688

Methods of waterproofing the floor svomi hands

All people are constantly in the process of life use water: hygiene, cooking, washing and cleaning. However, constructions in the building as opposed to the people feel better without water, and some types of construction materials and all are afraid of moisture or water. Even the constructions of reinforced concrete respond to moisture from humidity is very negative, and if such a medium will affect them continuously, it may destroy its integrity. The same can be said of finishing materials, wooden structures, ceilings and partition walls, drywall and other materials. In the aquatic environment takes place actively education and development of micro-organisms and fungi, the faster the biological and chemical corrosion, the plant pathogenic bacterial cultures, and insects.

It is for this reason waterproofing floors - is a necessary measure, especially for wet areas in the apartment. Such, for example, include a kitchen, a bathroom and a toilet even hallway. In areas where there is a higher level of moisture, waterproofing provides strong protection as the main floors, and decorative topcoat. In addition, as is possible to ensure the comfort and safety ekspluatatsiyu.Ustroystvo waterproofing can be achieved in several ways, which differ in the materials used and mounting technology.

Especially important is the implementation of high-quality waterproofing the floor to tie on the first floor of private house, which has no basement. Capillary moisture and water vapor, which rise from the ground, often have an alkaline or acidic environment, they are in an active interaction with the components concrete floor, so after a few years of Napoli can be formed cracks network, destroying the floor.

Variety of materials for waterproofing floor

Materials produced for a large array of waterproofing, all of which are difficult to enumerate and classify should select only the most popular and effective materials.

Thus, the most popular waterproofing materialamiyavlyayutsya following;

mastic and obmazochnye compositions;

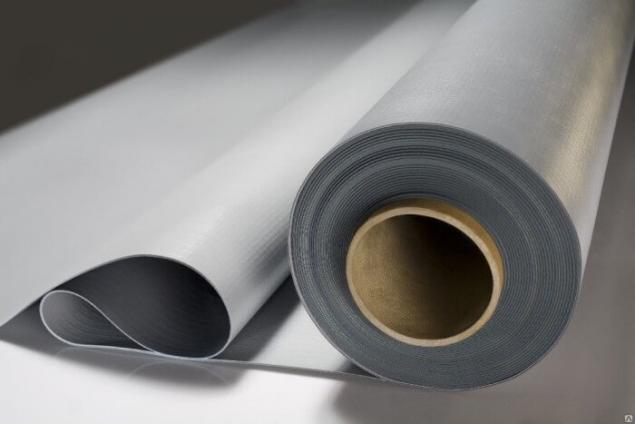

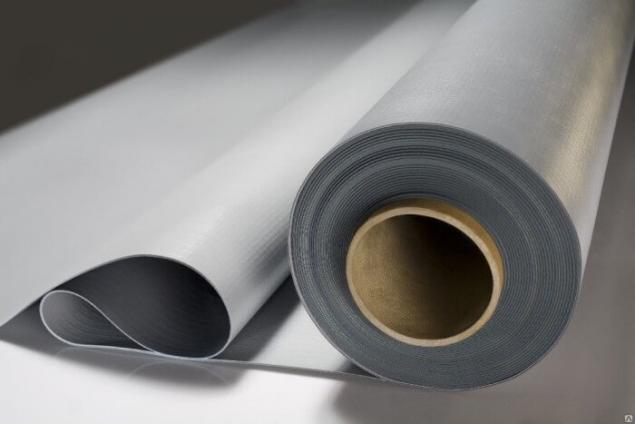

Wood banding and rolled materials;

nasypnyematerialy;

spetsialnyeshtukaturki;

sprayed polymers, liquid mixture

penetrating compounds.

If you plan an independent floor waterproofing, it is best to opt for plastering and of coating options. Suit also rolled materials, but they will be harder to work with, in addition, not everyone can install and connect such coating quality. It is acceptable to apply the self-penetrating waterproofing, but only in strict compliance with the instructions for its application and further care at Aging cover. You also need to perform some related procedures. Use penetrating compositions also implies that the base should be moistened profusely, which can lead to leakage of water to the bottom neighbors.

The bulk is used for waterproofing screed. They are special granules forming a gelatinous paste, interacting with water which prevents its subsequent leakage.

It is difficult to make your own hands polymeric floors, including three-dimensional self-leveling floors, as they are quite demanding and "capricious" to the surface condition and austerity following the instructions below. Instructions of the floor may seem very difficult without certain tools and skills.

Polymer sprayed coatings, for example, such as urea, should also be applied by specialists who are in the presence of an appropriate special equipment.

Regarding errors in the waterproofing should be noted that the floor tiles does not serve the waterproofing material, it is designed for finishing. Even if applied polyurethane or silicone grout, it is in any case will not give a guarantee that water when plumbing system crash will not flow down to the neighbors. Waterproofing also can not replace the varnish or oil paint. Such coatings can last no longer than five years, and then they will begin to crack and fall behind, especially the paint coating.

It is also necessary to take into account that in some cases, such as the bathroom, one floor waterproofing is not enough, because the walls bad absorb water, which flows down to the lower neighbors in the inner capillaries, In addition, the walls themselves too spoiled as their finishing and finishing in the adjacent areas.

The process of preparing the floor for application of waterproofing

Before you start waterproofing necessarily required to carry out the preparatory work on the draft field, which is to do the following:

First remove the old paint, available on the floor.

All garbage is collected carefully and floor surface vacuumed to get rid of dust.

All cracks and crevices which were found based on after treatment, as follows sealed.

Carried out via treatment with a primer composition to increase the adhesion of materials. You can choose a primer based on the recommendations of the manufacturer of waterproofing materials.

Technique cushion from gravel and sand

For gravel-sand pillow perform the following:

Prepare the base by leveling the ground for the future of sex and remove from it all topsoil, which contains organic impurities. This is done, as a rule, at the stage of preparing the site for construction.

On the prepared soil is poured gravel, having a fraction of a maximum of 50 millimeters. Filling is performed on all the area of the floor of the future. Pour gravel compacted and leveled, so as not to form a large height differences. The layer should have a thickness of at least 20 centimeters. in those areas where the groundwater is located close to the layer of gravel filling shall be not less than 50 centimeters.

Next, the backfilling of coarse sand layer thickness of 10-40 centimeters. Pour sand, watered and properly compacted using a hand roller.

Then pillow of sand and gravel layer of geotextile, which strips are glued using a hair dryer building. geotextile material acts as a shock absorber, protecting the waterproofing and insulation damage.

On the geotextile is placed on top butt foam insulation, for example, penoplex or polystyrene. It is not recommended because penoplastiz low degree of mechanical strength.

After completing these steps, you can start the prepared waterproofing the floor, using roll materials or to begin a floor screed.

Technology installing the floor with waterproofing roll materials

Waterproofing floor roll materials as follows:

Along the perimeter of the walls keeps the damper tape required in order to compensate for the expansion of the concrete screed due to the effects of temperature fluctuations. Damper tape fastened with dowels, nails or adhesive layer.

If necessary, the base is leveled, potholes filled with sand or overwritten solution of sand and cement.

If the polymer films are applied waterproofing, the concrete slabs primer treatment is not needed. Concrete slabs if desired, may be treated with a solution designed for penetrating waterproofing. When using the conventional roofing material requires pretreatment floor primers for Bituminous.

Roll waterproofing is laid on pre-prepared floor strips forming an overlap on the wall at least 15 centimeters. The strips are placed as overlapping each other, the width of the overlap is at least 10 centimeters. If the roofing material used, it is glued to the base using mastic asphalt. Generators also overlap joints are glued.

Facing materials, for example, stekloizol, fastened to the base by means of a gas burner. Films of the polymer are placed overlapping, welding together using a construction dryer.

How many layers will comprise waterproofing depends on the type of material used. Thus, for example, roofing material is laid is not less than two layers, and fusing the polymeric materials of the film - a layer

. Stacked roll waterproofing produce reinforcement and subsequent floor screed. When the coupler will harden, the excess serving damper tape and roll waterproofing trimmed flush with the floor.

Technique floor waterproofing with application of coating of waterproofing materials

For the treatment of the floor surface waterproofing do so:

From the debris, dirt and dust cleared a prepared base concrete. Special care is necessary to eliminate the cutting edges, sharp particles and protrusions stains from solvents, oils and chemically active substances as well as interacting with solutions, they can destroy the waterproofing.

The most common surface waterproofing is carried out by means of bitumen or bitumen-rubber mastic cold application. The surface of the floor before the start, it is recommended to process using a primer, namely primers for this type of mastic. It is advisable to use a primer that same komapnii manufacturer ...

The primer is applied in one coat with a brush, thoroughly missed all areas. It will reduce dusting surface, improved adhesion of mastic with it. Particular attention should be paid to the treatment of joints and wc tenoy space around the pipes. Typically the primer dry for no longer than two hours.

Mastic is applied using a roller or wide brush in several layers. Each new layer should be applied when the previous one is completely dry. Layers should be applied in different directions of motion roller or brush. In mestak junctions with walls and around pipes mastic applied with a fine brush, thoroughly missed all areas.

Usually surface waterproofing is completely dry for about two days. After it dries, you can begin the implementation of the screed. Stacking fittings, plastic guides should be used to avoid contact with surface waterproofing metal structures, since they can damage it under load.

Conclusion

Before the screed for the reliable waterproofing of flooring can be used multiple ways. For example, in a private house for waterproofing floor, where there is no basement, you can arrange a pillow of sand and gravel, over which is laid a layer of insulation, waterproofing film, and only then produced rebar installation and screed. To ground floor apartment situated above the basement, you can apply a waterproofing penetrating kind for IPT overlap, combining it with a roll of coating or waterproofing. For wet rooms in the apartment, located on the top floor of an apartment building in which any leakage can lead to involuntary damages caused to lower its neighbors, it is better to perform a double waterproofing. At the same time it will be run as a tie up and over it. In this case, for waterproofing under the screed roller applied material, and on top of the screed is carried out surface waterproofing.

The choice of method and waterproofing materials are a matter of taste and financial possibilities of each owner of the home or premises. Similarly, only that it is not permissible not to carry out waterproofing in the hope that the pipes will not leak. First, the water has a property to evaporation and settling on the ceiling, wall or floor. Also, it flows down to the floor because of the action of gravity. Second, the tenants in the apartment often dried linen, from which water flows. Water is also the case after taking a shower or using the washstand. In the third, it so happens that the kitchen sink drain clogs or overflowing bath. What to say about the hall room, which in the winter turns into a huge solid puddle of mud and slush.

The most reliable materials are considered to be liquid and Sprayable waterproofing, but they have a high cost of works and materials, but if there is a possibility, it is better to make expensive, but once and for sure. Very nice established itself as penetrating waterproofing that is able to stop the bad moisture, having served as much, and design itself. It is thus quite easily and quickly applied both under the screed and on top of it, even to the floor and the walls. At the same time the materials are much less liquid and sprayable formulations.

Given that in the house there are many sources of moisture, it is better to take care of your health and comfort in advance, preventing forced to pay for the repair of neighbors below by device-quality waterproofing the floor. It can be done with their own hands, or trust these procedures experienced specialists who will be able to choose the most suitable material and will perform all works quickly and accurately.

It is for this reason waterproofing floors - is a necessary measure, especially for wet areas in the apartment. Such, for example, include a kitchen, a bathroom and a toilet even hallway. In areas where there is a higher level of moisture, waterproofing provides strong protection as the main floors, and decorative topcoat. In addition, as is possible to ensure the comfort and safety ekspluatatsiyu.Ustroystvo waterproofing can be achieved in several ways, which differ in the materials used and mounting technology.

Especially important is the implementation of high-quality waterproofing the floor to tie on the first floor of private house, which has no basement. Capillary moisture and water vapor, which rise from the ground, often have an alkaline or acidic environment, they are in an active interaction with the components concrete floor, so after a few years of Napoli can be formed cracks network, destroying the floor.

Variety of materials for waterproofing floor

Materials produced for a large array of waterproofing, all of which are difficult to enumerate and classify should select only the most popular and effective materials.

Thus, the most popular waterproofing materialamiyavlyayutsya following;

mastic and obmazochnye compositions;

Wood banding and rolled materials;

nasypnyematerialy;

spetsialnyeshtukaturki;

sprayed polymers, liquid mixture

penetrating compounds.

If you plan an independent floor waterproofing, it is best to opt for plastering and of coating options. Suit also rolled materials, but they will be harder to work with, in addition, not everyone can install and connect such coating quality. It is acceptable to apply the self-penetrating waterproofing, but only in strict compliance with the instructions for its application and further care at Aging cover. You also need to perform some related procedures. Use penetrating compositions also implies that the base should be moistened profusely, which can lead to leakage of water to the bottom neighbors.

The bulk is used for waterproofing screed. They are special granules forming a gelatinous paste, interacting with water which prevents its subsequent leakage.

It is difficult to make your own hands polymeric floors, including three-dimensional self-leveling floors, as they are quite demanding and "capricious" to the surface condition and austerity following the instructions below. Instructions of the floor may seem very difficult without certain tools and skills.

Polymer sprayed coatings, for example, such as urea, should also be applied by specialists who are in the presence of an appropriate special equipment.

Regarding errors in the waterproofing should be noted that the floor tiles does not serve the waterproofing material, it is designed for finishing. Even if applied polyurethane or silicone grout, it is in any case will not give a guarantee that water when plumbing system crash will not flow down to the neighbors. Waterproofing also can not replace the varnish or oil paint. Such coatings can last no longer than five years, and then they will begin to crack and fall behind, especially the paint coating.

It is also necessary to take into account that in some cases, such as the bathroom, one floor waterproofing is not enough, because the walls bad absorb water, which flows down to the lower neighbors in the inner capillaries, In addition, the walls themselves too spoiled as their finishing and finishing in the adjacent areas.

The process of preparing the floor for application of waterproofing

Before you start waterproofing necessarily required to carry out the preparatory work on the draft field, which is to do the following:

First remove the old paint, available on the floor.

All garbage is collected carefully and floor surface vacuumed to get rid of dust.

All cracks and crevices which were found based on after treatment, as follows sealed.

Carried out via treatment with a primer composition to increase the adhesion of materials. You can choose a primer based on the recommendations of the manufacturer of waterproofing materials.

Technique cushion from gravel and sand

For gravel-sand pillow perform the following:

Prepare the base by leveling the ground for the future of sex and remove from it all topsoil, which contains organic impurities. This is done, as a rule, at the stage of preparing the site for construction.

On the prepared soil is poured gravel, having a fraction of a maximum of 50 millimeters. Filling is performed on all the area of the floor of the future. Pour gravel compacted and leveled, so as not to form a large height differences. The layer should have a thickness of at least 20 centimeters. in those areas where the groundwater is located close to the layer of gravel filling shall be not less than 50 centimeters.

Next, the backfilling of coarse sand layer thickness of 10-40 centimeters. Pour sand, watered and properly compacted using a hand roller.

Then pillow of sand and gravel layer of geotextile, which strips are glued using a hair dryer building. geotextile material acts as a shock absorber, protecting the waterproofing and insulation damage.

On the geotextile is placed on top butt foam insulation, for example, penoplex or polystyrene. It is not recommended because penoplastiz low degree of mechanical strength.

After completing these steps, you can start the prepared waterproofing the floor, using roll materials or to begin a floor screed.

Technology installing the floor with waterproofing roll materials

Waterproofing floor roll materials as follows:

Along the perimeter of the walls keeps the damper tape required in order to compensate for the expansion of the concrete screed due to the effects of temperature fluctuations. Damper tape fastened with dowels, nails or adhesive layer.

If necessary, the base is leveled, potholes filled with sand or overwritten solution of sand and cement.

If the polymer films are applied waterproofing, the concrete slabs primer treatment is not needed. Concrete slabs if desired, may be treated with a solution designed for penetrating waterproofing. When using the conventional roofing material requires pretreatment floor primers for Bituminous.

Roll waterproofing is laid on pre-prepared floor strips forming an overlap on the wall at least 15 centimeters. The strips are placed as overlapping each other, the width of the overlap is at least 10 centimeters. If the roofing material used, it is glued to the base using mastic asphalt. Generators also overlap joints are glued.

Facing materials, for example, stekloizol, fastened to the base by means of a gas burner. Films of the polymer are placed overlapping, welding together using a construction dryer.

How many layers will comprise waterproofing depends on the type of material used. Thus, for example, roofing material is laid is not less than two layers, and fusing the polymeric materials of the film - a layer

. Stacked roll waterproofing produce reinforcement and subsequent floor screed. When the coupler will harden, the excess serving damper tape and roll waterproofing trimmed flush with the floor.

Technique floor waterproofing with application of coating of waterproofing materials

For the treatment of the floor surface waterproofing do so:

From the debris, dirt and dust cleared a prepared base concrete. Special care is necessary to eliminate the cutting edges, sharp particles and protrusions stains from solvents, oils and chemically active substances as well as interacting with solutions, they can destroy the waterproofing.

The most common surface waterproofing is carried out by means of bitumen or bitumen-rubber mastic cold application. The surface of the floor before the start, it is recommended to process using a primer, namely primers for this type of mastic. It is advisable to use a primer that same komapnii manufacturer ...

The primer is applied in one coat with a brush, thoroughly missed all areas. It will reduce dusting surface, improved adhesion of mastic with it. Particular attention should be paid to the treatment of joints and wc tenoy space around the pipes. Typically the primer dry for no longer than two hours.

Mastic is applied using a roller or wide brush in several layers. Each new layer should be applied when the previous one is completely dry. Layers should be applied in different directions of motion roller or brush. In mestak junctions with walls and around pipes mastic applied with a fine brush, thoroughly missed all areas.

Usually surface waterproofing is completely dry for about two days. After it dries, you can begin the implementation of the screed. Stacking fittings, plastic guides should be used to avoid contact with surface waterproofing metal structures, since they can damage it under load.

Conclusion

Before the screed for the reliable waterproofing of flooring can be used multiple ways. For example, in a private house for waterproofing floor, where there is no basement, you can arrange a pillow of sand and gravel, over which is laid a layer of insulation, waterproofing film, and only then produced rebar installation and screed. To ground floor apartment situated above the basement, you can apply a waterproofing penetrating kind for IPT overlap, combining it with a roll of coating or waterproofing. For wet rooms in the apartment, located on the top floor of an apartment building in which any leakage can lead to involuntary damages caused to lower its neighbors, it is better to perform a double waterproofing. At the same time it will be run as a tie up and over it. In this case, for waterproofing under the screed roller applied material, and on top of the screed is carried out surface waterproofing.

The choice of method and waterproofing materials are a matter of taste and financial possibilities of each owner of the home or premises. Similarly, only that it is not permissible not to carry out waterproofing in the hope that the pipes will not leak. First, the water has a property to evaporation and settling on the ceiling, wall or floor. Also, it flows down to the floor because of the action of gravity. Second, the tenants in the apartment often dried linen, from which water flows. Water is also the case after taking a shower or using the washstand. In the third, it so happens that the kitchen sink drain clogs or overflowing bath. What to say about the hall room, which in the winter turns into a huge solid puddle of mud and slush.

The most reliable materials are considered to be liquid and Sprayable waterproofing, but they have a high cost of works and materials, but if there is a possibility, it is better to make expensive, but once and for sure. Very nice established itself as penetrating waterproofing that is able to stop the bad moisture, having served as much, and design itself. It is thus quite easily and quickly applied both under the screed and on top of it, even to the floor and the walls. At the same time the materials are much less liquid and sprayable formulations.

Given that in the house there are many sources of moisture, it is better to take care of your health and comfort in advance, preventing forced to pay for the repair of neighbors below by device-quality waterproofing the floor. It can be done with their own hands, or trust these procedures experienced specialists who will be able to choose the most suitable material and will perform all works quickly and accurately.

Take this simple procedure every morning and minus 10 years is guaranteed!

6 best alkaline foods to which you should pay attention