1223

Chusovoy Metallurgical Works

Chusovoy Steel Works - one of the oldest plants in the Urals city of Perm Krai Chusovoy. The largest iron and steel company with the full technological cycle of metal production.

The leading company in Russia for the production of ferrovanadium, a major supplier of complex shaped sections rolled spring band and high-quality ready-made automobile springs.

He writes: Leonid Varlamov

Photo report quite interesting, and the volume is composed of two parts.

Founded in 1879, the Franco-Russian Urals joint stock company established by Prince Golitsyn and French Barruenom Sh. Founded by the French project, the plant has long been the most modern steel plant in the Urals.

During the Civil War the production was badly damaged, but restored its steelmakers in the short term.

In 1930, the government decided on the specialization of the plant for the production of high quality steel and rolled metal production in the long term with a spring band for developing the automotive industry.

In 1931 was built the largest at the time the blast furnace number 3 of 280 cubic meters. m, in 1935 it started on a pilot smelting vanadium iron. Until this day she has not lived. In return, the plant has two other blast furnaces total volume of 1258 cubic meters. m

Unfortunately, during a visit to the plant furnace repairs were on, so to see them in action failed

...

Workers change firebricks

...

January 13, 1936 Chusovoy Metallurgical Works has been received the first domestic ferrovanadium.

In the fall of 1941 at CMP began work four shops for special purposes, are issued ammunition to the front. Chusovskye steelworkers built and sent to the front armored train "Shchors".

In 1943, at the request of the State Defense Committee in record time (seven months) was built blast furnace number 2 bis, which made it possible to increase the production of pig iron three times. In wartime develops new, higher-quality steel grades, manufactured armor plate, going to the production of tanks. The plant produces high-explosive flame throwers, parts for the famous "Katyusha" and anti-gun.

July 30, 1964 put into operation a new complex ferroalloy production and the construction of the largest in the Urals autoleaf production. A 2 November 1975 has been given a pilot batch Chusovskoy spring.

In 1976, by decision of the Council of Ministers of the USSR at the plant it built Europe's largest autoleaf shop. In 1982, the cheapest and quality sprung in the USSR was Chusovskaya. For 125 years, Chusovoy Metallurgical Works a few times to change the form of ownership. Since 1989, he became a public company. With the shareholders of the plant managed to win key positions on the market of ferrous metals in the Russian and international level.

If I had not messed up, it's air handling plant for open-hearth furnaces

Chusovoy Metallurgical Plant - the only enterprise in Russia a full cycle of vanadium with through titanomagnetite vanadium recovery from the raw materials to vanadium iron, vanadium slag, vanadium pentoxide and ferrovanadium

...

...

For a long time Russia did not have large reserves of its own rich vanadium ores, and was forced to buy ferrovanadium abroad. Thanks to the persistent efforts of researchers and technologists in 1935 Chusovoy plant in the blast furnaces of up to 300 cubic meters. m started regularly smelting vanadium iron titanium-magnetite ore deposits Kusinsk and Pervouralsk. Already in 1936 it was mastered: blast-furnace smelting to produce titanomagnetite iron; redistribution of iron for steel in open-hearth furnaces with a fair yield of vanadium slag; chemical processing of vanadium slag hearth to produce calcium vanadate and vanadium pentoxide; production of ferrovanadium.

...

...

In 1944 it came into operation CMP Bessemer duplex separation plant. Since then, the plant has mastered the processes devanadatsii iron in converters with bottom air-blown. Subsequently, the technology has been improved (converters transferred to the main lining, enriched air blast to the optimum limits of oxygen) to the present time is used in CMP

...

...

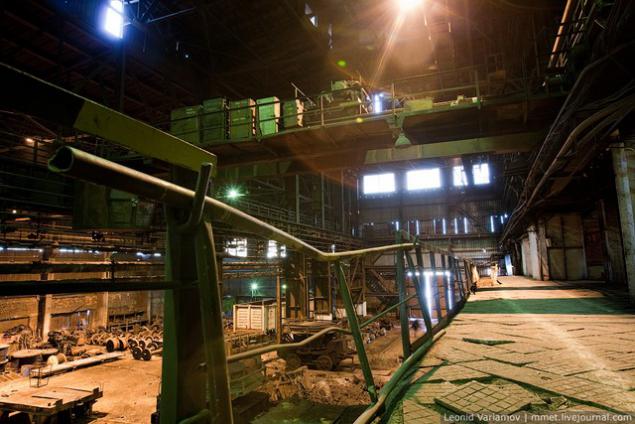

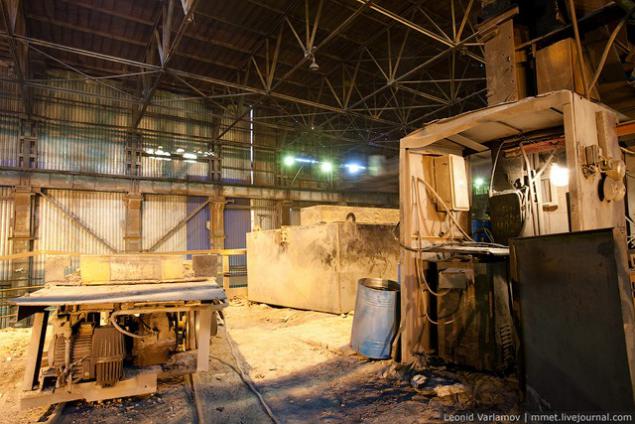

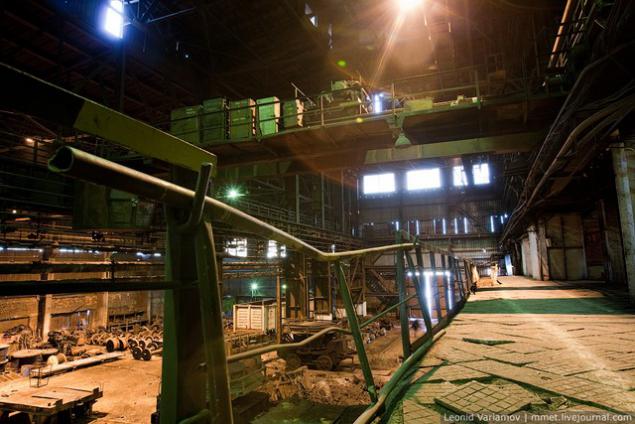

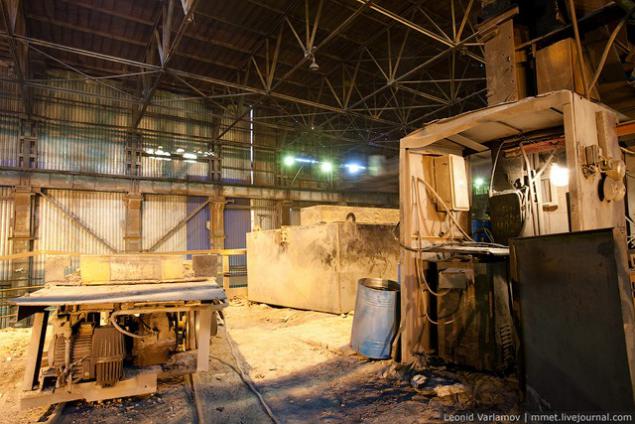

Well, a few photos of the factory floor. Since I'm in metallurgical processes do not make sense, then I can not give explanations.

...

...

...

The company has a small candle factory limestone quarry

...

...

...

As I guess it's an information board basic parameters of the furnace. Apparently, the furnace is under refueling, ie the metal charge is loaded slowly. The latter figure, I think, the duration of the previous heat. ? -20 Is quite normal for there the value of the units. Although I once simulated at 6-50 ... 7-00. So to say unsuccessful attempts to modernize

To scale from the bottom of the boxes placed workers

...

...

If I'm lying again, this open-hearth furnace. It emits a loud noise and intense heat

...

Filling machine. With its help in the open-hearth furnace fed trough material.

Crane lifts the top of these "containers" and taken to an unknown destination

"Containers", they are the same basin, designed to feed into the furnace solid and bulk materials, or otherwise charge. Starting from scrap, in other words - scrap, which, actually, is the starting material for the steel and ending with limestone and other deoxidizers.

...

Crane takes away trough on Stockyard where they are filled with scrap, scrap, or more than is necessary to obtain or

Notice how the Ukrainians translate the name into English voego plant

...

...

During the inspection of plants, I accidentally dropped his helmet into the blast furnace, and then almost knocked over a camera from a great height into a vat with slag. But in the end everything went well and someone still believes that I can be put on the production of hazardous

...

...

...

When I saw the wagon tips over a huge vat, joyfully anticipating a fiery stream, and a fountain of sparks. In fact, from the vat had the small handful of steaming slag

...

...

...

Today everything will be continued and further inspection of the plant. Flowers, teddy bears and a beautiful sunset sea is not expected

...

...

...

Formulations mold vertical containers, where the finished steel is cast. Continuous casting factory there, but talk has long gone, but ...

...

...

...

...

...

Pay attention to the trolley with the mold - to pour molten steel ingots are taken out then that adorn the second part of the story about the plant

...

...

...

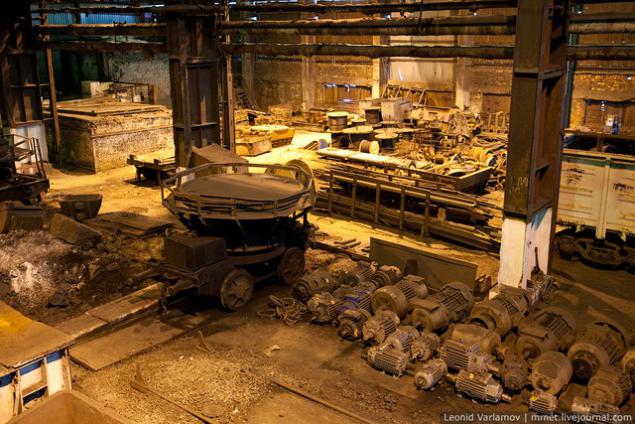

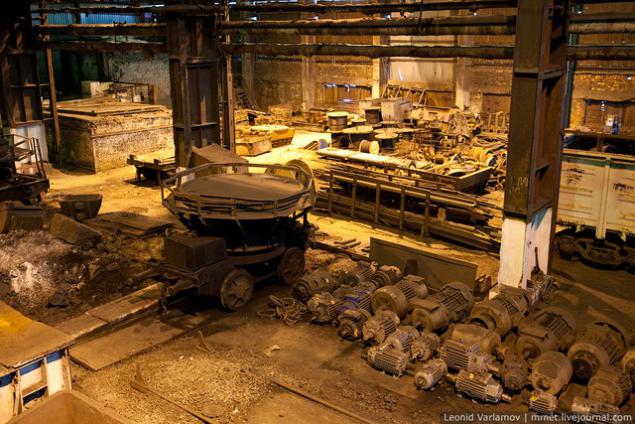

And below you can see another factory floor, warehouse and production director's muskrat hat!

What is the shop, I had completely forgotten. Remembered only that he is, whether to repair it, whether on the output

...

...

...

However, here in the great burning furnace and ingots were spread everywhere, emitting intense heat pohlesche any iron

Then they are rolled in a rolling mill. The upper part is not in processing of the large amount of metal in the gaseous phase, however it is cut and back into the furnace for remelting.

A molds can be seen in Photo 63, the first part of the story about the plant

This is actually one of the furnaces

...

...

...

On exit from the territory of the plant pass by one of the numerous finished products warehouse

...

...

...

...

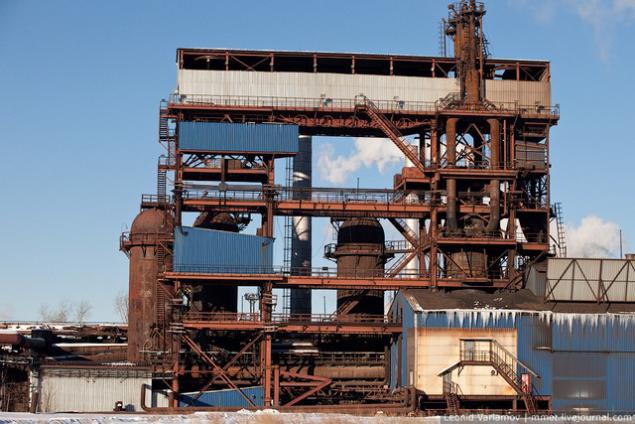

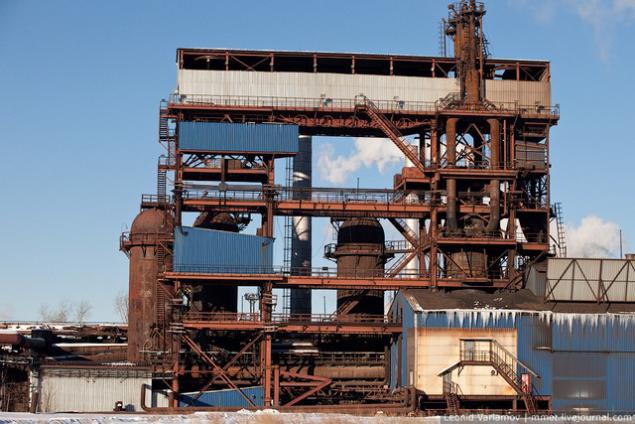

Blast furnace reconstruction

...

...

Monument metallurgists in the central square of the old town

...

A little beauty factory

...

...

...

...

...

Well, look at the end of the keyhole of an administrative body!

It is the last photo ...

Blogger: Leonid Varlamov

Source:

The leading company in Russia for the production of ferrovanadium, a major supplier of complex shaped sections rolled spring band and high-quality ready-made automobile springs.

He writes: Leonid Varlamov

Photo report quite interesting, and the volume is composed of two parts.

Founded in 1879, the Franco-Russian Urals joint stock company established by Prince Golitsyn and French Barruenom Sh. Founded by the French project, the plant has long been the most modern steel plant in the Urals.

During the Civil War the production was badly damaged, but restored its steelmakers in the short term.

In 1930, the government decided on the specialization of the plant for the production of high quality steel and rolled metal production in the long term with a spring band for developing the automotive industry.

In 1931 was built the largest at the time the blast furnace number 3 of 280 cubic meters. m, in 1935 it started on a pilot smelting vanadium iron. Until this day she has not lived. In return, the plant has two other blast furnaces total volume of 1258 cubic meters. m

Unfortunately, during a visit to the plant furnace repairs were on, so to see them in action failed

...

Workers change firebricks

...

January 13, 1936 Chusovoy Metallurgical Works has been received the first domestic ferrovanadium.

In the fall of 1941 at CMP began work four shops for special purposes, are issued ammunition to the front. Chusovskye steelworkers built and sent to the front armored train "Shchors".

In 1943, at the request of the State Defense Committee in record time (seven months) was built blast furnace number 2 bis, which made it possible to increase the production of pig iron three times. In wartime develops new, higher-quality steel grades, manufactured armor plate, going to the production of tanks. The plant produces high-explosive flame throwers, parts for the famous "Katyusha" and anti-gun.

July 30, 1964 put into operation a new complex ferroalloy production and the construction of the largest in the Urals autoleaf production. A 2 November 1975 has been given a pilot batch Chusovskoy spring.

In 1976, by decision of the Council of Ministers of the USSR at the plant it built Europe's largest autoleaf shop. In 1982, the cheapest and quality sprung in the USSR was Chusovskaya. For 125 years, Chusovoy Metallurgical Works a few times to change the form of ownership. Since 1989, he became a public company. With the shareholders of the plant managed to win key positions on the market of ferrous metals in the Russian and international level.

If I had not messed up, it's air handling plant for open-hearth furnaces

Chusovoy Metallurgical Plant - the only enterprise in Russia a full cycle of vanadium with through titanomagnetite vanadium recovery from the raw materials to vanadium iron, vanadium slag, vanadium pentoxide and ferrovanadium

...

...

For a long time Russia did not have large reserves of its own rich vanadium ores, and was forced to buy ferrovanadium abroad. Thanks to the persistent efforts of researchers and technologists in 1935 Chusovoy plant in the blast furnaces of up to 300 cubic meters. m started regularly smelting vanadium iron titanium-magnetite ore deposits Kusinsk and Pervouralsk. Already in 1936 it was mastered: blast-furnace smelting to produce titanomagnetite iron; redistribution of iron for steel in open-hearth furnaces with a fair yield of vanadium slag; chemical processing of vanadium slag hearth to produce calcium vanadate and vanadium pentoxide; production of ferrovanadium.

...

...

In 1944 it came into operation CMP Bessemer duplex separation plant. Since then, the plant has mastered the processes devanadatsii iron in converters with bottom air-blown. Subsequently, the technology has been improved (converters transferred to the main lining, enriched air blast to the optimum limits of oxygen) to the present time is used in CMP

...

...

Well, a few photos of the factory floor. Since I'm in metallurgical processes do not make sense, then I can not give explanations.

...

...

...

The company has a small candle factory limestone quarry

...

...

...

As I guess it's an information board basic parameters of the furnace. Apparently, the furnace is under refueling, ie the metal charge is loaded slowly. The latter figure, I think, the duration of the previous heat. ? -20 Is quite normal for there the value of the units. Although I once simulated at 6-50 ... 7-00. So to say unsuccessful attempts to modernize

To scale from the bottom of the boxes placed workers

...

...

If I'm lying again, this open-hearth furnace. It emits a loud noise and intense heat

...

Filling machine. With its help in the open-hearth furnace fed trough material.

Crane lifts the top of these "containers" and taken to an unknown destination

"Containers", they are the same basin, designed to feed into the furnace solid and bulk materials, or otherwise charge. Starting from scrap, in other words - scrap, which, actually, is the starting material for the steel and ending with limestone and other deoxidizers.

...

Crane takes away trough on Stockyard where they are filled with scrap, scrap, or more than is necessary to obtain or

Notice how the Ukrainians translate the name into English voego plant

...

...

During the inspection of plants, I accidentally dropped his helmet into the blast furnace, and then almost knocked over a camera from a great height into a vat with slag. But in the end everything went well and someone still believes that I can be put on the production of hazardous

...

...

...

When I saw the wagon tips over a huge vat, joyfully anticipating a fiery stream, and a fountain of sparks. In fact, from the vat had the small handful of steaming slag

...

...

...

Today everything will be continued and further inspection of the plant. Flowers, teddy bears and a beautiful sunset sea is not expected

...

...

...

Formulations mold vertical containers, where the finished steel is cast. Continuous casting factory there, but talk has long gone, but ...

...

...

...

...

...

Pay attention to the trolley with the mold - to pour molten steel ingots are taken out then that adorn the second part of the story about the plant

...

...

...

And below you can see another factory floor, warehouse and production director's muskrat hat!

What is the shop, I had completely forgotten. Remembered only that he is, whether to repair it, whether on the output

...

...

...

However, here in the great burning furnace and ingots were spread everywhere, emitting intense heat pohlesche any iron

Then they are rolled in a rolling mill. The upper part is not in processing of the large amount of metal in the gaseous phase, however it is cut and back into the furnace for remelting.

A molds can be seen in Photo 63, the first part of the story about the plant

This is actually one of the furnaces

...

...

...

On exit from the territory of the plant pass by one of the numerous finished products warehouse

...

...

...

...

Blast furnace reconstruction

...

...

Monument metallurgists in the central square of the old town

...

A little beauty factory

...

...

...

...

...

Well, look at the end of the keyhole of an administrative body!

It is the last photo ...

Blogger: Leonid Varlamov

Source: