725

What is IMPORTANT to consider the construction of a log home

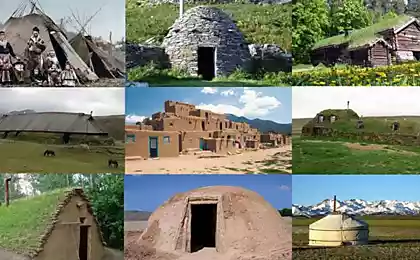

There are countless construction materials, but to give the first among equals, tree. In Russia, wood is always appreciated. For strength and lightness, the ability to maintain the warmth and accessibility of treatment. It was built everything from castles to tenements, did household items, and tools.

Wood built everything from castles to tenements, did household items, and tools.

In a wooden house to live comfortably: warm in winter and cool in summer, dry even in wet terrain and in wet weather. And today, the search for modern comfortable dwelling with fireplace and Underfloor heating, alarm and satellite TV choose a home from logs is a beautiful, cozy, environmentally-friendly, even healing atmosphere.

Our ancestors were mainly built their houses themselves, although the construction of the frame is a long, laborious and responsible. Today there are companies that take care of all the phases of construction, from Foundation to related works. However, there are subtleties, the understanding of which will be superfluous, whether you're building a house themselves or hiring a contractor. Let's look at them.

The Foundation of a log homeConstruction log home has the features that you need to know to live in it happily ever after. And the first thing you need to consider is the peculiarities of construction of the Foundation.

As the wooden house design is relatively easy, and the Foundation for it most often make not the most thorough: low-depth tape, columnar, columnar-strip or slab.

However, the height of the plinth shall not be less than 50 cm below a spray of rain and melted snow in the spring does not hit the bottom crown of the walls. In the strip Foundation should be prospirits provided to allow venting of the underground, which will eliminate the formation of mold. The important point here is the most thorough waterproofing. Normally it consists of promazyvanija Foundation with mastic and laying 3-4 layers of roofing material.

Requirements for woodLog wooden houses are built of softwood: spruce, larch, cedar, but most often pine, and is considered the best Northern pine of winter felling. It is the most dense, durable and moisture resistant. An exquisite rarity — dried on the vine North Karelian pine, Kelo.

What to consider when choosing logs?

It is known that the butt (lower part of the trunk) of the tree is thicker, and to the top its diameter is reduced. Therefore, debarked logs are selected according to thickness.

For a more exotic timbered buildings used logs with collavini skirts

Assembling the log structure, logs are placed, each time alternating the butt and top. Therefore, the wall frame turns solid and smooth. After Assembly, the frame stand a year and a half for drying and shrinkage of the logs. Only then you insert doors, Windows, communications spend, trim house.

In our days houses are built of logs hand-cut or rounded, i.e., processed on special machines.

CylinderingIn recent years, a new type of houses, the construction of which requires minimal manual labor. They are built from round logs. What are these logs differ from the usual?

Log houses from round logs. Photo from: stroybober.com

The advantages of round logsRound logs — beautiful and technologically advanced building material. Its use facilitates the construction, reducing it to the Assembly house from prepared parts according to drawings and process cards.

Disadvantages of round logsBut with all the advantages of mechanical training in the production destroys many natural advantages, the remaining wood prepared manually. After all removed not only the bark but also the other upper layers that protect the Mature Central part of the trunk from external damage. So logs require treatment with antiseptic, antifungal and antiseptic impregnations and means from insects. In the end, they are beautiful and smooth, but less durable and environmentally friendly.

The order of stacking logsFrom a log home has its own special procedure for erection of walls. Between the Foundation and the first two parallel (bottom) logs laying of a wreath placed on opposite sides of the Foundation must be thick "backer" Board. Their width is 150 mm, it is better that they were made of lime and impregnated with antiseptic. The wood of Linden trees is soft and allows you to smooth out all surface irregularities of the Foundation. The two bottom logs of the laying of a wreath cut off the bottom side so that the width of the slice, too, was not less than 150 mm. This is to ensure the walls of the house firmly relied through the "backer" Board to the Foundation. Stack the lower logs, aligning their position relative to each other.

When building a log house with hand-crafted logs them alternately placed the butt in the opposite side to withstand the horizontal rows. It is preferable to take into account the orientation of the annual rings, the positioning of the logs is more dense (North) side out. On this side, higher strength and lower permeability.

Over the centuries the construction of log homes there are many styles or types of cutting scarf joint angles. Nowadays use Russian, Norwegian, Swedish and canadian types of felling.

An example of the canadian technology

Russian cutting corners happen (some names are worth): "krepko", "KLOP", "cut", "needle","the model guaranteed", "into the groove", "in the bowl", "paw."

A pair of logs in the leg with lock

Most commonly used locking gusset "in the bowl", sometimes called "in oblo". Classic bowl — round ends of the logs beyond the boundaries of the frame on 30-50 cm.

This method of cutting is considered the most reliable. The corner of the house will be protected from rain and wind. However, the inner area reduced in size due to the protruding ends of the logs.

Paired with lock down visible "tail". Other teams call it "dark".

To increase the stability of the frame and prevent lateral displacement of the logs is recommended to bond them with each other a round or rectangular wooden nails from the dry dense wood birch or oak —pins. To do this:

When you pre-build a log house of logs be sure to mark

Assembled log house leave for a year and a half for drying, and precipitation, but not necessarily covered with a roof or just plastic wrap. Set the rafters on logs from the upper crown or on mauerlat (support beam for the rafters), rafters are fixed to the purlins and plank roof.

To protect the walls from rain roof overhang shall not be less than 60 cm, 90 cm and best However, there is no guarantee that this design can protect the walls from severe driving rain.

Windows, doors and partitions sets in a year after erection of the framework. As the wood breathes, expands on wetting and shrinks upon drying and shrinkage of the frame continues for another few years, Windows and doors are installed in a special casing of the box, which the top bar can move up and down. Therefore, the swelling of the doors in the autumn and spring period still it easily comes in the box. Although the house made of logs sits not strongly, casing of the box it needed.

As mortgage the crown should be well ventilated, for the floor joists embedded in the next aisle, but if necessary can be embedded in the mortgage.

Related workAfter the Assembly frame and the roof mounting frame caulk, i.e. fill insulation mezhventsovogo seams. The choice of insulation for caulking — another important feature of the construction of the log house.

Function of insulation to protect from heat loss. Therefore, in the process of operation of the house and the natural progress of the logs it should not form cracks. It needs :

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.7dach.ru/Oleg_Sanko/nyuansy-stroitelstva-brevenchatogo-doma-95525.html

Wood built everything from castles to tenements, did household items, and tools.

In a wooden house to live comfortably: warm in winter and cool in summer, dry even in wet terrain and in wet weather. And today, the search for modern comfortable dwelling with fireplace and Underfloor heating, alarm and satellite TV choose a home from logs is a beautiful, cozy, environmentally-friendly, even healing atmosphere.

Our ancestors were mainly built their houses themselves, although the construction of the frame is a long, laborious and responsible. Today there are companies that take care of all the phases of construction, from Foundation to related works. However, there are subtleties, the understanding of which will be superfluous, whether you're building a house themselves or hiring a contractor. Let's look at them.

The Foundation of a log homeConstruction log home has the features that you need to know to live in it happily ever after. And the first thing you need to consider is the peculiarities of construction of the Foundation.

As the wooden house design is relatively easy, and the Foundation for it most often make not the most thorough: low-depth tape, columnar, columnar-strip or slab.

However, the height of the plinth shall not be less than 50 cm below a spray of rain and melted snow in the spring does not hit the bottom crown of the walls. In the strip Foundation should be prospirits provided to allow venting of the underground, which will eliminate the formation of mold. The important point here is the most thorough waterproofing. Normally it consists of promazyvanija Foundation with mastic and laying 3-4 layers of roofing material.

Requirements for woodLog wooden houses are built of softwood: spruce, larch, cedar, but most often pine, and is considered the best Northern pine of winter felling. It is the most dense, durable and moisture resistant. An exquisite rarity — dried on the vine North Karelian pine, Kelo.

What to consider when choosing logs?

- Pay attention to the surface: it must be yellow or dark yellow.

- Slice thick and smooth, without the blue spots, and a darker core is a ¾ cut.

- The size of cracks in the beam — no more than a third of the slice.

- Solid logs — without resin pockets and the large number of knots, blue stain and rot are not twisted.

- At the blow of an axe on a log, the sound should be ringing.

- Logs should not be too wet after drying them can lead, they can be bent or badly cracked.

- To preserve the quality of wood need to observe proper storage conditions, transportation and drying of logs.

It is known that the butt (lower part of the trunk) of the tree is thicker, and to the top its diameter is reduced. Therefore, debarked logs are selected according to thickness.

For a more exotic timbered buildings used logs with collavini skirts

Assembling the log structure, logs are placed, each time alternating the butt and top. Therefore, the wall frame turns solid and smooth. After Assembly, the frame stand a year and a half for drying and shrinkage of the logs. Only then you insert doors, Windows, communications spend, trim house.

In our days houses are built of logs hand-cut or rounded, i.e., processed on special machines.

CylinderingIn recent years, a new type of houses, the construction of which requires minimal manual labor. They are built from round logs. What are these logs differ from the usual?

Log houses from round logs. Photo from: stroybober.com

- Preparation of logs is wood industry. There they corevault, dried in the drying units, with great precision ostragivajut on the machines to cylindrical shape, choose a slot and cut corner locks.

- In most cases, logs are prepared by the size of the specific object in accordance with the project documentation, but may make the so-called "pencils" without corner locks.

- Ready set collected at the production site to confirm the correct preparation, then the log is marked, the frame disassembled and transported to the construction site. And back together — finally.

The advantages of round logsRound logs — beautiful and technologically advanced building material. Its use facilitates the construction, reducing it to the Assembly house from prepared parts according to drawings and process cards.

Disadvantages of round logsBut with all the advantages of mechanical training in the production destroys many natural advantages, the remaining wood prepared manually. After all removed not only the bark but also the other upper layers that protect the Mature Central part of the trunk from external damage. So logs require treatment with antiseptic, antifungal and antiseptic impregnations and means from insects. In the end, they are beautiful and smooth, but less durable and environmentally friendly.

The order of stacking logsFrom a log home has its own special procedure for erection of walls. Between the Foundation and the first two parallel (bottom) logs laying of a wreath placed on opposite sides of the Foundation must be thick "backer" Board. Their width is 150 mm, it is better that they were made of lime and impregnated with antiseptic. The wood of Linden trees is soft and allows you to smooth out all surface irregularities of the Foundation. The two bottom logs of the laying of a wreath cut off the bottom side so that the width of the slice, too, was not less than 150 mm. This is to ensure the walls of the house firmly relied through the "backer" Board to the Foundation. Stack the lower logs, aligning their position relative to each other.

When building a log house with hand-crafted logs them alternately placed the butt in the opposite side to withstand the horizontal rows. It is preferable to take into account the orientation of the annual rings, the positioning of the logs is more dense (North) side out. On this side, higher strength and lower permeability.

Over the centuries the construction of log homes there are many styles or types of cutting scarf joint angles. Nowadays use Russian, Norwegian, Swedish and canadian types of felling.

An example of the canadian technology

Russian cutting corners happen (some names are worth): "krepko", "KLOP", "cut", "needle","the model guaranteed", "into the groove", "in the bowl", "paw."

A pair of logs in the leg with lock

Most commonly used locking gusset "in the bowl", sometimes called "in oblo". Classic bowl — round ends of the logs beyond the boundaries of the frame on 30-50 cm.

This method of cutting is considered the most reliable. The corner of the house will be protected from rain and wind. However, the inner area reduced in size due to the protruding ends of the logs.

Paired with lock down visible "tail". Other teams call it "dark".

To increase the stability of the frame and prevent lateral displacement of the logs is recommended to bond them with each other a round or rectangular wooden nails from the dry dense wood birch or oak —pins. To do this:

- Holes to a depth of more than one logs drilled vertically in each row, staggered, for a distance of not more than 1.5 m from each other.

- Pins hammer into them with little effort. The dowel diameter of 20-30 mm.

- Nagel connects 3 of the crown logs. The last two wreaths are not fixed. This is necessary for proper shrinkage.

When you pre-build a log house of logs be sure to mark

Assembled log house leave for a year and a half for drying, and precipitation, but not necessarily covered with a roof or just plastic wrap. Set the rafters on logs from the upper crown or on mauerlat (support beam for the rafters), rafters are fixed to the purlins and plank roof.

To protect the walls from rain roof overhang shall not be less than 60 cm, 90 cm and best However, there is no guarantee that this design can protect the walls from severe driving rain.

Windows, doors and partitions sets in a year after erection of the framework. As the wood breathes, expands on wetting and shrinks upon drying and shrinkage of the frame continues for another few years, Windows and doors are installed in a special casing of the box, which the top bar can move up and down. Therefore, the swelling of the doors in the autumn and spring period still it easily comes in the box. Although the house made of logs sits not strongly, casing of the box it needed.

As mortgage the crown should be well ventilated, for the floor joists embedded in the next aisle, but if necessary can be embedded in the mortgage.

Related workAfter the Assembly frame and the roof mounting frame caulk, i.e. fill insulation mezhventsovogo seams. The choice of insulation for caulking — another important feature of the construction of the log house.

Function of insulation to protect from heat loss. Therefore, in the process of operation of the house and the natural progress of the logs it should not form cracks. It needs :

- To be quite dense and yet flexible, to protect the joints of the crowns (especially in the corners) from blowing off.

- Depending on changes in the internal and external humidity to absorb and release moisture so as not to contribute to the development of fungi, mold and rot.

- To be environmentally friendly and durable.

- Tow in the form of hand-rolled strands are laid across the length of the log. Then stack the log following the wedding. After assembling the whole house oakum using caulking wooden hammer is pushed between the rows, wrapping it from the bottom, then the top and in the middle of the slit, and tightly plug the gap.

- Moss also laid out on the log and after laying wreath next cut off the excess with a sharp axe.

- Jute tapes are placed across the length of the deck evenly and attach to the lower crown staples.

- The effect of applying self-adhesive foam insulating tape is that when interacting with air, it increases in volume by 3-5 times and fills all voids in the joints of the crowns.

- Insulated joints crowns and injected under high pressure polyurethane foam that fills all voids and fills them. The method is rapid, not labour-intensive, but requires special equipment. However, the foam will break out of the smallest cracks, and after curing you will need to clear the frame and plug the holes with wooden plugs.

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.7dach.ru/Oleg_Sanko/nyuansy-stroitelstva-brevenchatogo-doma-95525.html