692

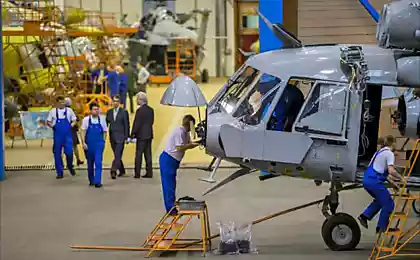

Report from Kazan Helicopters

JSC "Kazan Helicopters" - the manufacturer of helicopters Mi-8/17, following helicopter belongs to the Russian holding "Helicopters of Russia". The plant carries out a full cycle of helicopters from the development and serial production to after-sales support, training and repair. In the history of the company more than 12,000 Mi-4, Mi-8, Mi-14, Mi-17, & quot; «ANSAT & quot; and their modifications put in 100 countries.

28 ph + letter

LJ via

2.

3. Turning shop is equipped with machining centers Japanese company company Mazak.

4. Transporter ppallet on the automated line

5. The tool magazine machining center

6. lobed production

Kazan Helicopter Plant - the only one in Russia and in the world of enterprise producing blades in three fundamentally different technologies: the production of metal blades, composite blades by winding and calculations.

7. Production of metal blades.

The basis of the framework laid stiffness in the form of honeycomb. Stretching the cell block.

8. Stretch cell block

9. ribs

It is an element of the power set of cross-frame blades, designed to give them the shape of the profile.

10. Garter cell block to the ribs

11. The application of a primer on the spar

12. Trim the adhesive film with the heating pad assembly

13. Check the quality of the bond with the tail section spar

14.

15. Aggregate-assembly shop

16. Work on the drilling and riveting on wings hood picking stand (preparatory work before installing the bonnet on the fuselage)

17. The upper area of the stand mounting hoods of the power plant on the fuselage.

18. Assembling and riveting landing seat.

19. Riveted seams on the surface of the tail boom

20. Assembling and riveting parts (components) of the end beam

21. Assembling and riveting stabilizer

22. The assembly shop.

In the photo the product Mi-17V-5

23. Installation of bundles in the engine compartment

24. Installation of bundles in the cockpit

25.

26. Installation of bundles under the floor gruzkabiny Mi-38

27. Installation of a single dashboard

28. Russian-made helicopters manufactured in Kazan, the total flown more than 50 million flight hours worldwide.

For example, the Mi-17V-5 will fly to Azerbaijan ...

© Stepanov Thank

Source:

28 ph + letter

LJ via

2.

3. Turning shop is equipped with machining centers Japanese company company Mazak.

4. Transporter ppallet on the automated line

5. The tool magazine machining center

6. lobed production

Kazan Helicopter Plant - the only one in Russia and in the world of enterprise producing blades in three fundamentally different technologies: the production of metal blades, composite blades by winding and calculations.

7. Production of metal blades.

The basis of the framework laid stiffness in the form of honeycomb. Stretching the cell block.

8. Stretch cell block

9. ribs

It is an element of the power set of cross-frame blades, designed to give them the shape of the profile.

10. Garter cell block to the ribs

11. The application of a primer on the spar

12. Trim the adhesive film with the heating pad assembly

13. Check the quality of the bond with the tail section spar

14.

15. Aggregate-assembly shop

16. Work on the drilling and riveting on wings hood picking stand (preparatory work before installing the bonnet on the fuselage)

17. The upper area of the stand mounting hoods of the power plant on the fuselage.

18. Assembling and riveting landing seat.

19. Riveted seams on the surface of the tail boom

20. Assembling and riveting parts (components) of the end beam

21. Assembling and riveting stabilizer

22. The assembly shop.

In the photo the product Mi-17V-5

23. Installation of bundles in the engine compartment

24. Installation of bundles in the cockpit

25.

26. Installation of bundles under the floor gruzkabiny Mi-38

27. Installation of a single dashboard

28. Russian-made helicopters manufactured in Kazan, the total flown more than 50 million flight hours worldwide.

For example, the Mi-17V-5 will fly to Azerbaijan ...

© Stepanov Thank

Source: