost about,5-0,6 thousand. E. Wood, the insulation film can typically be double the cost of a cheap roofing material. Total cost of the kit for the roof — 1,5-1,8 thousand. E., and these costs can not be avoided. You should also install Windows and doors -0.5 thousand. E. For heating in Adobe houses often use oven. You can fold it with your hands, but need 1000 bricks (including about 150 PCs refractory) at a total cost of 0.2 thousand. E. Installation of the boiler with the wiring will cost at least 0.5 thousand. E.

In the end, to check the Adobe building (finishing and amenities), you need 3-4 thousand. E. and a couple of years of hard work. To fully bring the building to a residential state, you will need twice more time and money.

The cost of construction of Adobe houses a specialized company will cost not less than other materials, so as to provide professionals.

Features of construction

In the books, who are agitating for Adobe construction, emphasized the simplicity and accessibility of this technology. However, in Adobe home a special material is only wall — Adobe. The rest of the structure (foundations, floors, roof) do not differ from those used in other technologies. Therefore, in the construction of houses of Adobe the necessary knowledge and adherence to modern construction processes.

There are a number of Adobe technologies, and inside each of them — the options recipes material and methods of installation. But some common features must be considered.

First of all, requires an individual approach to the production of the material. The proportions of its components and the quality of the Samana largely depend on the properties of the clay (usually it is taken at the site or nearby). Use different components, of which we are in constant water, clay and straw, used as sand. Depending on the composition varies the conductivity, bearing capacity, shrinkage of the walls. The more sand in the composition of the Samana, the less the shrinkage and cracking of the material, the more straw, the warmer the material, the clay provides strength in compression. Making and drying multiple samples with different composition, look to see which of them will provide the strength, cracks when dry, the lowest shrinkage.

Depending on the volume ratio of straw and clay Adobe, it can be heavy or light. Heavy material (clay and sand 40 % or more) are used for the construction of load-bearing walls in single and two storey homes, and light (in which straw 70-90 %) — for walls that are not based ceiling, partitions, as well as filling the frame walls.

House of heavy Samana, you can make a monolithic (in the mold or without) or folded out of the blocks. Each method has advantages and disadvantages. Building with monolithic walls built up faster than blocks with hard work it can be erected over the spring, summer and autumn. Monolithic walls will dry and shrink within a year, and only after that they will be able to install Windows and doors (temporarily for the winter they clog the boards), plastering (although Adobe will fully dry in three years after the construction). The house may be one storey or attic.

In the construction of Adobe blocks for more than a year will be spent on the production and drying of the material, at least a year on the walls. Blocks are prepared on-site, dried and stored under cover. Wall put a similar brick, with clay-sand mortar of thickness not more than 1.2, see the Wall of blocks does not produce significant shrinkage. The building is two-story to do, but first you should check the strength of the blocks in the laboratory. Usually the bearing capacity of the heavy blocks of Adobe is the same as that of brick low marks (maximum M50). To be confident in the strength of the material, Adobe blocks you can buy ( on a one-story house will require 1.5-2 thousand bricks).

When building a house made of light material in the walls will need a double frame with struts on struts, standing on the wrapping beams at the perimeter of the house. On the external side or both sides establish a timbering from boards, Adobe tightly pressed into the wall between the uprights. The frame is excluded due to the overall shrinkage of the wall, however, the formation of cracks between the frame and the filling. Once dry mix wall plaster clay and sand or lime mortar. Use of the framework in the wall — additional costs. However, if the wall light you can save on Foundation. In addition, a frame house made of light Adobe can be erected quickly, within a few months, he may be two-storey.

Speed of Adobe construction depends significantly on the weather. When the rain is absolutely impossible to build. But in hot weather the solution dries quickly, and the day it is possible to stack more layer of material.

The inner walls of the frame make with filling easy Adobe, cane, straw or just Adobe smaller thickness and density.

The Foundation under the walls of heavy material, make the belt, laying it below the depth of soil freezing (in case of insufficient depth of possible differential shrinkage of the base, which is especially dangerous for the fragile Adobe). The walls of light material can offer a more economical pier Foundation.

Energy efficiency

How warm is the specific Adobe house, you can only learn after wintering in it. The heat loss will depend on the thickness and composition of the wall, the compactness of the building, size and orientation of openings, roof insulation and floor.

Living in Adobe buildings, note that due to the high massiveness and thermal inertia of the walls of heavy Adobe, cool in summer and winter fluctuations in external temperature have little effect on the temperature in the house. However, the walls of heavy material is not always quite energy efficient, they have to insulate.

Wall of heavy Adobe, dense and without voids (density -1200-1600 kg/m3), similar in its characteristics to effective thermal conductivity (hollow) brick or foam (depending on the ratio of clay and straw material) and has a coefficient of thermal conductivity of 0.3-0.6 W/(m x °C). It will be the warmer, the more its content of straw. In Russia, the wall thickness of such a thermal conductivity of the material should be about a meter, difficult to implement and unprofitable work. Therefore, the wall of heavy Adobe usually made with a thickness of 40-50 cm, and then insulated and plastered.

Adobe requires the use of vapor permeable insulation. Excludes Styrofoam, mineral wool enthusiasts Adobe building is considered polluting. Experts recommend the use of a cane (reed) that does not absorb moisture, does not rot and has a tubular structure with the air inside the stems. It is used in the form of mats, are placed layer is not less than u cm long and is firmly fixed to the wall with dowels. On top of a heater is applied 2-3 cm of clay or lime plaster (the latter is more durable).

The coldest places of any home is the corners. The advantage of Adobe technology — a possible to avoid problem areas, making the corners of the exterior walls rounded, somewhat increasing the thickness of the walls in these places.

Walls of light material and do not have high inertia, but have a high energy saving capacity (at a density of 500 kg/m3 and below the material can be used as the insulator). As a rule, make the wall thickness of 30-40 cm (with a smaller thickness there is a danger that they will be blown through like a shell). The denser the compacted Adobe, the warmer design.

Due to the fact that in the construction of walls includes a frame, a light density of Samana can be significantly reduced, achieving a high level of insulation with a thin wall. However, it is important to exclude the formation of cracks, to avoid through-draughts.

Cracks can occur when loose laying and compaction of the material around the window frames, the contact areas of Samana to the frame, while cracking plaster. However, they are easy to cover up, plaster to be updated (Adobe house easy to repair).

For floor insulation in the house usually use concrete block or lightweight Adobe.

Consult with professionals

To contact the experts and initially correctly designed the house much more reasonable and even cheaper than unknowingly make mistakes, and then try to fix them.

Unskilled the house is built, even from such organic material, like Adobe, will not be better for healthy living than urban high-rise building, and sometimes dangerous. Among the possible problems — high humidity and lack of fresh air in the house, fungus and mould on the cold walls and wooden structures, threats to the sustainability of the building — subsidence of the Foundation, moisture walls and through cracks. Disadvantages may not be immediately apparent, and housing every year will bring more worries.

The source of many problems — lack of or incorrect installation of ventilation. The house needed air — fresh air supply in the room (the window should be provided with a vent or slit opening) and the removal of exhaust air and moisture (in the kitchen, the bathroom should be arranged vent channels). If the house has a furnace and there is no inflow, you can not use it, it can create a reverse thrust (the flow of combustion products into the house). In low traction in the home there is increased humidity, and with little heating of the condensate drops on the walls.

From experience of Adobe construction

We love our home and take pride in building it yourself, using natural and safe materials. Saman — lovely living material, in this house felt a natural comfort and breathe easily. But it says a lot. But the complexities of information is not enough. Meanwhile, the construction of a house of any material difficult. I want to tell, what problems were faced and how we overcame them.

About the cost

Our two-storey building is not completely finished — walls, roof, are Windows and doors made of insulation and external plaster, erected a furnace Kuznetsova. Inside the finish yet, still need to do plumbing and sanitation, without which the house is not completely habitable.

Housing was built on the receipt of money for five years. Its value in General, we have not counted because the terms and the market during this time has varied considerably. But we have seen that box at home for just 30 % of the total cost. Don't think that Adobe building is much cheaper than from other material. You can save only on the walls and what we do. Expensive, no less than the walls, there is a tree for the roof, the ceiling, partitions (10 м3мы paid about $ 2000.e.). The Foundation and ground floor at the end of 2005 at a cost of 1000. E. (built, helped my dad), the material web 50. E. A wooden floor on the second floor, as we considered, will cost about $ 700. that is, without the cost of laying and coating varnish or paint.

On the construction site

It is important to consider where to take materials for construction. Clay need a lot more than it seems — it is loose and the Adobe volume is reduced by 3 times. We have to manufacture bricks went all the clay mined when leveling the site for the house on the slope, digging trenches for the Foundation and cellar. Had to make another pit on the site. Straw harvested during pre-harvesting, because in the spring to find it problematic. The whole house (85 m2) went 3000 bricks that we produced 3 years (in spare time). The house should be carefully protected from moisture, so the question long-lasting and durable exterior plaster of the main. By chance we found that if the clay-sand mortar plaster mix and leave for a couple of weeks, the plaster is solid as a rock. Now we knead (clay and sand in the ratio 1:1, a little straw) in the two holes and use one while the other Matures in the solution. The plastering of the facades was gone all last summer.

About energy efficiency

Heavy Adobe not as warm as it is accepted to speak-better than brick, but warm enough to be without insulation in it was comfortable to live in winter. Low energy efficiency of the walls is not so noticeable if the house is small and a furnace for heating sufficiently. Previously built a small house and so, apparently, was born the myth of a warm Adobe.

In our large two-story house, the thickness of the Samana -40 cm, with plaster thickness of the wall is 45-47 cm to achieve the required thermal insulation we insulate her cane mats. After plating at home reed was noticeably warmer, the temperature of the inner surface of the wall does not fall below 18 °C. to reduce heat loss through Windows, use curtains made of thick material. The cold remains of the lower part of the wall adjacent to the basement, and plan to insulate the basement and blind area.

Comfort and aesthetics

The construction of Adobe houses is an integral part of the implementation of the philosophy of environmentally friendly and economical way of life in which comfort is ensured by the closeness to nature and use its gifts. The decoration of the housing used natural materials (clay, lime or gypsum plaster on walls, wood, and ceramics on the floor), for heating and cooking often use the furnace (especially simple and economical to operate the furnace Kuznetsova). But there are no obstacles to equip the Adobe house with modern engineering equipment, to hold in the gas, plug in electric or gas boiler. Effective solution, given the massiveness of heavy Adobe and its ability to accumulate heat, will the system "warm floor". Utilities is easy to hide in the floor and walls. Can be used to finish the last completely eco-friendly plasterboard and acrylic plaster and paint, treated wood structures modern protective impregnation. The combination of ancient methods of Adobe construction with modern technology enhances the comfort in the house.

The owners take pride in their homes originality, expressiveness and originality of the interiors. And this, perhaps, the main attraction of Adobe construction. Of plastic material is possible to perform the rounded walls, arches, benches and couches, right in the walls to make shelves, window openings of various shapes, e.g. with rounded corners, and windowed glass wall directly to the wall without a frame. In creating the interior can participate, even children need only time and imagination. Creativity captures, and, having mastered the technology, the construction of a building, some don't stop: plan to build out of Adobe workshop, a garage, a house for guests or parents. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: bestproject.ws/stati/78-proekt-ekokologicheskogo-doma-chastnyj-dom-iz-samana-neobychno-i-aktualno.html

The choice for the construction of houses of Adobe technology is usually associated with the desire to live in the most ecologically clean environment, the reluctance (or inability) to invest in building significant funds, principled position that housing should be build with their own hands, embodying in it his own ideas about comfort.

Such ideas feasible: of Adobe, a material based on natural components, it is possible to obtain unique architecture, eco-friendly, comfortable, durable home. Save on independent fabrication and erection of walls is an essential attractive feature of the Adobe (the brick and ceramic blocks is also composed of clay, like Adobe, eco-friendly, but the walls of them will cost significantly more).

But to build a cob house is more complicated than it seems some Amateur developers. Therefore, to realize a dream, you should thoroughly examine the features of the material and construction technology, consult with experts, to present the real costs associated with creation of comfortable accommodation and mind - but to determine its size.

Manageable

First of all, the risk of Adobe construction is associated with the lack of information. Government regulations and professional literature according to Adobe there is no construction, the quality of the material not studied by professionals. Enthusiasts who are building out of clay, learning mostly on their own experience and share them on Internet forums and seminars. The guiding and inspiring document for them is the book "the Construction of Adobe. Philosophy and practice" Ianto Evans, Michael George. Smith and Linda Smiley.

Meanwhile, in Russia it is possible to find professionals that will give comprehensive recommendations for Adobe construction. Furthermore, it is always useful will be the assistance of any experienced architect or designer. So Adobe is really to build a solid house at a carefully calculated project.

Another risk is that the properties of the Adobe undefined, depend on the characteristics of production and construction. Different behaves this material in different climatic conditions. All parameters from the compressive strength and Flexural strength to thermal conductivity is estimated. As depends on them the opportunity to load the walls (the frequency of the laying of the floor beams, the erection of a second floor, etc.), thickness design, the need of insulation, size of Windows, the required capacity of the heating equipment. To determine the quality of Adobe can be made by examining samples of bricks in the construction of the laboratory (it is possible for the product of industrial manufacturing). Developers often find themselves exploring the material manufactured, heavily loading the blocks, checking whether they crack upon impact.

The risks are significantly reduced if you build one-storey house using planning techniques that improve energy efficiency, and to provide for the possibility of warming in the future.

How much is the house worth?

The Declaration that the house of Adobe, you can build almost for free, often are the main reason encouraging people to use Adobe technologies. The economy arises due to the self-construction and practically free material for walls, including their finishing.

But in the course of construction you can be sure that this is only a small part of the investments required a full house-all the rest will have to buy.

Usually the cost of a box with a roof is 40-50% of your home's value, and 50-60 % goes to finishing and engineering equipment. The price of the material for the walls is only 20-25 % of the cost of the box and of the total amount -10-15 %.

Adobe homes are not built in large, the most popular square — 60-80 m2. The cost of such a turnkey building of brick at the professional building will be 35-65 y. that is, when the squatter with the purchase and delivery of materials -20-40 thousand. e Value-2 to 4 thousand. E. for self-fabrication of the wall material this amount can be reduced to the cost of delivery of the material. If the clay is on the site and in the construction of walls is not provided the tree, they will cost all free.

Savings on the walls is very important because one of the aspects of the attractiveness of the Adobe house is the opportunity to get a roof over their head, and so on — to settle. But the walls must stand on the Foundation that will cost about 1 thousand. E. Also need a roof, and therefore the acquisition of a minimum of wood for the truss system and roofing material. Economical material, such as metal, will cost about,5-0,6 thousand. E. Wood, the insulation film can typically be double the cost of a cheap roofing material. Total cost of the kit for the roof — 1,5-1,8 thousand. E., and these costs can not be avoided. You should also install Windows and doors -0.5 thousand. E. For heating in Adobe houses often use oven. You can fold it with your hands, but need 1000 bricks (including about 150 PCs refractory) at a total cost of 0.2 thousand. E. Installation of the boiler with the wiring will cost at least 0.5 thousand. E.

In the end, to check the Adobe building (finishing and amenities), you need 3-4 thousand. E. and a couple of years of hard work. To fully bring the building to a residential state, you will need twice more time and money.

The cost of construction of Adobe houses a specialized company will cost not less than other materials, so as to provide professionals.

Features of construction

In the books, who are agitating for Adobe construction, emphasized the simplicity and accessibility of this technology. However, in Adobe home a special material is only wall — Adobe. The rest of the structure (foundations, floors, roof) do not differ from those used in other technologies. Therefore, in the construction of houses of Adobe the necessary knowledge and adherence to modern construction processes.

There are a number of Adobe technologies, and inside each of them — the options recipes material and methods of installation. But some common features must be considered.

First of all, requires an individual approach to the production of the material. The proportions of its components and the quality of the Samana largely depend on the properties of the clay (usually it is taken at the site or nearby). Use different components, of which we are in constant water, clay and straw, used as sand. Depending on the composition varies the conductivity, bearing capacity, shrinkage of the walls. The more sand in the composition of the Samana, the less the shrinkage and cracking of the material, the more straw, the warmer the material, the clay provides strength in compression. Making and drying multiple samples with different composition, look to see which of them will provide the strength, cracks when dry, the lowest shrinkage.

Depending on the volume ratio of straw and clay Adobe, it can be heavy or light. Heavy material (clay and sand 40 % or more) are used for the construction of load-bearing walls in single and two storey homes, and light (in which straw 70-90 %) — for walls that are not based ceiling, partitions, as well as filling the frame walls.

House of heavy Samana, you can make a monolithic (in the mold or without) or folded out of the blocks. Each method has advantages and disadvantages. Building with monolithic walls built up faster than blocks with hard work it can be erected over the spring, summer and autumn. Monolithic walls will dry and shrink within a year, and only after that they will be able to install Windows and doors (temporarily for the winter they clog the boards), plastering (although Adobe will fully dry in three years after the construction). The house may be one storey or attic.

In the construction of Adobe blocks for more than a year will be spent on the production and drying of the material, at least a year on the walls. Blocks are prepared on-site, dried and stored under cover. Wall put a similar brick, with clay-sand mortar of thickness not more than 1.2, see the Wall of blocks does not produce significant shrinkage. The building is two-story to do, but first you should check the strength of the blocks in the laboratory. Usually the bearing capacity of the heavy blocks of Adobe is the same as that of brick low marks (maximum M50). To be confident in the strength of the material, Adobe blocks you can buy ( on a one-story house will require 1.5-2 thousand bricks).

When building a house made of light material in the walls will need a double frame with struts on struts, standing on the wrapping beams at the perimeter of the house. On the external side or both sides establish a timbering from boards, Adobe tightly pressed into the wall between the uprights. The frame is excluded due to the overall shrinkage of the wall, however, the formation of cracks between the frame and the filling. Once dry mix wall plaster clay and sand or lime mortar. Use of the framework in the wall — additional costs. However, if the wall light you can save on Foundation. In addition, a frame house made of light Adobe can be erected quickly, within a few months, he may be two-storey.

Speed of Adobe construction depends significantly on the weather. When the rain is absolutely impossible to build. But in hot weather the solution dries quickly, and the day it is possible to stack more layer of material.

The inner walls of the frame make with filling easy Adobe, cane, straw or just Adobe smaller thickness and density.

The Foundation under the walls of heavy material, make the belt, laying it below the depth of soil freezing (in case of insufficient depth of possible differential shrinkage of the base, which is especially dangerous for the fragile Adobe). The walls of light material can offer a more economical pier Foundation.

Energy efficiency

How warm is the specific Adobe house, you can only learn after wintering in it. The heat loss will depend on the thickness and composition of the wall, the compactness of the building, size and orientation of openings, roof insulation and floor.

Living in Adobe buildings, note that due to the high massiveness and thermal inertia of the walls of heavy Adobe, cool in summer and winter fluctuations in external temperature have little effect on the temperature in the house. However, the walls of heavy material is not always quite energy efficient, they have to insulate.

Wall of heavy Adobe, dense and without voids (density -1200-1600 kg/m3), similar in its characteristics to effective thermal conductivity (hollow) brick or foam (depending on the ratio of clay and straw material) and has a coefficient of thermal conductivity of 0.3-0.6 W/(m x °C). It will be the warmer, the more its content of straw. In Russia, the wall thickness of such a thermal conductivity of the material should be about a meter, difficult to implement and unprofitable work. Therefore, the wall of heavy Adobe usually made with a thickness of 40-50 cm, and then insulated and plastered.

Adobe requires the use of vapor permeable insulation. Excludes Styrofoam, mineral wool enthusiasts Adobe building is considered polluting. Experts recommend the use of a cane (reed) that does not absorb moisture, does not rot and has a tubular structure with the air inside the stems. It is used in the form of mats, are placed layer is not less than u cm long and is firmly fixed to the wall with dowels. On top of a heater is applied 2-3 cm of clay or lime plaster (the latter is more durable).

The coldest places of any home is the corners. The advantage of Adobe technology — a possible to avoid problem areas, making the corners of the exterior walls rounded, somewhat increasing the thickness of the walls in these places.

Walls of light material and do not have high inertia, but have a high energy saving capacity (at a density of 500 kg/m3 and below the material can be used as the insulator). As a rule, make the wall thickness of 30-40 cm (with a smaller thickness there is a danger that they will be blown through like a shell). The denser the compacted Adobe, the warmer design.

Due to the fact that in the construction of walls includes a frame, a light density of Samana can be significantly reduced, achieving a high level of insulation with a thin wall. However, it is important to exclude the formation of cracks, to avoid through-draughts.

Cracks can occur when loose laying and compaction of the material around the window frames, the contact areas of Samana to the frame, while cracking plaster. However, they are easy to cover up, plaster to be updated (Adobe house easy to repair).

For floor insulation in the house usually use concrete block or lightweight Adobe.

Consult with professionals

To contact the experts and initially correctly designed the house much more reasonable and even cheaper than unknowingly make mistakes, and then try to fix them.

Unskilled the house is built, even from such organic material, like Adobe, will not be better for healthy living than urban high-rise building, and sometimes dangerous. Among the possible problems — high humidity and lack of fresh air in the house, fungus and mould on the cold walls and wooden structures, threats to the sustainability of the building — subsidence of the Foundation, moisture walls and through cracks. Disadvantages may not be immediately apparent, and housing every year will bring more worries.

The source of many problems — lack of or incorrect installation of ventilation. The house needed air — fresh air supply in the room (the window should be provided with a vent or slit opening) and the removal of exhaust air and moisture (in the kitchen, the bathroom should be arranged vent channels). If the house has a furnace and there is no inflow, you can not use it, it can create a reverse thrust (the flow of combustion products into the house). In low traction in the home there is increased humidity, and with little heating of the condensate drops on the walls.

From experience of Adobe construction

We love our home and take pride in building it yourself, using natural and safe materials. Saman — lovely living material, in this house felt a natural comfort and breathe easily. But it says a lot. But the complexities of information is not enough. Meanwhile, the construction of a house of any material difficult. I want to tell, what problems were faced and how we overcame them.

About the cost

Our two-storey building is not completely finished — walls, roof, are Windows and doors made of insulation and external plaster, erected a furnace Kuznetsova. Inside the finish yet, still need to do plumbing and sanitation, without which the house is not completely habitable.

Housing was built on the receipt of money for five years. Its value in General, we have not counted because the terms and the market during this time has varied considerably. But we have seen that box at home for just 30 % of the total cost. Don't think that Adobe building is much cheaper than from other material. You can save only on the walls and what we do. Expensive, no less than the walls, there is a tree for the roof, the ceiling, partitions (10 м3мы paid about $ 2000.e.). The Foundation and ground floor at the end of 2005 at a cost of 1000. E. (built, helped my dad), the material web 50. E. A wooden floor on the second floor, as we considered, will cost about $ 700. that is, without the cost of laying and coating varnish or paint.

On the construction site

It is important to consider where to take materials for construction. Clay need a lot more than it seems — it is loose and the Adobe volume is reduced by 3 times. We have to manufacture bricks went all the clay mined when leveling the site for the house on the slope, digging trenches for the Foundation and cellar. Had to make another pit on the site. Straw harvested during pre-harvesting, because in the spring to find it problematic. The whole house (85 m2) went 3000 bricks that we produced 3 years (in spare time). The house should be carefully protected from moisture, so the question long-lasting and durable exterior plaster of the main. By chance we found that if the clay-sand mortar plaster mix and leave for a couple of weeks, the plaster is solid as a rock. Now we knead (clay and sand in the ratio 1:1, a little straw) in the two holes and use one while the other Matures in the solution. The plastering of the facades was gone all last summer.

About energy efficiency

Heavy Adobe not as warm as it is accepted to speak-better than brick, but warm enough to be without insulation in it was comfortable to live in winter. Low energy efficiency of the walls is not so noticeable if the house is small and a furnace for heating sufficiently. Previously built a small house and so, apparently, was born the myth of a warm Adobe.

In our large two-story house, the thickness of the Samana -40 cm, with plaster thickness of the wall is 45-47 cm to achieve the required thermal insulation we insulate her cane mats. After plating at home reed was noticeably warmer, the temperature of the inner surface of the wall does not fall below 18 °C. to reduce heat loss through Windows, use curtains made of thick material. The cold remains of the lower part of the wall adjacent to the basement, and plan to insulate the basement and blind area.

Comfort and aesthetics

The construction of Adobe houses is an integral part of the implementation of the philosophy of environmentally friendly and economical way of life in which comfort is ensured by the closeness to nature and use its gifts. The decoration of the housing used natural materials (clay, lime or gypsum plaster on walls, wood, and ceramics on the floor), for heating and cooking often use the furnace (especially simple and economical to operate the furnace Kuznetsova). But there are no obstacles to equip the Adobe house with modern engineering equipment, to hold in the gas, plug in electric or gas boiler. Effective solution, given the massiveness of heavy Adobe and its ability to accumulate heat, will the system "warm floor". Utilities is easy to hide in the floor and walls. Can be used to finish the last completely eco-friendly plasterboard and acrylic plaster and paint, treated wood structures modern protective impregnation. The combination of ancient methods of Adobe construction with modern technology enhances the comfort in the house.

The owners take pride in their homes originality, expressiveness and originality of the interiors. And this, perhaps, the main attraction of Adobe construction. Of plastic material is possible to perform the rounded walls, arches, benches and couches, right in the walls to make shelves, window openings of various shapes, e.g. with rounded corners, and windowed glass wall directly to the wall without a frame. In creating the interior can participate, even children need only time and imagination. Creativity captures, and, having mastered the technology, the construction of a building, some don't stop: plan to build out of Adobe workshop, a garage, a house for guests or parents. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: bestproject.ws/stati/78-proekt-ekokologicheskogo-doma-chastnyj-dom-iz-samana-neobychno-i-aktualno.html