666

Technology of floor insulation in a wooden house

One of the prerequisites of comfort, home coziness is warm. To the insulation of the floor in a wooden house as effective as possible, it is required to comply with certain technology. To work can with your hands or seek the services of professionals

Causes cold floorit is Possible to allocate some reasons the cold floor:

How to insulate a floor in a wooden housemeasures for insulation of the floor with your hands is best done in the house: the Foundation, the basement floor itself.

The Foundation

Insulation basement in a wooden house

Exterior insulation allows you to avoid plenty of troubles associated with the displacement of the dew point — humidity inside the basement, the formation on the surfaces of its walls condensate.

You can insulate with expanded clay or insulation — foam, mineral wool. The most expensive but most reliable option is brick veneer, stone.

First, the perimeter of the house dug a trench depth of about 80 cm, a width of two feet. The surface of the Foundation is thoroughly cleaned from dirt, and the necessary restoration activities. Then it is processed waterproof, antiseptic liquids.

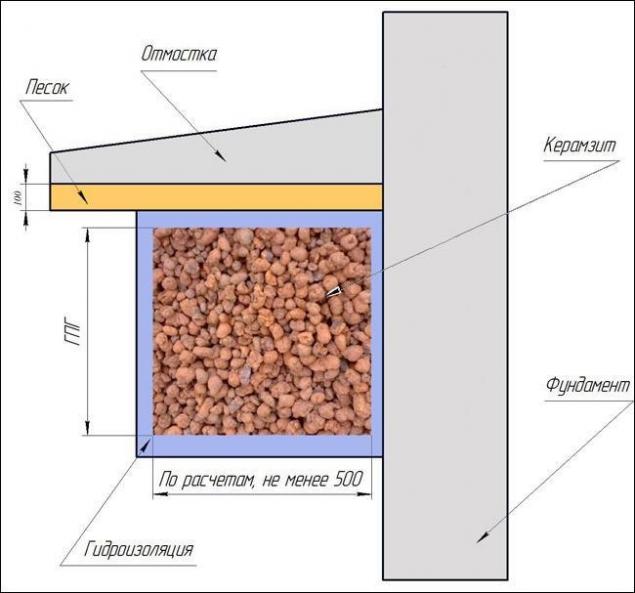

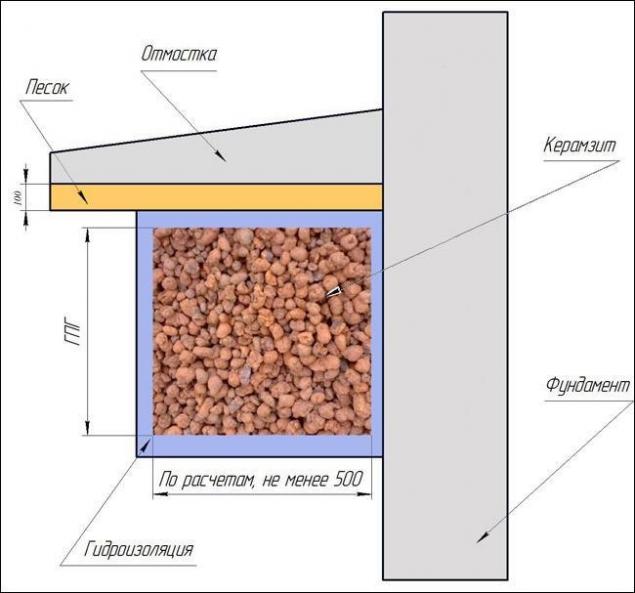

Expanded clayInsulation basement in a wooden house expanded clay — a detailed diagram

Insulation basement in a wooden house expanded clay — a detailed diagram

The bottom of the trench compacted. On a sandy pillow (about 10 cm) is laid waterproofing canvas — ruberoid, film-type materials.

Important! When the decision to save money by using inexpensive polyethylene film, it is better to give preference to the double-layered fabric.

The top is filled with expanded clay (about 60 cm), which also covers waterproof material.

Foam, mineral woolInsulation is attached to the outer surface of the Foundation of adhesives, screws, dowels. The fastener type is selected depending on the selected type of insulation, of the core material.

For the attachment of the finish — stucco, siding on the overground part of Foundation mounted system reinforcement (mesh) or crate made of timber, galvanized profile.

On a solid bottom of the trench is poured a layer of sand approximately 15 – 20 cm, then a layer of gravel about 50 cm.

Brick or stoneCompacted the bottom of the trench is covered with sandy-gravel cushion 10 cm sand, 15 cm of gravel. The sand layer is levelled, compacted — the water is poured out.

Then fit reinforcement bars.

Important! The decision to connect the elements of rebar welding should purchase the rod with the marking of the letter "C".Concrete is poured a solution. It is desirable that the surface of concrete raised above the ground at least 20 cm.

After the concrete hardens, the formwork is removed, the entire structure is covered around the perimeter with a double layer of roofing material — bend outside.

Laying may be 1 – 1.5 brick. The distance between the old and the new base is filled with sand, expanded clay, sawdust or slag during masonry work every 3 – 5 rows.

Regardless of the option selected at the final stage on the perimeter of the building is poured concrete or laid tile.

Insulated basementWith insulation of a basement should take into account that a perfect seal is also not useful in building construction. So at the same time it is necessary to provide ventilation.

Tip! Cheap domestic fan, is inserted into the vent and improve the conditions of its operation.Regardless of what will insulate the surface of the basement — foam, mineral wool, you need a thorough cleaning from dirt, water-repellent treatment, antiseptic — mastic liquid.

For attaching fibrous materials will require sheathing, vapor barrier fabric. If you plan on insulation foam, the sheets can be fastened normal "fungi".

Insulated wooden floor in the roomIf thermal insulation of Foundation and basement for any reason is difficult, for example, in late autumn, you can begin work in the living room. Typically, the insulation of the floor in a wooden house is lighter materials:

Insulated floor in the wooden house their hands

Removed all layers of old flooring to the ground. The very Foundation carefully set in order. Using putty, foam, wooden panels are sealed all the cracks.

The surface is leveled, treated with antiseptics. Then laid waterproofing material — sunset on the wall to 20 cm

After approximately half a meter mounted timber joists. The space between the timber is filled with a selected insulation.

Important! If you plan on warming your hands with foam, mineral wool, the distance between logs should match the size of the insulation plates.When the filling expanded clay, sawdust, slag, need to pay attention to their condition — loose material should be dry, without dust, signs of mold, rot.

Tree — a living material, so the insulation on top of vapor barrier membrane is offered.

Then the top is placed a Board, chipboard, OSB, moistureproof plywood.

How to choose a heaterEach material has its pluses, minuses. The only insulation recommended for floor insulation — fiberglass. Work with it involve the use of a full range of personal protective equipment — gloves, mask.

Foam — easily assembled, waterproof, so you can save on a vapor barrier. Minus — warm material like rodents. Basalt fiber (mineral wool) — clean, almost no fuel. Cases detected in the stone wool nests of mice is not fixed. Minus — requires a vapor barrier. Sawdust — "old-fashioned" insulation. Eco-friendly, hygroscopic, combustible but, loved by insects and rodents. Over time dry out, you want the crust. Slag. Actively used in the Soviet era. Not lit, not damaged by rodents, has antibacterial properties. The expanded clay. Easy hygroscopic material, without serious drawbacks.

A common disadvantage of all bulk materials — shrinkage. Therefore, when you use them in a vertical insulation systems shall be provided to the bedding — in 20 years.

Sometimes owners of private houses prefer to start with the insulation of the floor inside, trying to save. In order to verify the infidelity of this approach, it is sufficient to look back into the recent past.

In the old village houses on wooden stilts with a cap or two layers of planks and filling with sawdust, the floor was a single layer! No "draft". The upper planed surface served as a floor in the room, and the bottom, not treated — ceiling "underground". On this floor in the winter went barefoot! published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: utepleniedoma.com/uteplenie/pol/texnologiya-utepleniya-pola-v-derevyannom-dome

Causes cold floorit is Possible to allocate some reasons the cold floor:

- the cracks in the ceiling;

- poor tightness of the space under the floor;

- poor insulation of the Foundation.

How to insulate a floor in a wooden housemeasures for insulation of the floor with your hands is best done in the house: the Foundation, the basement floor itself.

The Foundation

Insulation basement in a wooden house

Exterior insulation allows you to avoid plenty of troubles associated with the displacement of the dew point — humidity inside the basement, the formation on the surfaces of its walls condensate.

You can insulate with expanded clay or insulation — foam, mineral wool. The most expensive but most reliable option is brick veneer, stone.

First, the perimeter of the house dug a trench depth of about 80 cm, a width of two feet. The surface of the Foundation is thoroughly cleaned from dirt, and the necessary restoration activities. Then it is processed waterproof, antiseptic liquids.

Expanded clayInsulation basement in a wooden house expanded clay — a detailed diagram

Insulation basement in a wooden house expanded clay — a detailed diagram

The bottom of the trench compacted. On a sandy pillow (about 10 cm) is laid waterproofing canvas — ruberoid, film-type materials.

Important! When the decision to save money by using inexpensive polyethylene film, it is better to give preference to the double-layered fabric.

The top is filled with expanded clay (about 60 cm), which also covers waterproof material.

Foam, mineral woolInsulation is attached to the outer surface of the Foundation of adhesives, screws, dowels. The fastener type is selected depending on the selected type of insulation, of the core material.

For the attachment of the finish — stucco, siding on the overground part of Foundation mounted system reinforcement (mesh) or crate made of timber, galvanized profile.

On a solid bottom of the trench is poured a layer of sand approximately 15 – 20 cm, then a layer of gravel about 50 cm.

Brick or stoneCompacted the bottom of the trench is covered with sandy-gravel cushion 10 cm sand, 15 cm of gravel. The sand layer is levelled, compacted — the water is poured out.

Then fit reinforcement bars.

Important! The decision to connect the elements of rebar welding should purchase the rod with the marking of the letter "C".Concrete is poured a solution. It is desirable that the surface of concrete raised above the ground at least 20 cm.

After the concrete hardens, the formwork is removed, the entire structure is covered around the perimeter with a double layer of roofing material — bend outside.

Laying may be 1 – 1.5 brick. The distance between the old and the new base is filled with sand, expanded clay, sawdust or slag during masonry work every 3 – 5 rows.

Regardless of the option selected at the final stage on the perimeter of the building is poured concrete or laid tile.

Insulated basementWith insulation of a basement should take into account that a perfect seal is also not useful in building construction. So at the same time it is necessary to provide ventilation.

Tip! Cheap domestic fan, is inserted into the vent and improve the conditions of its operation.Regardless of what will insulate the surface of the basement — foam, mineral wool, you need a thorough cleaning from dirt, water-repellent treatment, antiseptic — mastic liquid.

For attaching fibrous materials will require sheathing, vapor barrier fabric. If you plan on insulation foam, the sheets can be fastened normal "fungi".

Insulated wooden floor in the roomIf thermal insulation of Foundation and basement for any reason is difficult, for example, in late autumn, you can begin work in the living room. Typically, the insulation of the floor in a wooden house is lighter materials:

- expanded clay;

- foam;

- sawdust;

- with mineral wool.

Insulated floor in the wooden house their hands

Removed all layers of old flooring to the ground. The very Foundation carefully set in order. Using putty, foam, wooden panels are sealed all the cracks.

The surface is leveled, treated with antiseptics. Then laid waterproofing material — sunset on the wall to 20 cm

After approximately half a meter mounted timber joists. The space between the timber is filled with a selected insulation.

Important! If you plan on warming your hands with foam, mineral wool, the distance between logs should match the size of the insulation plates.When the filling expanded clay, sawdust, slag, need to pay attention to their condition — loose material should be dry, without dust, signs of mold, rot.

Tree — a living material, so the insulation on top of vapor barrier membrane is offered.

Then the top is placed a Board, chipboard, OSB, moistureproof plywood.

How to choose a heaterEach material has its pluses, minuses. The only insulation recommended for floor insulation — fiberglass. Work with it involve the use of a full range of personal protective equipment — gloves, mask.

Foam — easily assembled, waterproof, so you can save on a vapor barrier. Minus — warm material like rodents. Basalt fiber (mineral wool) — clean, almost no fuel. Cases detected in the stone wool nests of mice is not fixed. Minus — requires a vapor barrier. Sawdust — "old-fashioned" insulation. Eco-friendly, hygroscopic, combustible but, loved by insects and rodents. Over time dry out, you want the crust. Slag. Actively used in the Soviet era. Not lit, not damaged by rodents, has antibacterial properties. The expanded clay. Easy hygroscopic material, without serious drawbacks.

A common disadvantage of all bulk materials — shrinkage. Therefore, when you use them in a vertical insulation systems shall be provided to the bedding — in 20 years.

Sometimes owners of private houses prefer to start with the insulation of the floor inside, trying to save. In order to verify the infidelity of this approach, it is sufficient to look back into the recent past.

In the old village houses on wooden stilts with a cap or two layers of planks and filling with sawdust, the floor was a single layer! No "draft". The upper planed surface served as a floor in the room, and the bottom, not treated — ceiling "underground". On this floor in the winter went barefoot! published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: utepleniedoma.com/uteplenie/pol/texnologiya-utepleniya-pola-v-derevyannom-dome

The main problem of married people

How not to spoil the efficiency of the radiators with decorative screen