874

What and how do Belarusian condensed milk

Who among us has not dreamed as a child from her mother secretly eat a can of condensed milk, and sometimes more than one? Of course, many of us have wondered, from what and how is such a welcome treat. Finally, it was possible to carry out a childhood dream, and the veil of secrecy over the process of production of the world famous condensed milk in cans with the traditional white and blue label kindly agreed to reveal the employees of OJSC "Glubokoye Milk Factory" in Vitebsk region.

Sanitary regulations at the plant in the town of Deep - akin orders in a surgical operating room. Complete sterility! Even for the largest Belarusian Journalists Portal are no exceptions has not been done: had to wear special clothing, sign the appropriate register of the absence of infectious diseases and undergo sanitization. It is in itself a very interesting procedure.

Hands before visiting the JSC MCC should be washed thoroughly - and not just with liquid soap and water, but with a special antiseptic. Tap water basins fed automatically - there are infrared sensors. This is to ensure that employees and visitors not touch the taps, because if a man touches his dirty hands, and the other - clean, the effect of washing can be reduced to nothing.

But that's not all! At the entrance to the workshop is necessary to put both hands into a special machine, the turnstile, which pour in the palm of a little disinfectant to wipe them. Simultaneously, the shoe soles are handled specially disinfectant. Only after the triggering device to pass the green light, and allows the turnstile to go inside.

Of course, all employees of the company are regularly required medical examination. Hands come into contact directly with the milk and dairy products they do not have, the entire process is automated, but especially food production require full guarantees.

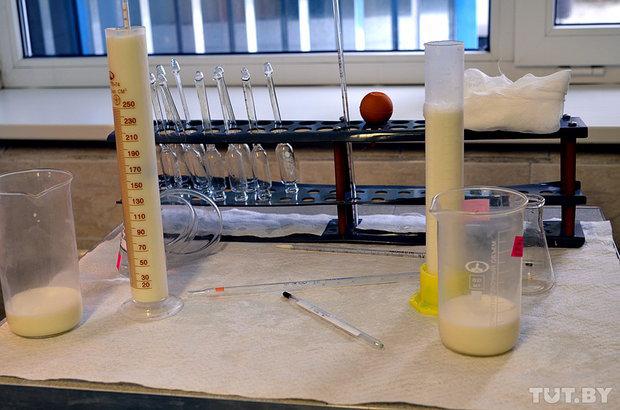

- We introduced the system in the enterprise security production of condensed milk cans of ISO 22000 and the system HASSP requirements which we are obliged to strictly observe, - says the Deputy Director for Operations Ludmila Duc. - First of all incoming milk is tested for antibiotics, as they can seriously affect human health. It uses a special device - HEAT-sensor. If so, for example, tetracycline or other drugs that are sometimes used by veterinarians to treat cows are found in milk - this party under any circumstances, we will not be accepted. If no antibiotics in milk, it undergoes a number of other laboratory tests that should determine the purity of the raw materials group, the percentage of fat mass fraction and, of course, organoleptic properties - in other words, taste, color and smell of the product. According to approved methods, milk before it is heated up to exactly 35 degrees to determine the odor and to the reflux temperature, followed by cooling to identify taste. And bring it to the plant suppliers are required only chilled to 10 degrees, because the bactericidal phase milk is stored for only two hours after its production. The veterinary certificate stating that it was obtained from healthy cows, as required.

According to Lyudmila Georgievna, raw material base of "Glubokoye Dairy Plant" is represented not only native to Glubokoe district enterprise, but also two more - Sharkovshchina and Braslavsky. And, although the suppliers of many years of cooperation with the ICC is more than proven, and the regions themselves - an environmentally clean, each party coming to the company's milk is subjected to strict incoming inspection, because it affects the safety of people.

How and what do Belarusian condensed milk? Photo: Roman Protasiewicz, TUT.BY

Irina Vaskovich

Irina Vaskovich kindly agreed to conduct with correspondents TUT.BY tour on the same route, which passes for admission to the company each batch of raw materials: from the "arrival" in the tank farm, milk tanker sent to consumers in the form of packaged jars of delicious condensed milk.

- There are unloaded or, as we say, "Unrolling" milk tankers, - says Irina Konstantinova. - What you see now - is cleaning tanks after unloading. This means that the party arrived milk passed laboratory tests proved high-quality and has been accepted.

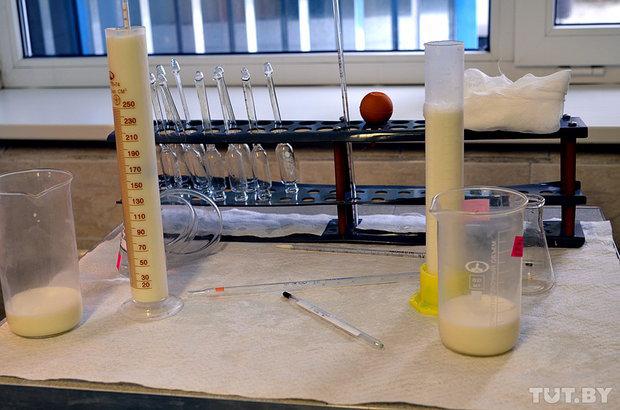

We looked at the receiving laboratory, which, for convenience, the process is close to the area of acceptance. It IWC experts vengeance conjured a cunning devices that can detect even a tiny percentage of content in the milk of antibiotics and other potentially dangerous substances for the consumer. Other devices determines the degree of purity of the product, its richness and variety, and organoleptic qualities were tested by laboratory is very simple: milk is considered closely, sniffed and, of course, tried. Today's raw materials had excellent taste and smell, as it should, the natural fresh milk, and very appetizing.

Here

More

Meanwhile Newly milk is pumped into the storage compartment - of course, over the counter. In a special window that process could even watch.

Storage tanks for newly arrived materials is also close to the zone of acceptance, only slightly lower, and, of course, the milk they receive only after cooling. Interior storage is a bit like a submarine: the same set of tubes (but only from shining stainless steel food) and round hatches sealed.

More

Of course, all the threads "rivers of milk" in the enterprise need to somehow manage. This successfully makes fully computerized system, the operator of which may directly from your workstation to manage the process - to open and close the valves manually, as a few decades ago, is no longer required.

Source:

Sanitary regulations at the plant in the town of Deep - akin orders in a surgical operating room. Complete sterility! Even for the largest Belarusian Journalists Portal are no exceptions has not been done: had to wear special clothing, sign the appropriate register of the absence of infectious diseases and undergo sanitization. It is in itself a very interesting procedure.

Hands before visiting the JSC MCC should be washed thoroughly - and not just with liquid soap and water, but with a special antiseptic. Tap water basins fed automatically - there are infrared sensors. This is to ensure that employees and visitors not touch the taps, because if a man touches his dirty hands, and the other - clean, the effect of washing can be reduced to nothing.

But that's not all! At the entrance to the workshop is necessary to put both hands into a special machine, the turnstile, which pour in the palm of a little disinfectant to wipe them. Simultaneously, the shoe soles are handled specially disinfectant. Only after the triggering device to pass the green light, and allows the turnstile to go inside.

Of course, all employees of the company are regularly required medical examination. Hands come into contact directly with the milk and dairy products they do not have, the entire process is automated, but especially food production require full guarantees.

- We introduced the system in the enterprise security production of condensed milk cans of ISO 22000 and the system HASSP requirements which we are obliged to strictly observe, - says the Deputy Director for Operations Ludmila Duc. - First of all incoming milk is tested for antibiotics, as they can seriously affect human health. It uses a special device - HEAT-sensor. If so, for example, tetracycline or other drugs that are sometimes used by veterinarians to treat cows are found in milk - this party under any circumstances, we will not be accepted. If no antibiotics in milk, it undergoes a number of other laboratory tests that should determine the purity of the raw materials group, the percentage of fat mass fraction and, of course, organoleptic properties - in other words, taste, color and smell of the product. According to approved methods, milk before it is heated up to exactly 35 degrees to determine the odor and to the reflux temperature, followed by cooling to identify taste. And bring it to the plant suppliers are required only chilled to 10 degrees, because the bactericidal phase milk is stored for only two hours after its production. The veterinary certificate stating that it was obtained from healthy cows, as required.

According to Lyudmila Georgievna, raw material base of "Glubokoye Dairy Plant" is represented not only native to Glubokoe district enterprise, but also two more - Sharkovshchina and Braslavsky. And, although the suppliers of many years of cooperation with the ICC is more than proven, and the regions themselves - an environmentally clean, each party coming to the company's milk is subjected to strict incoming inspection, because it affects the safety of people.

How and what do Belarusian condensed milk? Photo: Roman Protasiewicz, TUT.BY

Irina Vaskovich

Irina Vaskovich kindly agreed to conduct with correspondents TUT.BY tour on the same route, which passes for admission to the company each batch of raw materials: from the "arrival" in the tank farm, milk tanker sent to consumers in the form of packaged jars of delicious condensed milk.

- There are unloaded or, as we say, "Unrolling" milk tankers, - says Irina Konstantinova. - What you see now - is cleaning tanks after unloading. This means that the party arrived milk passed laboratory tests proved high-quality and has been accepted.

We looked at the receiving laboratory, which, for convenience, the process is close to the area of acceptance. It IWC experts vengeance conjured a cunning devices that can detect even a tiny percentage of content in the milk of antibiotics and other potentially dangerous substances for the consumer. Other devices determines the degree of purity of the product, its richness and variety, and organoleptic qualities were tested by laboratory is very simple: milk is considered closely, sniffed and, of course, tried. Today's raw materials had excellent taste and smell, as it should, the natural fresh milk, and very appetizing.

Here

More

Meanwhile Newly milk is pumped into the storage compartment - of course, over the counter. In a special window that process could even watch.

Storage tanks for newly arrived materials is also close to the zone of acceptance, only slightly lower, and, of course, the milk they receive only after cooling. Interior storage is a bit like a submarine: the same set of tubes (but only from shining stainless steel food) and round hatches sealed.

More

Of course, all the threads "rivers of milk" in the enterprise need to somehow manage. This successfully makes fully computerized system, the operator of which may directly from your workstation to manage the process - to open and close the valves manually, as a few decades ago, is no longer required.

Source: