1833

Samana house of mud and straw with his hands

Return to partially forgotten building technologies associated with the trend of using natural materials. They provide a natural home for tourists and have good environmental qualities. A classic example of such buildings are adobe houses, the basic material of which is a mixture of clay and straw. His popularity got a building for sustainability, the natural regulation of the microclimate in the premises and the relative simplicity of the construction.

Samana house. What is it?

Analogs of modern houses of straw and clay existed in ancient times. Some of them are preserved to this day - in the arid regions of Asia and Africa can meet the whole adobe city. Improving building technology has led to the widespread dissemination of clay buildings in the central Europe and Russia today. Properly constructed mud houses have more than a century of service life and safe for occupants.

Visually adobe buildings are not always different from the ordinary, although their main "charm" is the ability to make the walls of any shape and adapt a home interior. Numerous recesses bath and smooth transitions strikingly isolated clay buildings from brick and other cement-block structures.

Old technology is rarely used in its original form, as the operating parameters of modern houses are rising due to the use of modern additives. Natural clay fireproof properties, is prone to bake at elevated temperature are improved by the introduction of components that increase the strength characteristics.

Adobe construction technology 1. Materials that should be reserved in advance:

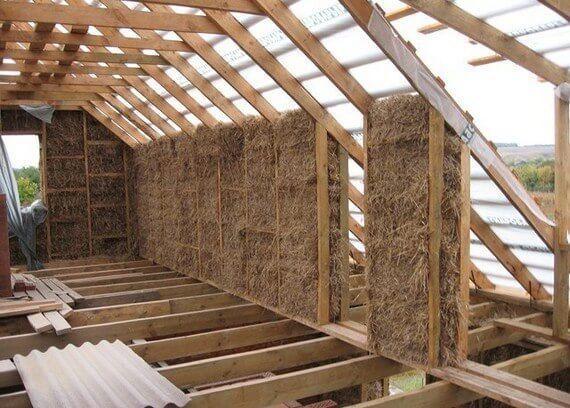

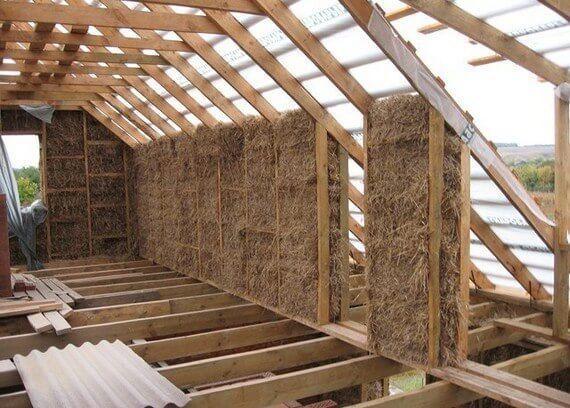

wooden planks and beams for the construction of frame walls and roof;

clay;

sand;

straw;

water (well or central water supply).

Additional materials that are useful in the preparatory stages and finishes include:

gravel - for making bedding for the foundation;

material for the manufacture of unit-cast or brick foundation;

flat wooden slats upholstery house walls;

wood (metal) formwork or mold for manufacturing units.

Although the house is clay, it is better to make a classical foundation - belt. Robust and elevated above the ground base will increase the life of the house and reduce the impact of meltwater on the lower part of the walls.

The construction site should be selected away from the lowlands, and access to the water table. The optimal arrangement of a clay house -. On a hill

To get the most solid construction, suitable for our latitude, the wall is better to be produced by pouring the solution into the mold. You can also use clay blocks that are placed similarly to a classic block design.

A significant decrease in the cost of construction is achieved by obtaining self-clay on the site. Straw in small amounts is cheap, and the greatest costs will be connected with the purchase of sand and timber.

Straw should be dry and free of rot. It is best to buy it immediately after the harvest season crops, and then leave for the winter in a dry and ventilated area.

2. Preparation

solution Many authors are advised not to use the pure clay and mix it with sand. Since sand and clay composition differ for different regions can test their different proportions (2: 1, 1: 1, 1: 2, etc.). Clay-sand mixture in which water is added to obtain a paste-like consistency, it should be clenched in a fist and drop on a solid base with a height of 1, 5-2 m. A lump of suitable composition must not crack or severely flattened in the fall.

To prepare the solution, you can use the mixer or a flat base with turned-up edges (the solution was stirred feet). The clay is ground to a finely divided state before it is added to the sand and water. The latter should not be a lot to the mixture retained a highly viscous consistency and is not leaking from the formwork.

The straw is added to the resulting clay-sand mortar in an amount of from 30 to 60%. The more straw, the lower the thermal conductivity of the walls and their strength (have to be limited to one floor). The resulting solution is poured into the formwork form, exposed at the edges of the wooden frame house.

The frame is assembled from the boards and is the vertical and horizontal guides. On top of the workpiece to be under the roof, because after the pouring of the walls is necessary to immediately take its covering. Pouring the solution occurs in steps (up to 30 cm per day), and then the wall must be given time to dry. With self-construction of the wall is usually "grows" in the 10-15 cm per day cycle.

The exterior walls are covered crate of straw or reeds - they create an additional heat insulating layer. Crate fastened a thin layer that is pressed against the wall, flat wooden slats (nailed to wooden supports). Outside crate daubed clay or lime plaster.

Optimal use of lime plaster, because it prevents the appearance of parasites inside the walls.

3. The roof is made of straw and clay

On top, padded roof frame boards, stacked related straw bundles, which then leveled (fastening of the rope is cut). Fix the straw as well as lathing on a wall - wooden slats. After coating the roof can begin to coating any of its clay-sand mortar.

The process is carried out from the lower edge of the roof to the ridge. After curing, the coating will not miss moisture, but the opportunity to leave the room to "breathe" and support the optimal humidity level 50-55%.

Feature: Fill the roof should be done alternately and evenly on both slopes, to avoid skewing

. 4. Finish the room's walls

Inside the house is made of wooden planks interior, which is then plastered. In contrast to the clay plaster, lime can be glued on top of the wallpaper (will not be damaged by parasites). Clay plaster can not always protect against the appearance of insects, but it is cheaper.

What makes modern houses of the old buildings?

To give additional tensile strength solution of clay (partly cope with this straw), previously widely used cattle manure. The same solution plastered walls of the room, called "wattle and daub". The main disadvantage of these homes is the abundance of insects in the walls.

Now to increase the strength and natural chaff used fire. A couple of centuries ago, they were hard to get, and now it is the plants processing waste.

Increasing strength and decreasing the drying shrinkage increases the gravel or expanded clay additive. Subsidiary element is the sand. To increase the cure speed of the clay-sand mortar or cement can enter lime. These additives are used in the construction of wet weather, aiming at reducing the risk of wetting the walls still wet material.

Raise the viscosity of the solution during operation helps casein, starch, and water glass. The latter is a preservative, so further prevents the appearance of mold and insects.

The use of modern construction technology, including sublimation of a solid foundation, increases the strength and stability of the building. Instead of clay roof can be laid out conventional Ruberoid covering which is closed on top with slate or tiles. This does not worsen the ecological properties of the house, but will improve the performance.

To protect the house from rodents, you need to ensure that there are thin metal mesh under the crate.

Features care thatched houses

A separate item in the operation of buildings is fire safety. Clay house with plaster exterior and interior surfaces of clay or lime mortar, less prone to destruction by fire than usual. In the event of fire the straw as part of the walls are not flammable, as air access to it is closed a layer of clay.

Despite the high resistance to the fire walls of adobe houses, the wooden parts of the roof do not possess it. To reduce the possibility of fire, there should be fire-retardant treatment of wood. They do not provide absolute protection against fire, but very effective, subject to the application of technology.

Construction companies involved in the construction of houses made of mud and straw, assure the practical impossibility of the emergence of insects in the walls. This is only true while maintaining a low humidity, it is not always possible. Do not neglect the advice to use lime plaster, which clog the wall for the ingress of moisture and will inhibit the development of insects.

Before the construction of the house provides an arrangement of the furnace and a bathroom. The points of contact with hot surfaces need to place reflective screens and wet locations perform waterproofing.

Samana house: the pros and cons of the structure

Advantages of adobe buildings:

clean and healthy "environment»;

inside the building cool in summer and warm in winter;

cheap building materials;

the relative simplicity of construction.

Disadvantages of houses made of straw:

construction can not be conducted in the winter;

with dampness in the walls infest insects that "gnaw" wallpaper;

weak strength hurricane winds (less important on rough terrain).

No need to magnify durability and safety of mud houses, but they downplay and not worth it. Samana house is ideal for a summer residence or as a summer house on the plot. Properly constructed house made of clay will stand no less than its predecessors, but it will bring more pleasant feelings and health.

Samana house. What is it?

Analogs of modern houses of straw and clay existed in ancient times. Some of them are preserved to this day - in the arid regions of Asia and Africa can meet the whole adobe city. Improving building technology has led to the widespread dissemination of clay buildings in the central Europe and Russia today. Properly constructed mud houses have more than a century of service life and safe for occupants.

Visually adobe buildings are not always different from the ordinary, although their main "charm" is the ability to make the walls of any shape and adapt a home interior. Numerous recesses bath and smooth transitions strikingly isolated clay buildings from brick and other cement-block structures.

Old technology is rarely used in its original form, as the operating parameters of modern houses are rising due to the use of modern additives. Natural clay fireproof properties, is prone to bake at elevated temperature are improved by the introduction of components that increase the strength characteristics.

Adobe construction technology 1. Materials that should be reserved in advance:

wooden planks and beams for the construction of frame walls and roof;

clay;

sand;

straw;

water (well or central water supply).

Additional materials that are useful in the preparatory stages and finishes include:

gravel - for making bedding for the foundation;

material for the manufacture of unit-cast or brick foundation;

flat wooden slats upholstery house walls;

wood (metal) formwork or mold for manufacturing units.

Although the house is clay, it is better to make a classical foundation - belt. Robust and elevated above the ground base will increase the life of the house and reduce the impact of meltwater on the lower part of the walls.

The construction site should be selected away from the lowlands, and access to the water table. The optimal arrangement of a clay house -. On a hill

To get the most solid construction, suitable for our latitude, the wall is better to be produced by pouring the solution into the mold. You can also use clay blocks that are placed similarly to a classic block design.

A significant decrease in the cost of construction is achieved by obtaining self-clay on the site. Straw in small amounts is cheap, and the greatest costs will be connected with the purchase of sand and timber.

Straw should be dry and free of rot. It is best to buy it immediately after the harvest season crops, and then leave for the winter in a dry and ventilated area.

2. Preparation

solution Many authors are advised not to use the pure clay and mix it with sand. Since sand and clay composition differ for different regions can test their different proportions (2: 1, 1: 1, 1: 2, etc.). Clay-sand mixture in which water is added to obtain a paste-like consistency, it should be clenched in a fist and drop on a solid base with a height of 1, 5-2 m. A lump of suitable composition must not crack or severely flattened in the fall.

To prepare the solution, you can use the mixer or a flat base with turned-up edges (the solution was stirred feet). The clay is ground to a finely divided state before it is added to the sand and water. The latter should not be a lot to the mixture retained a highly viscous consistency and is not leaking from the formwork.

The straw is added to the resulting clay-sand mortar in an amount of from 30 to 60%. The more straw, the lower the thermal conductivity of the walls and their strength (have to be limited to one floor). The resulting solution is poured into the formwork form, exposed at the edges of the wooden frame house.

The frame is assembled from the boards and is the vertical and horizontal guides. On top of the workpiece to be under the roof, because after the pouring of the walls is necessary to immediately take its covering. Pouring the solution occurs in steps (up to 30 cm per day), and then the wall must be given time to dry. With self-construction of the wall is usually "grows" in the 10-15 cm per day cycle.

The exterior walls are covered crate of straw or reeds - they create an additional heat insulating layer. Crate fastened a thin layer that is pressed against the wall, flat wooden slats (nailed to wooden supports). Outside crate daubed clay or lime plaster.

Optimal use of lime plaster, because it prevents the appearance of parasites inside the walls.

3. The roof is made of straw and clay

On top, padded roof frame boards, stacked related straw bundles, which then leveled (fastening of the rope is cut). Fix the straw as well as lathing on a wall - wooden slats. After coating the roof can begin to coating any of its clay-sand mortar.

The process is carried out from the lower edge of the roof to the ridge. After curing, the coating will not miss moisture, but the opportunity to leave the room to "breathe" and support the optimal humidity level 50-55%.

Feature: Fill the roof should be done alternately and evenly on both slopes, to avoid skewing

. 4. Finish the room's walls

Inside the house is made of wooden planks interior, which is then plastered. In contrast to the clay plaster, lime can be glued on top of the wallpaper (will not be damaged by parasites). Clay plaster can not always protect against the appearance of insects, but it is cheaper.

What makes modern houses of the old buildings?

To give additional tensile strength solution of clay (partly cope with this straw), previously widely used cattle manure. The same solution plastered walls of the room, called "wattle and daub". The main disadvantage of these homes is the abundance of insects in the walls.

Now to increase the strength and natural chaff used fire. A couple of centuries ago, they were hard to get, and now it is the plants processing waste.

Increasing strength and decreasing the drying shrinkage increases the gravel or expanded clay additive. Subsidiary element is the sand. To increase the cure speed of the clay-sand mortar or cement can enter lime. These additives are used in the construction of wet weather, aiming at reducing the risk of wetting the walls still wet material.

Raise the viscosity of the solution during operation helps casein, starch, and water glass. The latter is a preservative, so further prevents the appearance of mold and insects.

The use of modern construction technology, including sublimation of a solid foundation, increases the strength and stability of the building. Instead of clay roof can be laid out conventional Ruberoid covering which is closed on top with slate or tiles. This does not worsen the ecological properties of the house, but will improve the performance.

To protect the house from rodents, you need to ensure that there are thin metal mesh under the crate.

Features care thatched houses

A separate item in the operation of buildings is fire safety. Clay house with plaster exterior and interior surfaces of clay or lime mortar, less prone to destruction by fire than usual. In the event of fire the straw as part of the walls are not flammable, as air access to it is closed a layer of clay.

Despite the high resistance to the fire walls of adobe houses, the wooden parts of the roof do not possess it. To reduce the possibility of fire, there should be fire-retardant treatment of wood. They do not provide absolute protection against fire, but very effective, subject to the application of technology.

Construction companies involved in the construction of houses made of mud and straw, assure the practical impossibility of the emergence of insects in the walls. This is only true while maintaining a low humidity, it is not always possible. Do not neglect the advice to use lime plaster, which clog the wall for the ingress of moisture and will inhibit the development of insects.

Before the construction of the house provides an arrangement of the furnace and a bathroom. The points of contact with hot surfaces need to place reflective screens and wet locations perform waterproofing.

Samana house: the pros and cons of the structure

Advantages of adobe buildings:

clean and healthy "environment»;

inside the building cool in summer and warm in winter;

cheap building materials;

the relative simplicity of construction.

Disadvantages of houses made of straw:

construction can not be conducted in the winter;

with dampness in the walls infest insects that "gnaw" wallpaper;

weak strength hurricane winds (less important on rough terrain).

No need to magnify durability and safety of mud houses, but they downplay and not worth it. Samana house is ideal for a summer residence or as a summer house on the plot. Properly constructed house made of clay will stand no less than its predecessors, but it will bring more pleasant feelings and health.