566

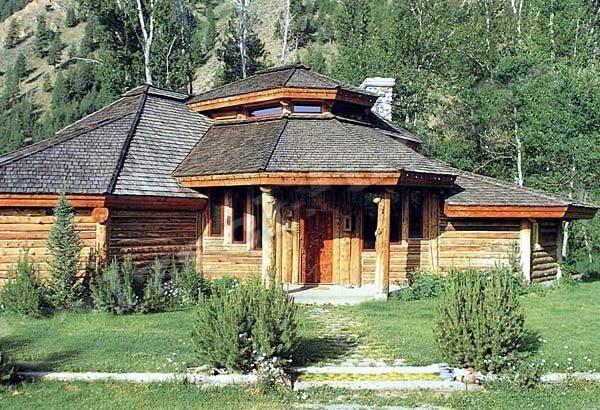

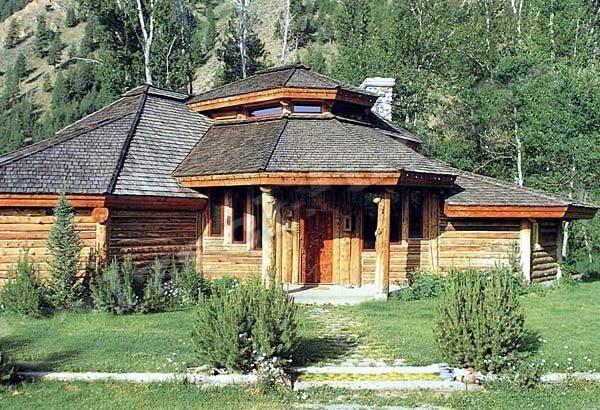

Roofing shingles: production and features of the device

The advantage of natural material for roofs is confirmed by a long history of its use. For covering roofs, widespread use is made of oak, fir, beech, larch, cedar.

Different people call the roofing material of wood in different ways: shingle, shingle, shingles, sinhalas. In this article we will talk about what characteristics and features has a roof of shingles.

The shingles on the roof

Manufacture of shingles

The types of shingles

Shingles for roofing made from coniferous wood of the best quality oak, Siberian larch, cedar. This material is mostly hand-made, in the form of plates of wood.

Shingles can be of several types:

This material is an excellent alternative to modern roofing, particularly for roofs of those objects that are affected:

Shingles on complex roofs

Modern production methods allow shingles more often in the construction to give preference to option – roof + shingles. This material is successfully used on roofs having curved shapes and complex configuration.

Depending on the purpose of the object shingles fit into 3-5 layers. Multilayer coating constructs for complex roofs tight and waterproof roofing cover.

Technology of laying ofRoof of shingles is different from other coatings not only properties, but also the technology of the installation, which is determined by the nature of the material. Shingles placed on the roof similar to how stacked the scales in spruce cones.

When exposed to rain and high humidity wooden plates a little swell and increase in size. Due to this, the material pooling on the roof.

The roof looks like a bump. In the process of drying the plates, curving, raised dome, this ensures removal of moisture from under the roof of the house.

This natural cover in Sunny weather shows its unique properties. If you compare materials such as metal, tiles, that the wooden surface does not transmit heat. This causes the home cool during the hottest time of the year.

The outer surface of the coating is characterized by a relief structure.

This circumstance protects the roof space from the noise arising from:

Mainly shingle as a roofing coating has such advantages:

The roofingshingle is light weight. The flooring is carried out on solid or rare crate, for the manufacture of which are bars with a thickness of 6 cm distance between the coating layer 4 and bars is 25 cm.

Plank shingles toward the ridge. For the first row of the first and second layer used the shortened plate. Wooden plates in the first layer is secured to the lower end of the Board, and the top – to the bar.

Material fastened with nails of a length of 5 cm, so they passed through a layer that precedes the one that fits.

Council. In order for the shingles not subjected to wind loads, are required by TEC to hem the overhang from the bottom surface of the rafter.SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

http://cdn00.vidyomani.com/c/1/2/4/66ertw57fesi/index.html

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

Features of installation

The placement of shingles on the sheathing

The first row of shingles is placed to close was located at 4 cm from the sheathing on the leeward side. If you make a first row is different then the eaves begin to prematurely crack and blacken from the effects of the environment.

Bars for crates are squared in two of Kant. The sheathing device is carried out from the eaves to the ridge. Along the overhang is attached to the Board, after the slats of the crates. Each strap is fixed at the intersection with rafter beam.

Shingle roofing is laid with planks, one of which acts as a guide for laying the base material, and the other is to hold the guide.

Subsidiary boards should be at least two. In the process of laying shingles moves guide.

In places the descent of the roof instead of the bars fastening shingles to produce to the Board, having a width of 350 mm – for installation of three-layer coating, 400 mm for stacking four-layer cover.

For extreme number of used Board with a width of 100-250 mm.

Boards under the roof covering processed oil paint in 2 layers and covered with hot bitumen. Due to the processing of the Board is to nourish the water in the event of a leak through the shingles.

In places the slopes of the roof roofing wears out faster, so the coating layer on the descents increases by one time compared with the thickness of the primary coating. For example, when laying on the surface of the roof shingles in three layers, on the place of descent it is necessary to lay four.

Laying boards on the descent is carried out so that the regeneration of three-layer coating shingles are positioned at the same level against the slats of the crates, which are stacked above the Board. This plan is attached in the second row of shingles. It promotes a dense adjunction of rows of shingles to the previously laid layers.

It is undesirable to use a natural roof device razzhelobkov. They are longer rays, therefore at their device it is necessary to lay auxiliary plank sheathing every two rows dranochnyh coverage.

To make the roof waterproof the ridge and cornice of the roof is placed a shortened plates, and the main cover uses a full shingle. In the first row at the eaves shingle is laid in the direction of pile on the surface down into the other rows of the fuzzy side facing up.

Attention. Adjacent wooden plates stacked vakrou, the overlap width of equal to 40 cm, the Roof of shingles requires care.

It is as follows:

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: krovlyakryshi.ru/estestvenye/derevyannaya/krovlya-iz-dranki-374

Different people call the roofing material of wood in different ways: shingle, shingle, shingles, sinhalas. In this article we will talk about what characteristics and features has a roof of shingles.

The shingles on the roof

Manufacture of shingles

The types of shingles

Shingles for roofing made from coniferous wood of the best quality oak, Siberian larch, cedar. This material is mostly hand-made, in the form of plates of wood.

Shingles can be of several types:

- puncture;

- sawn;

- mosaic.

This material is an excellent alternative to modern roofing, particularly for roofs of those objects that are affected:

- the effects of the harsh climate;

- extremely low temperature;

- significant precipitation in form of snow.

Shingles on complex roofs

Modern production methods allow shingles more often in the construction to give preference to option – roof + shingles. This material is successfully used on roofs having curved shapes and complex configuration.

Depending on the purpose of the object shingles fit into 3-5 layers. Multilayer coating constructs for complex roofs tight and waterproof roofing cover.

Technology of laying ofRoof of shingles is different from other coatings not only properties, but also the technology of the installation, which is determined by the nature of the material. Shingles placed on the roof similar to how stacked the scales in spruce cones.

When exposed to rain and high humidity wooden plates a little swell and increase in size. Due to this, the material pooling on the roof.

The roof looks like a bump. In the process of drying the plates, curving, raised dome, this ensures removal of moisture from under the roof of the house.

This natural cover in Sunny weather shows its unique properties. If you compare materials such as metal, tiles, that the wooden surface does not transmit heat. This causes the home cool during the hottest time of the year.

The outer surface of the coating is characterized by a relief structure.

This circumstance protects the roof space from the noise arising from:

- hail;

- rain;

- gusty winds.

Mainly shingle as a roofing coating has such advantages:

- ensures the long term integrity of the roof;

- the cover is completely in harmony with the environment;

- the lightness of the material (1 sq. m. the load ranges from 14 to 18 kg);

- without a doubt, it is an environmentally friendly coating;

- when carrying out installation work there is an almost waste-free production;

- the coating does not accumulate static electricity;

- under the wooden plates is not condensed;

- resistance to sharp temperature fluctuations, precipitation and wind loads;

- possibility of use in various climatic conditions at temperatures from +40 to-70 degrees.

The roofingshingle is light weight. The flooring is carried out on solid or rare crate, for the manufacture of which are bars with a thickness of 6 cm distance between the coating layer 4 and bars is 25 cm.

Plank shingles toward the ridge. For the first row of the first and second layer used the shortened plate. Wooden plates in the first layer is secured to the lower end of the Board, and the top – to the bar.

Material fastened with nails of a length of 5 cm, so they passed through a layer that precedes the one that fits.

Council. In order for the shingles not subjected to wind loads, are required by TEC to hem the overhang from the bottom surface of the rafter.SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

http://cdn00.vidyomani.com/c/1/2/4/66ertw57fesi/index.html

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

Features of installation

The placement of shingles on the sheathing

The first row of shingles is placed to close was located at 4 cm from the sheathing on the leeward side. If you make a first row is different then the eaves begin to prematurely crack and blacken from the effects of the environment.

Bars for crates are squared in two of Kant. The sheathing device is carried out from the eaves to the ridge. Along the overhang is attached to the Board, after the slats of the crates. Each strap is fixed at the intersection with rafter beam.

Shingle roofing is laid with planks, one of which acts as a guide for laying the base material, and the other is to hold the guide.

Subsidiary boards should be at least two. In the process of laying shingles moves guide.

In places the descent of the roof instead of the bars fastening shingles to produce to the Board, having a width of 350 mm – for installation of three-layer coating, 400 mm for stacking four-layer cover.

For extreme number of used Board with a width of 100-250 mm.

Boards under the roof covering processed oil paint in 2 layers and covered with hot bitumen. Due to the processing of the Board is to nourish the water in the event of a leak through the shingles.

In places the slopes of the roof roofing wears out faster, so the coating layer on the descents increases by one time compared with the thickness of the primary coating. For example, when laying on the surface of the roof shingles in three layers, on the place of descent it is necessary to lay four.

Laying boards on the descent is carried out so that the regeneration of three-layer coating shingles are positioned at the same level against the slats of the crates, which are stacked above the Board. This plan is attached in the second row of shingles. It promotes a dense adjunction of rows of shingles to the previously laid layers.

It is undesirable to use a natural roof device razzhelobkov. They are longer rays, therefore at their device it is necessary to lay auxiliary plank sheathing every two rows dranochnyh coverage.

To make the roof waterproof the ridge and cornice of the roof is placed a shortened plates, and the main cover uses a full shingle. In the first row at the eaves shingle is laid in the direction of pile on the surface down into the other rows of the fuzzy side facing up.

Attention. Adjacent wooden plates stacked vakrou, the overlap width of equal to 40 cm, the Roof of shingles requires care.

It is as follows:

- snow from the roof is removed the broom from the roof ridge to the eaves;

- the coating is checked for defects.

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: krovlyakryshi.ru/estestvenye/derevyannaya/krovlya-iz-dranki-374

5 healthy recipes from dandelions

Find out how to rid the area of diseases, pests and weeds in one fell swoop!