640

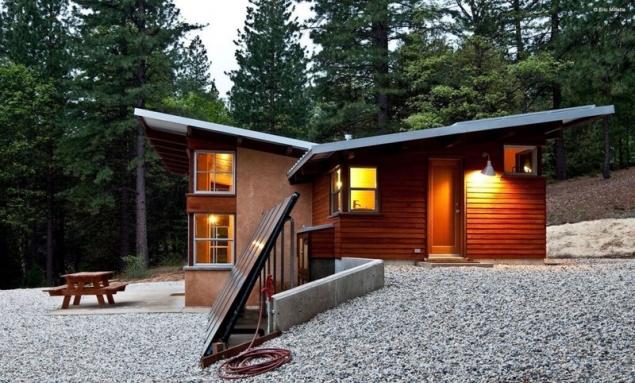

Fireproof the house of straw!

Straw houses are built and loved around the world! In the North-West of the first such buildings were built 10 years ago. Reliable, warm, cozy, they have stood the test of our climate! However, until now, modern construction technology of pressed straw we have known a few.

Modern technology straw construction (in the West it is called strawbale-house) based on the best qualities of this unique natural material. In an extruded form, having transformed itself from a bundle of dry stalks of straw in the unit, it becomes an excellent building material. Compressed straw is the best insulation. Straw-the stalks of the plants tubular and hollow. In them and between them contains air, which are known for its low thermal conductivity. Because of its porosity straw has good sound quality.

The composition of the straw of cereals, as the composition of wood includes cellulose, polycellulose, lignin. In the straw contains a lot of silica, 2 to 3 times more than in wood. Thanks to this element, the straw is an enviable vitality. There are examples of exploitation of thatched homes for over 100 years.

The Council

Because the walls of straw are lightweight, the design of the Foundation can be quite easy and economical. Geological research will help to accurately calculate the preferred type and amount of material for the Foundation.

For the manufacture of blocks and construction of buildings best suited straw rye, flax, wheat, hemp. In the United States was used baled hay. As raw material for blocks must use dry straw. By pressing set the desired value of density. Ready straw block has the correct form of a parallelepiped. It is tightly bound with metal wire or plastic cord. Produced blocks of different parameters. For construction best suited the dimensions: length 50-120 m, width 50cm, height 40cm with a weight of about 23 kg. the international experience straw housing has even "elephant" Jumbo bales with dimensions of 0.5 by 1.0 to (1,6–2,2) m. They are double the density of 160-180 kg/cubic meters for stacking blocks in this case would require a crane, and, therefore, the construction will cost more.

Frame plus strawa House of straw can be constructed as a frameless and frame method. The frame method on the Foundation, build the frame of wood, between which the stacked straw blocks. Before laying blocks to build the roof in the event of rainfall, the straw is not wet. The blocks are fastened together in the same ways as in the frameless technique. The first row of straw bales placed on a dais above the floor to protect from moisture.

Wall align (shave straw) special hand saw or ordinary chain saw. On top of straw bales covered with mesh and several layers of plaster with thickness up to 75 mm. Sometimes plaster without a grid in the crate. It's cheaper but more time-consuming process. Plaster mix consists of clay, sand, water. The ratio of components is due to their qualities and determined by experience. In top layer of plaster add flour paste (it was not dirty) or linseed oil (improves the level of moisture protection). There is a method of processing straw bales and clay, when the block for a short time dipped in clay or it is applied to the straw surface with your hands in 3 layers. The overall proportion of clay in the construction of the wall will be no more than 10%. These walls are stronger, better protected from fire, but the technology itself is more time-consuming. The walls are heavier, long time to dry. At the height of the frame-straw technology is limited to the carrying capacity of the frame, i.e. in principle it is possible to build even a straw skyscraper.At present, there are already five-storey thatched houses.

For a straw wall

Humidity is one of the most important factors taken into account when building a house of straw. In our rainy climate, with high moisture content in the air throughout the year, with the temperature difference of the straw wall is properly constructed house feel great.

The Council

Straw house, fit a roof of any shape. During construction, avoid heavy roofing materials. With straw walls will be in harmony with natural roofing, such as shingles. It is important to contact the walls of the straw with the falling precipitation was minimized, so design the overhang to less than 60 cm.

The technology is a natural ability of straw to evaporate excess moisture. Straw "breathes" even better than wood. She has a good porozumienie properties. Already there are examples when in a thatched house arranged bath and pool, not using porozumienie film.

The equilibrium moisture content of straw in the wall is not more than 8%.

It is extremely important when building a straw house to ensure that the humidity closed in the wall of the straw no more than 18%, otherwise you can commence organic process of decay. You can, of course, to handle the bales with antiseptic, but then violated the principle of ecological purity of the materials. While respecting the right technology straw design will take even brief flooding. But the lasting hydration, structures of straw can not stand.

It seems that the phrase "fire-resistant straw house" sounds paradoxical. Plastered wall of straw the fire is not terrible. The bales are covered with plaster, on the test stand 2 hours of exposure to an open flame. Straw block, opened on one side only, does not support combustion. The density of pressed bales of 200-300 kg/cubic meter also prevents burning. But on site it is necessary to observe measures of fire safety, because the stalks of straw, scattered on the territory, highly flammable.

Frame technology straw construction allows to provide the stability at home to the strong wind and not be afraid of a storm warning declared by forecasters. You can get the required amount of air tightness of walls, varying the thickness of the plaster and the structure of the external facade decoration.

How to protect the straw walls from rodents?

In a straw house construction has its own tricks that prevent the settlement of rodents. For example, it is seen that mice do not like rye straw. Still piles pour slaked lime.

The first straw houses started in the U.S., Nebraska, in the nineteenth century.

In the CIS, with government support, to build straw bale houses in Belarus. This type of material for the Republic is familiar. In modern construction of straw houses one of the pioneers and promoters is E. I. Shirokov, now President of the Belarusian branch of international Academy of ecology. In 1996, under his leadership in Belarus was built the first wooden frame house made of straw.

Construction technology with the use of straw is certified in many countries, including in Belarus. In Russia patented the Moscow company "Sereda habitat".

The Council

Saved by walling the money can be spent on various new technologies for home improvement. For example, system solar lighting, smart home, alternative energy. As a result of the cost of traditional construction to create a truly eco-friendly and energy efficient home.

In the Leningrad region of the thatched houses was started in 2000 with the participation of Norwegian ecoarchitectural. Under their leadership was constructed straw houses in the Vsevolozhsk district initiatives School House in the village of Ryzhkovo and charity project "Svetlana". So we already have the first ecovillage. Perhaps in the near future such settlements safe from the environmental point of view, Russia will be more!

The house of straw you can build your own. It is no coincidence that this technology belongs to the category of open-source, i.e. the information about it is in the public domain. Self-construction will save on the wages of hired builders.

Whether straw construction model?In Russia annually produces about 800 million tons of rye and wheat straw. A substantial part of it burned. But half of the resulting straw is sufficient for the construction of 390 million square metres of housing per year, or 2.6 million homes in 150 sq. m. straw is a quickly renewable natural resource. It gets us almost nothing. The cost of straw for the cottage of average size (150-200 sq m) will be about 30 thousand rubles. Because straw blocks enough of the easy stuff, the cost of the device base will be minimal.

Straw houses have many advantages. Builders do not need to have any special skills. In the presence of a qualified supervisor they could cope with the process.

While the construction of straw houses have cost-is costing-level wooden mansion, because there is no infrastructure for the production of blocks of straw. The straw has to be dry, but hot and dry summer we have is rare. Yes, and the construction process is time consuming and troublesome to cut and "shave" the wall, leveling, plastering.

Nevertheless, proponents of green building believe that straw houses are big and bright future. Our builders think about the development of model projects. Very promising is the idea of a house of finished modules. This house is built in the calculation of the growth of a family, a future addition to the family. published

Text: Irina Khlyzova

P. S. And remember, only by changing their consumption — together we change the world! © Join us at Facebook , Vkontakte, Odnoklassniki

Source: zs-z.ru/zagorodnoe-stroitelstvo/domostroenie/texnologii-stroitelstva/ognestojkij-dom-iz-solomyi.html

Modern technology straw construction (in the West it is called strawbale-house) based on the best qualities of this unique natural material. In an extruded form, having transformed itself from a bundle of dry stalks of straw in the unit, it becomes an excellent building material. Compressed straw is the best insulation. Straw-the stalks of the plants tubular and hollow. In them and between them contains air, which are known for its low thermal conductivity. Because of its porosity straw has good sound quality.

The composition of the straw of cereals, as the composition of wood includes cellulose, polycellulose, lignin. In the straw contains a lot of silica, 2 to 3 times more than in wood. Thanks to this element, the straw is an enviable vitality. There are examples of exploitation of thatched homes for over 100 years.

The Council

Because the walls of straw are lightweight, the design of the Foundation can be quite easy and economical. Geological research will help to accurately calculate the preferred type and amount of material for the Foundation.

For the manufacture of blocks and construction of buildings best suited straw rye, flax, wheat, hemp. In the United States was used baled hay. As raw material for blocks must use dry straw. By pressing set the desired value of density. Ready straw block has the correct form of a parallelepiped. It is tightly bound with metal wire or plastic cord. Produced blocks of different parameters. For construction best suited the dimensions: length 50-120 m, width 50cm, height 40cm with a weight of about 23 kg. the international experience straw housing has even "elephant" Jumbo bales with dimensions of 0.5 by 1.0 to (1,6–2,2) m. They are double the density of 160-180 kg/cubic meters for stacking blocks in this case would require a crane, and, therefore, the construction will cost more.

Frame plus strawa House of straw can be constructed as a frameless and frame method. The frame method on the Foundation, build the frame of wood, between which the stacked straw blocks. Before laying blocks to build the roof in the event of rainfall, the straw is not wet. The blocks are fastened together in the same ways as in the frameless technique. The first row of straw bales placed on a dais above the floor to protect from moisture.

Wall align (shave straw) special hand saw or ordinary chain saw. On top of straw bales covered with mesh and several layers of plaster with thickness up to 75 mm. Sometimes plaster without a grid in the crate. It's cheaper but more time-consuming process. Plaster mix consists of clay, sand, water. The ratio of components is due to their qualities and determined by experience. In top layer of plaster add flour paste (it was not dirty) or linseed oil (improves the level of moisture protection). There is a method of processing straw bales and clay, when the block for a short time dipped in clay or it is applied to the straw surface with your hands in 3 layers. The overall proportion of clay in the construction of the wall will be no more than 10%. These walls are stronger, better protected from fire, but the technology itself is more time-consuming. The walls are heavier, long time to dry. At the height of the frame-straw technology is limited to the carrying capacity of the frame, i.e. in principle it is possible to build even a straw skyscraper.At present, there are already five-storey thatched houses.

For a straw wall

Humidity is one of the most important factors taken into account when building a house of straw. In our rainy climate, with high moisture content in the air throughout the year, with the temperature difference of the straw wall is properly constructed house feel great.

The Council

Straw house, fit a roof of any shape. During construction, avoid heavy roofing materials. With straw walls will be in harmony with natural roofing, such as shingles. It is important to contact the walls of the straw with the falling precipitation was minimized, so design the overhang to less than 60 cm.

The technology is a natural ability of straw to evaporate excess moisture. Straw "breathes" even better than wood. She has a good porozumienie properties. Already there are examples when in a thatched house arranged bath and pool, not using porozumienie film.

The equilibrium moisture content of straw in the wall is not more than 8%.

It is extremely important when building a straw house to ensure that the humidity closed in the wall of the straw no more than 18%, otherwise you can commence organic process of decay. You can, of course, to handle the bales with antiseptic, but then violated the principle of ecological purity of the materials. While respecting the right technology straw design will take even brief flooding. But the lasting hydration, structures of straw can not stand.

It seems that the phrase "fire-resistant straw house" sounds paradoxical. Plastered wall of straw the fire is not terrible. The bales are covered with plaster, on the test stand 2 hours of exposure to an open flame. Straw block, opened on one side only, does not support combustion. The density of pressed bales of 200-300 kg/cubic meter also prevents burning. But on site it is necessary to observe measures of fire safety, because the stalks of straw, scattered on the territory, highly flammable.

Frame technology straw construction allows to provide the stability at home to the strong wind and not be afraid of a storm warning declared by forecasters. You can get the required amount of air tightness of walls, varying the thickness of the plaster and the structure of the external facade decoration.

How to protect the straw walls from rodents?

In a straw house construction has its own tricks that prevent the settlement of rodents. For example, it is seen that mice do not like rye straw. Still piles pour slaked lime.

The first straw houses started in the U.S., Nebraska, in the nineteenth century.

In the CIS, with government support, to build straw bale houses in Belarus. This type of material for the Republic is familiar. In modern construction of straw houses one of the pioneers and promoters is E. I. Shirokov, now President of the Belarusian branch of international Academy of ecology. In 1996, under his leadership in Belarus was built the first wooden frame house made of straw.

Construction technology with the use of straw is certified in many countries, including in Belarus. In Russia patented the Moscow company "Sereda habitat".

The Council

Saved by walling the money can be spent on various new technologies for home improvement. For example, system solar lighting, smart home, alternative energy. As a result of the cost of traditional construction to create a truly eco-friendly and energy efficient home.

In the Leningrad region of the thatched houses was started in 2000 with the participation of Norwegian ecoarchitectural. Under their leadership was constructed straw houses in the Vsevolozhsk district initiatives School House in the village of Ryzhkovo and charity project "Svetlana". So we already have the first ecovillage. Perhaps in the near future such settlements safe from the environmental point of view, Russia will be more!

The house of straw you can build your own. It is no coincidence that this technology belongs to the category of open-source, i.e. the information about it is in the public domain. Self-construction will save on the wages of hired builders.

Whether straw construction model?In Russia annually produces about 800 million tons of rye and wheat straw. A substantial part of it burned. But half of the resulting straw is sufficient for the construction of 390 million square metres of housing per year, or 2.6 million homes in 150 sq. m. straw is a quickly renewable natural resource. It gets us almost nothing. The cost of straw for the cottage of average size (150-200 sq m) will be about 30 thousand rubles. Because straw blocks enough of the easy stuff, the cost of the device base will be minimal.

Straw houses have many advantages. Builders do not need to have any special skills. In the presence of a qualified supervisor they could cope with the process.

While the construction of straw houses have cost-is costing-level wooden mansion, because there is no infrastructure for the production of blocks of straw. The straw has to be dry, but hot and dry summer we have is rare. Yes, and the construction process is time consuming and troublesome to cut and "shave" the wall, leveling, plastering.

Nevertheless, proponents of green building believe that straw houses are big and bright future. Our builders think about the development of model projects. Very promising is the idea of a house of finished modules. This house is built in the calculation of the growth of a family, a future addition to the family. published

Text: Irina Khlyzova

P. S. And remember, only by changing their consumption — together we change the world! © Join us at Facebook , Vkontakte, Odnoklassniki

Source: zs-z.ru/zagorodnoe-stroitelstvo/domostroenie/texnologii-stroitelstva/ognestojkij-dom-iz-solomyi.html