1207

Log cabin with his own hands.

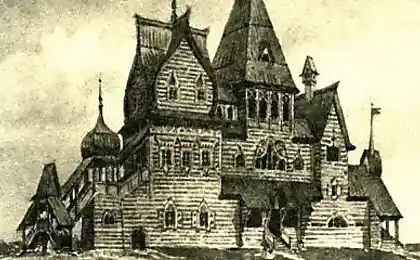

We live in a three-room apartment, we decided to carry out long-held dream to have their own house. Namely, wooden frame. Bought 2 years ago, 6 acres of land not far from the city on the banks of rivers. Year watched, studied, compared, a lot of sites, a portfolio of projects. And found the man, as it turned out, not mistaken. A few more months of design work, eventually came to a solution that suited me and my mate. Prepayments and tedious wait dream home.

74 pictures

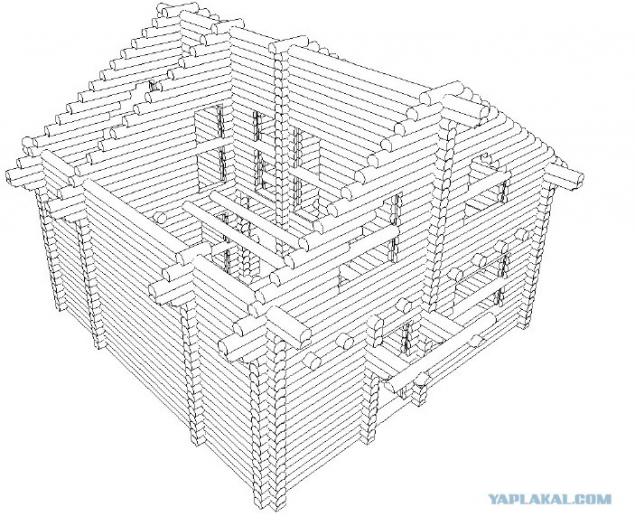

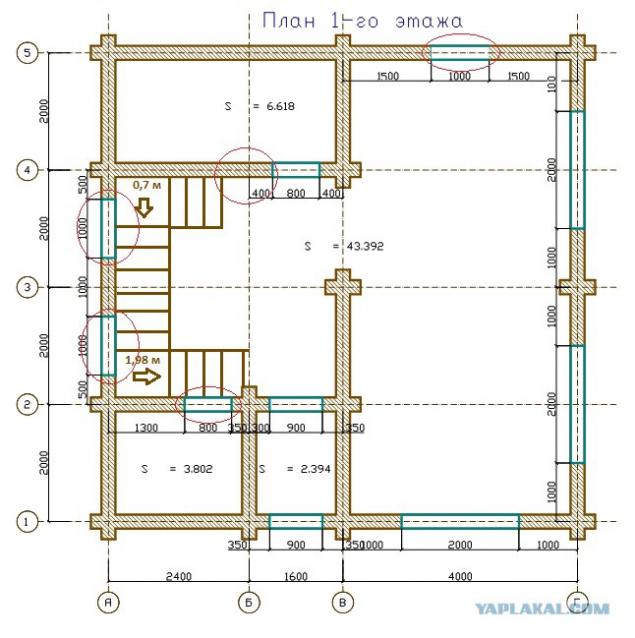

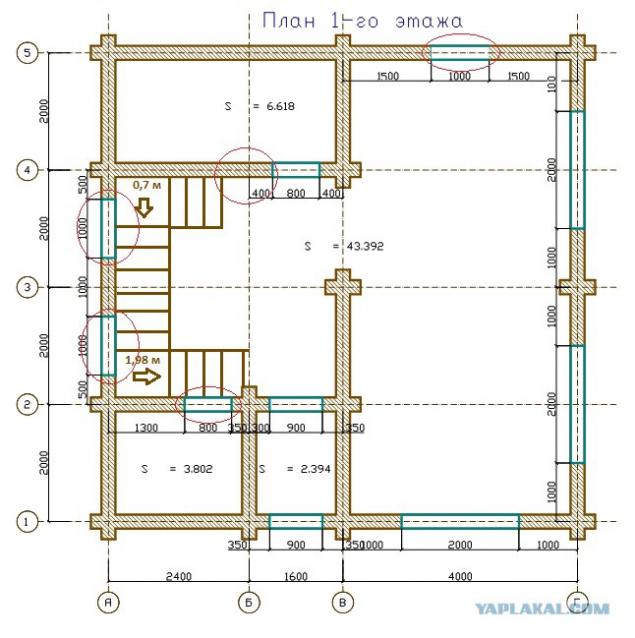

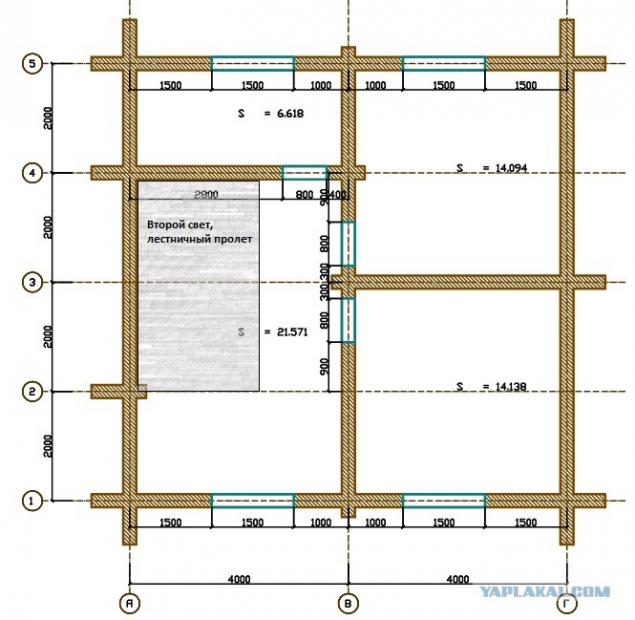

1st floor.

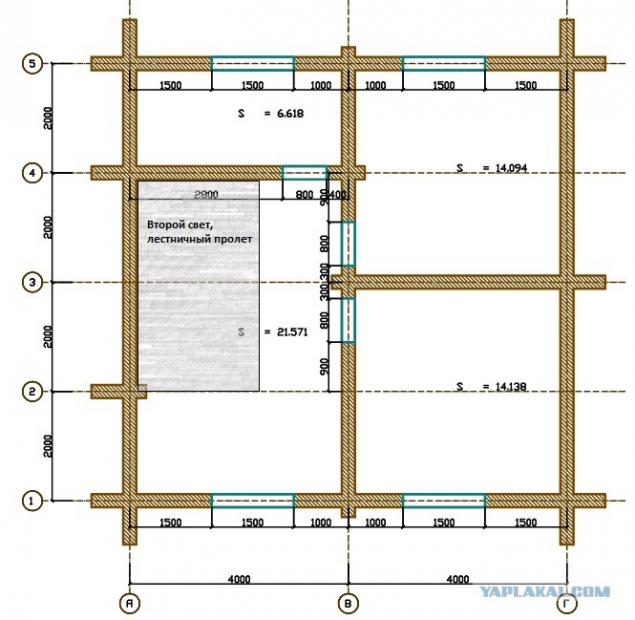

2nd floor.

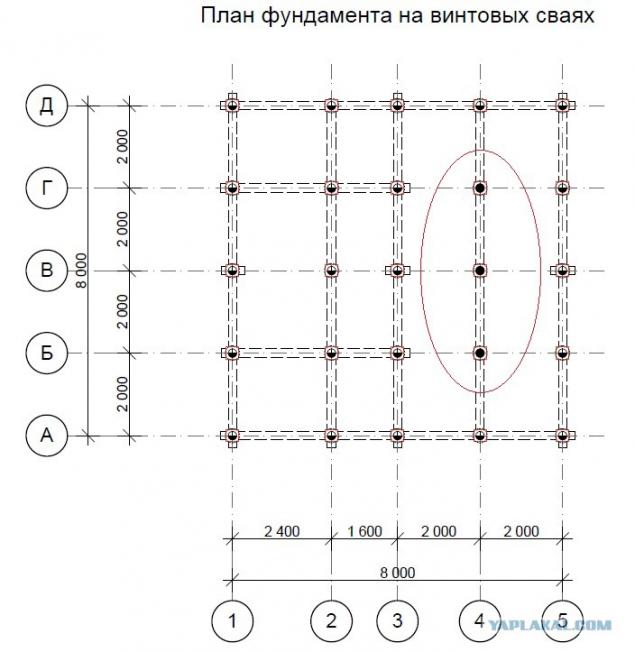

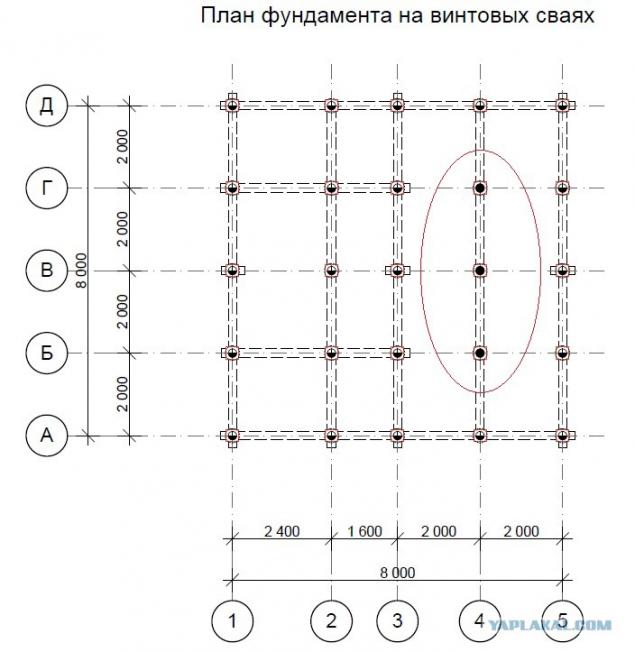

4. The foundation decided to make it easy for bearing structures, namely screw piles. The companies were counted 25 pieces of 108 mm piles with end walls for the safety margin of 133 chosen diameter that can withstand up to 8 tons. Total can accommodate them up to 200 tons. The house itself weighs about 50 tonnes, not including snow load, windows, doors, refrigerators, and SonyPlayStation 3.

5. Make a plan section and screw with his father and father-in first pile. It is the first pile is the easiest.

6. Having measured 8 meters a second hardboiled

7. I realized that without assistants not where, lured to the area friends samovar.

8. The efficiency has increased dramatically, making the deepening of 10 cm for screw + blade hole leading to the direction of the barrel, all the technology of manual screwing. 133 diameter of the screw can be more hands on only machine. By the end of tightening scrap turned into the letter S.

9. The pile is not very heavy, if it carry together. (I'm not in the photo)

10. The test is appropriate from a scientific point of view, with all his experience in construction, a special thank you to him for being helped.

11. Well, one side is ready, and the like are exactly on the line.

12. eyelet is inserted into the scrap pile, and a pipe 2, five of them can be twist. It is possible and three, but the shoulder is necessary to take more than a meter 3-4.

13. Aides were different, physically strong, this fellow office worker.

14. And these were not, they worked well just waiting for the start of physical work leading after drilling the hole.

15. Perimeter ready, then I do not need to measure just another thread slugger place piles. (promerka only for validation)

16. Well, that's another pile was less stock and more on the site where it is waiting for a demanding job, to bring our house for yourself.

17. Taken from a family friend laser level thing. And recaptured the horizon on which it was necessary to cut the piles in one level.

18. I then dreamed that such things would have been more powerful laser, which would hit the button, I lay on the ground. A laser cut everything, including fences, trees and neighbors, and the house and so on. All in one flat rate. Eh! Beauty.

19. A friend had taken a large Bulgarian and the whole day I spoke with their 4 mm in thickness and 133 mm in diameter friends, they did circumcision.

20. Cut a pleasure, an uncomfortable position, a lot of sparks constantly bites.

21. 240 Stoch drive so that if it is put on a small grinder it can not cut.

22. Cut off 1 day themselves piles Screw the 4 days.

23. Inside the concrete is poured, the process is not fotkal, poured together, it was not. Then grab headroom, the technology that would not be moved during assembly of the backing bar. I scalded in a circle.

24. Tractor another story, asked to dig a trench under the water bucket 40 cm, in the end he began to dig on the other hand, failed in his own trench razshafranil it to 1.5 meters and barrels dug to a depth of 2.2 meters. I'm in laying pipe in waders almost drowned there for groundwater level was one meter high water.

25. One friend was a welder and was immediately summoned to the welding, or anything else does not know, and he was granted a brush and paste, I was sitting in a chair drinking a beer, and directed. (Joke)

26. barhanik fell asleep, and razravnen other friends.

27. The foundation is ready, the cost of which is 100 000.

28. 1 Came the car, drove grain loaded shaft without seals and packs that have climbed over and ordered another car, unloaded Vorovaiki on the basis of KAMAZ, for 10 hours in the rain, it was PPC. Logs were all udelat in the mud.

29. I had to wash Karcher each log, lit on 6 acres of this mud, his legs sank knee-deep puddles. This is washed logs. Diameter 240 mm.

30. These sutyrki, Korotyshev and srednyachki preparing to sink.

31. There is one machine, while hardly imagine where to place the second, and it is good that she went three days later. The foundation expects to take over 50 tons of wood!

32. While my friend and comrade of the log with the Kirov prepares backing board, Alex Hello!

33. The smell of the forest is spread throughout the dacha cooperative.

34. Bruce is almost ready, the piles were not perfectly vertical and were errors in the amount of 1 cm, which did not play a large impact on the training bar. I think for the first time his hands is ideal.

35. It Tajik card, handed it to me the day after my conversion to the neighbors builders needed a hand wash timber. Friends samovar has not been maintained.

36. And here is the same dirt and lots of stained logs, which still had to wash.

37. Lining timber ready, error plane amounted to 5 mm, which is very good.

38. Dirt, Karcher, logs. 4 days washed.

39. Went polubrevno axis A B G. In the far right is the processing of wood against mold, bugs, rot and so on.

40. Arrangement of the first floor. Also visible paper tape that pulls polubrevna.

41. The washed and processed logs, waiting in the wings to go by their numbers, but as long as they will need to make the room, goes to the second machine.

42. Logs are cut, is preparing the subfloor, and processing boards.

43. Like all razgrebli and a little dried up.

44. Under the foundation.

45. Under the foundation 2.

46. The second car came, cheers washing is not necessary, but unloaded 12 hours picking out each log. 6 acres is not enough to store the tree.

47. This bunch had to go through and process these employees, students, their missing for 2 days.

48. The working platform is ready, the house is growing up! The mood is good night river and a pint of cold beer.

49. Tests with kuvaldometrom father and knife.

50. Oh, the smell of a tree, we log this savagery, Astrakhan forests there.

51. Center timber from which ultimately measures the diagonal, making the conscience as I remember, 11 m 031 cm 5 mm. As layers hopped a maximum of 5-8 mm.

52. The first acquaintance with shkantami I hammer under close supervision contract supervision. Nashkantilis finally we pleased, 5 drills there.

53. Father-Hollofayber targets, it was the main task of his father and father in law.

54. This is already visible outlines of windows and something similar at home.

55. And now, anteroom with a flight of stairs.

56. Prior to the ceiling of the first floor were manually later installed winch.

57. One of the main assistants, taking the log on his shoulder and carried. And while we do promerku walls and exhibiting a level shot.

58. Drill a 1-kW weak, eventually burned. Prior to that was 1.5 kW broke both handles.

59. The walls are already issued and behind the house there is a shadow.

60. Hello!

61. Walk on logs is not scary, then had to crawl krabikom.

62. Here the ridges under logs overlap between the first and second floor, have cut production not right cup and Alex had to manually dopilivat 24 bowl 1.7 cm more, otherwise the gap remained. 4 days it was killed.

63. It is already possible to imagine the scale of the house is impressive. It seems that he bolshevat 6 acres.

64. And the walls higher and more shade.

65. And here is the very cup.

66. While the cups are cut, we are all small things.

67. Drill stands in the corner, languishing, she could live for 2 days.

68. Right Teschin room.

69. Cup finished and we are happy to prem further up.

70. Well, that's the second floor went in a good mood.

71. From left to right: Oil TAD17, Kuvaldometr, level of gasoline. And all this in our dream house.

72. It is made out of the second floor, see the runners, which we raised logs and covered with roofing material winch.

73. That's the way the whole tree breezing up.

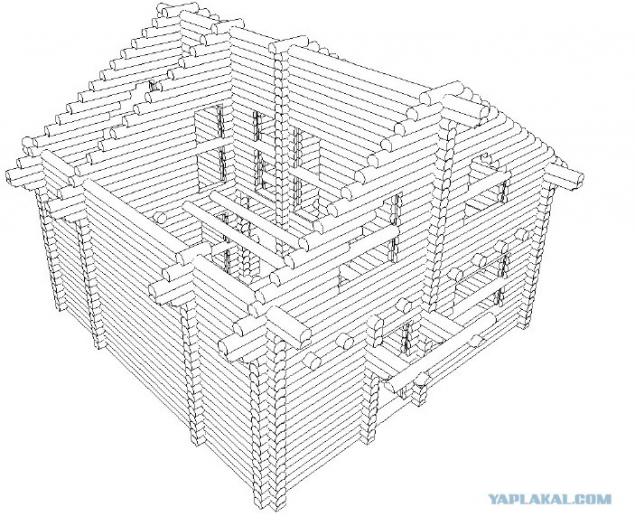

74. It is the last photo, unfortunately, little fotkal the second floor, for a vacation coming to an end and I will have to pick up the box. Here is a house turned out in the end =) eyes fear hands do. Now on weekends I engaged in the fence. Ask.

Source:

74 pictures

1st floor.

2nd floor.

4. The foundation decided to make it easy for bearing structures, namely screw piles. The companies were counted 25 pieces of 108 mm piles with end walls for the safety margin of 133 chosen diameter that can withstand up to 8 tons. Total can accommodate them up to 200 tons. The house itself weighs about 50 tonnes, not including snow load, windows, doors, refrigerators, and SonyPlayStation 3.

5. Make a plan section and screw with his father and father-in first pile. It is the first pile is the easiest.

6. Having measured 8 meters a second hardboiled

7. I realized that without assistants not where, lured to the area friends samovar.

8. The efficiency has increased dramatically, making the deepening of 10 cm for screw + blade hole leading to the direction of the barrel, all the technology of manual screwing. 133 diameter of the screw can be more hands on only machine. By the end of tightening scrap turned into the letter S.

9. The pile is not very heavy, if it carry together. (I'm not in the photo)

10. The test is appropriate from a scientific point of view, with all his experience in construction, a special thank you to him for being helped.

11. Well, one side is ready, and the like are exactly on the line.

12. eyelet is inserted into the scrap pile, and a pipe 2, five of them can be twist. It is possible and three, but the shoulder is necessary to take more than a meter 3-4.

13. Aides were different, physically strong, this fellow office worker.

14. And these were not, they worked well just waiting for the start of physical work leading after drilling the hole.

15. Perimeter ready, then I do not need to measure just another thread slugger place piles. (promerka only for validation)

16. Well, that's another pile was less stock and more on the site where it is waiting for a demanding job, to bring our house for yourself.

17. Taken from a family friend laser level thing. And recaptured the horizon on which it was necessary to cut the piles in one level.

18. I then dreamed that such things would have been more powerful laser, which would hit the button, I lay on the ground. A laser cut everything, including fences, trees and neighbors, and the house and so on. All in one flat rate. Eh! Beauty.

19. A friend had taken a large Bulgarian and the whole day I spoke with their 4 mm in thickness and 133 mm in diameter friends, they did circumcision.

20. Cut a pleasure, an uncomfortable position, a lot of sparks constantly bites.

21. 240 Stoch drive so that if it is put on a small grinder it can not cut.

22. Cut off 1 day themselves piles Screw the 4 days.

23. Inside the concrete is poured, the process is not fotkal, poured together, it was not. Then grab headroom, the technology that would not be moved during assembly of the backing bar. I scalded in a circle.

24. Tractor another story, asked to dig a trench under the water bucket 40 cm, in the end he began to dig on the other hand, failed in his own trench razshafranil it to 1.5 meters and barrels dug to a depth of 2.2 meters. I'm in laying pipe in waders almost drowned there for groundwater level was one meter high water.

25. One friend was a welder and was immediately summoned to the welding, or anything else does not know, and he was granted a brush and paste, I was sitting in a chair drinking a beer, and directed. (Joke)

26. barhanik fell asleep, and razravnen other friends.

27. The foundation is ready, the cost of which is 100 000.

28. 1 Came the car, drove grain loaded shaft without seals and packs that have climbed over and ordered another car, unloaded Vorovaiki on the basis of KAMAZ, for 10 hours in the rain, it was PPC. Logs were all udelat in the mud.

29. I had to wash Karcher each log, lit on 6 acres of this mud, his legs sank knee-deep puddles. This is washed logs. Diameter 240 mm.

30. These sutyrki, Korotyshev and srednyachki preparing to sink.

31. There is one machine, while hardly imagine where to place the second, and it is good that she went three days later. The foundation expects to take over 50 tons of wood!

32. While my friend and comrade of the log with the Kirov prepares backing board, Alex Hello!

33. The smell of the forest is spread throughout the dacha cooperative.

34. Bruce is almost ready, the piles were not perfectly vertical and were errors in the amount of 1 cm, which did not play a large impact on the training bar. I think for the first time his hands is ideal.

35. It Tajik card, handed it to me the day after my conversion to the neighbors builders needed a hand wash timber. Friends samovar has not been maintained.

36. And here is the same dirt and lots of stained logs, which still had to wash.

37. Lining timber ready, error plane amounted to 5 mm, which is very good.

38. Dirt, Karcher, logs. 4 days washed.

39. Went polubrevno axis A B G. In the far right is the processing of wood against mold, bugs, rot and so on.

40. Arrangement of the first floor. Also visible paper tape that pulls polubrevna.

41. The washed and processed logs, waiting in the wings to go by their numbers, but as long as they will need to make the room, goes to the second machine.

42. Logs are cut, is preparing the subfloor, and processing boards.

43. Like all razgrebli and a little dried up.

44. Under the foundation.

45. Under the foundation 2.

46. The second car came, cheers washing is not necessary, but unloaded 12 hours picking out each log. 6 acres is not enough to store the tree.

47. This bunch had to go through and process these employees, students, their missing for 2 days.

48. The working platform is ready, the house is growing up! The mood is good night river and a pint of cold beer.

49. Tests with kuvaldometrom father and knife.

50. Oh, the smell of a tree, we log this savagery, Astrakhan forests there.

51. Center timber from which ultimately measures the diagonal, making the conscience as I remember, 11 m 031 cm 5 mm. As layers hopped a maximum of 5-8 mm.

52. The first acquaintance with shkantami I hammer under close supervision contract supervision. Nashkantilis finally we pleased, 5 drills there.

53. Father-Hollofayber targets, it was the main task of his father and father in law.

54. This is already visible outlines of windows and something similar at home.

55. And now, anteroom with a flight of stairs.

56. Prior to the ceiling of the first floor were manually later installed winch.

57. One of the main assistants, taking the log on his shoulder and carried. And while we do promerku walls and exhibiting a level shot.

58. Drill a 1-kW weak, eventually burned. Prior to that was 1.5 kW broke both handles.

59. The walls are already issued and behind the house there is a shadow.

60. Hello!

61. Walk on logs is not scary, then had to crawl krabikom.

62. Here the ridges under logs overlap between the first and second floor, have cut production not right cup and Alex had to manually dopilivat 24 bowl 1.7 cm more, otherwise the gap remained. 4 days it was killed.

63. It is already possible to imagine the scale of the house is impressive. It seems that he bolshevat 6 acres.

64. And the walls higher and more shade.

65. And here is the very cup.

66. While the cups are cut, we are all small things.

67. Drill stands in the corner, languishing, she could live for 2 days.

68. Right Teschin room.

69. Cup finished and we are happy to prem further up.

70. Well, that's the second floor went in a good mood.

71. From left to right: Oil TAD17, Kuvaldometr, level of gasoline. And all this in our dream house.

72. It is made out of the second floor, see the runners, which we raised logs and covered with roofing material winch.

73. That's the way the whole tree breezing up.

74. It is the last photo, unfortunately, little fotkal the second floor, for a vacation coming to an end and I will have to pick up the box. Here is a house turned out in the end =) eyes fear hands do. Now on weekends I engaged in the fence. Ask.

Source: