1087

Rostvertol - Rostov Helicopter Plant

Complex production is always fascinating. Especially when it is a full cycle. As if by magic from a roll of metal there are a lot of details. Some less, some more. A thousand sets of eventually appears airplane or helicopter. There is a downside - it's hard for a short time to view the entire cycle. And even more so in a short report to show everything from A to Z. So we watch the fun!

At this time, let us enter a visit to Rostov Helicopter Plant, which is part of the holding "Russian Helicopters". By the way, now in operation around the world more than 8,500 cars in Russia. At the general global market share of sales of the holding is 14%.

As of 2013 the holding enterprises produced 35% of the world fleet of combat helicopters, 17% of superheavy (maximum takeoff weight of more than 20 tons) and 56% moderate helicopters with a maximum take-off weight of 8 to 15 tons.

And now let us return to the secret plant, which produces combat helicopters Mi-28N, Mi-35M and multipurpose helicopter Mi-26T. Some time ago to provide such a trip was impossible. Now - easily. In addition, a group of foreign journalists.

During the visit we were shown Workshops №№ 3, 5, 12 and vane plant. Under the cut, you will learn what it is and what they do.

1. Our tour begins with a workshop №12 -GLUING electroplating on the details.

2. Before assembly, all aluminum parts of the helicopter to protect against corrosion. Do it on a plot of anodizing. Processing parts in various chemical solutions, under the influence of an electric current on the metal surface to create a solid oxide film that protects it.

3. The oxide film has micropores, which may be of corrosion, since they have access through to the base metal. To eliminate this, the items must pass the stage of filling, during which all possible pores will be closed from the environment. For this purpose different solutions. They also give a new color aluminum.

4. Aviation, production, kote and beautiful girl. All in one shot!

5. In the factory airfield is a small museum. I can not say that there were some unique exhibits, but still shows those machines which were produced at the plant. Here is a flying crane Mi-10K. The main purpose of the basic version was supposed to be shipping cruise and ballistic missiles, but this was soon abandoned. The helicopter remained unclaimed, but the project was transformed into a flying crane, which has found application in the national economy.

6. Helicopter with a smile.

7. Instead of TV cameras did not justify itself to control the helicopter during the loading and unloading of the Mi-10K was equipped with a second, false pilot cabin with all-round visibility and a third set of controls. I had to fly backwards!

8. Lena and Mi-1. The first serial Soviet helicopter.

9. Mi-6. When I first saw it a long time, he is very surprised with their wings. By the way, for the first time in the USSR on this helicopter was provided freight on external sling. This helicopter is the first time in the world in 1961 has overcome the barrier of 300 km / h, which was then considered the limit for helicopters.

10. Brazilian AH-2 Sabre, aka Mi-35M-3.

11. In 2008, a contract was signed to supply 12 Mi-35M to $ 150 million.

12. Name of the Mi-35 was first introduced to denote export version of the Mi-24V, put into service in 1976.

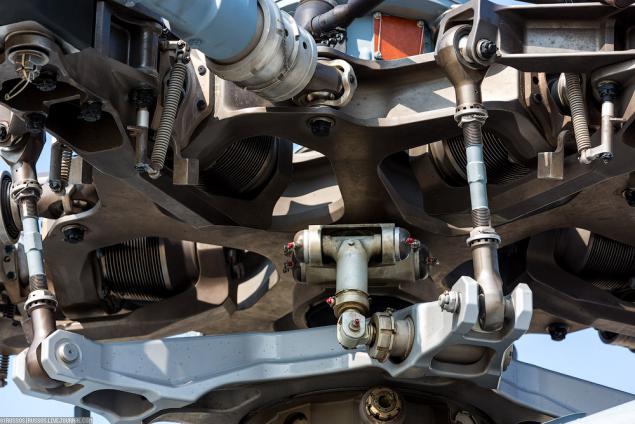

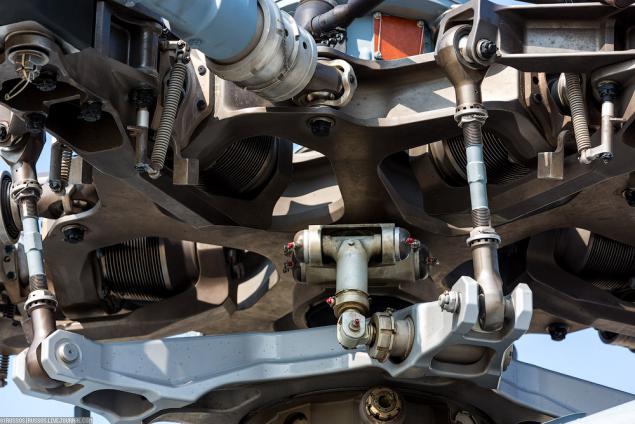

13. One of the most beautiful technical solutions - swashplate.

14. When you create a Mi-35M used technology that has been implemented in the new generation helicopter Mi-28N "Night Hunter".

15. This training version of the Mi-28 index UB. Apparently, combat training.

16. The first flight of the car is perfect, as you can see, the ninth of August this year.

17. This workshop №5 - flight test station.

18. There is carried out ground tests and flight testing of all types of helicopters, manufactured at the factory.

19. The unofficial name "Crocodile". Became the first Soviet and the second in the world (after the AH-1 "Cobra") specialized attack helicopters.

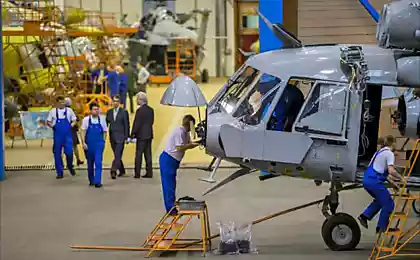

20. Workshop №3 - final assembly shop.

21. There a lot of parts and components is finally becoming a helicopter.

22. Installation of the equipment in the cockpit of the Mi-26T.

23. As you can see, the helicopters in order to save space without the cost of the blades. They put only then. pictured helicopter truth and without sleeves yet :)

24. The cargo compartment of the Mi-26. What is he big!

25. Mi-26T. Apparently awaiting repairs.

26. swashplate Mi-28N.

27. Installation of the equipment in the cockpit of the Mi-35M

28. Hundreds of wires.

29. The fuselage of the Mi-26T.

30. But the most interesting, as it turned out, was on a blade factory. The photograph steel spar from the Mi-26. This is a tricky harvesting, variable cross-section and thickness.

31. Pay attention to the white tube. They then pulled out, creating links between the coil and the spar. The fact that the additional control in the inert gas is injected into the spar. In the case of crack it emerges from these channels and reaches the receiving reservoir and mechanically triggers the sensor.

32. Plot winding spar blades and tail rotor.

33. Further, in one day is done shaping spar.

34. In contrast to steel, composite spar is more resistant to battle damage.

35. Various blade. By the way, one blade of the Mi-26 weighs 399 kg!

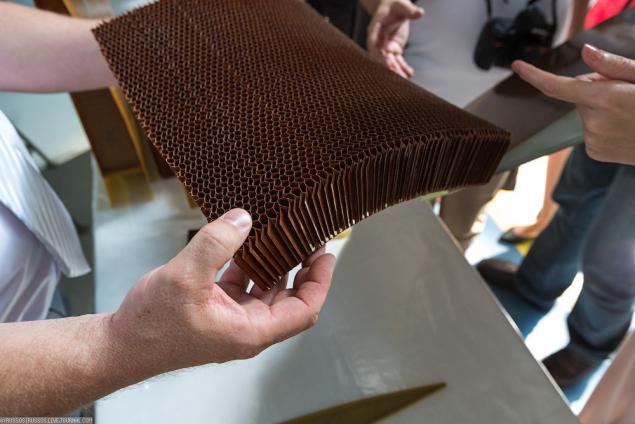

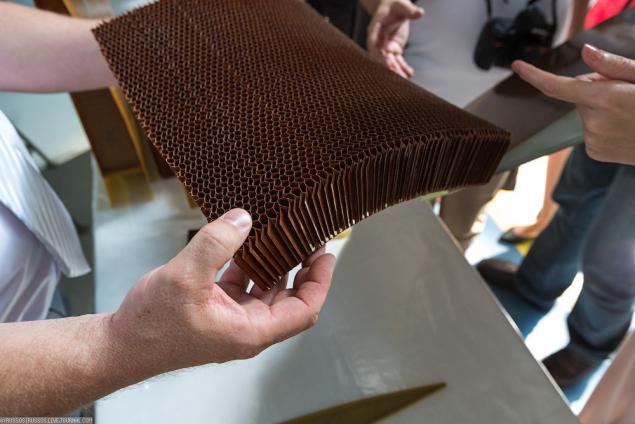

36. Honeycomb, which is used in the endings of the blade.

37. Built-icing system and a visual indicator of the gas leak spar.

38. !!!

Source:

At this time, let us enter a visit to Rostov Helicopter Plant, which is part of the holding "Russian Helicopters". By the way, now in operation around the world more than 8,500 cars in Russia. At the general global market share of sales of the holding is 14%.

As of 2013 the holding enterprises produced 35% of the world fleet of combat helicopters, 17% of superheavy (maximum takeoff weight of more than 20 tons) and 56% moderate helicopters with a maximum take-off weight of 8 to 15 tons.

And now let us return to the secret plant, which produces combat helicopters Mi-28N, Mi-35M and multipurpose helicopter Mi-26T. Some time ago to provide such a trip was impossible. Now - easily. In addition, a group of foreign journalists.

During the visit we were shown Workshops №№ 3, 5, 12 and vane plant. Under the cut, you will learn what it is and what they do.

1. Our tour begins with a workshop №12 -GLUING electroplating on the details.

2. Before assembly, all aluminum parts of the helicopter to protect against corrosion. Do it on a plot of anodizing. Processing parts in various chemical solutions, under the influence of an electric current on the metal surface to create a solid oxide film that protects it.

3. The oxide film has micropores, which may be of corrosion, since they have access through to the base metal. To eliminate this, the items must pass the stage of filling, during which all possible pores will be closed from the environment. For this purpose different solutions. They also give a new color aluminum.

4. Aviation, production, kote and beautiful girl. All in one shot!

5. In the factory airfield is a small museum. I can not say that there were some unique exhibits, but still shows those machines which were produced at the plant. Here is a flying crane Mi-10K. The main purpose of the basic version was supposed to be shipping cruise and ballistic missiles, but this was soon abandoned. The helicopter remained unclaimed, but the project was transformed into a flying crane, which has found application in the national economy.

6. Helicopter with a smile.

7. Instead of TV cameras did not justify itself to control the helicopter during the loading and unloading of the Mi-10K was equipped with a second, false pilot cabin with all-round visibility and a third set of controls. I had to fly backwards!

8. Lena and Mi-1. The first serial Soviet helicopter.

9. Mi-6. When I first saw it a long time, he is very surprised with their wings. By the way, for the first time in the USSR on this helicopter was provided freight on external sling. This helicopter is the first time in the world in 1961 has overcome the barrier of 300 km / h, which was then considered the limit for helicopters.

10. Brazilian AH-2 Sabre, aka Mi-35M-3.

11. In 2008, a contract was signed to supply 12 Mi-35M to $ 150 million.

12. Name of the Mi-35 was first introduced to denote export version of the Mi-24V, put into service in 1976.

13. One of the most beautiful technical solutions - swashplate.

14. When you create a Mi-35M used technology that has been implemented in the new generation helicopter Mi-28N "Night Hunter".

15. This training version of the Mi-28 index UB. Apparently, combat training.

16. The first flight of the car is perfect, as you can see, the ninth of August this year.

17. This workshop №5 - flight test station.

18. There is carried out ground tests and flight testing of all types of helicopters, manufactured at the factory.

19. The unofficial name "Crocodile". Became the first Soviet and the second in the world (after the AH-1 "Cobra") specialized attack helicopters.

20. Workshop №3 - final assembly shop.

21. There a lot of parts and components is finally becoming a helicopter.

22. Installation of the equipment in the cockpit of the Mi-26T.

23. As you can see, the helicopters in order to save space without the cost of the blades. They put only then. pictured helicopter truth and without sleeves yet :)

24. The cargo compartment of the Mi-26. What is he big!

25. Mi-26T. Apparently awaiting repairs.

26. swashplate Mi-28N.

27. Installation of the equipment in the cockpit of the Mi-35M

28. Hundreds of wires.

29. The fuselage of the Mi-26T.

30. But the most interesting, as it turned out, was on a blade factory. The photograph steel spar from the Mi-26. This is a tricky harvesting, variable cross-section and thickness.

31. Pay attention to the white tube. They then pulled out, creating links between the coil and the spar. The fact that the additional control in the inert gas is injected into the spar. In the case of crack it emerges from these channels and reaches the receiving reservoir and mechanically triggers the sensor.

32. Plot winding spar blades and tail rotor.

33. Further, in one day is done shaping spar.

34. In contrast to steel, composite spar is more resistant to battle damage.

35. Various blade. By the way, one blade of the Mi-26 weighs 399 kg!

36. Honeycomb, which is used in the endings of the blade.

37. Built-icing system and a visual indicator of the gas leak spar.

38. !!!

Source: