659

Painting a wooden house. How to protect your fortress

If you are the owner of a wooden house, you probably know how about the merits and some shortcomings of wood. Wooden house like no other in need of special care and protection. To protect it from external influences — rain, snow, sun and so on — you need to cover the wood with a special paint. However, the right to paint the house is not as easy as it seems at first glance.

Stages protective obrabatyvatsya think about how and what to paint, at the stage of construction of the house. And many manufacturers offer paint materials for protection of wood entire painting system:

1. Impregnation antiseptic Used for effective protection of wooden elements indoors and outdoors from the appearance of fungi, blue stain and insect pests. Treated with an antiseptic does not protect against UV rays from the swelling and cracking of wood. The formed film is washed off, depending on the manufacturer, for 1-3 months.

2. Lacquer or enamel Gives the decorative appearance of wood products and is used to protect inside and outside areas. This coating endures the effects of the weather and UV rays.

Lacquer or enamel protects from rain and UV radiation, but can not cope with the bruising, fungus and spoilage. There are small dark spots, which then develop into lesions. The wood becomes loose, the paint cracks and flakes off.

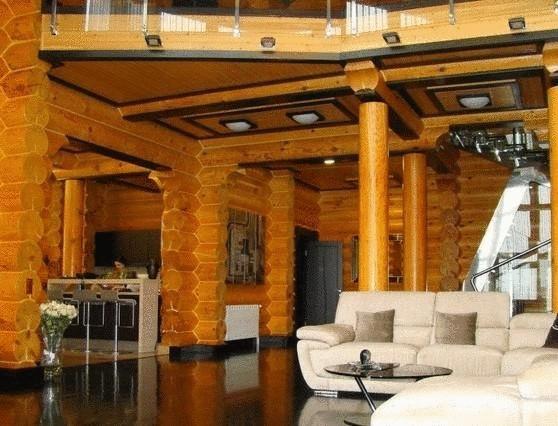

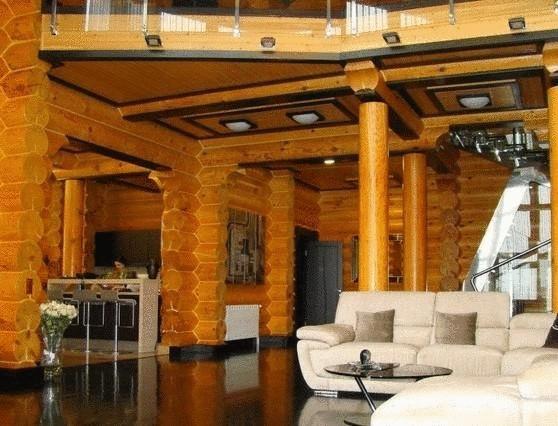

Therefore, we recommend at least these two stages of protective coloration the house. The photo is an example of what it looks like correctly processed wooden house. He seemed lit from within!

3. Mastic for sealing of edges and joints

As a rule, also included in the recommended painting system. The end of the wood absorbs water 2-3 times more than the longitudinal side. Cracking and blueing starts with an unprotected end.

In the photo below you can see how it will look treated according to all rules the end of a log, covered with tinted varnish.

And look treated the joints of the logs.

4. Fire protection Many people ask about the need for treatment of wood flame retardants. In Russia, widespread formulations based on concentrated salt solutions. Salt absorbed into the wood, forming a less flammable surface.

Three factors to consider when you wish to handle the house onebusaway:

1. Manufacturers usually write on the jars: "...the Total flow for providing flame retardant properties in group I (slow-wood) not less than 600 g/sq m (1.6 and 1.7 sq. m/kg)...". Let us examine this point in more detail.

Polished pine wood absorbs the first layer of 100-120 g/sqm when applied with a brush. The total flow rate with three-layer coating of about 180-200 g/sq m, with five – 250-300 g/sq. m. Only in industrial conditions (in an autoclave under pressure) to achieve the required flow rate and, consequently, to make your house the fire-resistant properties (not to be confused with non-combustible). When a serious fire will smolder.

2. In case of wood processing fire protection formed the so-called "efflorescence", get rid of them is almost impossible. Further decorative and protective treatment of wood also becomes impossible as a lacquer or enamel not keep on such wood. To leave the house without protection from UV rays is impossible, as after 3-4 months the wood begins to darken and crumble. In most cases, it is necessary to apply a phased grinding.

3. Treatment outside the house will not be saved from fire due to the circuit wiring inside the building.

Paint materialise coating materials can be divided into two groups according to the type of diluent:

Water-based. Features: no smell, fast drying, easy to clean tool. The organic diluent. Features: the smell, long drying time (sometimes up to 24 hours for each layer), possible buildup of debris, dust, flies on the surface. The type of foaming agent (a substance that gives a protective film) are the main types of paints, used for painting of wooden houses:

Alcide synthetic — penetrate deeply into the wood, inexpensive but destroyed under the action of UV rays. Acrylic — acrylates of the latest generation penetrate deeply into the wood, elastic, resistant to UV radiation, but have high price. Natural oils — penetrate deep into the wood, eco-friendly, but also expensive; in addition, it is necessary to refresh the surface. Gardeners often ask the question — when can we paint the building. Houses from glued beams whose humidity 10-12%, can be painted immediately after Assembly. Structure of profiled timber and round log homes are better treated with antiseptic and allow to stand for 3-4 months before painting.

This photo shows a log house in the process of processing and painting.

How to repair an old painting donaudelta procedure - repair and painting of the house. If to do "on conscience", it is necessary to estimate the size of the works. Often there are houses with cracked floors, bruising, blackening of the wood. In such cases, does not always help the initial grinding, often have to resort to bleaching. The bleaching process is based on the oxidation of wood, so the solution should be thoroughly washed. Further processing is carried out on the same principle as the original color of the house.

In conclusion, a few rules, the observance of which is obligatory:

I hope that these tips will help you to understand the painting process and select appropriate materials. And let your wooden house for a long time serves you faithfully! published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.7dach.ru

Stages protective obrabatyvatsya think about how and what to paint, at the stage of construction of the house. And many manufacturers offer paint materials for protection of wood entire painting system:

1. Impregnation antiseptic Used for effective protection of wooden elements indoors and outdoors from the appearance of fungi, blue stain and insect pests. Treated with an antiseptic does not protect against UV rays from the swelling and cracking of wood. The formed film is washed off, depending on the manufacturer, for 1-3 months.

2. Lacquer or enamel Gives the decorative appearance of wood products and is used to protect inside and outside areas. This coating endures the effects of the weather and UV rays.

Lacquer or enamel protects from rain and UV radiation, but can not cope with the bruising, fungus and spoilage. There are small dark spots, which then develop into lesions. The wood becomes loose, the paint cracks and flakes off.

Therefore, we recommend at least these two stages of protective coloration the house. The photo is an example of what it looks like correctly processed wooden house. He seemed lit from within!

3. Mastic for sealing of edges and joints

As a rule, also included in the recommended painting system. The end of the wood absorbs water 2-3 times more than the longitudinal side. Cracking and blueing starts with an unprotected end.

In the photo below you can see how it will look treated according to all rules the end of a log, covered with tinted varnish.

And look treated the joints of the logs.

4. Fire protection Many people ask about the need for treatment of wood flame retardants. In Russia, widespread formulations based on concentrated salt solutions. Salt absorbed into the wood, forming a less flammable surface.

Three factors to consider when you wish to handle the house onebusaway:

1. Manufacturers usually write on the jars: "...the Total flow for providing flame retardant properties in group I (slow-wood) not less than 600 g/sq m (1.6 and 1.7 sq. m/kg)...". Let us examine this point in more detail.

Polished pine wood absorbs the first layer of 100-120 g/sqm when applied with a brush. The total flow rate with three-layer coating of about 180-200 g/sq m, with five – 250-300 g/sq. m. Only in industrial conditions (in an autoclave under pressure) to achieve the required flow rate and, consequently, to make your house the fire-resistant properties (not to be confused with non-combustible). When a serious fire will smolder.

2. In case of wood processing fire protection formed the so-called "efflorescence", get rid of them is almost impossible. Further decorative and protective treatment of wood also becomes impossible as a lacquer or enamel not keep on such wood. To leave the house without protection from UV rays is impossible, as after 3-4 months the wood begins to darken and crumble. In most cases, it is necessary to apply a phased grinding.

3. Treatment outside the house will not be saved from fire due to the circuit wiring inside the building.

Paint materialise coating materials can be divided into two groups according to the type of diluent:

Water-based. Features: no smell, fast drying, easy to clean tool. The organic diluent. Features: the smell, long drying time (sometimes up to 24 hours for each layer), possible buildup of debris, dust, flies on the surface. The type of foaming agent (a substance that gives a protective film) are the main types of paints, used for painting of wooden houses:

Alcide synthetic — penetrate deeply into the wood, inexpensive but destroyed under the action of UV rays. Acrylic — acrylates of the latest generation penetrate deeply into the wood, elastic, resistant to UV radiation, but have high price. Natural oils — penetrate deep into the wood, eco-friendly, but also expensive; in addition, it is necessary to refresh the surface. Gardeners often ask the question — when can we paint the building. Houses from glued beams whose humidity 10-12%, can be painted immediately after Assembly. Structure of profiled timber and round log homes are better treated with antiseptic and allow to stand for 3-4 months before painting.

This photo shows a log house in the process of processing and painting.

How to repair an old painting donaudelta procedure - repair and painting of the house. If to do "on conscience", it is necessary to estimate the size of the works. Often there are houses with cracked floors, bruising, blackening of the wood. In such cases, does not always help the initial grinding, often have to resort to bleaching. The bleaching process is based on the oxidation of wood, so the solution should be thoroughly washed. Further processing is carried out on the same principle as the original color of the house.

In conclusion, a few rules, the observance of which is obligatory:

- wood moisture content should be less than 25%;

- you can't paint immediately after rain and under the scorching rays of the sun;

- the time from sanding wood before painting should be no more than 3 days;

- it is better to apply the material by brush, as thus it is rubbed into the surface and penetrates deeper into the wood.

I hope that these tips will help you to understand the painting process and select appropriate materials. And let your wooden house for a long time serves you faithfully! published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.7dach.ru