644

Waterproofing the floor in a private house

In the process of operation at home excessive moisture can cause irreparable harm to its design. If in apartment buildings, waterproofing of floors required only in order to not flood the neighbors below in the case of breaking of pipes, waterproofing the floor in a private house is a gross necessity.

The water contained in the soil and rises up the capillaries and penetrate into the room, changes the microclimate in it, and violates the integrity and structure of the floor and Foundation of the building. Dissolved in water acids, alkalis and salts adversely affect the wood and concrete. To protect the floors from the negative effects of water required to produce a number of works. About what exactly, we will cover in this article.

For waterproofing of floors on the ground should start with the bedding still in the construction phase

The waterproof floor on the ground

In private houses the ground floor is equipped directly on the soil, which causes some difficulties in providing protection from moisture. Lifting through the capillaries from the deep soil layers, water can penetrate the structure of wood or concrete, saturating it with moisture. In addition to the damaging effects of salts contained in the water, there is another negative factor. Saturated wood or concrete, chilled, and then, thaw, lose their integrity in the concrete, which produces air bubbles, and the wood starts to trahnut that in the future will lead to destruction. That is why all the work of waterproofing the floor can not use new-fangled modern materials, and with the right equipment "pillows" under the structure.

Important! A waterproof floor on the ground should be taken at the construction stage. In already exploited the structure of all the efforts made to seal the floor will be in the nature of "half-measures" that do not bring 100% result.Technology implementation of "feeding" for ensuring quality of waterproofing:

Important! It is impossible to replace the layer of rubble in the bedding on the concrete block, as the latter gains in water and swells. But if groundwater is very far away, the soil is constantly dry, then for the filling you can use expanded clay. In this case, all the crust will not perform the functions of waterproofing, but only qualitative grounds.The above-described "stabilization" is required if the groundwater level above 2 m. otherwise, it is optional, but desirable, as a safety net. After running the cushion there are two ways to perform wood floor joists or concrete floors. The technology of waterproofing varies.

Waterproofing of the wooden floor

For the arrangement of the wooden floor is necessary to build the support posts under the joists. They can be made of brick or in-situ concrete poured into formwork. After drying, the concrete surface of the columns should be treated with membrane waterproofing on all sides. On top of the columns, you can put a rolled material, for example, roofing material. Thus, we will protect the joists in the ground near to the supporting pillars from the effects of moisture. After laying the lag is necessary to equip the rough floor. For this you can use thick sheets of plywood and nail them to the joists from the underside. And you can make a traditional – plank subfloor.

Waterproofing the subfloor looks like this:

The base sub-floor from waterproof plywood, you can seal tight plastic wrap

Waterproofing concrete floor

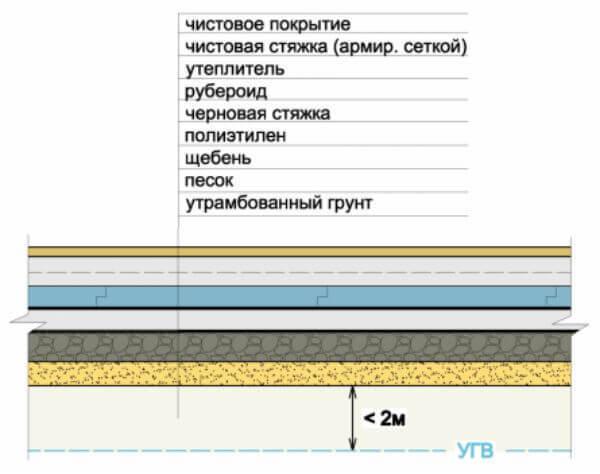

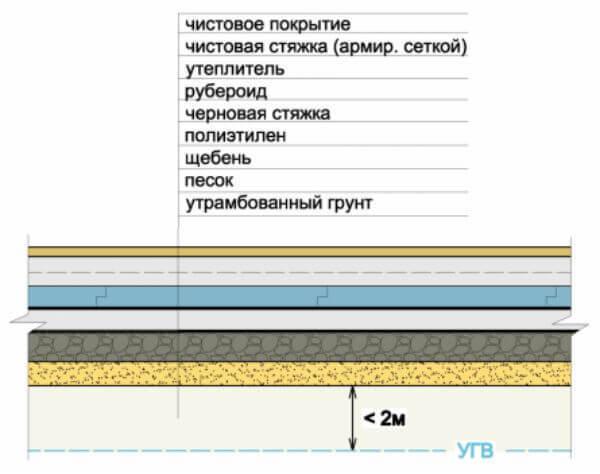

Scheme of arrangement of concrete floor waterproofing layers

The arrangement of the concrete floor on the ground is complicated by the fact that you need to create a monolithic structure in the conditions of rolling of the soil. After performing a "cushion" should make a rough screed. For this there are two ways.

The first option. On top of the sand, which is the finishing layer of "bedding", pour a layer of gravel. Then kneaded cement-sand mortar, slightly liquid consistency and pour it over the gravel so that the top was a layer of rough screed at least 3 – 5 cm After drying of concrete to lay on it, roll the waterproofing in two layers, for example, roofing material or roofing felt, make sure no toppings. Carefully glue all the joints with a gas burner. Then put the insulation and perform the finishing screed.

The second option. On top of the sand to lay a polyethylene film thickness of 200 microns. Flatten it well and glue all the joints with tape. It is necessary to act very carefully so as not to tear the film. Top films of roughing screed of cement-sand mixture (normal consistence). This layer is also called "lean concrete", as it is only necessary to perform the waterproofing. The layer must be a thickness of 5 – 7 cm For solution preparation is used, the gravel fraction 5-10 mm (small), sand – only river.

For waterproofing of concrete floor in rough screed can be spread rolled waterproofing materials

For roughing screed, you can also spread a layer of waterproofing (roofing or PVC membrane). On top is placed a heater, and then finishing screed. Described above is sufficient for ensuring quality of waterproofing in most cases, but there are situations that require additional waterproofing.

Do you need additional waterproofing of the floor

When the water table are too close to the surface, may require additional measures to protect against it. To determine whether you need additional insulation, it is possible, by performing appropriate calculations. This involved a specialized company that executes projects for the construction of houses. Undertake analysis of the soil, measurements of water level in different seasons and based on the data obtained a verdict.

Additional work to ensure the waterproofing of the floor:

Waterproofing the floor in the kitchen

The floor of the kitchen susceptible to moisture not only from below – from the ground, but from above – in the process of cleaning, cooking and other kitchen works on the floor gets a lot of water. Therefore, to protect the floor it is necessary not only from below as it was written above, but from the top. The principle of waterproofing the floor in the kitchen is largely dependent on floor finish. To build a wooden floor in the kitchen is impractical, as it is most affected by moisture, and to protect him will be difficult. If, however, decided to lay on the kitchen parquet, parquet Board or solid wood, should reveal the surface thereof with a waterproof varnish.

For additional waterproofing of the floor in the kitchen, you can handle concrete base painting material

If the quality finish of the kitchen you plan to use the linoleum, then a concrete base on which it is placed, should be treated with waterproofing material, e.g., paint or coating method. Then put the linoleum on the glue. In this case, the linoleum itself will act as a waterproofing material.

Ceramic tile also has water-repellent properties, but as a safety net not be amiss to handle concrete screed bitumen-polymer mastics, paints or other means. And for better adhesion of the tile adhesive with the base on top of waterproofing need to be impregnated with a special primer.

Waterproofing the floor in a private house – it is very responsible. If this is not done in time and qualitatively, over time, may appear fungus and other mold, which will be impossible to withdraw. And the design of the whole house will gradually deteriorate. About high indoor humidity, which leads to frequent allergies and other diseases, can not speak. Better to think it through and execute on time than to rebuild and repair.

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: mrpol.su/ustrojstvo-polov/izolyaciya/gidroizolyaciya-pola-v-chastnom-dome.html

The water contained in the soil and rises up the capillaries and penetrate into the room, changes the microclimate in it, and violates the integrity and structure of the floor and Foundation of the building. Dissolved in water acids, alkalis and salts adversely affect the wood and concrete. To protect the floors from the negative effects of water required to produce a number of works. About what exactly, we will cover in this article.

For waterproofing of floors on the ground should start with the bedding still in the construction phase

The waterproof floor on the ground

In private houses the ground floor is equipped directly on the soil, which causes some difficulties in providing protection from moisture. Lifting through the capillaries from the deep soil layers, water can penetrate the structure of wood or concrete, saturating it with moisture. In addition to the damaging effects of salts contained in the water, there is another negative factor. Saturated wood or concrete, chilled, and then, thaw, lose their integrity in the concrete, which produces air bubbles, and the wood starts to trahnut that in the future will lead to destruction. That is why all the work of waterproofing the floor can not use new-fangled modern materials, and with the right equipment "pillows" under the structure.

Important! A waterproof floor on the ground should be taken at the construction stage. In already exploited the structure of all the efforts made to seal the floor will be in the nature of "half-measures" that do not bring 100% result.Technology implementation of "feeding" for ensuring quality of waterproofing:

- The soil at the bottom of the pit under the building carefully stamped;

- Fill it with gravel fraction of 30 to 50 mm (largest) layer of 7 cm to 10 cm and more;

- Stamps crushed stone;

- Fill the sand layer 7 – 10 cm, you Can use any river, ravine (career).

- Carefully tamp the sand.

Important! It is impossible to replace the layer of rubble in the bedding on the concrete block, as the latter gains in water and swells. But if groundwater is very far away, the soil is constantly dry, then for the filling you can use expanded clay. In this case, all the crust will not perform the functions of waterproofing, but only qualitative grounds.The above-described "stabilization" is required if the groundwater level above 2 m. otherwise, it is optional, but desirable, as a safety net. After running the cushion there are two ways to perform wood floor joists or concrete floors. The technology of waterproofing varies.

Waterproofing of the wooden floor

For the arrangement of the wooden floor is necessary to build the support posts under the joists. They can be made of brick or in-situ concrete poured into formwork. After drying, the concrete surface of the columns should be treated with membrane waterproofing on all sides. On top of the columns, you can put a rolled material, for example, roofing material. Thus, we will protect the joists in the ground near to the supporting pillars from the effects of moisture. After laying the lag is necessary to equip the rough floor. For this you can use thick sheets of plywood and nail them to the joists from the underside. And you can make a traditional – plank subfloor.

Waterproofing the subfloor looks like this:

- If we use moisture proof plywood, she will have to perform some of the functions of waterproofing;

The base sub-floor from waterproof plywood, you can seal tight plastic wrap

- Plank to the plywood layer of the roll of waterproofing membrane. For example, a polyethylene film 200 microns or diffuse of the membrane. Be sure to build with an overlap of 10 – 15 cm, prokliima the joints with tape. Put the insulation.

- Laid a rough wooden floor on joists.

- On the rough floor again rolling out the plastic sheeting, make the overlap at the walls 20 cm

- As additional insulation puts a layer of polyethylene foam, which also has certain waterproofing properties.

Waterproofing concrete floor

Scheme of arrangement of concrete floor waterproofing layers

The arrangement of the concrete floor on the ground is complicated by the fact that you need to create a monolithic structure in the conditions of rolling of the soil. After performing a "cushion" should make a rough screed. For this there are two ways.

The first option. On top of the sand, which is the finishing layer of "bedding", pour a layer of gravel. Then kneaded cement-sand mortar, slightly liquid consistency and pour it over the gravel so that the top was a layer of rough screed at least 3 – 5 cm After drying of concrete to lay on it, roll the waterproofing in two layers, for example, roofing material or roofing felt, make sure no toppings. Carefully glue all the joints with a gas burner. Then put the insulation and perform the finishing screed.

The second option. On top of the sand to lay a polyethylene film thickness of 200 microns. Flatten it well and glue all the joints with tape. It is necessary to act very carefully so as not to tear the film. Top films of roughing screed of cement-sand mixture (normal consistence). This layer is also called "lean concrete", as it is only necessary to perform the waterproofing. The layer must be a thickness of 5 – 7 cm For solution preparation is used, the gravel fraction 5-10 mm (small), sand – only river.

For waterproofing of concrete floor in rough screed can be spread rolled waterproofing materials

For roughing screed, you can also spread a layer of waterproofing (roofing or PVC membrane). On top is placed a heater, and then finishing screed. Described above is sufficient for ensuring quality of waterproofing in most cases, but there are situations that require additional waterproofing.

Do you need additional waterproofing of the floor

When the water table are too close to the surface, may require additional measures to protect against it. To determine whether you need additional insulation, it is possible, by performing appropriate calculations. This involved a specialized company that executes projects for the construction of houses. Undertake analysis of the soil, measurements of water level in different seasons and based on the data obtained a verdict.

Additional work to ensure the waterproofing of the floor:

- Tamp the subgrade; a Stacked layer of fat clay or roofing felt, 2 layers;

- Laid gravel and sand;

- Impregnate layers of gravel and sand with bitumen;

- Stacked rough screed of "lean concrete";

- Performed waterproofing sub-floor roll material or coating mastics.

- Put a vapor barrier.

Waterproofing the floor in the kitchen

The floor of the kitchen susceptible to moisture not only from below – from the ground, but from above – in the process of cleaning, cooking and other kitchen works on the floor gets a lot of water. Therefore, to protect the floor it is necessary not only from below as it was written above, but from the top. The principle of waterproofing the floor in the kitchen is largely dependent on floor finish. To build a wooden floor in the kitchen is impractical, as it is most affected by moisture, and to protect him will be difficult. If, however, decided to lay on the kitchen parquet, parquet Board or solid wood, should reveal the surface thereof with a waterproof varnish.

For additional waterproofing of the floor in the kitchen, you can handle concrete base painting material

If the quality finish of the kitchen you plan to use the linoleum, then a concrete base on which it is placed, should be treated with waterproofing material, e.g., paint or coating method. Then put the linoleum on the glue. In this case, the linoleum itself will act as a waterproofing material.

Ceramic tile also has water-repellent properties, but as a safety net not be amiss to handle concrete screed bitumen-polymer mastics, paints or other means. And for better adhesion of the tile adhesive with the base on top of waterproofing need to be impregnated with a special primer.

Waterproofing the floor in a private house – it is very responsible. If this is not done in time and qualitatively, over time, may appear fungus and other mold, which will be impossible to withdraw. And the design of the whole house will gradually deteriorate. About high indoor humidity, which leads to frequent allergies and other diseases, can not speak. Better to think it through and execute on time than to rebuild and repair.

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: mrpol.su/ustrojstvo-polov/izolyaciya/gidroizolyaciya-pola-v-chastnom-dome.html

Alexander Volkov: "I" and the body is not the same thing!

As for the whole family to coexist in the same room