1278

Chelyabinsk Metallurgical Plant

Chelyabinsk Metallurgical Plant - Russia's largest integrated steel cycle for the production of high-quality steels. This is one of the few companies in the country, which is entitled to assign its own index products - ES (Chelyabinsk Steel). In this post you can see how tough guys produced the famous Chelyabinsk steel.

Caution Under the cut is very hot.

Once iron is produced at the stake in clay pots or pits without any special tools. After a long process of treatment of iron ancient people could make a arrowheads and jewelry for women. In today's world needs people have little left from those times - he just needs some metal. But today, after almost four millenniums history of the development of production technology of metal, instead of fires in the steelworks blast furnaces used - units, the largest of which can produce up to 12 thousand tons of molten iron per day.

Blast Furnace - a perfect metallurgical device that works non-stop. Only sometimes, once in 10-20 years, when many elements of its design worn by many years of operation, the furnace is shut down for an overhaul. The main purpose of the blast furnace - providing a first liquid metal from iron ore.

Almost the entire volume of the furnace, the height of which can reach several tens of floors, takes charge of the - a mixture of certain proportions. It consists of the enriched ore, coke as fuel and flux - a substance which forms during the smelting slag, helping to separate the gangue and ashes from the metal. This feedstock through a complicated design backfill apparatus continuously loaded into a blast furnace from the top and in the heating process is gradually descends. Towards the bottom of solid materials under high pressure oxygen-enriched air is fed heated to a temperature of 1100-1400 degrees Celsius.

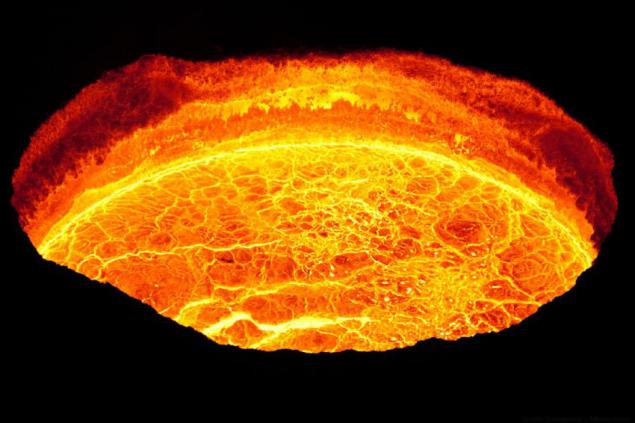

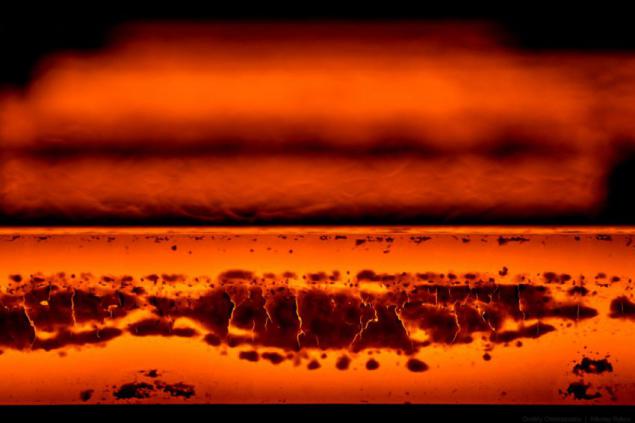

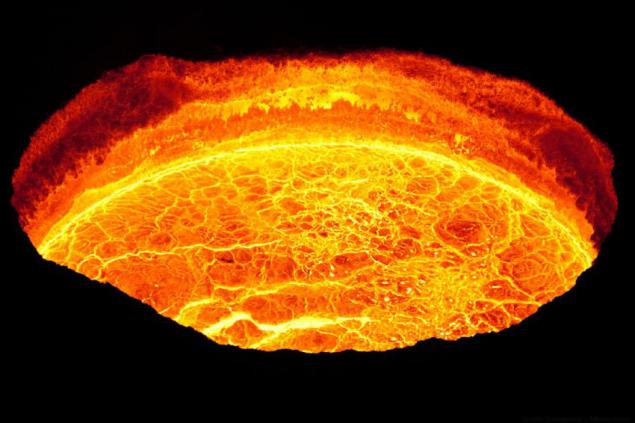

In this mode, ore passes all the way from top to bottom for 4-6 hours and, before reaching the bottom of the furnace - of the hearth, is already in a liquid state in the form of molten iron and slag. In mountainous accumulated up to a thousand or more tons of melt, which constantly fills this part of the furnace and forms a so-called "dead layer", whose height is 0, 6-1, 7 meters. When going to a sufficient amount of blast furnace pig iron and slag, they are released through a special refractory holes - notch, to this end each time punched drill machine running furnaceman.

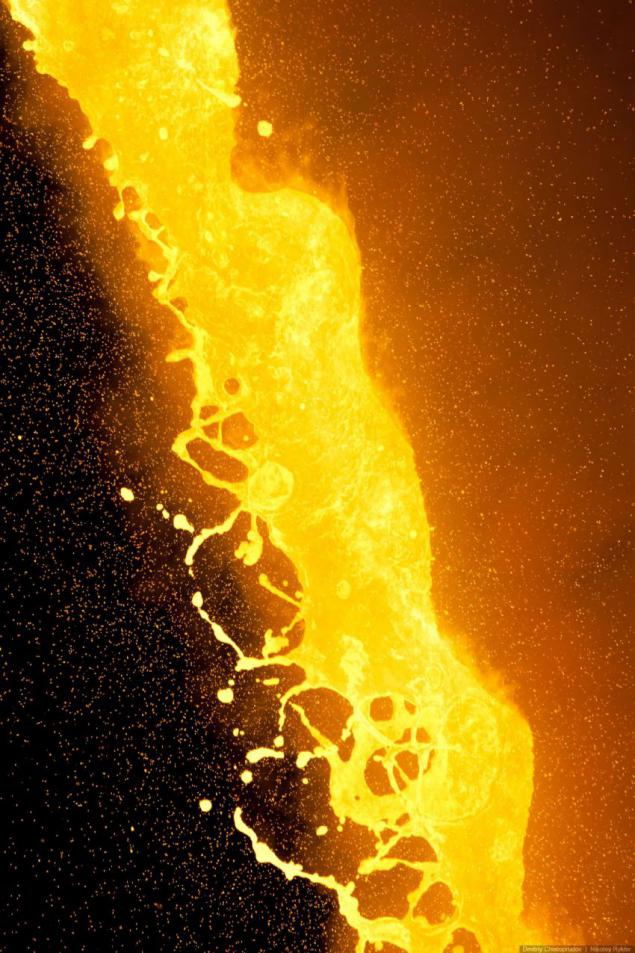

Release of iron occurs on average every 40 minutes. Having a way out of the blast furnace, the molten metal is strong jet hits out of the hole, enters the system equipped with gutters and flowing through the foundry poured into chugunovozy.

Hearth blast furnace - the first who began working with the newly obtained melt. He leads the technological process, watching the progress of melting visually or by instrument readings, and timely produces iron and slag from the blast furnace. In many ways, from his skill and experience success or failure depends on the whole team blast furnace shop.

With each heat the sample is taken. Chilled cast iron ingot goes to express laboratory responsible for analyzing its chemical composition. On the basis of these data, technology blast furnace shop can adjust the composition of the charge loaded into a blast furnace, or change the technological parameters of the blast furnace. Also, the data analysis are taken into account in the further processing of pig iron in the converter shop.

BOF shop. SUMMARY conversion process iron into steel is to reduce the content of unwanted impurities in the iron by oxidation thereof with oxygen. Removal of these elements gives the steel strength and ductility, and also makes it more compliant during processing.

Chugunovozy come here on railroad tracks, which are held directly in the shop.

The main materials that are loaded into the converter are scrap metal and iron. The ratio of these components is called the charge and measured about one to four. Iron comes from the blast furnace shop in special buckets-chugunovozah capacity from 150 to 600 tons.

As scrap metal commonly used rolling mills and trim products Vtorchermet. The metal is poured into the unit through a special system of bunkers and metering scales located above the converter. Himself Converter is a cylindrical vessel with a tapered neck and spherical bottom. It is fixed in a robust carrier ring whose design allows it to rotate relative to the transverse axis 360 degrees in any direction.

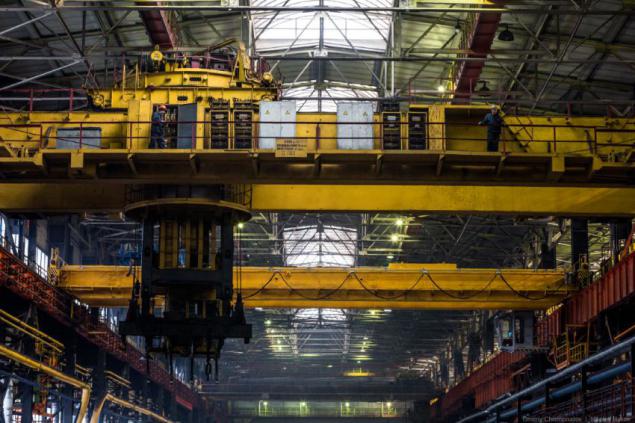

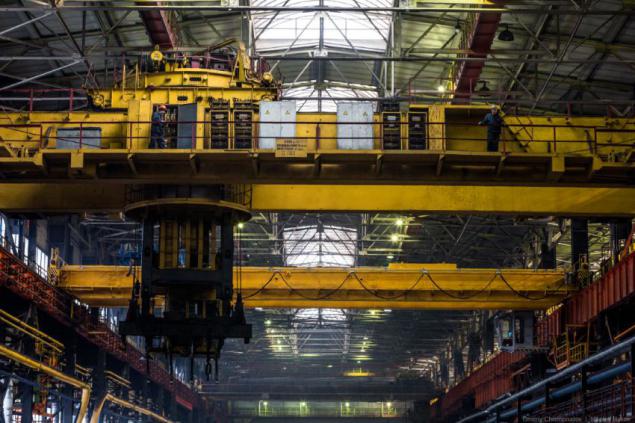

To pour cast iron ladle liquid metal by means of an overhead crane to lift the neck tilted converter. Then mechanisms of the crane tilted iron ladles - and the melt is poured.

Once the basic materials are loaded, it starts blowing oxygen.

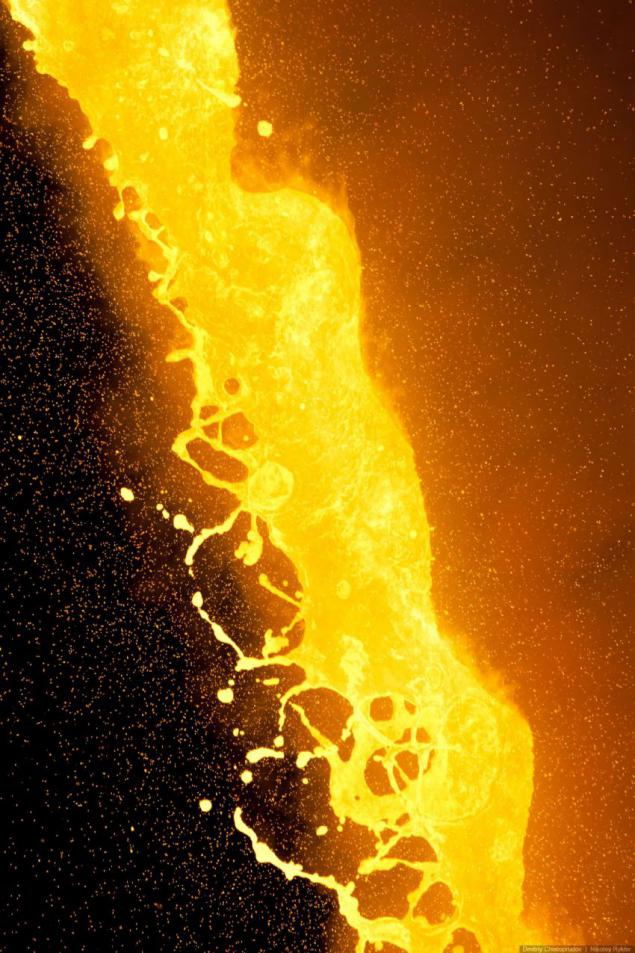

Drain slag.

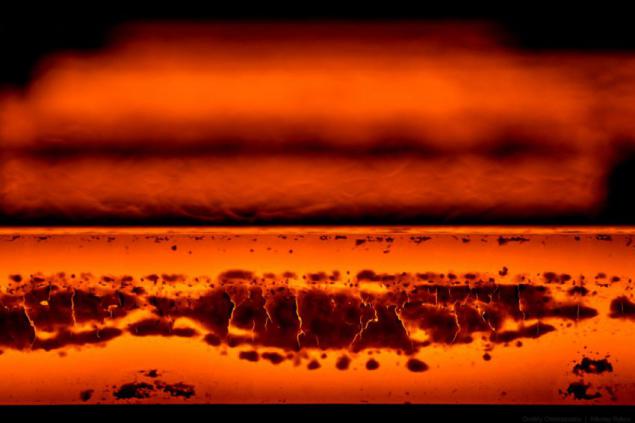

In some periods of blowing a layer of foamed slag 30-50 times greater than the thickness of the slag in a calm state, and its level reaches 6 meters from the surface of a quiet bath. At the same time the foam molten metal approaches the converter mouth and some spikes thrown through it. Sometimes she emulsion is poured through the neck, what happens in cases of spontaneous increase in gas volume. Naturally, such emissions and bursts represent a serious danger to people, so stay close to the converter during blowing is prohibited.

Protective wall with loopholes through which you can run the boiler temperature sensor. Through holes are so hot, that the clothes steelmaker starts to smoke within seconds.

Boiling steel.

Chelyabinsk Metallurgical Plant holds the 5th place among Russia's steel industry in terms of production of steel and is the largest producer of stainless steel in the country.

The plant covers an area of over 22 square kilometers and is a major employer, providing jobs for more than 17 thousand people.

For seven decades, plant has produced 175 million tons of coke, 120 million tons of sinter, 200 million tons of iron, 270 million tons of steel and shipped 225 million tons of steel products.

Steel casting - the final stage of the steelmaking process, during which the steel from liquid state into solid and acquires certain shape, size and weight. Until recently, the only method used in factories was pouring into molds. In this case, smelted in the converter steel is poured into special molds of different sizes and allowed for the gradual cooling. Then ready ingots recovered from the mold, cut off the excess and sent for further processing. However, this method is very labor intensive, requires a lot of molds and their periodic replacement and consumes a significant amount of refractory materials.

A more economical casting method, allows to obtain a steel billet of square or rectangular cross section directly from molten metal, a method of continuous casting of steel. Going machines is that until the end of casting from one bucket served the next advance. Changing the bucket is made without stopping the casting process due to the use of the metal in the intermediate tank. Steelmakers such a method referred to as "melting in the melting."

The liquid metal is divided into six streams. Behind every "creek" looks steelworker.

It is necessary to constantly monitor not to slaughter the neck molds in which the steel cools and hardens.

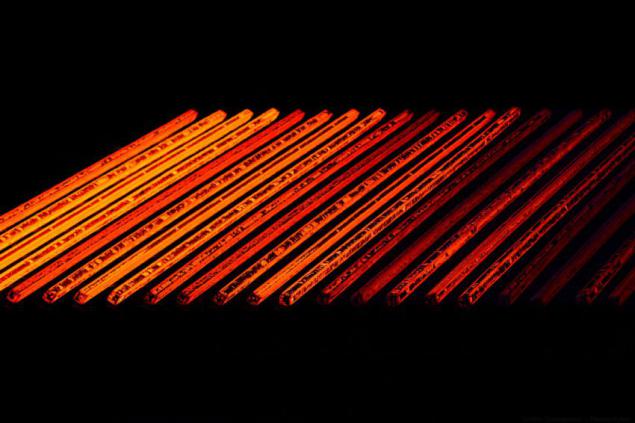

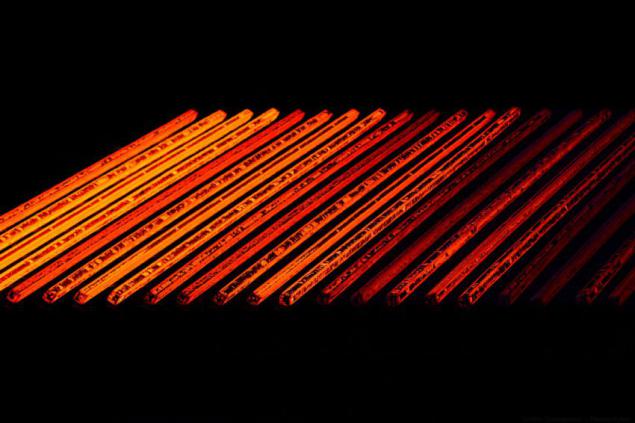

Infinite metal bars smoothly flow from the mold and cut gas oxygen burner to length.

Finished steel slabs, requiring a gradual cooling are sent in a separate workshop where with the help of an overhead crane in a certain order are stacked on the floor covered in sand.

. This is another plant complex - universal rolling mill, which produced the rails up to 100 meters with the latest technology of rolling, tempering, straightening, finishing and quality control. Such rails are used in the construction of high-speed railways.

According to the law of meanness on the day of our arrival, the camp was on transshipment. We have repeatedly been in other rolling mill, but such large-scale production is not yet seen.

For the construction of the new mill produced 15,500 tons of steel - this is two of the Eiffel Tower. Area rail and manufacture of more than 180, 000 square meters. This area is easy to fit 26 fields in the Luzhniki Olympic stadium.

In the device of the foundation took 144,500 cubic meters of concrete. By volume 35 is a large swimming pool.

The length of the rail blank is only 8, 1 m, weight - about a ton. The rail or beam is produced by a peal steel billet, which is preheated in the heating furnace. The production time of one 100-meter rail is just over 2 minutes.

We managed to see only a small part of the plant. To appreciate the full scale of the enterprise, it is necessary to come to a couple of weeks with tents ...

Source: chistoprudov.livejournal.com

Caution Under the cut is very hot.

Once iron is produced at the stake in clay pots or pits without any special tools. After a long process of treatment of iron ancient people could make a arrowheads and jewelry for women. In today's world needs people have little left from those times - he just needs some metal. But today, after almost four millenniums history of the development of production technology of metal, instead of fires in the steelworks blast furnaces used - units, the largest of which can produce up to 12 thousand tons of molten iron per day.

Blast Furnace - a perfect metallurgical device that works non-stop. Only sometimes, once in 10-20 years, when many elements of its design worn by many years of operation, the furnace is shut down for an overhaul. The main purpose of the blast furnace - providing a first liquid metal from iron ore.

Almost the entire volume of the furnace, the height of which can reach several tens of floors, takes charge of the - a mixture of certain proportions. It consists of the enriched ore, coke as fuel and flux - a substance which forms during the smelting slag, helping to separate the gangue and ashes from the metal. This feedstock through a complicated design backfill apparatus continuously loaded into a blast furnace from the top and in the heating process is gradually descends. Towards the bottom of solid materials under high pressure oxygen-enriched air is fed heated to a temperature of 1100-1400 degrees Celsius.

In this mode, ore passes all the way from top to bottom for 4-6 hours and, before reaching the bottom of the furnace - of the hearth, is already in a liquid state in the form of molten iron and slag. In mountainous accumulated up to a thousand or more tons of melt, which constantly fills this part of the furnace and forms a so-called "dead layer", whose height is 0, 6-1, 7 meters. When going to a sufficient amount of blast furnace pig iron and slag, they are released through a special refractory holes - notch, to this end each time punched drill machine running furnaceman.

Release of iron occurs on average every 40 minutes. Having a way out of the blast furnace, the molten metal is strong jet hits out of the hole, enters the system equipped with gutters and flowing through the foundry poured into chugunovozy.

Hearth blast furnace - the first who began working with the newly obtained melt. He leads the technological process, watching the progress of melting visually or by instrument readings, and timely produces iron and slag from the blast furnace. In many ways, from his skill and experience success or failure depends on the whole team blast furnace shop.

With each heat the sample is taken. Chilled cast iron ingot goes to express laboratory responsible for analyzing its chemical composition. On the basis of these data, technology blast furnace shop can adjust the composition of the charge loaded into a blast furnace, or change the technological parameters of the blast furnace. Also, the data analysis are taken into account in the further processing of pig iron in the converter shop.

BOF shop. SUMMARY conversion process iron into steel is to reduce the content of unwanted impurities in the iron by oxidation thereof with oxygen. Removal of these elements gives the steel strength and ductility, and also makes it more compliant during processing.

Chugunovozy come here on railroad tracks, which are held directly in the shop.

The main materials that are loaded into the converter are scrap metal and iron. The ratio of these components is called the charge and measured about one to four. Iron comes from the blast furnace shop in special buckets-chugunovozah capacity from 150 to 600 tons.

As scrap metal commonly used rolling mills and trim products Vtorchermet. The metal is poured into the unit through a special system of bunkers and metering scales located above the converter. Himself Converter is a cylindrical vessel with a tapered neck and spherical bottom. It is fixed in a robust carrier ring whose design allows it to rotate relative to the transverse axis 360 degrees in any direction.

To pour cast iron ladle liquid metal by means of an overhead crane to lift the neck tilted converter. Then mechanisms of the crane tilted iron ladles - and the melt is poured.

Once the basic materials are loaded, it starts blowing oxygen.

Drain slag.

In some periods of blowing a layer of foamed slag 30-50 times greater than the thickness of the slag in a calm state, and its level reaches 6 meters from the surface of a quiet bath. At the same time the foam molten metal approaches the converter mouth and some spikes thrown through it. Sometimes she emulsion is poured through the neck, what happens in cases of spontaneous increase in gas volume. Naturally, such emissions and bursts represent a serious danger to people, so stay close to the converter during blowing is prohibited.

Protective wall with loopholes through which you can run the boiler temperature sensor. Through holes are so hot, that the clothes steelmaker starts to smoke within seconds.

Boiling steel.

Chelyabinsk Metallurgical Plant holds the 5th place among Russia's steel industry in terms of production of steel and is the largest producer of stainless steel in the country.

The plant covers an area of over 22 square kilometers and is a major employer, providing jobs for more than 17 thousand people.

For seven decades, plant has produced 175 million tons of coke, 120 million tons of sinter, 200 million tons of iron, 270 million tons of steel and shipped 225 million tons of steel products.

Steel casting - the final stage of the steelmaking process, during which the steel from liquid state into solid and acquires certain shape, size and weight. Until recently, the only method used in factories was pouring into molds. In this case, smelted in the converter steel is poured into special molds of different sizes and allowed for the gradual cooling. Then ready ingots recovered from the mold, cut off the excess and sent for further processing. However, this method is very labor intensive, requires a lot of molds and their periodic replacement and consumes a significant amount of refractory materials.

A more economical casting method, allows to obtain a steel billet of square or rectangular cross section directly from molten metal, a method of continuous casting of steel. Going machines is that until the end of casting from one bucket served the next advance. Changing the bucket is made without stopping the casting process due to the use of the metal in the intermediate tank. Steelmakers such a method referred to as "melting in the melting."

The liquid metal is divided into six streams. Behind every "creek" looks steelworker.

It is necessary to constantly monitor not to slaughter the neck molds in which the steel cools and hardens.

Infinite metal bars smoothly flow from the mold and cut gas oxygen burner to length.

Finished steel slabs, requiring a gradual cooling are sent in a separate workshop where with the help of an overhead crane in a certain order are stacked on the floor covered in sand.

. This is another plant complex - universal rolling mill, which produced the rails up to 100 meters with the latest technology of rolling, tempering, straightening, finishing and quality control. Such rails are used in the construction of high-speed railways.

According to the law of meanness on the day of our arrival, the camp was on transshipment. We have repeatedly been in other rolling mill, but such large-scale production is not yet seen.

For the construction of the new mill produced 15,500 tons of steel - this is two of the Eiffel Tower. Area rail and manufacture of more than 180, 000 square meters. This area is easy to fit 26 fields in the Luzhniki Olympic stadium.

In the device of the foundation took 144,500 cubic meters of concrete. By volume 35 is a large swimming pool.

The length of the rail blank is only 8, 1 m, weight - about a ton. The rail or beam is produced by a peal steel billet, which is preheated in the heating furnace. The production time of one 100-meter rail is just over 2 minutes.

We managed to see only a small part of the plant. To appreciate the full scale of the enterprise, it is necessary to come to a couple of weeks with tents ...

Source: chistoprudov.livejournal.com

Gold bullion from the United States contain tungsten!

The first exhibition of children modeling in Chelyabinsk