445

Basement waterproofing: choosing the best way

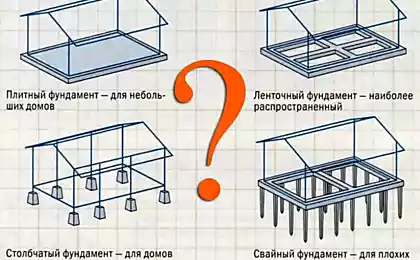

The basement will always be dry, and the building will last long only if its Foundation is protected from water. Concrete, which usually manufactured design, subject to the negative influence of moisture. A porous material it easily absorbs and begins to break down. Especially, the process proceeds under conditions of seasonal temperature fluctuations when water in the pores of the material freezes and bursts it from within. For this reason, the Foundation is in dire need of waterproofing.

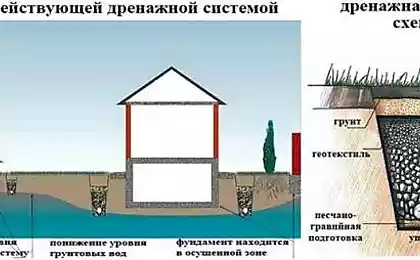

It may seem that the main threat comes from rainfall or melt water, which not only penetrates into the concrete structure, but also can seep through into the basement. In fact, it is not so. The danger comes from ground water, they are deposited in the soil at different depths. And if their level is above floor level in the basement, the latter will always be full of water. No pumping and base isolation will not help. You will need the arrangement of the waterproof barrier, shaped like a trough across the surface of the basement. If the water table is low, waterproofing the basement would be sufficient. All work to create an impermeable water barrier are held outside, at the stage of laying designs.

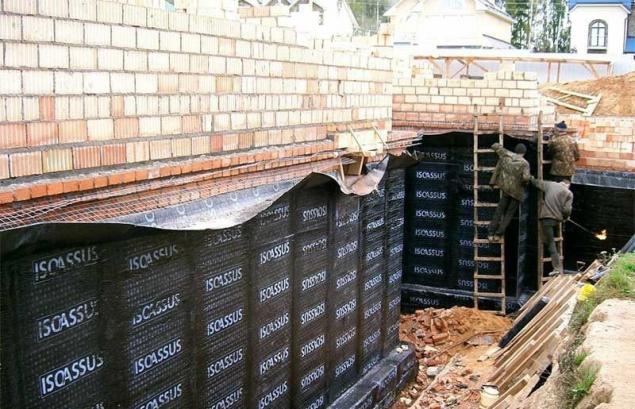

Waterproofing basement can be done in different ways. The most popular among developers can be considered three of them: gluing, coating or penetrating method. A detailed look at each of them. Okleechnoy waterproofing materials are applied on a flat surface with a weld or glued on a special mastic. They are multi-layered panel consisting of several insulating layers are placed between the reinforcing materials. Available okleechnoy waterproofing in the form of a coiled roll of canvases. On them in the factory applied adhesive layer and a protective film.

After protection is lifted, will only roll out the cloth on the designated place. This is the simplest method of laying okleechnoy isolation. Filler materials are mounted differently. Their bottom layer is first heated with a torch to a semi-liquid state, after which the fabric is glued to the base. In any case, for the arrangement of high-quality waterproofing must be laid not less than two layers of material. Each strip is placed with an overlap of at least 10 cm. the Main advantage of okleechnoy insulation is resistant to cracking. In addition, the waterproofing of this type is characterized by high strength and durability.

The most important disadvantage of covering and lining materials is a laborious installation. This is especially true for filler pieces. Efficiently laid this coating can only specialists. Another disadvantage is the high risk of delamination of the insulation, due to its insufficiently strong adhesion. The price of such materials is quite high. Okleechnoy insulation is widely used for exterior applications and almost not used for internal.

Waterproofing mixture represents various waterproof solutions which are applied to the base like a paint or plaster. You can find mastic bitumen based or the more modern polymer coatings. The material is applied to the insulated plane with a brush or spatula. The choice of tool is determined by the consistency of the composition. Usually the base is applied at least three layers of a solution. For thick mastics, if necessary, between them can be laid gives strength reinforcing mesh. Indisputable advantages of coating insulation are considered as low cost, ease of application and flexibility. The latter property makes the insulation resistant to mechanical damage.

The disadvantages of the material include a tendency to crack. Especially brightly this property is manifested with sudden temperature drops. Manufacturers of insulation compounds claim that they can be used both indoors and outdoor applications. However, practice shows that when high water pressure coming from the inside of the structure, the coating may flake off. Accordingly, coating solutions are used for external insulation of basements and foundations.

Penetrating waterproofing is a fundamentally new way of protection from water. A special squad that handled the concrete surface, penetrates the pores of the substrate and reacts with the cement. It results in the concrete appear not soluble in water crystals. They securely close all the pores, cracks and capillaries in the material. The reaction starts and proceeds only in the presence of moisture. While it spreads in all directions until the complete disappearance of water. The appearance of moisture in the process of crystal formation starts again.

The dry composition is diluted with water and applied to the base. If it is monolithic, then training is not required. If the Foundation is assembled from individual elements, you first need to putty and prepare seams. The solution is applied by roller or brush, after drying the excess is swept off the surface.

The main advantage of penetrating waterproofing is that it not only creates a reliable waterproof barrier, but also makes the base more durable. It is easy to apply and can be used for both internal and external works. The disadvantages of penetrating structures carry a high cost. In addition, they are designed for concrete substrates. There is a technology for application of penetrating insulation on the brick, but it is very time consuming and expensive.

The Foundation of any building is experiencing a serious load. Reliability – the key to a long lasting structure. That is why it is important to protect it from the adverse effects of moisture, which will inevitably lead to the destruction of the structure and gradual deformation of other elements of the building. Properly designed waterproofing protects the Foundation from damage and the owner will not have to spend its time consuming and expensive repair. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.stroitelstvo365.ru/stroitelnie-materiali/gidroizolyatsiya-fundamenta

It may seem that the main threat comes from rainfall or melt water, which not only penetrates into the concrete structure, but also can seep through into the basement. In fact, it is not so. The danger comes from ground water, they are deposited in the soil at different depths. And if their level is above floor level in the basement, the latter will always be full of water. No pumping and base isolation will not help. You will need the arrangement of the waterproof barrier, shaped like a trough across the surface of the basement. If the water table is low, waterproofing the basement would be sufficient. All work to create an impermeable water barrier are held outside, at the stage of laying designs.

Waterproofing basement can be done in different ways. The most popular among developers can be considered three of them: gluing, coating or penetrating method. A detailed look at each of them. Okleechnoy waterproofing materials are applied on a flat surface with a weld or glued on a special mastic. They are multi-layered panel consisting of several insulating layers are placed between the reinforcing materials. Available okleechnoy waterproofing in the form of a coiled roll of canvases. On them in the factory applied adhesive layer and a protective film.

After protection is lifted, will only roll out the cloth on the designated place. This is the simplest method of laying okleechnoy isolation. Filler materials are mounted differently. Their bottom layer is first heated with a torch to a semi-liquid state, after which the fabric is glued to the base. In any case, for the arrangement of high-quality waterproofing must be laid not less than two layers of material. Each strip is placed with an overlap of at least 10 cm. the Main advantage of okleechnoy insulation is resistant to cracking. In addition, the waterproofing of this type is characterized by high strength and durability.

The most important disadvantage of covering and lining materials is a laborious installation. This is especially true for filler pieces. Efficiently laid this coating can only specialists. Another disadvantage is the high risk of delamination of the insulation, due to its insufficiently strong adhesion. The price of such materials is quite high. Okleechnoy insulation is widely used for exterior applications and almost not used for internal.

Waterproofing mixture represents various waterproof solutions which are applied to the base like a paint or plaster. You can find mastic bitumen based or the more modern polymer coatings. The material is applied to the insulated plane with a brush or spatula. The choice of tool is determined by the consistency of the composition. Usually the base is applied at least three layers of a solution. For thick mastics, if necessary, between them can be laid gives strength reinforcing mesh. Indisputable advantages of coating insulation are considered as low cost, ease of application and flexibility. The latter property makes the insulation resistant to mechanical damage.

The disadvantages of the material include a tendency to crack. Especially brightly this property is manifested with sudden temperature drops. Manufacturers of insulation compounds claim that they can be used both indoors and outdoor applications. However, practice shows that when high water pressure coming from the inside of the structure, the coating may flake off. Accordingly, coating solutions are used for external insulation of basements and foundations.

Penetrating waterproofing is a fundamentally new way of protection from water. A special squad that handled the concrete surface, penetrates the pores of the substrate and reacts with the cement. It results in the concrete appear not soluble in water crystals. They securely close all the pores, cracks and capillaries in the material. The reaction starts and proceeds only in the presence of moisture. While it spreads in all directions until the complete disappearance of water. The appearance of moisture in the process of crystal formation starts again.

The dry composition is diluted with water and applied to the base. If it is monolithic, then training is not required. If the Foundation is assembled from individual elements, you first need to putty and prepare seams. The solution is applied by roller or brush, after drying the excess is swept off the surface.

The main advantage of penetrating waterproofing is that it not only creates a reliable waterproof barrier, but also makes the base more durable. It is easy to apply and can be used for both internal and external works. The disadvantages of penetrating structures carry a high cost. In addition, they are designed for concrete substrates. There is a technology for application of penetrating insulation on the brick, but it is very time consuming and expensive.

The Foundation of any building is experiencing a serious load. Reliability – the key to a long lasting structure. That is why it is important to protect it from the adverse effects of moisture, which will inevitably lead to the destruction of the structure and gradual deformation of other elements of the building. Properly designed waterproofing protects the Foundation from damage and the owner will not have to spend its time consuming and expensive repair. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.stroitelstvo365.ru/stroitelnie-materiali/gidroizolyatsiya-fundamenta