695

How to insulate a house with plaster: tips and recommendations

There are many ways of warming the house. The choice of a variant of warming depends on various factors such as climatic features of the area and material preferences of the owners. The use of warm plaster can significantly reduce heat loss, while not altering the thickness of the wall. About the peculiarities of execution of works on warming plaster will be discussed further.

Winterizing a house with plaster features and benefits toperformance of works on thermal insulation of the building has a number of advantages. Among them we note:

In addition, the insulating material protects the building from moisture, humidity, mold, excessive wind. However, these advantages are relevant only in the case if the materials for insulation have been selected in relation to the individual characteristics of the premises, and all work was carried out, taking into account all of the recommendations and technologies for their implementation.

If the house had not been insulated, it is exposed to constant heat losses. Heat leaves the building not only through Windows and doors, but also through the surface of the walls, if they were not previously insulated. So, first of all, part of the facade of the building should be insulated.

Before beginning insulation of the building, you should do the following:

1. Identify the most vulnerable places of the house against heat losses. That is, you need to find the thermal bridges through which heat passes very quickly.

2. After that, determines the best method of warming. Insulation is both internal and external. Most often used the second option, since the internal insulation reduces usable area of the house. Although the internal insulation of the house is characterized by a simple execution, rather than external.

Among the benefits of performing outdoors types of insulation note:

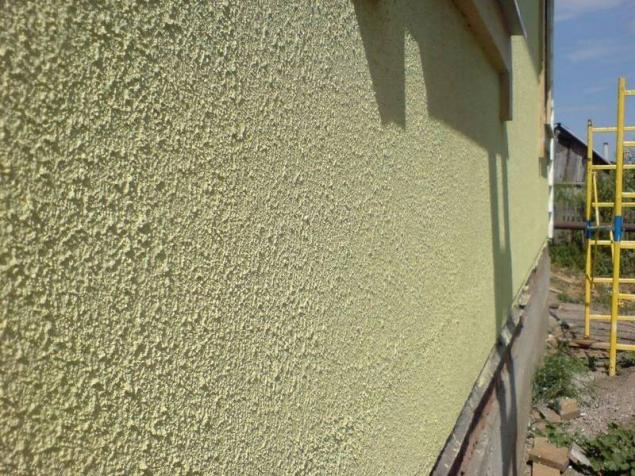

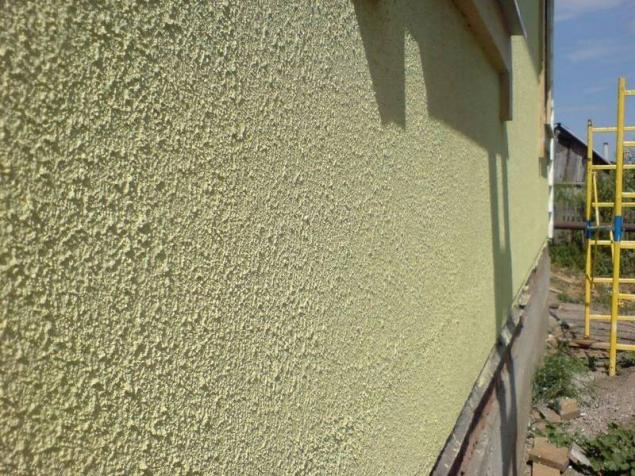

External or exterior insulation features a number of technologies for its implementation. Offer to stay on the facade insulation “warm plaster”. In this case, insulation is applied to the wall inside the building, while carrying out a function not only of preventing heat loss, but also a decorative function enhance the appearance of the house.

After choosing insulation, you should determine the scheme of its installation. These parameters depend on the operating conditions of the building, seasonal and daily fluctuations in temperature, wind, rainfall and other climatic characteristics of the region. In the process of determining methods of warming, these factors are considered mandatory. Otherwise, problems may occur with the insulation and premature wear.

Home insulation plaster has the following advantages:

In addition, comparing warm the plaster with other types of insulation, it should be noted are its benefits:

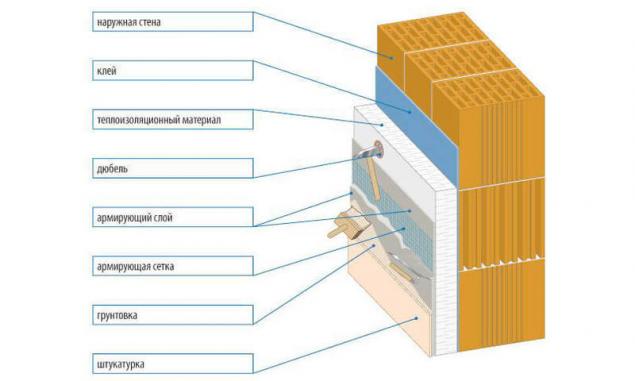

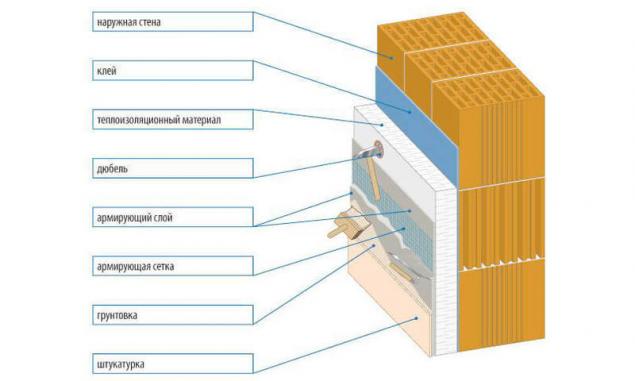

There are two main methods of providing insulation under the plaster. The first involves the use of insulating material, which further oshtukaturivanija. The second is the use of special warm plaster, without additional insulation.

Among the materials used as supplementary insulation note:

1. Mineral wool is among its advantages include a high level of vapour permeability, resistance to combustion, good protection from heat loss, exposure to rodents, mould and mildew. In addition, this material has a high service life, good resists chemical and biological attack. This material has a slab design.

2. The foam is the cheaper option of insulation than mineral wool. For its production using waste oil product. However, this material is highly flammable, is unsustainable in front of a high level of moisture and mechanical factors.

3. Plate on the basis of basalt rocks for production using materials in the form of superfine basalt fibers and the bentonite clay-based. This material has high insulation characteristics, it also perfectly protects the room from extraneous sounds. Plate on a basalt — based totally eco-friendly and harmless to the environment.

4. Material based on glass foam is a versatile insulation which has high resistance to mechanical impact factors, long term use, low density, absence of shrinkage and ease of installation works. This material does not lose its properties during the entire period of operation. In addition, the insulation withstands moisture, so frequently used in the process of insulating foundations.

Varieties of plaster facade insulation

Distinguish a certain kind of plaster, called heat. This plaster contains in its composition the filler and the cement-based type that holds it. Plaster for heat insulation is different from the usual in that its composition includes the filler having a low thermal conductivity.

Most often, the filler materials are used in the form of sawdust, granules, perlite or vermiculite based, as well as beads based on polystyrene. In addition, the certain variant filler contains in its composition of foamed silicon or foamed glass. It is from the physical qualities of the filler depends on the quality and function of heat insulating plaster. Determining the type of plaster used in home insulation, should pay attention to the following characteristics:

1. Warm plaster as a filler which uses sawdust. Considering this version of the plaster should be immediately noted his shortcomings, which determines the severity of their weight and lowest energy efficiency. This insulation is used exclusively indoors as sawdust unstable front of high humidity. The room, which is insulated using this method, you should periodically ventilate, as excessive humidity will result in absorption of moisture plaster and its otvarivanie. Also, damp walls suggest the formation of fungus and mold, so it is the insulation is the least popular.

2. Warm the plaster with a filler of Styrofoam. This plaster has good adhesion with any kind of surface, good insulation characteristics. However, this plaster requires no additional waterproofing and finishing. Also, when burning, Styrofoam emit substances, deadly to human life.

3. Thermal plaster based on expanded perlite and vermiculite. These substances are mineral for their manufacture vspuchilis specific substances with exposure to high temperatures. Data granules in the process of roasting increase in size and become extremely light. In addition, they change the structure, which later becomes porous. The thermal conductivity of this material is low, so they are used for insulation. Among the advantages of this type of plaster note:

However, this variant of the plaster has some shortcomings, which manifest themselves in too high absorption of moisture. Therefore, before beginning the installation should ensure reliable waterproofing. After installation of plaster is its finishing, which also need to protect it from moisture.

4. Materials based on foamed glass or foamed silicon have unique characteristics. During processing of these materials produces balls, which differ in the fine-pored structure. This plaster is characterized by a resistance to moisture, but it also is not breathable. After hardening of the plaster is durable, water resistance, resistance to burning, furthermore, the finishing, after applying plaster is not needed. It features an attractive textured white, which if necessary, can be painted with facade paint.

So, plaster on the basis of sawdust, though you'll be the lowest cost, has a number of drawbacks, among which above all celebrates the instability before moisture. External plaster wall insulation with the help of this option, plaster — impossible because its scope is limited to internal insulation works. Polystyrene plaster although it has excellent adhesion, the need to perform additional waterproofing and finishing. Plaster which is based on the use of mineral rocks are perfectly opposed to biological factors, fire and different absolute environmental safety. However, they are very good to absorb moisture, so the need for additional waterproofing.

In the plaster foam glass or silicon deficiencies do not exist, as it forms a durable coating that requires no additional waterproofing or finishing. For insulation of facades decorative plaster of this type is the best option.

Facade insulation mineral wool under the plaster: the technology of the worksIn the process of insulation mineral wool under the plaster will need to have:

1. First of all you should prepare the walls for installation of mineral wool. They should be cleaned from dirt, dust, grease or oil. The walls are subject to mandatory alignment, in case of irregularities. After that, proceed to the next stage.

2. Before installing the mineral wool should be mounted on the wall guides through which the material is fixed in two directions. For these purposes it is allowed to use timber or steel profile. Fixing horizontal rail is at a distance of about 60 cm from the ground. For fixing use screws, but in order to fix the plate of the mineral wool used mechanisms in the form of special dowels. Additional fixing of mineral wool is performed by using a special liquid adhesive that is distributed throughout the material.

3. In order that the plate be closely rested on the wall, it is secured with dowels installed at the corners and the center plate. To drive the dowels, use a regular hammer. After the mineral wool installed on all the walls, install reinforcing mesh. For this purpose, mineral wool is covered with a glutinous solution, and after that, the mesh installed on the surface. Choosing the net, choose the fine option, which is resistant to alkalis and moisture.

4. After the mesh is installed and the glue is dry, made the finishing of the walls with plaster. For these purposes use a variety of options for decorative piece by the Turks. If necessary, the alignment of the surface, apply an additional coat, after drying of the plaster which is applied to decorate the surface.

Wall insulation foam and plaster is the same technology as with mineral wool. published

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

http://cdn00.vidyomani.com/c/1/9/4/ry0l96tx1929/index.html

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: strport.ru/izolyatsionnye-materialy/utepliteli/uteplenie-shtukaturkoi-sovety-i-rekomendatsii

Winterizing a house with plaster features and benefits toperformance of works on thermal insulation of the building has a number of advantages. Among them we note:

- increasing the duration of operation of the building;

- the decrease in cost of heating homes;

- improving comfort in the room.

In addition, the insulating material protects the building from moisture, humidity, mold, excessive wind. However, these advantages are relevant only in the case if the materials for insulation have been selected in relation to the individual characteristics of the premises, and all work was carried out, taking into account all of the recommendations and technologies for their implementation.

If the house had not been insulated, it is exposed to constant heat losses. Heat leaves the building not only through Windows and doors, but also through the surface of the walls, if they were not previously insulated. So, first of all, part of the facade of the building should be insulated.

Before beginning insulation of the building, you should do the following:

1. Identify the most vulnerable places of the house against heat losses. That is, you need to find the thermal bridges through which heat passes very quickly.

2. After that, determines the best method of warming. Insulation is both internal and external. Most often used the second option, since the internal insulation reduces usable area of the house. Although the internal insulation of the house is characterized by a simple execution, rather than external.

Among the benefits of performing outdoors types of insulation note:

- reliable protection of the walls from external stimuli such as humidity, temperature, wind, etc.;

- the lack of condensation, which destroys the building and leads to the formation of mold and mildew;

- the improvement in sound insulation performance of the building.

External or exterior insulation features a number of technologies for its implementation. Offer to stay on the facade insulation “warm plaster”. In this case, insulation is applied to the wall inside the building, while carrying out a function not only of preventing heat loss, but also a decorative function enhance the appearance of the house.

After choosing insulation, you should determine the scheme of its installation. These parameters depend on the operating conditions of the building, seasonal and daily fluctuations in temperature, wind, rainfall and other climatic characteristics of the region. In the process of determining methods of warming, these factors are considered mandatory. Otherwise, problems may occur with the insulation and premature wear.

Home insulation plaster has the following advantages:

- reducing the cost of air conditioning and heating, and improvement of a healthy microclimate inside the building;

- improving sound insulation performance of the house;

- plaster does not load the extra weight of the building, thereby reducing the cost of its construction is estimated;

- the increase of the internal area of the building by 2-4 %;

- the insulation of the building with the help of this technique increases the lifespan of several decades;

- technologically correct insulation with plaster minimizes thermal deformation vibrations outside the building;

- technology is used for almost any type of building regardless of the material of its execution;

- stucco not only protects the building from heat loss, but also improves its attractiveness;

- if the building has interpanel seams, they are also sealed with plaster.

In addition, comparing warm the plaster with other types of insulation, it should be noted are its benefits:

- incombustibility;

- environmental safety;

- ease of installation and repair, if necessary;

- the adaptability of the application.

There are two main methods of providing insulation under the plaster. The first involves the use of insulating material, which further oshtukaturivanija. The second is the use of special warm plaster, without additional insulation.

Among the materials used as supplementary insulation note:

1. Mineral wool is among its advantages include a high level of vapour permeability, resistance to combustion, good protection from heat loss, exposure to rodents, mould and mildew. In addition, this material has a high service life, good resists chemical and biological attack. This material has a slab design.

2. The foam is the cheaper option of insulation than mineral wool. For its production using waste oil product. However, this material is highly flammable, is unsustainable in front of a high level of moisture and mechanical factors.

3. Plate on the basis of basalt rocks for production using materials in the form of superfine basalt fibers and the bentonite clay-based. This material has high insulation characteristics, it also perfectly protects the room from extraneous sounds. Plate on a basalt — based totally eco-friendly and harmless to the environment.

4. Material based on glass foam is a versatile insulation which has high resistance to mechanical impact factors, long term use, low density, absence of shrinkage and ease of installation works. This material does not lose its properties during the entire period of operation. In addition, the insulation withstands moisture, so frequently used in the process of insulating foundations.

Varieties of plaster facade insulation

Distinguish a certain kind of plaster, called heat. This plaster contains in its composition the filler and the cement-based type that holds it. Plaster for heat insulation is different from the usual in that its composition includes the filler having a low thermal conductivity.

Most often, the filler materials are used in the form of sawdust, granules, perlite or vermiculite based, as well as beads based on polystyrene. In addition, the certain variant filler contains in its composition of foamed silicon or foamed glass. It is from the physical qualities of the filler depends on the quality and function of heat insulating plaster. Determining the type of plaster used in home insulation, should pay attention to the following characteristics:

- thermal conductivity;

- susceptibility to burning;

- resistance to moisture;

- weight;

- harmless to the environment;

- resistance to biological pests;

- resistance to chemicals;

- vozduhoplavatel.

1. Warm plaster as a filler which uses sawdust. Considering this version of the plaster should be immediately noted his shortcomings, which determines the severity of their weight and lowest energy efficiency. This insulation is used exclusively indoors as sawdust unstable front of high humidity. The room, which is insulated using this method, you should periodically ventilate, as excessive humidity will result in absorption of moisture plaster and its otvarivanie. Also, damp walls suggest the formation of fungus and mold, so it is the insulation is the least popular.

2. Warm the plaster with a filler of Styrofoam. This plaster has good adhesion with any kind of surface, good insulation characteristics. However, this plaster requires no additional waterproofing and finishing. Also, when burning, Styrofoam emit substances, deadly to human life.

3. Thermal plaster based on expanded perlite and vermiculite. These substances are mineral for their manufacture vspuchilis specific substances with exposure to high temperatures. Data granules in the process of roasting increase in size and become extremely light. In addition, they change the structure, which later becomes porous. The thermal conductivity of this material is low, so they are used for insulation. Among the advantages of this type of plaster note:

- resistance to fire;

- environmental safety;

- resistance to biological factors.

However, this variant of the plaster has some shortcomings, which manifest themselves in too high absorption of moisture. Therefore, before beginning the installation should ensure reliable waterproofing. After installation of plaster is its finishing, which also need to protect it from moisture.

4. Materials based on foamed glass or foamed silicon have unique characteristics. During processing of these materials produces balls, which differ in the fine-pored structure. This plaster is characterized by a resistance to moisture, but it also is not breathable. After hardening of the plaster is durable, water resistance, resistance to burning, furthermore, the finishing, after applying plaster is not needed. It features an attractive textured white, which if necessary, can be painted with facade paint.

So, plaster on the basis of sawdust, though you'll be the lowest cost, has a number of drawbacks, among which above all celebrates the instability before moisture. External plaster wall insulation with the help of this option, plaster — impossible because its scope is limited to internal insulation works. Polystyrene plaster although it has excellent adhesion, the need to perform additional waterproofing and finishing. Plaster which is based on the use of mineral rocks are perfectly opposed to biological factors, fire and different absolute environmental safety. However, they are very good to absorb moisture, so the need for additional waterproofing.

In the plaster foam glass or silicon deficiencies do not exist, as it forms a durable coating that requires no additional waterproofing or finishing. For insulation of facades decorative plaster of this type is the best option.

Facade insulation mineral wool under the plaster: the technology of the worksIn the process of insulation mineral wool under the plaster will need to have:

- mineral wool in slab form;

- dowels made of plastic, with a broad hat;

- the special composition of the adhesive;

- hammer;

- electric drills;

- plaster decorating the facade;

- reinforcing mesh.

1. First of all you should prepare the walls for installation of mineral wool. They should be cleaned from dirt, dust, grease or oil. The walls are subject to mandatory alignment, in case of irregularities. After that, proceed to the next stage.

2. Before installing the mineral wool should be mounted on the wall guides through which the material is fixed in two directions. For these purposes it is allowed to use timber or steel profile. Fixing horizontal rail is at a distance of about 60 cm from the ground. For fixing use screws, but in order to fix the plate of the mineral wool used mechanisms in the form of special dowels. Additional fixing of mineral wool is performed by using a special liquid adhesive that is distributed throughout the material.

3. In order that the plate be closely rested on the wall, it is secured with dowels installed at the corners and the center plate. To drive the dowels, use a regular hammer. After the mineral wool installed on all the walls, install reinforcing mesh. For this purpose, mineral wool is covered with a glutinous solution, and after that, the mesh installed on the surface. Choosing the net, choose the fine option, which is resistant to alkalis and moisture.

4. After the mesh is installed and the glue is dry, made the finishing of the walls with plaster. For these purposes use a variety of options for decorative piece by the Turks. If necessary, the alignment of the surface, apply an additional coat, after drying of the plaster which is applied to decorate the surface.

Wall insulation foam and plaster is the same technology as with mineral wool. published

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

http://cdn00.vidyomani.com/c/1/9/4/ry0l96tx1929/index.html

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: strport.ru/izolyatsionnye-materialy/utepliteli/uteplenie-shtukaturkoi-sovety-i-rekomendatsii

Exam: fatigue, dullness and fear

MiniPRO by Ninebot Segway: self-balancing electric scooter with power reserve, 25 km