1244

Chelyabinsk. Height 239.

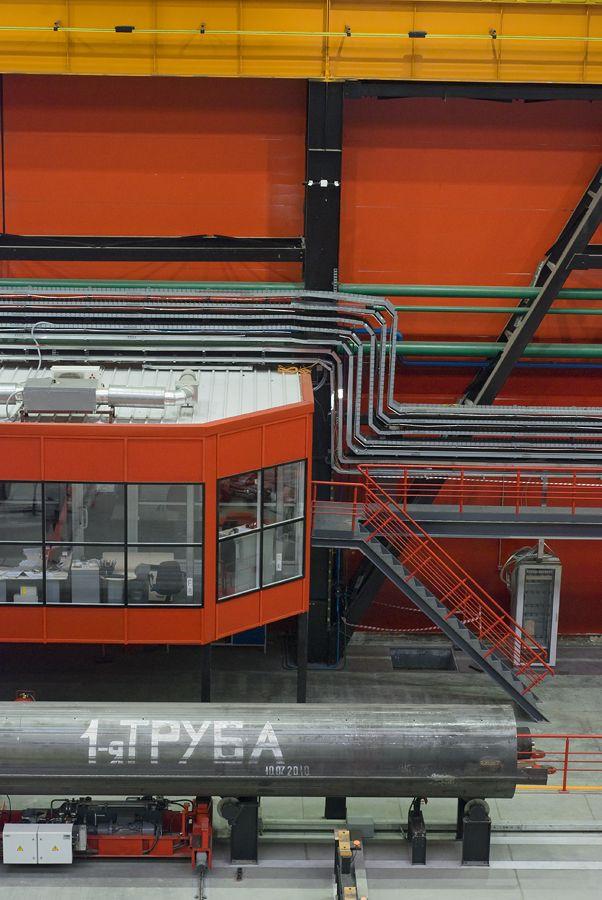

CTRP - Industry Group of the metallurgical complex of Russia is one of the largest domestic manufacturers of tubular products with a total market share of about 20%. Revenue in excess of $ 2 billion, in the factories ChTPZ runs about 20 000 people. Among the ten largest companies in the world pipe. ChTPZ includes enterprises and companies of ferrous metallurgy: OJSC "Chelyabinsk Tube Rolling Plant", JSC "Pervouralsk New Pipe Plant" and others. The unusual name of the new production is because the 239 meters - the height of the geographical point where the new plant, the corresponding height of the southern part of the Ural Mountains above sea level. The shop produces large-diameter pipes for oil and gas pipelines. They are intended for use in the construction of pipelines in the areas of offshore development, seismically active areas, permafrost areas, difficult terrain, the laying of submarine pipelines and offshore.

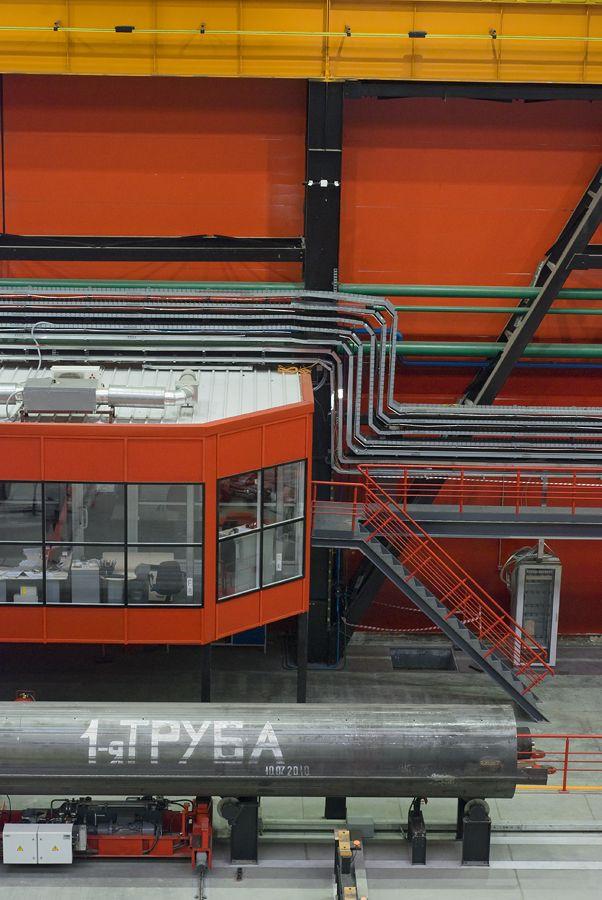

The plant is unusual everything from paint fences to highlighting all the communications and support facilities

Workshop "height" is inside of another protected perimeter - this is due to the REFERENCE in the production of unique technologies, many of which are industrial secrets. And, of course, though not much of a selection of the personnel, the Russian factor is theft of production has not been canceled. Checkpoint "height» Photobucket

Communications

General view of the "height»

The size of the shop-striking area is the area of 14 football fields

The second communicating

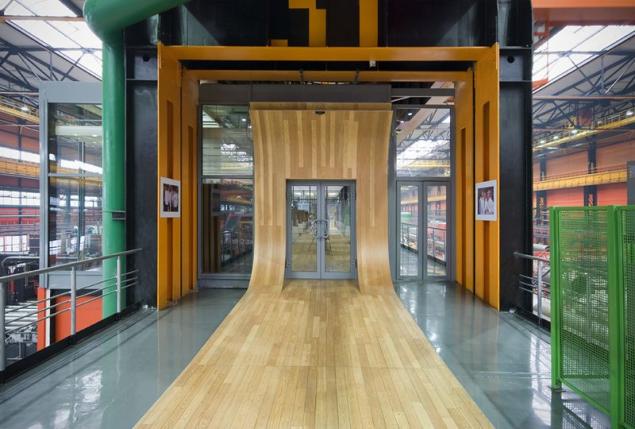

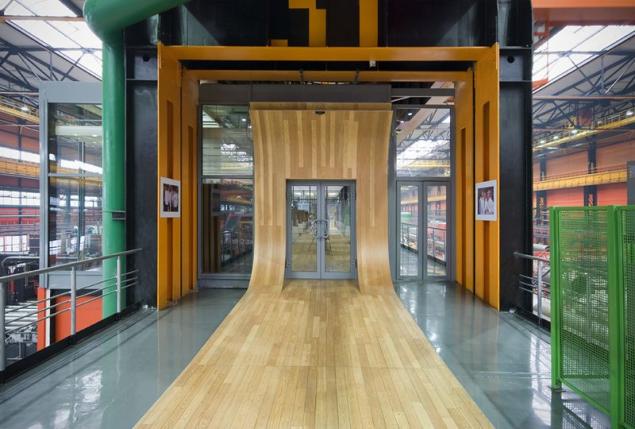

Entrance to the hall is made very interesting - you enter the elevator, climb, passing through a small glass pipe and find yourself ... find yourself and where and why it is there, will talk about later)

239m - a mark above sea level

Gold "arch" - technological passages to repair machines and other auxiliary transport

So we went up the elevator and get inside the shop and found extremely interesting gallery kakby hovering over production. This is because, as the production is divided arbitrarily into two parts-operation with the steel sheet, from which the property and makes pipe and operations already molded pipe (welding, grinding, all kinds of testing rengenom and ultrasound, the final forming, washing, etc.). And gallery separates these 2 cycles, and under it there are all sorts of necessary and useful facilities such as switchboard.

The trees, by the way, live-laurel

All colorful fun-

In semi-natural flooring

Exactly in the middle of the gallery, and it is about a kilometer long, it is dispatching department, but also about her later

Left-gallery on the right, all sorts of mechanisms for movies predvizheniya pipes

Two monster the size of a five-storey house in the foreground is the "main" workshop equipment, the mighty press, bending steel sheet thickness of 2 cm into the pipe. Well, almost tube-press after the pipe has the shape of a closed circle Pochi is seen by the way-pipes lie to the press. Then they expect welding and turning in one piece tube

Left-empty tub of the tree, once a month the trees take on a routine inspection

Technical pass over the gallery

Products

Steel sheet crawling on a conveyer in a press

Jib

Each leg gallery called "axis" and Numbered

A dispatch and pass on to the gallery

The second half-gelerei after a dispatch. Even without a parquet-floor-filler but other design farms

Completing the picture. To her left are seen ready pipe, and on the right, the very beginning of the production of steel plate warehouse

Products

View a dispatch from the "rear" of the gallery

Dispatching shop "Height 239". Left-main control production, and on the right, a large monitor with a picture of the entire production cycle

Boardroom

Parquet "nodules" on the right - the continuation of the parquet gallery

All very concisely, strictly and transparently

A dispatch-view from the shop. Inside the head of the shop talking with German experts working in the factory

Some of the preparations in the steel sheet

Gas cutting of steel bars welded to the sheet - it is necessary for a perfect fold circumferentially

Press

Mechanisms

Let me remind you that this - the "main" unit in the shop, it was he who bends sheet steel pipe

The product after the press

"Monster»

Another common type of production

Gallery

End of "front" of the galleries and dispatching

The ChTPZ Group are confident that the new shop with modern equipment and technology, a fundamentally new accents in the work culture, which is the international quality standards, must have his face. Hence the memorable name and a unique design and architecture department, razarabotanny the way by the architectural department of ChTPZ and "Yo-program" - Ilyshev, Yudanov and Nikolaev.

via source

The plant is unusual everything from paint fences to highlighting all the communications and support facilities

Workshop "height" is inside of another protected perimeter - this is due to the REFERENCE in the production of unique technologies, many of which are industrial secrets. And, of course, though not much of a selection of the personnel, the Russian factor is theft of production has not been canceled. Checkpoint "height» Photobucket

Communications

General view of the "height»

The size of the shop-striking area is the area of 14 football fields

The second communicating

Entrance to the hall is made very interesting - you enter the elevator, climb, passing through a small glass pipe and find yourself ... find yourself and where and why it is there, will talk about later)

239m - a mark above sea level

Gold "arch" - technological passages to repair machines and other auxiliary transport

So we went up the elevator and get inside the shop and found extremely interesting gallery kakby hovering over production. This is because, as the production is divided arbitrarily into two parts-operation with the steel sheet, from which the property and makes pipe and operations already molded pipe (welding, grinding, all kinds of testing rengenom and ultrasound, the final forming, washing, etc.). And gallery separates these 2 cycles, and under it there are all sorts of necessary and useful facilities such as switchboard.

The trees, by the way, live-laurel

All colorful fun-

In semi-natural flooring

Exactly in the middle of the gallery, and it is about a kilometer long, it is dispatching department, but also about her later

Left-gallery on the right, all sorts of mechanisms for movies predvizheniya pipes

Two monster the size of a five-storey house in the foreground is the "main" workshop equipment, the mighty press, bending steel sheet thickness of 2 cm into the pipe. Well, almost tube-press after the pipe has the shape of a closed circle Pochi is seen by the way-pipes lie to the press. Then they expect welding and turning in one piece tube

Left-empty tub of the tree, once a month the trees take on a routine inspection

Technical pass over the gallery

Products

Steel sheet crawling on a conveyer in a press

Jib

Each leg gallery called "axis" and Numbered

A dispatch and pass on to the gallery

The second half-gelerei after a dispatch. Even without a parquet-floor-filler but other design farms

Completing the picture. To her left are seen ready pipe, and on the right, the very beginning of the production of steel plate warehouse

Products

View a dispatch from the "rear" of the gallery

Dispatching shop "Height 239". Left-main control production, and on the right, a large monitor with a picture of the entire production cycle

Boardroom

Parquet "nodules" on the right - the continuation of the parquet gallery

All very concisely, strictly and transparently

A dispatch-view from the shop. Inside the head of the shop talking with German experts working in the factory

Some of the preparations in the steel sheet

Gas cutting of steel bars welded to the sheet - it is necessary for a perfect fold circumferentially

Press

Mechanisms

Let me remind you that this - the "main" unit in the shop, it was he who bends sheet steel pipe

The product after the press

"Monster»

Another common type of production

Gallery

End of "front" of the galleries and dispatching

The ChTPZ Group are confident that the new shop with modern equipment and technology, a fundamentally new accents in the work culture, which is the international quality standards, must have his face. Hence the memorable name and a unique design and architecture department, razarabotanny the way by the architectural department of ChTPZ and "Yo-program" - Ilyshev, Yudanov and Nikolaev.

via source