501

Insulated ceiling: warm in winter, cool in summer!

For good physical well-being of the person in the first place need thermal comfort. However, in addition to temperature mode here, a role played by humidity, the speed of movement of air masses. Optimum comfortable conditions of stay of the person in the room can be achieved if used to heat the building in cold season, put in a conditioning system, when it is hot, to minimize the temperature difference between the ceiling, walls and the indoor air by artificial heat or forced ventilation. All of the above activities entail significant financial costs.

To create favorable conditions for a person in the room, thus reducing material waste on maintaining the microclimate in the room at the proper level, helps home insulation.

This event will not only keep warm in cold season, but also will prevent the penetration of hot air masses during the warm season. If the need for thermal insulation of walls and floor – apparently, many owners of private houses do not pay enough attention to insulating the ceiling. And it is through this part of the structure is about 30% of all heat loss.

Economy version of the ceiling insulationToday, building market offers a wide range of insulating materials. However, of greater interest to people is the most economical option.

Analyzed the ratio of the useful properties of thermal insulation and its price, you have come to the conclusion that the economy variant can be attributed to sawdust (derived from it) and the foam.

Insulate the ceiling with sawdust

The sawdust insulation ceiling of wooden house from the attic is a safe and proven method of insulation.

The benefits are obvious.

First, sawdust and derivatives of this material are completely environmentally friendly. Secondly, the low price of this technique. Thirdly, for the low price you get very good heat and sound insulation properties.

Today, on the basis of wood-shaving materials known the following:

themselves sawdust is used as the dry material and the composition of the cement mixture. They perfectly fill the hard to reach places; the wood-blocks is based on acts shavings of wood treated with copper sulphate and mixed with cement. Sawdust is first treated with a solution of copper sulphate, dried. At the stage of insulation of a wooden house, the first layer is the waterproofing of the ceiling, then the mixture of sawdust and cement (ratio 1:8 plus water until a uniform damp mass). It fits between the bars, pre-nailed on top of the waterproofing. The mixture is placed evenly and well tamped. Depends on the level of shrinkage and the quality of the final layer. Give the cement stone to ripen, periodically wetting the surface of the insulation with water. The result is a cost – effective option for insulation of the ceiling in a wooden house; pellets from sawdust – also applies to economy variant of the insulation of the ceiling in a wooden house. In this case, the ceiling is covered with pellets, composed of sawdust, glue on the basis of carboxymethyl cellulose and flame retardant; the Latter plays the role of an antiseptic. This material belongs to the second group of combustibility and recommended for use in residential buildings; opilkobeton consists of mixtures based on sawdust, cement, sand and water. But its technical characteristics superior to politely cinder block and brick. However, demands in thermal insulation of the ceiling in a wooden house, the presence of waterproofing on both sides; arbolit – used in construction in the form of blocks or slabs, acts as an excellent heat and sound insulation. It is made of cement, chemical additives and 80% wood chips. It is durable to bending, restores its original shape after prolonged action of limit loads on the surface. Important! Sawdust as a building material has excellent water vapor permeability properties because the insulation based on them will provide excellent air exchange between rooms and environment that will eliminate any possibility of condensation on the surface of the walls.

The stages of the insulation of the ceiling with sawdust:

Important! The ceiling is insulated with sawdust, if they are at least a year, they don't have the smell of damp and mold. Wood chips need to be large enough, otherwise the preparation of the coating will take a lot of cement, it will overwrite thermoisolation properties of the material.

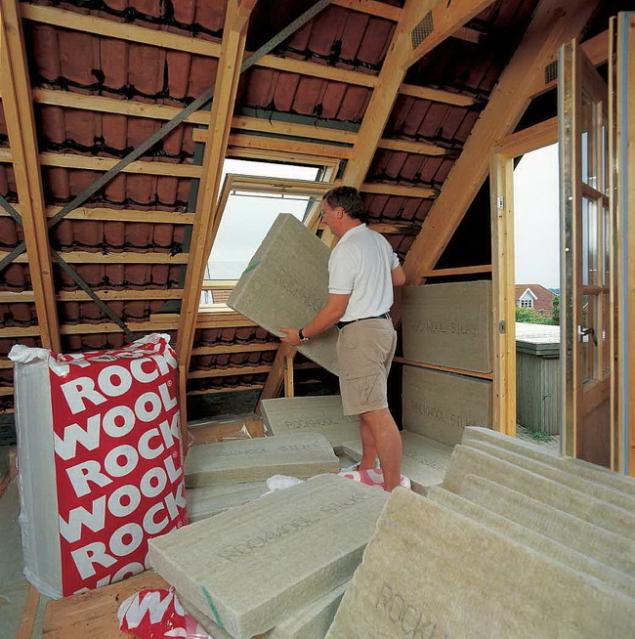

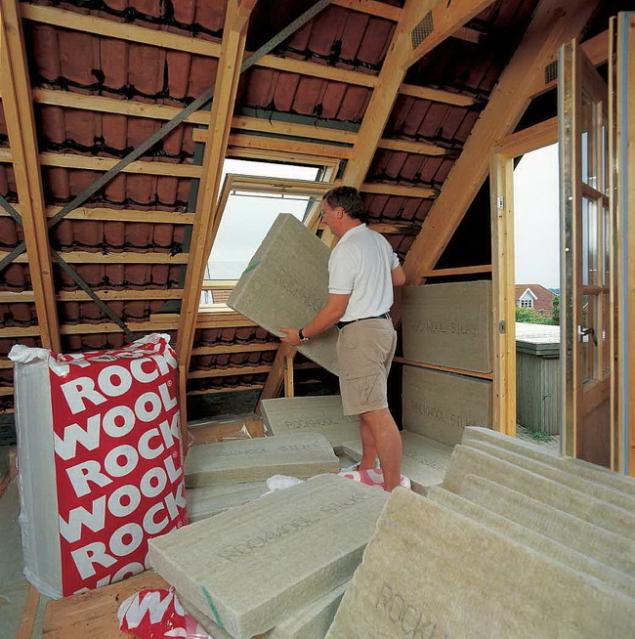

Insulate the ceiling with mineral wool or Cellulose insulation

Insulate the ceiling with mineral wool or Cellulose insulation in a wooden house is better from the attic. The reasons for this decision are several:

if the insulation is carried out with the inside room, the "dew point" – the point of condensation, the shift to the thickness of the insulation material or between it into a ceiling tile. The result – the insulation picks up moisture and loses its specifications; walls and ceiling in the room accumulate heat easily and can thus maintain a constant comfortable temperature for several days. The layer of mineral wool or Cellulose insulation denies this possibility. The stages of work:

Joints of insulation should be no gaps. They will lead to the formation of cold bridges and condensation that will minimize all the insulating properties of the layer.

Reinforcing fiberglass mesh will connect the layer of mineral wool or Cellulose insulation, thus will give him additional strength and will act as the basis for a decorative finish, if such is provided.

Important! The ideal option is mineral wool insulation or Cellulose insulation – when the size of the plates or of the rolls corresponds to the distance between the beams. Thus, the material is deposited vraspor. The result is fewer seams and higher quality coating.published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: utepleniedoma.com/uteplenie/potolok/penoplast-i-opilki-uteplyaem-potolok

To create favorable conditions for a person in the room, thus reducing material waste on maintaining the microclimate in the room at the proper level, helps home insulation.

This event will not only keep warm in cold season, but also will prevent the penetration of hot air masses during the warm season. If the need for thermal insulation of walls and floor – apparently, many owners of private houses do not pay enough attention to insulating the ceiling. And it is through this part of the structure is about 30% of all heat loss.

Economy version of the ceiling insulationToday, building market offers a wide range of insulating materials. However, of greater interest to people is the most economical option.

Analyzed the ratio of the useful properties of thermal insulation and its price, you have come to the conclusion that the economy variant can be attributed to sawdust (derived from it) and the foam.

Insulate the ceiling with sawdust

The sawdust insulation ceiling of wooden house from the attic is a safe and proven method of insulation.

The benefits are obvious.

First, sawdust and derivatives of this material are completely environmentally friendly. Secondly, the low price of this technique. Thirdly, for the low price you get very good heat and sound insulation properties.

Today, on the basis of wood-shaving materials known the following:

themselves sawdust is used as the dry material and the composition of the cement mixture. They perfectly fill the hard to reach places; the wood-blocks is based on acts shavings of wood treated with copper sulphate and mixed with cement. Sawdust is first treated with a solution of copper sulphate, dried. At the stage of insulation of a wooden house, the first layer is the waterproofing of the ceiling, then the mixture of sawdust and cement (ratio 1:8 plus water until a uniform damp mass). It fits between the bars, pre-nailed on top of the waterproofing. The mixture is placed evenly and well tamped. Depends on the level of shrinkage and the quality of the final layer. Give the cement stone to ripen, periodically wetting the surface of the insulation with water. The result is a cost – effective option for insulation of the ceiling in a wooden house; pellets from sawdust – also applies to economy variant of the insulation of the ceiling in a wooden house. In this case, the ceiling is covered with pellets, composed of sawdust, glue on the basis of carboxymethyl cellulose and flame retardant; the Latter plays the role of an antiseptic. This material belongs to the second group of combustibility and recommended for use in residential buildings; opilkobeton consists of mixtures based on sawdust, cement, sand and water. But its technical characteristics superior to politely cinder block and brick. However, demands in thermal insulation of the ceiling in a wooden house, the presence of waterproofing on both sides; arbolit – used in construction in the form of blocks or slabs, acts as an excellent heat and sound insulation. It is made of cement, chemical additives and 80% wood chips. It is durable to bending, restores its original shape after prolonged action of limit loads on the surface. Important! Sawdust as a building material has excellent water vapor permeability properties because the insulation based on them will provide excellent air exchange between rooms and environment that will eliminate any possibility of condensation on the surface of the walls.

The stages of the insulation of the ceiling with sawdust:

- clean attics from trash;

- spread waterproofing, securely it is fixed. Waterproofing is placed overlapping the joints sealed with tape;

- you can prepare a mixture. It should have a gray color and, when compressed it in a fist, it should not allocate water;

- put the mixture on the surface of the attic evenly, lightly tamped.

Important! The ceiling is insulated with sawdust, if they are at least a year, they don't have the smell of damp and mold. Wood chips need to be large enough, otherwise the preparation of the coating will take a lot of cement, it will overwrite thermoisolation properties of the material.

Insulate the ceiling with mineral wool or Cellulose insulation

Insulate the ceiling with mineral wool or Cellulose insulation in a wooden house is better from the attic. The reasons for this decision are several:

if the insulation is carried out with the inside room, the "dew point" – the point of condensation, the shift to the thickness of the insulation material or between it into a ceiling tile. The result – the insulation picks up moisture and loses its specifications; walls and ceiling in the room accumulate heat easily and can thus maintain a constant comfortable temperature for several days. The layer of mineral wool or Cellulose insulation denies this possibility. The stages of work:

- the surface of the attic space from dust and debris;

- hardwood floors treated with antiseptic;

- fit vapour-barrier film. It should be on top of the beams, otherwise the moisture will cause them to decay;

- fit mineral wool or Cellulose insulation;

- fit a reinforcing fiberglass mesh.

Joints of insulation should be no gaps. They will lead to the formation of cold bridges and condensation that will minimize all the insulating properties of the layer.

Reinforcing fiberglass mesh will connect the layer of mineral wool or Cellulose insulation, thus will give him additional strength and will act as the basis for a decorative finish, if such is provided.

Important! The ideal option is mineral wool insulation or Cellulose insulation – when the size of the plates or of the rolls corresponds to the distance between the beams. Thus, the material is deposited vraspor. The result is fewer seams and higher quality coating.published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: utepleniedoma.com/uteplenie/potolok/penoplast-i-opilki-uteplyaem-potolok

28 impressive photos of lake Baikal

9 incredibly simple and effective ways to cleanse the body with lemons