2435

Blood and Iron: as forged Soviet victory in the war

War - it is horror and death, human stuffing, roasted in a skillet history. However, life is so ironic is arranged, what war is one of the most powerful engines for mankind. In ancient times, she opened horizons, contributed to the creation of new trade routes and the interpenetration of cultures. In the XX century it as it may sound cynical, became the most powerful driver of the development of science and economy.

Everything for the front, everything for victory!

Major wars in our history was the Second mirovaya.Dlya to survive for so long confrontation took exert every effort not only at the front, but also in the rear. In the shortest time period in the Soviet Union was a modern defense industry, which has provided an army of advanced weapons at the time. In honor of the holiday on May 9 want to remember the legendary plants that have made a significant contribution to the greatest victory in the history. All of these companies operate today, the combined corporation Rostec, and continue to play a significant role in the economy and to ensure the defense of our country.

Raw -the first step in the chain of production of weapons. Without high-quality steel or aircraft or tank is not gather. One of the most important companies in the development and production of steel alloys was Salda Metallurgical Production Association. But it its current name. Initially, the plant was running at Moscow and called him by number - «№95». The opening took place July 1, 1933.

Panorama Factory №95. Setun, 1933

Here before the war under the leadership of chief metallurgist plant S. M.Voronova developed a new high-strength alloys - M-95, which was used in the manufacture of load-bearing elements bomber ANT-40. In 1935, production was started forging alloys AK5 and AK6, used to make parts for aircraft dvigateley.V 1941 the plant was evacuated to the Urals, the city Upper Salda. There he teamed up with the plant №519 Commissariat and non-ferrous metallurgy in 1942 production reached pre-war level, and in 1943 the design capacity was exceeded 6 times. This allowed the company to fully meet the needs of our military aviation. Of course, the production of the plant is used not only there. Shipbuilding and tank-building, production of ammunition and weapons - all this not without metal smelted in Upper Salda.

Aluminium alloys

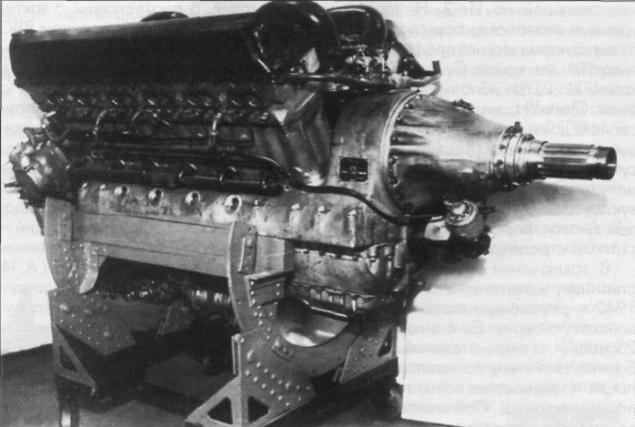

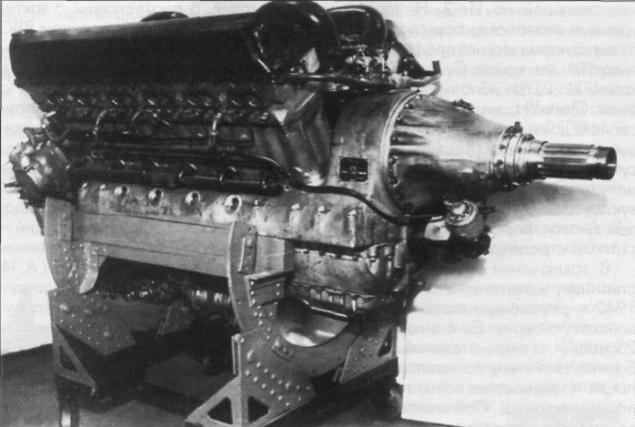

AM-42 engine for IL-8. Parts for aircraft engines made of alloys produced in Upper Salda

In 1945, in honor of the Victory factory team was awarded the highest award of the time - the Order of Lenin. Since the mid-1950s, the plant specializes in the production of titanium. Now VSMPO - part of the titanium corporation "VSMPO", which is included in Rostec. This is one of the largest companies in the world producing titanium.

VSMPO today

Rifle - faithful companion soldier. One of the main centers for the production of weapons during the war became Izhevsk. On the "Izhmash" (Kalashnikov Concern) development of all types of small arms and growth rates of production were by leaps and bounds.

Employees Izhmash-fulfill military norm

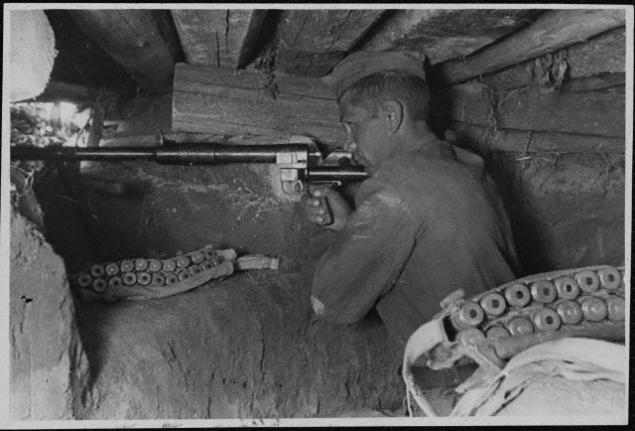

In 1941 the production of Mosin rifle reached 12 thousand pieces a day, that is the day the plant armed the entire Infantry Division. In November 1941, less than a month specialists of the plant mastered the production of anti-tank gun Degtyarev. Then, in November 1941 began the production of anti-tank rifle Simonov. It was urgently needed: the German army rapidly advanced into the country, and Soviet soldiers desperately lacked weapons. By early 1942, the plant sent to the front a large batch of anti-tank rifles: the production of a new type of weapon was mastered in just a month and a half.

The Soviet soldiers are firing on German armored personnel carriers from the anti-tank rifle PTRD, 1942

Soldiers with PTRD ready to repel the attack.

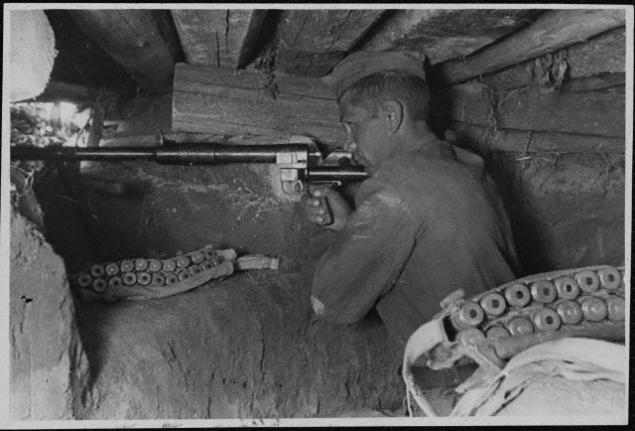

In the dugout. Soldiers, armed PTRD, in anticipation of an attack.

The same accelerated pace on the "Izhmash" was mastered the production of aircraft machine guns Berezina (UB-12, 7), pistoletovTT and revolvers Nagant.

The main building of the factory "Izhmash" in our time.

In 1941 here nazavode number 387, was initiated production of Po-2 biplanes. During the war it was released more than 10,000 aircraft, that is, 10% of all aircraft manufactured in the Soviet Union during this time. The plane is often used as a light night bomber, who slapped on the enemy's rear neighbors. Po-2 could raise up to 300 kg bombs.

Light bomber Po-2.

In 1951 the production of Mi helicopters. Over the years the plant was issued more than 10 000 Mi-4, Mi-8, Mi-14, Mi-17 helicopters and their modifications. In 1993 the factory was privatized and became known as JSC "Kazan Helicopters". Now he enters the Rostec and is one of the leaders in its industry.

Assembling the Mi-17V-5.

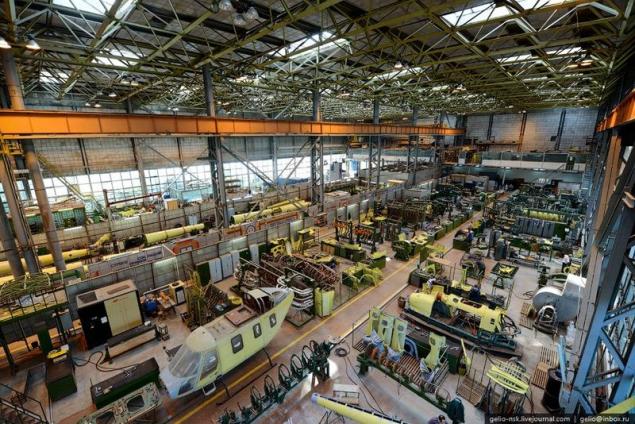

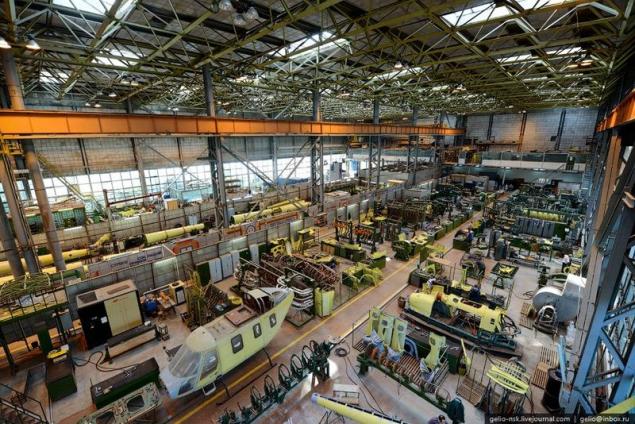

Assembly shop "Kazan Helicopter Plant" today

Mi-17V-5

However, the production of aircraft is impossible without high-quality components. Their production has been established in Kuibyshev factory "Aviaagregat" .With 1941 to 1945, the company specialized in the production of propellers. It provides nine aircraft factories and current Air Force and Navy. During the war on "Aviaagregat" produced more than 90,000 screws, 40 000 of them - for the legendary Il-2.

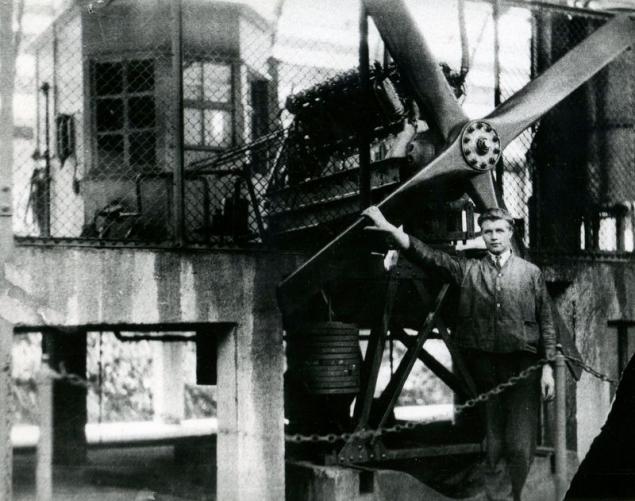

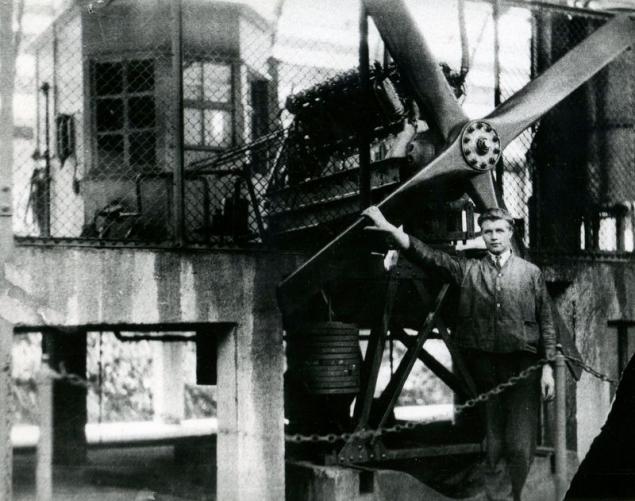

Construction Corps screw factory aviakombinata, 1935

Engines for aircraft made in Perm. Perm Engine Company in the early months of the war took on its territory 6 evacuated enterprises.

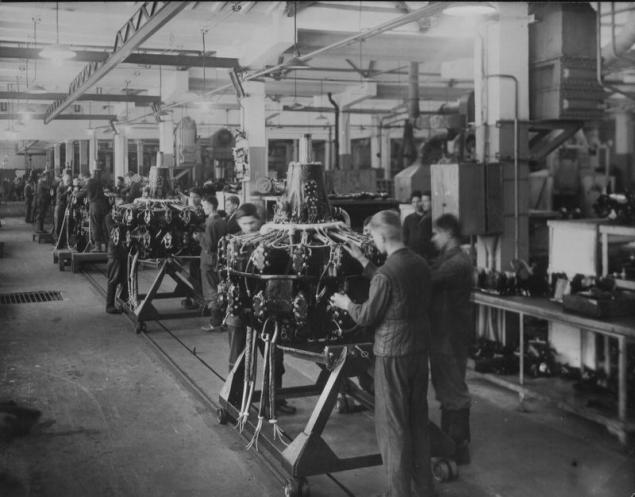

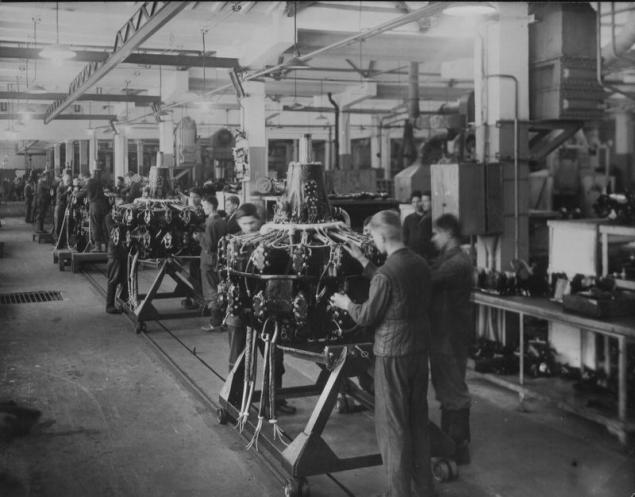

Engine assembly process.

During the war there were produced more than 30,000 engines for Soviet fighters (I-16, I-153, the La-5 and La-7) and bombers (Su-2 Su-4, Tu-2). Factory team 19 times, became the winner of the All-Union competition, celebrated Banner T-bills, the Order of the Red Banner.

Tu-2.

Optics for all types of weapons produced at the Ural Optical and Mechanical Plant, leading its history since 1837, still with the company Swiss citizen Theodore Schwabe. In 1943, there were developed 17 types of weapons, including new aircraft sight. In addition to the actual sights for air and ground weapons in the enterprise producing the receiver to the machine gun "Maxim", the shutter assembly to the legendary "Katyusha" and Tank prism enclosing the driver from the bullets.

Observation armed optics eye

Now UOMZ - one of the main companies of the optical holding "Schwabe", whose products are sold in 83 countries around the world.

The latest quantum optical-location station 13cm-1 is designed for installation on aircraft MiG.

In Chelyabinsk during the war at the plant №78 of the evacuees factory was established one bronekorpusnoy plant №200. It was the only company in the USSR, which were produced armored housing for heavy tanks and artillery self-propelled guns. In the neighborhood worked with him Chelyabinsk Tractor Plant, which produced the legendary T-34 tank. And in the early years of the war the city got its second name - Tankograd.

Assembling the tank

Chelyabinsk tanks -uboynaya strength of the Soviet Army.

After the war, he returned to the factory bronekorpusny civilian production - machines for the industry. Now he calls "Stankomash." It is the only Russian developer and manufacturer of minesweepers.

Rut mine sweeper KMT-8 on the T-72. Mode trawling.

"Stankomash" today.

War demanded not only increase production of already known models of weapons, but also the development of new ones. This involved numerous bureaus and NGOs. In 1935 was created bureau under the leadership of Klimov. In 1938, he developed a series of engines M-103, M-105, Yak-1, Yak-3, Su-1 and Su-3, LaGG-3 bombers and SB-3, Pe-2, C-2. In December 1941, Rybinsk plant, CB Klimov and Rybinsk Aviation Institute. Ordzhonikidze were evacuated to the area of Ufa aircraft engine plant.

The assembly of the aircraft engine factory №26 Ufa.

Ufa Engine Plant, the beginning of the 1940s.

Already in 1944, serial production was resumed and the Rybinsk plant. Today in Rybinsk acts "Saturn" (included in the UEC), specializing in the design and manufacture of gas turbine engines for military and civil aircraft and naval vessels. In particular, together with the French company «Snecma» «Saturn" produces PowerJet SaM146, the engine for the aircraft "Sukhoi Superjet 100»

SaM146 at the Paris Air Show 2011.

List all the companies that have contributed to our victory, of course, is simply impossible. But the good news is many of them are still and still make support our industry.

Thank you for the Victory!

Source: vsirin.livejournal.com

Everything for the front, everything for victory!

Major wars in our history was the Second mirovaya.Dlya to survive for so long confrontation took exert every effort not only at the front, but also in the rear. In the shortest time period in the Soviet Union was a modern defense industry, which has provided an army of advanced weapons at the time. In honor of the holiday on May 9 want to remember the legendary plants that have made a significant contribution to the greatest victory in the history. All of these companies operate today, the combined corporation Rostec, and continue to play a significant role in the economy and to ensure the defense of our country.

Raw -the first step in the chain of production of weapons. Without high-quality steel or aircraft or tank is not gather. One of the most important companies in the development and production of steel alloys was Salda Metallurgical Production Association. But it its current name. Initially, the plant was running at Moscow and called him by number - «№95». The opening took place July 1, 1933.

Panorama Factory №95. Setun, 1933

Here before the war under the leadership of chief metallurgist plant S. M.Voronova developed a new high-strength alloys - M-95, which was used in the manufacture of load-bearing elements bomber ANT-40. In 1935, production was started forging alloys AK5 and AK6, used to make parts for aircraft dvigateley.V 1941 the plant was evacuated to the Urals, the city Upper Salda. There he teamed up with the plant №519 Commissariat and non-ferrous metallurgy in 1942 production reached pre-war level, and in 1943 the design capacity was exceeded 6 times. This allowed the company to fully meet the needs of our military aviation. Of course, the production of the plant is used not only there. Shipbuilding and tank-building, production of ammunition and weapons - all this not without metal smelted in Upper Salda.

Aluminium alloys

AM-42 engine for IL-8. Parts for aircraft engines made of alloys produced in Upper Salda

In 1945, in honor of the Victory factory team was awarded the highest award of the time - the Order of Lenin. Since the mid-1950s, the plant specializes in the production of titanium. Now VSMPO - part of the titanium corporation "VSMPO", which is included in Rostec. This is one of the largest companies in the world producing titanium.

VSMPO today

Rifle - faithful companion soldier. One of the main centers for the production of weapons during the war became Izhevsk. On the "Izhmash" (Kalashnikov Concern) development of all types of small arms and growth rates of production were by leaps and bounds.

Employees Izhmash-fulfill military norm

In 1941 the production of Mosin rifle reached 12 thousand pieces a day, that is the day the plant armed the entire Infantry Division. In November 1941, less than a month specialists of the plant mastered the production of anti-tank gun Degtyarev. Then, in November 1941 began the production of anti-tank rifle Simonov. It was urgently needed: the German army rapidly advanced into the country, and Soviet soldiers desperately lacked weapons. By early 1942, the plant sent to the front a large batch of anti-tank rifles: the production of a new type of weapon was mastered in just a month and a half.

The Soviet soldiers are firing on German armored personnel carriers from the anti-tank rifle PTRD, 1942

Soldiers with PTRD ready to repel the attack.

In the dugout. Soldiers, armed PTRD, in anticipation of an attack.

The same accelerated pace on the "Izhmash" was mastered the production of aircraft machine guns Berezina (UB-12, 7), pistoletovTT and revolvers Nagant.

The main building of the factory "Izhmash" in our time.

In 1941 here nazavode number 387, was initiated production of Po-2 biplanes. During the war it was released more than 10,000 aircraft, that is, 10% of all aircraft manufactured in the Soviet Union during this time. The plane is often used as a light night bomber, who slapped on the enemy's rear neighbors. Po-2 could raise up to 300 kg bombs.

Light bomber Po-2.

In 1951 the production of Mi helicopters. Over the years the plant was issued more than 10 000 Mi-4, Mi-8, Mi-14, Mi-17 helicopters and their modifications. In 1993 the factory was privatized and became known as JSC "Kazan Helicopters". Now he enters the Rostec and is one of the leaders in its industry.

Assembling the Mi-17V-5.

Assembly shop "Kazan Helicopter Plant" today

Mi-17V-5

However, the production of aircraft is impossible without high-quality components. Their production has been established in Kuibyshev factory "Aviaagregat" .With 1941 to 1945, the company specialized in the production of propellers. It provides nine aircraft factories and current Air Force and Navy. During the war on "Aviaagregat" produced more than 90,000 screws, 40 000 of them - for the legendary Il-2.

Construction Corps screw factory aviakombinata, 1935

Engines for aircraft made in Perm. Perm Engine Company in the early months of the war took on its territory 6 evacuated enterprises.

Engine assembly process.

During the war there were produced more than 30,000 engines for Soviet fighters (I-16, I-153, the La-5 and La-7) and bombers (Su-2 Su-4, Tu-2). Factory team 19 times, became the winner of the All-Union competition, celebrated Banner T-bills, the Order of the Red Banner.

Tu-2.

Optics for all types of weapons produced at the Ural Optical and Mechanical Plant, leading its history since 1837, still with the company Swiss citizen Theodore Schwabe. In 1943, there were developed 17 types of weapons, including new aircraft sight. In addition to the actual sights for air and ground weapons in the enterprise producing the receiver to the machine gun "Maxim", the shutter assembly to the legendary "Katyusha" and Tank prism enclosing the driver from the bullets.

Observation armed optics eye

Now UOMZ - one of the main companies of the optical holding "Schwabe", whose products are sold in 83 countries around the world.

The latest quantum optical-location station 13cm-1 is designed for installation on aircraft MiG.

In Chelyabinsk during the war at the plant №78 of the evacuees factory was established one bronekorpusnoy plant №200. It was the only company in the USSR, which were produced armored housing for heavy tanks and artillery self-propelled guns. In the neighborhood worked with him Chelyabinsk Tractor Plant, which produced the legendary T-34 tank. And in the early years of the war the city got its second name - Tankograd.

Assembling the tank

Chelyabinsk tanks -uboynaya strength of the Soviet Army.

After the war, he returned to the factory bronekorpusny civilian production - machines for the industry. Now he calls "Stankomash." It is the only Russian developer and manufacturer of minesweepers.

Rut mine sweeper KMT-8 on the T-72. Mode trawling.

"Stankomash" today.

War demanded not only increase production of already known models of weapons, but also the development of new ones. This involved numerous bureaus and NGOs. In 1935 was created bureau under the leadership of Klimov. In 1938, he developed a series of engines M-103, M-105, Yak-1, Yak-3, Su-1 and Su-3, LaGG-3 bombers and SB-3, Pe-2, C-2. In December 1941, Rybinsk plant, CB Klimov and Rybinsk Aviation Institute. Ordzhonikidze were evacuated to the area of Ufa aircraft engine plant.

The assembly of the aircraft engine factory №26 Ufa.

Ufa Engine Plant, the beginning of the 1940s.

Already in 1944, serial production was resumed and the Rybinsk plant. Today in Rybinsk acts "Saturn" (included in the UEC), specializing in the design and manufacture of gas turbine engines for military and civil aircraft and naval vessels. In particular, together with the French company «Snecma» «Saturn" produces PowerJet SaM146, the engine for the aircraft "Sukhoi Superjet 100»

SaM146 at the Paris Air Show 2011.

List all the companies that have contributed to our victory, of course, is simply impossible. But the good news is many of them are still and still make support our industry.

Thank you for the Victory!

Source: vsirin.livejournal.com