1214

Warm floors in wooden house: the peculiarities of installation

Underfloor heating for wooden housesthe wooden house there is a different system flooring, especially when their insulation. It is important that in the end, the scheme was still working and properly heating the building. Warm floors in wooden house equipped with different systems, which are:

1. Electrical installation is not as acceptable, because may cause fires and short circuits, and fire wood is used. One of the advantages discover the small dimensions of the circuits and eliminates the need to use heavy cable ties and the formation of multilayer devices of the sexes.

2. Radiant floor heating in a wooden house is completely safe in the process of installation and operation. However, the probability of floor heating is reduced, since the Board does not have a high level of thermal conductivity.

The design options of floor heating are equally applied. Importantly, during the installation process, carefully follow all the safety measures and to comply with the requirements and recommendations of specialists. Ways of folding floor in the house different on different parameters and principles of installation. Before to perform particular installation, it is recommended to study the variation of the device warm floor in the wooden house. By design, they can be divided into two groups: the floor is made of boards and concrete.

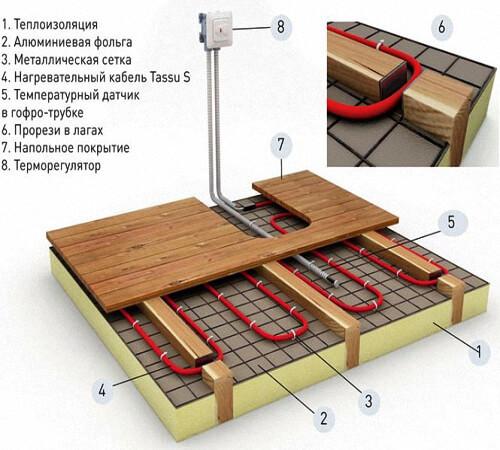

Features of installation of the wooden floorthe Wooden floor forms a base in several layers that creates a draft portion of the stacking of insulating layers, followed by a fine covered and surface finish. In the overall design between the layers is placed a heating system, such as pipes or special cables that allow you to complete the heating system in the house.

Wooden warm floor in a private house is characterized by a circuit construction that anticipates the installation on poles with a concrete Foundation or on logs. With in-situ concrete pouring to build the floor is much easier in its absence the whole structure is built with beams. They have a width of 4 meters of stairs and broke out in house walls on the supporting pillars. In essence, this pier foundations for buildings, beams which are not bonded. The distance between the posts is from 0.7 to 1 meter and top cover made of roofing material in 3 rows. The cross beam needs to rely entirely on the support elements, and for better fixing use wedges or gaskets that fasten parts with nails.

Warm floor in the wooden house of the screed divided into two types:

1. Single layer constructions which are installed and joists, or on other grounds. The choice of preference depends on the gap between the beams and the thickness of the boards. In the construction of floor joists, planks, spread directly on the beam, but it is important that the distance between them was not more than 0.5 meters.

2. Double-layer design foresees the establishment of a sub-floor with the attachment of boards on both sides of the beams. Over them is placed a layer of insulation, for example, sheet material or expanded clay range, and its height should be about 80 millimeters. In an additional heater is placed a layer between rough and finish floors. In this case, leaving a gap of about 4 mm that will allow to create air circulation between the boards and bring them destruction.

Floor insulationWood and concrete floor it is always necessary to insulate using different materials and ways of heating. Many builders for greater effect, try to apply additional layers of insulation that will fill the space between the rows of rough and clean floor.

Among the current materials used for polyurethane, mineral wool, and among the natural ways you can meet sawdust and shavings, dry leaves, and so on. When using any insulating material for the floor is recommended to leave a gap of about 15 or 20 mm for air exchange.

Subfloor: installation ofelectric floor heating in a wooden house or infrared are required equally ventilated and be strong at the base. To circuit insulation was high-quality and functional, this set a floor, which should meet the following requirements:

When building a house on their own, the builders believe that the rough structures are the reason for a floor covering, but it is not. Essence in that the substrate is a packing of plywood or particle Board or similar boards on the joists. They are applied to the subsequent stacking of materials in their flat position and measured the gravity separation of the entire ceiling on the floor. Such substrates are used in buildings made of wood and monolith.

The rough floor is also the lowest layer among the base of the boards as cover on the joists or beams, depending on the device building. As a rule, layers are the floor boards, which are located in diagonal position relative to the finishing of masonry. In this case, a fortress of the overlap formed by the options of flooring boards. Paul creates a double insulation design, in order to keep warm, as well as to fix the insulating layers and to regulate the thermal flow in the house.

The procedure for the installation of floor heating is in the following steps:

1. The creation of the ventilation shaft allows you to make the air exchange between the slats of the boards that they did not succumb to decay. The setting process is carried out in drilling the corners of the house a few holes with a diameter of approximately 50 to 60 mm. They should be rounded, which after a closed special lattices as a decorative material. Over rough floors, they should be located at a height of 5 or 6 cm, so as not to allow water to get inside. In some cases, rough ventilation installed in the baseboard.

2. Basement waterproofing is an important part of the installation of floor heating in a wooden house with his own hands. As a building material is a roofing material or other insulating objects which are placed on the first step of warming the building.

3. Logs, wreaths, and all boards should be thoroughly treated with antiseptics that will allow you to remove and to provide wood from the appearance of fungus or mold as well as insects. Some builders use ordinary engine oil or other objects of protection.

4. Laying the sub-floor are three options:

5. After selecting the installation method, it is preferable to position the planks on cranial bars, you need to lay the waterproofing layer. The best option may be mineral wool as insulation, and the latter spread a vapor barrier.

6. After laying put the floor finish. For the use of tongue and groove boards or chipboard. On top of them was covered laminate or linoleum.

It should be noted that the temperature should not differ from the temperature of the room and the floor more than two degrees, so to come to the floor insulation should be carefully. Experts recommend to carefully select all the insulating materials that retain heat in the room. Among the important properties are the high degree of conduction of energy, the lack of non-combustible components and allergic substances. Also, the insulating material must be durable and rugged in structure and easy to use in construction works.

The most suitable option think of mineral wool, which is hygroscopic and absorbs moisture perfectly, not allowing it to seep through the Board. Other insulating materials are susceptible to burning, although small in weight, an example is foam plastic and polystyrene. Waterproofing great items will be roofing felt, plastic film and so on. To the question: how to make a warm floor in the wooden house? The procedure for laying of all layers is carried out with the installation of the first row of the floor, and then flooring all waterproofing after thermal insulating materials, and the last row will be the vapor barrier.

Floor finish: installationthe Last step is the folding of the finished floor, which consists in the following steps. Select the milled boards that are fastened to the base of the spikes and grooves. Their size should be 28-44х98-145 mm, which have a special produhi on the back edge of 2 cm, which are determined for permanent ventilation.

In the absence of these boards, you can use other variations, such as the Board spiked a straight or trapezoidal shape, and raked in the pile, and the like. The only disadvantage of these boards is the lack of produhi. It is important to remember that when laying the boards, they should be sent to the various parties and determined by the rings on a tree.

Installation of concrete floors in a wooden housein establishing a concrete floor do not need to put many layers of boards and insulating material. For this you need to make a screed, but it's important to remember some factors and aspects. The concrete floor has advantages, which are:

Laying of concrete on the ground: worksInfrared warm floor in the wooden house or water are installed after the casting process the concrete base. The sequence of operations is carried out in a similar way:

1. To determine the level of fill for a concrete floor. Marks made by means of a cord and measured is the perimeter of the base approximately 10 cm.

2. On the ground sprinkled a layer of gravel, so that the present pegs need to compare with level. Then the labels are extracted.

3. On the gravel, poured the sand, which seals the previous layers.

4. Put a layer of waterproofing with the use of plastic film. She drifted onto the sand, but the edges need to be higher than the floor.

5. This is followed by pouring concrete on the waterproofing material, which is evenly leveled.

6. Solution cover with foil, but the base must be constantly moistened with water.

Concrete floor leave it for 3-4 weeks, and the solution hardened and became solid. After two months you can start to make a screed of cement. At the beginning of the work should determine the type of floor heating: electric or water. In this episode, the thickness of layers shall not exceed 25 mm, which will fit after laying tiles, linoleum or laminate.

Radiant floor heatinginstallation Process water floor better known solution in wooden houses. It is suitable for cement screed and folding boards. In case of tie, the design and sequence of layers would be as follows:

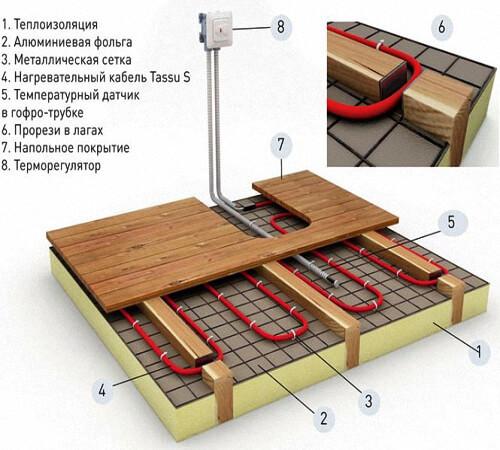

The device of electric floor heating in a wooden house videos which will talk more about the specifics of the installation. This system fits the same option on the joists or tie. In the second case, the system of carrying out heat the same as water heating.

For the use of cable and lay it on the grid values in 50x50mm and fasten design on the joists. They saw through the gaps with a height of 50 mm, and the distance between them is required to be 5 cm, which is insulated with foil. Cable that warms the floor, placed in these gaps.

Installation of floor heating in wooden houses has its own characteristics that are determined by the type of Foundation, building and so on. I hope the article you will learn all the essential parts of laying the floor by design and device. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: strport.ru/uchastok/teplye-poly-v-derevyannom-dome-osobennosti-montazha

1. Electrical installation is not as acceptable, because may cause fires and short circuits, and fire wood is used. One of the advantages discover the small dimensions of the circuits and eliminates the need to use heavy cable ties and the formation of multilayer devices of the sexes.

2. Radiant floor heating in a wooden house is completely safe in the process of installation and operation. However, the probability of floor heating is reduced, since the Board does not have a high level of thermal conductivity.

The design options of floor heating are equally applied. Importantly, during the installation process, carefully follow all the safety measures and to comply with the requirements and recommendations of specialists. Ways of folding floor in the house different on different parameters and principles of installation. Before to perform particular installation, it is recommended to study the variation of the device warm floor in the wooden house. By design, they can be divided into two groups: the floor is made of boards and concrete.

Features of installation of the wooden floorthe Wooden floor forms a base in several layers that creates a draft portion of the stacking of insulating layers, followed by a fine covered and surface finish. In the overall design between the layers is placed a heating system, such as pipes or special cables that allow you to complete the heating system in the house.

Wooden warm floor in a private house is characterized by a circuit construction that anticipates the installation on poles with a concrete Foundation or on logs. With in-situ concrete pouring to build the floor is much easier in its absence the whole structure is built with beams. They have a width of 4 meters of stairs and broke out in house walls on the supporting pillars. In essence, this pier foundations for buildings, beams which are not bonded. The distance between the posts is from 0.7 to 1 meter and top cover made of roofing material in 3 rows. The cross beam needs to rely entirely on the support elements, and for better fixing use wedges or gaskets that fasten parts with nails.

Warm floor in the wooden house of the screed divided into two types:

1. Single layer constructions which are installed and joists, or on other grounds. The choice of preference depends on the gap between the beams and the thickness of the boards. In the construction of floor joists, planks, spread directly on the beam, but it is important that the distance between them was not more than 0.5 meters.

2. Double-layer design foresees the establishment of a sub-floor with the attachment of boards on both sides of the beams. Over them is placed a layer of insulation, for example, sheet material or expanded clay range, and its height should be about 80 millimeters. In an additional heater is placed a layer between rough and finish floors. In this case, leaving a gap of about 4 mm that will allow to create air circulation between the boards and bring them destruction.

Floor insulationWood and concrete floor it is always necessary to insulate using different materials and ways of heating. Many builders for greater effect, try to apply additional layers of insulation that will fill the space between the rows of rough and clean floor.

Among the current materials used for polyurethane, mineral wool, and among the natural ways you can meet sawdust and shavings, dry leaves, and so on. When using any insulating material for the floor is recommended to leave a gap of about 15 or 20 mm for air exchange.

Subfloor: installation ofelectric floor heating in a wooden house or infrared are required equally ventilated and be strong at the base. To circuit insulation was high-quality and functional, this set a floor, which should meet the following requirements:

- its structure should be rigid, which further distributes the load;

- as purpose serve as a basis for insulation or fillers and creates an intermediate waterproofing layer;

- the air space between the draft and final layer carries out system of ventilation, which does not allow wooden planks to anger and spoiled.

When building a house on their own, the builders believe that the rough structures are the reason for a floor covering, but it is not. Essence in that the substrate is a packing of plywood or particle Board or similar boards on the joists. They are applied to the subsequent stacking of materials in their flat position and measured the gravity separation of the entire ceiling on the floor. Such substrates are used in buildings made of wood and monolith.

The rough floor is also the lowest layer among the base of the boards as cover on the joists or beams, depending on the device building. As a rule, layers are the floor boards, which are located in diagonal position relative to the finishing of masonry. In this case, a fortress of the overlap formed by the options of flooring boards. Paul creates a double insulation design, in order to keep warm, as well as to fix the insulating layers and to regulate the thermal flow in the house.

The procedure for the installation of floor heating is in the following steps:

1. The creation of the ventilation shaft allows you to make the air exchange between the slats of the boards that they did not succumb to decay. The setting process is carried out in drilling the corners of the house a few holes with a diameter of approximately 50 to 60 mm. They should be rounded, which after a closed special lattices as a decorative material. Over rough floors, they should be located at a height of 5 or 6 cm, so as not to allow water to get inside. In some cases, rough ventilation installed in the baseboard.

2. Basement waterproofing is an important part of the installation of floor heating in a wooden house with his own hands. As a building material is a roofing material or other insulating objects which are placed on the first step of warming the building.

3. Logs, wreaths, and all boards should be thoroughly treated with antiseptics that will allow you to remove and to provide wood from the appearance of fungus or mold as well as insects. Some builders use ordinary engine oil or other objects of protection.

4. Laying the sub-floor are three options:

- the location of the boards is installed on the beam zaplecza that resemble the letter "T" upside down;

- laying on cranial bars that act as the same zaplecze, but is attached to the edges of the beams;

- the establishment of boards in special slots, which are prepared in the initial stages of construction.

5. After selecting the installation method, it is preferable to position the planks on cranial bars, you need to lay the waterproofing layer. The best option may be mineral wool as insulation, and the latter spread a vapor barrier.

6. After laying put the floor finish. For the use of tongue and groove boards or chipboard. On top of them was covered laminate or linoleum.

It should be noted that the temperature should not differ from the temperature of the room and the floor more than two degrees, so to come to the floor insulation should be carefully. Experts recommend to carefully select all the insulating materials that retain heat in the room. Among the important properties are the high degree of conduction of energy, the lack of non-combustible components and allergic substances. Also, the insulating material must be durable and rugged in structure and easy to use in construction works.

The most suitable option think of mineral wool, which is hygroscopic and absorbs moisture perfectly, not allowing it to seep through the Board. Other insulating materials are susceptible to burning, although small in weight, an example is foam plastic and polystyrene. Waterproofing great items will be roofing felt, plastic film and so on. To the question: how to make a warm floor in the wooden house? The procedure for laying of all layers is carried out with the installation of the first row of the floor, and then flooring all waterproofing after thermal insulating materials, and the last row will be the vapor barrier.

Floor finish: installationthe Last step is the folding of the finished floor, which consists in the following steps. Select the milled boards that are fastened to the base of the spikes and grooves. Their size should be 28-44х98-145 mm, which have a special produhi on the back edge of 2 cm, which are determined for permanent ventilation.

In the absence of these boards, you can use other variations, such as the Board spiked a straight or trapezoidal shape, and raked in the pile, and the like. The only disadvantage of these boards is the lack of produhi. It is important to remember that when laying the boards, they should be sent to the various parties and determined by the rings on a tree.

Installation of concrete floors in a wooden housein establishing a concrete floor do not need to put many layers of boards and insulating material. For this you need to make a screed, but it's important to remember some factors and aspects. The concrete floor has advantages, which are:

- the durability of the material, its reliability and durability;

- modern methods of construction will allow you to create a perfectly smooth base with no flaws. Without problems you can put linoleum or laminate.

Laying of concrete on the ground: worksInfrared warm floor in the wooden house or water are installed after the casting process the concrete base. The sequence of operations is carried out in a similar way:

1. To determine the level of fill for a concrete floor. Marks made by means of a cord and measured is the perimeter of the base approximately 10 cm.

2. On the ground sprinkled a layer of gravel, so that the present pegs need to compare with level. Then the labels are extracted.

3. On the gravel, poured the sand, which seals the previous layers.

4. Put a layer of waterproofing with the use of plastic film. She drifted onto the sand, but the edges need to be higher than the floor.

5. This is followed by pouring concrete on the waterproofing material, which is evenly leveled.

6. Solution cover with foil, but the base must be constantly moistened with water.

Concrete floor leave it for 3-4 weeks, and the solution hardened and became solid. After two months you can start to make a screed of cement. At the beginning of the work should determine the type of floor heating: electric or water. In this episode, the thickness of layers shall not exceed 25 mm, which will fit after laying tiles, linoleum or laminate.

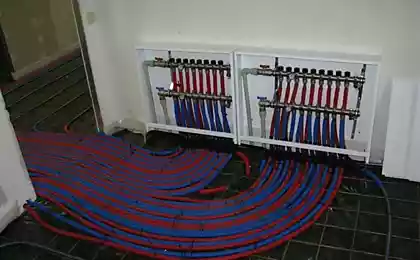

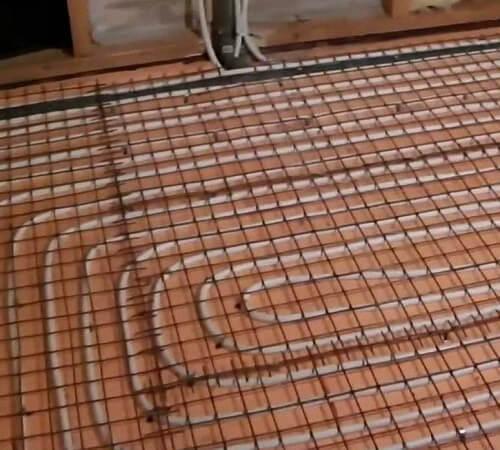

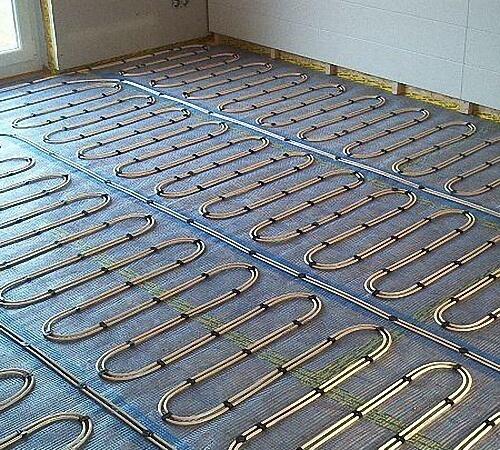

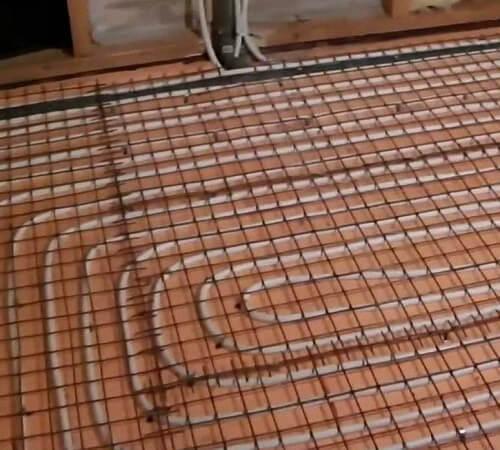

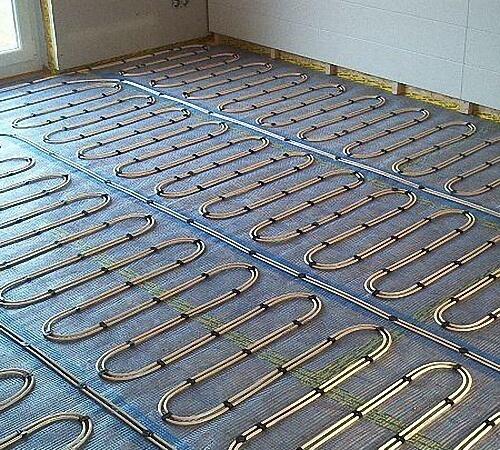

Radiant floor heatinginstallation Process water floor better known solution in wooden houses. It is suitable for cement screed and folding boards. In case of tie, the design and sequence of layers would be as follows:

- pouring concrete on the ground;

- the insulating layer in the 25-100 mm;

- mesh reinforcement;

- pipe for water system insulation that is bonded between the mesh with clamps, the distance between them should be between 100 and 300 mm;

- substrate;

- floor finish: ceramic tile, parquet, laminate and more.

The device of electric floor heating in a wooden house videos which will talk more about the specifics of the installation. This system fits the same option on the joists or tie. In the second case, the system of carrying out heat the same as water heating.

For the use of cable and lay it on the grid values in 50x50mm and fasten design on the joists. They saw through the gaps with a height of 50 mm, and the distance between them is required to be 5 cm, which is insulated with foil. Cable that warms the floor, placed in these gaps.

Installation of floor heating in wooden houses has its own characteristics that are determined by the type of Foundation, building and so on. I hope the article you will learn all the essential parts of laying the floor by design and device. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: strport.ru/uchastok/teplye-poly-v-derevyannom-dome-osobennosti-montazha

5 rules how to arrange an environmentally friendly cottage

How to instill in children a love of green smoothies