1644

Kazan Helicopter Plant

Writes Marina Lystseva:

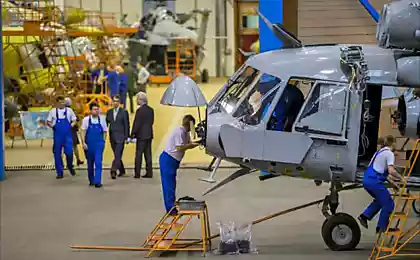

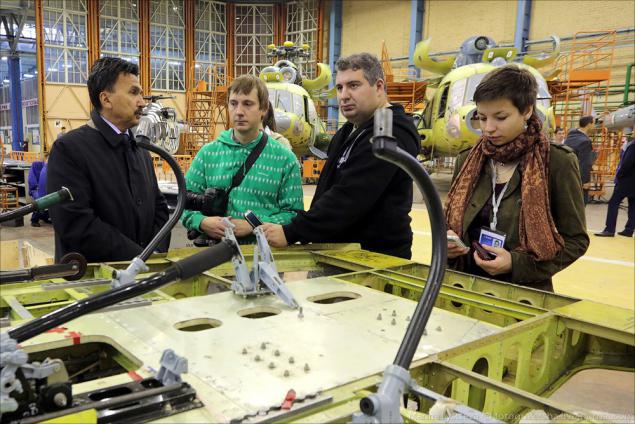

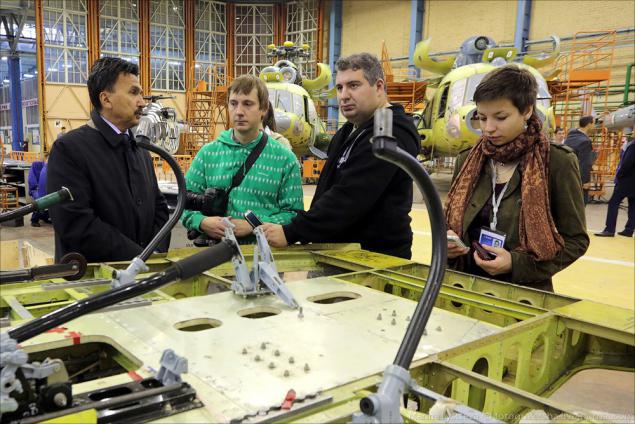

In October, I, Sergey and Lesch visited the Kazan Helicopter Plant, a subsidiary of the holding "Russian Helicopters", as bloggers are up there we have never been. We were shown the mechanical-assembly shop, final assembly, a little territory of the factory, and even test flight of the Mi-8.

But first things first.

History of the Kazan helicopter plant originates in 1933, when banks of the Volga in Kazan was founded on the production of processed wood. And the plant itself calculates its history since 4 September 1940, when the Order of People's Commissariat of the aviation industry was created by the Leningrad Aviation Plant number 387, which was later evacuated to Kazan and teamed up with the plant denote parts №169. Aviation fate of the company was defined in 1940, from this date is the history of the current count of "Kazan Helicopters". In 1941 he became the first biplane light aircraft issued by the plant.

50 pictures and text

2. The number of Po-2 issued during the war exceeded 10,000 (11,334 to be precise) aircraft, which was 10% of all aircraft produced in the Soviet Union during the war.

In 1951 he started serial production of the Mi-1 Mil constructed. To replace the Mi-1, Mi-4 came.

3. In 1956, the Kazan Helicopter Plant began supplying helicopters for export.

In 1965 began the production of the Mi-8. It was a turning point in the history of the plant. Modern helicopter Mi-17 and its modifications - is the result of the vast experience gained during the production and operation of Mi-8 helicopters.

Kazan Helicopter Production Association in 1993 transformed into a joint-stock company Kazan Helicopter Plant, and in 1996 was open - JSC "Kazan Helicopter Plant»

4. In the same year it was created for the development of CB Ansat light multipurpose.

Production of helicopters:

2006 - 53

2007 - 38

2008 - 58

2009 - 67

2010 - 81

2011 - 94

2012 - 103

In 2013 it is expected to increase about 10%

6. To date, CVD remains the world's largest helicopter manufacturer of the middle class.

7. The traditional Russian helicopter markets: Russia, the CIS countries, the nations of Southeast Asia, Africa, Central and South America. Currently, CVD technique provides about 90 countries (production holding "Helicopters of Russia" as a whole is represented in more than 110 countries).

8. This year is planned to reach a level of more than 100 cars per year, with almost unchanged composition of the working group - about 7 thousand people with an average age of 36 years (in the workshops of mechanical production, the plant the average age of today - 43, 2 years). And this is achieved due to the reorganization of production, which began in the early 2000s to the repair shops.

9. No less important stage of reorganization followed with the purchase of new equipment in machining production. Bought foreign-made machines, in connection with which labor input fell, while labor productivity increased by 4 times.

10. Frames are now processed on four three- and five - axis machines, which replaced 24 old (three lines of 8 machines each). Russia, unfortunately, does not produce such a machine level. In the photo - stamping treated prior to coating.

11. Ready-made frames go for further assembly.

12. Detail of the swash plate to "Ansat" was made before 18 hours, and is now 12. Because of the processing on multiple machines marriage was a large percentage. Now all of the turning, milling, drilling carried out in a single cycle. And so it is with many details.

In the photo the ring frame, which goes to the tail boom of a serial helicopter.

13. The hub damper. Not every customer orders it. Previously, the manufacture of the nave took 136 hours, is now 18 - time fell by almost eight times!

14. Service of the Chief Technologist is right there in the shop behind a glass partition and not have to wait long, as before, a specialist until he comes from another body.

15. The shop milling direction has 2 lines of the company «Mazak». One (4 machine) handles light alloy (Duralumin), the other (3 machines), only steel. Each machine has its own shop on 120 instruments, and "Steel" line more and shop center for 240 units. Replacing the instrument to "Steel" line is generated automatically - this inherent software.

16. Suppose cutters ended resource, computer program indicates the completion of the assigned resource, run the carriage picks up the cutter from the machine, exchanges and goes further processing details. And the operator picks up the spent your cutter. The tool goes to the regrinding, its characteristics change and it goes to another production. All tools with chips, which recorded the history of the life of parts.

17. During the restructuring department increased its capacity by more than three times. If you did earlier 6000 standard hours, but now the plan is coming to 21,000, and from January 2014 will be even more.

18. Before leaving here every day laden Dump duralumin chips currently waste was 4 times more, but the chips are converted into easy to transport briquettes, which after melting are in other industries.

Every 28 seconds from the press cake falls duralumin. Every 32 seconds - steel. Briquettes market cost 4-5 times more than the chips. Utrambovschik twisted chips into briquettes can not do, so it falls into the "meat grinder" and after grinding, also takes up less space.

19. Environmental Protection. The plant not found rats and mice.

20. Clean - the guarantee of economic growth in production.

21. Moving to the assembly plant.

From the beginning of the build up to the first flight of a helicopter is here an average of once a month, including house painting production.

22. JSC "Kazan Helicopter Plant", included in the holding company "Russian Helicopters", produces a family of Mi-8/17, which are operated in more than 100 countries.

23.

24. A wide range of modifications of these helicopters: transport, passenger, rescue, troop transport, and many others.

25. Since 1997, JSC "Kazan Helicopter Plant" has been certified developer helicopters today in mass production is light twin-engine helicopter "ANSAT».

26. Holding "Helicopters of Russia" - one of the world's leading helicopter industry, the only developer and manufacturer of helicopters in Russia, one of the few companies in the world, with capacity to design, manufacture, testing and maintenance of modern civil and military helicopters.

27. As of 2013, the enterprises "Helicopters of Russia" made 35% of the world fleet of combat helicopters, 17% of the world fleet of super-heavy helicopters maximum takeoff weight of more than 20 tons, and 56% of the world fleet moderate helicopters maximum takeoff weight of 8 to 15 tons .

28. Available in Kazan modification of the Mi-8/17 - a new generation of machines.

29. The unique performance characteristics, the most advanced avionics and special production equipment of Russian and foreign companies allow to fly at high altitudes in adverse weather conditions, at any time, automatically.

30. Multi-purpose helicopter capable of performing a wide range of tasks: transportation of cargoes, passengers, fire fighting, search and rescue, evacuation of the wounded.

31. For a short time the Mi-8/17 can be converted from transport to fire, rescue or ambulance. The options "salon", "flying hospital" and others.

32. The high level of security, reliability, simplicity and low cost of operation and maintenance is converted Mi-8/17 in one of the best selling helicopter in its class.

33. The blades are of two types - the metal and composite. In the above composite resource and less weight, but it requires a more expensive service at replacement or repair.

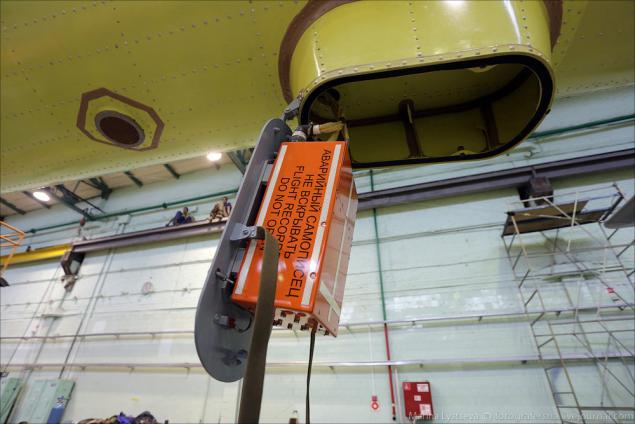

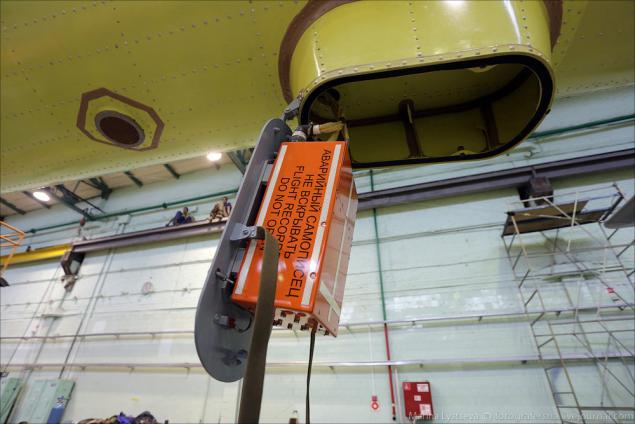

34. Black Box in the tail boom.

35.

36. Average freight and passenger Mi-38.

This helicopter is a new generation is able to provide a new level of comfort and safety in the performance of passenger transport and special works for category A (FAR-29). In the basic version of the Mi-38 can carry 30 passengers.

37. Today, the project of the Mi-38 entered a new stage.

The third flight prototype is being tested in flight test base of OJSC "Moscow Helicopter Plant. ML Mile "(part of" Helicopters of Russia "). This prototype is equipped with two turboshaft engines TV7-117V development of JSC "Klimov".

38. The first prototype of the Mi-38 OP-1 made its first flight (hovering) December 22, 2003, and the second prototype of the Mi-38 OP-2 - 24 January 2010. Both helicopters were equipped with one set of turboshaft engines Pratt & Whitney Canada PW127 / 5. The first Mi-38 OP-1 after removal from engines PW127 / 5 was in 2011 converted into a prototype version of the Mi-38-2 with the installation of engines TV7-117V.

39. JSC "Kazan Helicopters" started assembly of the fourth flight of the prototype. Helicopter type design OP-4 will be different from the prototype OP-3 shock-resistant fuel system of the company «Aerazur» enlarged openings and windows.

In addition to the manufacture of prototypes flying in 2013, in the framework of the ROC on the Mi-38, the process of manufacturing the fuselage and a set of separate units for fatigue tests, as well as components and assemblies for the test bench. OP-4 - the latest prototype of the helicopter before the start of serial production planned for 2015.

40. "ANSAT" in the Tatar language means "comfortable", "easy».

In 1993, CVD was created CB, whose goal was to develop a helicopter with a maximum takeoff weight of 3, 3 m, which must meet the requirements of aviation PAR-29.

41. In February 1997, "KHP" receives a certificate from the Interstate Aviation Committee, which allows for the development of these helicopters. The first flight of light multipurpose helicopter "ANSAT" was implemented in 1999 as a test pilot V.M.Rusetskim.

The scheduled performance

The maximum speed of 275 km / h

Cruising speed of 220 km / h

Max. range with the main tanks 520 km

Service ceiling 5,500 m

Static ceiling out of ground effect 3300 m

Mass Properties

Max. take-off weight 3300 kg

Max. payload kg 1184

GT Motors (2hPW207K, Pratt & Whitney)

The power takeoff 630 hp

Power to the emergency mode 710 hp

Dimensions salon

Length 5700 mm

Width 1770 mm

Height 1370 mm

Volume 8, 0 m3

Capacity

The flight crew 1-2

Passengers 7 +1

43. "ANSAT" - the only Russian helicopter, equipped with a digital electric remote control system (CCS-A). The presence of a digital control system allows the engine to simulate the engine off mode without stopping.

Transport-passenger helicopter modification is designed to perform a wide range of tasks:

- Transportation of cargoes and passengers to remote and inaccessible locations;

- Used as an air taxi in the city and between the settlements;

- Delivery of watches workers on offshore rigs;

- The use of a helicopter for corporate transport and general aviation.

45. Lifetime tests "Ansat" go to "KHP" since 1999.

46. Study modification of the helicopter "Ansat-U" designed to teach piloting a helicopter flight school cadets and civilians, as well as for the retraining of pilots and improve their skills. Equipment helicopter two turbine engines, combined with duplication of the most important basic units and systems provides a high level of safety to the specific conditions of flight training.

47. The entire territory was not allowed to take pictures of us, only a few helicopters. Because the secret has not been canceled.

48. We were lucky - we found a test flight of the Mi-17V-5. The machine flew away for half an hour, then returned.

49. That such beauty produces CVD - one of the leading enterprises of the holding company "Russian Helicopters", stepped 70-year milestone. The company does not cease to increase the pace of production from year to year. Workhorses made in Kazan, the total flown more than 50 million flight hours over the world, performing a variety of missions in the service of man. The main thing that a man chooses the task increasingly peaceful - and the helicopters do not disappoint!

Thank you for a detailed tour of the Director of Marketing and Sales Kazan Helicopters Valery Aleksandrovich Pashkov, chief machining production Kalyupa Igor, Galina and Vlade press service.

Source:

In October, I, Sergey and Lesch visited the Kazan Helicopter Plant, a subsidiary of the holding "Russian Helicopters", as bloggers are up there we have never been. We were shown the mechanical-assembly shop, final assembly, a little territory of the factory, and even test flight of the Mi-8.

But first things first.

History of the Kazan helicopter plant originates in 1933, when banks of the Volga in Kazan was founded on the production of processed wood. And the plant itself calculates its history since 4 September 1940, when the Order of People's Commissariat of the aviation industry was created by the Leningrad Aviation Plant number 387, which was later evacuated to Kazan and teamed up with the plant denote parts №169. Aviation fate of the company was defined in 1940, from this date is the history of the current count of "Kazan Helicopters". In 1941 he became the first biplane light aircraft issued by the plant.

50 pictures and text

2. The number of Po-2 issued during the war exceeded 10,000 (11,334 to be precise) aircraft, which was 10% of all aircraft produced in the Soviet Union during the war.

In 1951 he started serial production of the Mi-1 Mil constructed. To replace the Mi-1, Mi-4 came.

3. In 1956, the Kazan Helicopter Plant began supplying helicopters for export.

In 1965 began the production of the Mi-8. It was a turning point in the history of the plant. Modern helicopter Mi-17 and its modifications - is the result of the vast experience gained during the production and operation of Mi-8 helicopters.

Kazan Helicopter Production Association in 1993 transformed into a joint-stock company Kazan Helicopter Plant, and in 1996 was open - JSC "Kazan Helicopter Plant»

4. In the same year it was created for the development of CB Ansat light multipurpose.

Production of helicopters:

2006 - 53

2007 - 38

2008 - 58

2009 - 67

2010 - 81

2011 - 94

2012 - 103

In 2013 it is expected to increase about 10%

6. To date, CVD remains the world's largest helicopter manufacturer of the middle class.

7. The traditional Russian helicopter markets: Russia, the CIS countries, the nations of Southeast Asia, Africa, Central and South America. Currently, CVD technique provides about 90 countries (production holding "Helicopters of Russia" as a whole is represented in more than 110 countries).

8. This year is planned to reach a level of more than 100 cars per year, with almost unchanged composition of the working group - about 7 thousand people with an average age of 36 years (in the workshops of mechanical production, the plant the average age of today - 43, 2 years). And this is achieved due to the reorganization of production, which began in the early 2000s to the repair shops.

9. No less important stage of reorganization followed with the purchase of new equipment in machining production. Bought foreign-made machines, in connection with which labor input fell, while labor productivity increased by 4 times.

10. Frames are now processed on four three- and five - axis machines, which replaced 24 old (three lines of 8 machines each). Russia, unfortunately, does not produce such a machine level. In the photo - stamping treated prior to coating.

11. Ready-made frames go for further assembly.

12. Detail of the swash plate to "Ansat" was made before 18 hours, and is now 12. Because of the processing on multiple machines marriage was a large percentage. Now all of the turning, milling, drilling carried out in a single cycle. And so it is with many details.

In the photo the ring frame, which goes to the tail boom of a serial helicopter.

13. The hub damper. Not every customer orders it. Previously, the manufacture of the nave took 136 hours, is now 18 - time fell by almost eight times!

14. Service of the Chief Technologist is right there in the shop behind a glass partition and not have to wait long, as before, a specialist until he comes from another body.

15. The shop milling direction has 2 lines of the company «Mazak». One (4 machine) handles light alloy (Duralumin), the other (3 machines), only steel. Each machine has its own shop on 120 instruments, and "Steel" line more and shop center for 240 units. Replacing the instrument to "Steel" line is generated automatically - this inherent software.

16. Suppose cutters ended resource, computer program indicates the completion of the assigned resource, run the carriage picks up the cutter from the machine, exchanges and goes further processing details. And the operator picks up the spent your cutter. The tool goes to the regrinding, its characteristics change and it goes to another production. All tools with chips, which recorded the history of the life of parts.

17. During the restructuring department increased its capacity by more than three times. If you did earlier 6000 standard hours, but now the plan is coming to 21,000, and from January 2014 will be even more.

18. Before leaving here every day laden Dump duralumin chips currently waste was 4 times more, but the chips are converted into easy to transport briquettes, which after melting are in other industries.

Every 28 seconds from the press cake falls duralumin. Every 32 seconds - steel. Briquettes market cost 4-5 times more than the chips. Utrambovschik twisted chips into briquettes can not do, so it falls into the "meat grinder" and after grinding, also takes up less space.

19. Environmental Protection. The plant not found rats and mice.

20. Clean - the guarantee of economic growth in production.

21. Moving to the assembly plant.

From the beginning of the build up to the first flight of a helicopter is here an average of once a month, including house painting production.

22. JSC "Kazan Helicopter Plant", included in the holding company "Russian Helicopters", produces a family of Mi-8/17, which are operated in more than 100 countries.

23.

24. A wide range of modifications of these helicopters: transport, passenger, rescue, troop transport, and many others.

25. Since 1997, JSC "Kazan Helicopter Plant" has been certified developer helicopters today in mass production is light twin-engine helicopter "ANSAT».

26. Holding "Helicopters of Russia" - one of the world's leading helicopter industry, the only developer and manufacturer of helicopters in Russia, one of the few companies in the world, with capacity to design, manufacture, testing and maintenance of modern civil and military helicopters.

27. As of 2013, the enterprises "Helicopters of Russia" made 35% of the world fleet of combat helicopters, 17% of the world fleet of super-heavy helicopters maximum takeoff weight of more than 20 tons, and 56% of the world fleet moderate helicopters maximum takeoff weight of 8 to 15 tons .

28. Available in Kazan modification of the Mi-8/17 - a new generation of machines.

29. The unique performance characteristics, the most advanced avionics and special production equipment of Russian and foreign companies allow to fly at high altitudes in adverse weather conditions, at any time, automatically.

30. Multi-purpose helicopter capable of performing a wide range of tasks: transportation of cargoes, passengers, fire fighting, search and rescue, evacuation of the wounded.

31. For a short time the Mi-8/17 can be converted from transport to fire, rescue or ambulance. The options "salon", "flying hospital" and others.

32. The high level of security, reliability, simplicity and low cost of operation and maintenance is converted Mi-8/17 in one of the best selling helicopter in its class.

33. The blades are of two types - the metal and composite. In the above composite resource and less weight, but it requires a more expensive service at replacement or repair.

34. Black Box in the tail boom.

35.

36. Average freight and passenger Mi-38.

This helicopter is a new generation is able to provide a new level of comfort and safety in the performance of passenger transport and special works for category A (FAR-29). In the basic version of the Mi-38 can carry 30 passengers.

37. Today, the project of the Mi-38 entered a new stage.

The third flight prototype is being tested in flight test base of OJSC "Moscow Helicopter Plant. ML Mile "(part of" Helicopters of Russia "). This prototype is equipped with two turboshaft engines TV7-117V development of JSC "Klimov".

38. The first prototype of the Mi-38 OP-1 made its first flight (hovering) December 22, 2003, and the second prototype of the Mi-38 OP-2 - 24 January 2010. Both helicopters were equipped with one set of turboshaft engines Pratt & Whitney Canada PW127 / 5. The first Mi-38 OP-1 after removal from engines PW127 / 5 was in 2011 converted into a prototype version of the Mi-38-2 with the installation of engines TV7-117V.

39. JSC "Kazan Helicopters" started assembly of the fourth flight of the prototype. Helicopter type design OP-4 will be different from the prototype OP-3 shock-resistant fuel system of the company «Aerazur» enlarged openings and windows.

In addition to the manufacture of prototypes flying in 2013, in the framework of the ROC on the Mi-38, the process of manufacturing the fuselage and a set of separate units for fatigue tests, as well as components and assemblies for the test bench. OP-4 - the latest prototype of the helicopter before the start of serial production planned for 2015.

40. "ANSAT" in the Tatar language means "comfortable", "easy».

In 1993, CVD was created CB, whose goal was to develop a helicopter with a maximum takeoff weight of 3, 3 m, which must meet the requirements of aviation PAR-29.

41. In February 1997, "KHP" receives a certificate from the Interstate Aviation Committee, which allows for the development of these helicopters. The first flight of light multipurpose helicopter "ANSAT" was implemented in 1999 as a test pilot V.M.Rusetskim.

The scheduled performance

The maximum speed of 275 km / h

Cruising speed of 220 km / h

Max. range with the main tanks 520 km

Service ceiling 5,500 m

Static ceiling out of ground effect 3300 m

Mass Properties

Max. take-off weight 3300 kg

Max. payload kg 1184

GT Motors (2hPW207K, Pratt & Whitney)

The power takeoff 630 hp

Power to the emergency mode 710 hp

Dimensions salon

Length 5700 mm

Width 1770 mm

Height 1370 mm

Volume 8, 0 m3

Capacity

The flight crew 1-2

Passengers 7 +1

43. "ANSAT" - the only Russian helicopter, equipped with a digital electric remote control system (CCS-A). The presence of a digital control system allows the engine to simulate the engine off mode without stopping.

Transport-passenger helicopter modification is designed to perform a wide range of tasks:

- Transportation of cargoes and passengers to remote and inaccessible locations;

- Used as an air taxi in the city and between the settlements;

- Delivery of watches workers on offshore rigs;

- The use of a helicopter for corporate transport and general aviation.

45. Lifetime tests "Ansat" go to "KHP" since 1999.

46. Study modification of the helicopter "Ansat-U" designed to teach piloting a helicopter flight school cadets and civilians, as well as for the retraining of pilots and improve their skills. Equipment helicopter two turbine engines, combined with duplication of the most important basic units and systems provides a high level of safety to the specific conditions of flight training.

47. The entire territory was not allowed to take pictures of us, only a few helicopters. Because the secret has not been canceled.

48. We were lucky - we found a test flight of the Mi-17V-5. The machine flew away for half an hour, then returned.

49. That such beauty produces CVD - one of the leading enterprises of the holding company "Russian Helicopters", stepped 70-year milestone. The company does not cease to increase the pace of production from year to year. Workhorses made in Kazan, the total flown more than 50 million flight hours over the world, performing a variety of missions in the service of man. The main thing that a man chooses the task increasingly peaceful - and the helicopters do not disappoint!

Thank you for a detailed tour of the Director of Marketing and Sales Kazan Helicopters Valery Aleksandrovich Pashkov, chief machining production Kalyupa Igor, Galina and Vlade press service.

Source: