659

Thatched roof with his own hands - the features of the device

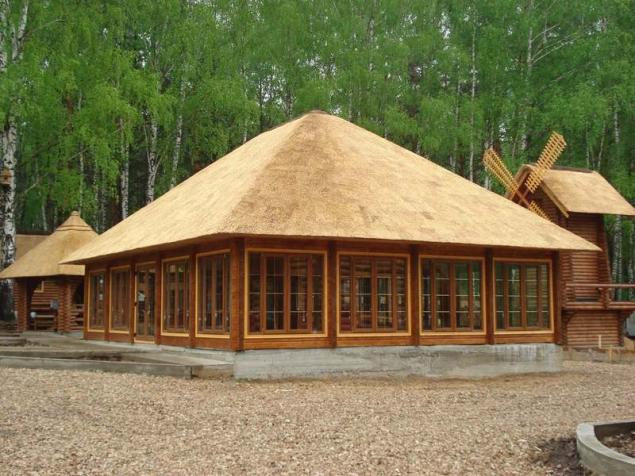

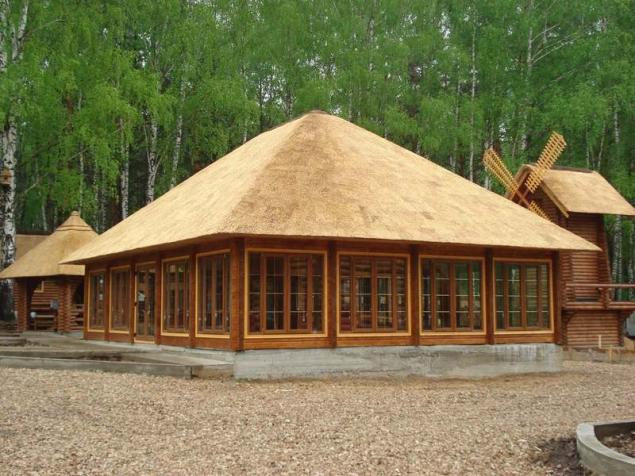

The roof is made of straw was almost an integral part of the roof of an ancient hut. One of the main reasons why thatched roofs enjoy such popularity is the availability of the material and its good quality. And even today all the positive properties of straw valued, so the material, though not always, but sometimes used as a roofing coating.

This roof is not only attractive and unusual appearance, she's also reliable, durable and capable of creating unique and, of course, a favorable microclimate. Any house with a thatched roof will look very stylish and original.

Today, when the market of building materials with the most modern and innovative designs, many developers, however, often give preference to natural materials. Thanks to the advanced production technology, the roof of straw is characterized not only by strength and significant durability. Evidence of this is its service life which can reach 50 years, which greatly exceeds the life of even some much more expensive and advanced materials.

Myths about thatch the roof

Because of the many erroneous opinions regarding the characteristics of straw as a roof covering many of the myths about this material should be dispelled. These include the following:

Source: kryshadoma.com/vidy-krovli-kryshi/solomennaya-krysha-svoimi-rukami-osobennosti-ustroystva.html

This roof is not only attractive and unusual appearance, she's also reliable, durable and capable of creating unique and, of course, a favorable microclimate. Any house with a thatched roof will look very stylish and original.

Today, when the market of building materials with the most modern and innovative designs, many developers, however, often give preference to natural materials. Thanks to the advanced production technology, the roof of straw is characterized not only by strength and significant durability. Evidence of this is its service life which can reach 50 years, which greatly exceeds the life of even some much more expensive and advanced materials.

Myths about thatch the roof

Because of the many erroneous opinions regarding the characteristics of straw as a roof covering many of the myths about this material should be dispelled. These include the following:

- cane or straw roof does not flash from any spark, as mistakenly believed by many. Before you fit the roof made of straw with their hands, the material is pre-treated with flame retardants. So, its Flammability, the material can be compared, for example, popular today with Onduline;

- the roof is made of straw will not become a habitat for mice, which is so feared by many owners, because the material fit tightly, and fixing each individual Smuta to a pole by using wire. In this laying to penetrate under the roof can not only mouse, but also any external moisture;

- the myth that a thatched roof with their hands will look poor and will give the house a view of the village huts. This is not so, in fact, received such widespread today country style is perfectly combined with roof of straw. In addition, the stacking process can be to get creative by running original and unique design.

- the material is extremely environmentally friendly, in the process of operation, he naturally no harmful substances are not allocated; the resulting stacking design is a strong, but lightweight, resulting in load-bearing wall construction of heavy loads is not provided;

- the main raw material for the manufacture of material – straw with long stalks and reeds, which have a low cost and completely affordable. In addition, thatched roof with his own hands would be enough;

- due to the unique properties of straw inside the house at any period of the year, created a favorable climate: in winter the house is warm in the summer – cool.

- plasma crate on the basis of the sheet OSP;

- strap clamp in the center of the ridge; the stiffener under the OSB;

- bundles of straw, fortified with a special pagename;

- covering the ridge of a grid of metal;

- either the shingles, or sheaves of straw on the roof ridge.

- the material should be solid and have a smooth color, without rot and any signs of erosion;

- the clamping wire is best to use galvanized. The distance of the first clamp away from the bar shall be 200 mm, the second 120 mm after the first, after that, every 260 – 300 mm;

- the locking wire should have a section size of 1 mm;

- thickness, on which is laid a layer of coating depends on parameters of the slope – length and slope. If the inclination does not exceed 40 degrees, and the length is 7 meters, the thickness of the layer can be 22 cm in the center of the ridge and 25 centimeters in the area of the base

Source: kryshadoma.com/vidy-krovli-kryshi/solomennaya-krysha-svoimi-rukami-osobennosti-ustroystva.html