1592

The past greatness: the atomic icebreaker "Lenin"

Let friends, another Temko about the past greatness of the country.

Many seas surrounding our country, in the winter covered with ice. This makes it difficult and often completely interrupted navigation. Then come to the aid of ships powerful icebreakers. Through the thick ice convoys they spend at the destination port.

Of particular importance acquired icebreakers on the Northern Sea Route, linking the west and east of the Soviet Union. This difficult trail along its entire length covered during the long months of heavy polar ice.

Swimming in the Arctic is limited to the short Arctic summer. It often happens that in the summer and ice prevent the movement of ships. Without icebreakers can not do.

Modern icebreakers - a mighty steel giants, leading a bitter struggle with the ice. But how long is sailing without calling at the ports they can not. Even the best icebreakers with diesel power-plant fuel reserves are not more than 30-40 days. In the harsh conditions of the Arctic, this is clearly not enough: after a struggle with the ice requires a lot of fuel. An hour a powerful icebreaker often burns up to three tons. Although fuel reserves make up almost one third of the weight of the icebreaker in the Arctic during the navigation has to ship several times to enter the base to refuel. There were cases when convoys wintered in polar ice just because fuel supplies ran low on ice breakers ahead of time.

The success of Soviet scientists in the peaceful use of nuclear energy will help in the service of our national economy a new type of fuel. The Soviet people have learned to use the energy of the atom, and water transport. Thus was born the idea of creating an icebreaker, moving with the help of nuclear energy. This idea was realized only after our country was put into operation the world's first nuclear power plant and has accumulated the necessary experience for further work on the establishment of nuclear power plants.

So the world's first nuclear-powered icebreaker "Lenin»

20 ph and text, respectively

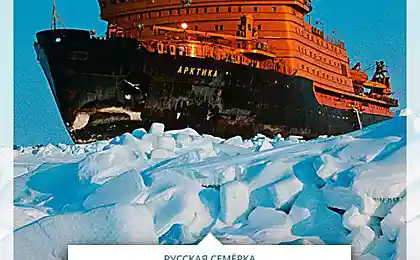

Nuclear-powered icebreaker "Lenin»,

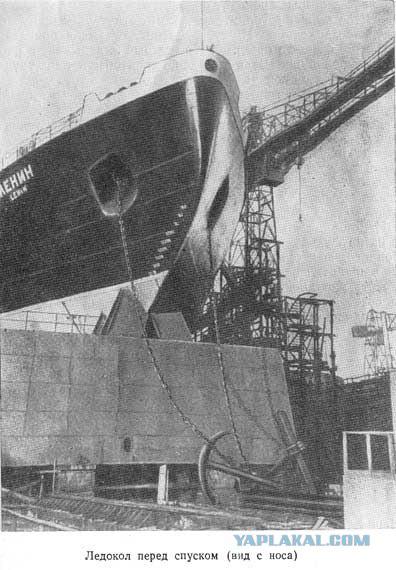

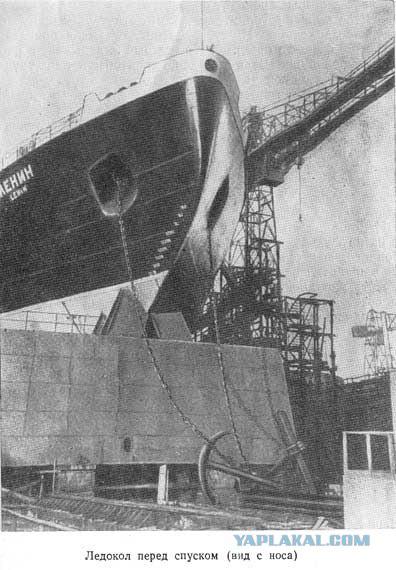

the world's first ship civilian nuclear power plant established in the USSR. A. l. "Lenin" was launched on 5 December 1957; He came into operation in late 1959. It is intended for posting cargo ships along the Northern Sea route and diving expedition in the Arctic. Main features: displacement (without ballast) 16 thous. Tonnes, power of main turbine 32, 4 MW (44 thous. Liters. S.), The maximum length of 134, 0 m, width 27, 6 m, depth 16, 1 m, speed in pure water of 18 kt (33 3 km / h). It has good ice passability. A. l. "Lenin" - a flush vessel with an elongated bridge structure and two masts, aft of the available runway platform for helicopter ice reconnaissance. Nuclear steam capacity of the installation of water-water type, located in the central part of the vessel produces steam for the 4 main turbine generators supplying direct current propulsion motors 3, the latter is driven 3 propellers (2 onboard and 1 medium) particularly robust design. There are two stand-alone auxiliary power. Control mechanisms, devices and systems - remote. The crew created good living conditions for the long Arctic navigation. Fully provided radiation safety personnel icebreaker and the environment.

The Communist Party and the Soviet government, to appreciate the achievements of our scientists decided to wide use of nuclear energy in the national economy.

XX Congress of the CPSU aimed at the deployment of works on creation of nuclear power plants for transport purposes, to build a nuclear-powered icebreaker.

It was about the creation of a vessel which can float for very long without calling at ports for fuel.

Scientists estimate that the nuclear-powered icebreaker will consume 45 grams per day of nuclear fuel - as much as will fit in a matchbox. That's why the icebreaker, having virtually unlimited navigation area, will be able to visit in one trip, and in the Arctic, and off the coast of Antarctica. For vessels with nuclear power plant range of distance - not an obstacle.

Honorable and responsible task of construction of the first nuclear-powered icebreaker in the world has been entrusted to the Admiralty Shipyard in Leningrad.

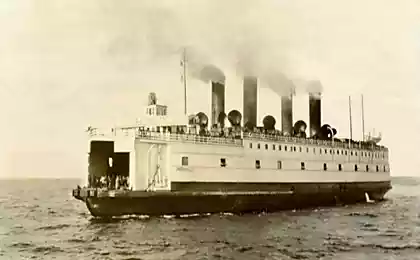

Admiralteytsy had a lot of experience in repair and construction of icebreakers. Back in 1928, they overhauled the "grandfather of the icebreaker fleet" - the famous "Ermak" (pictured below). Its renovation was a good school for admiralteytsev allowed in the future go to the construction of icebreakers.

There was, first of all, the question of how to create a compact nuclear power plant, which would have, and high power, and high survivability under pitching, shock and vibration.

Next, the team was required to ensure the safety of the icebreaker from the harmful effects of radiation associated with the operation of the nuclear reactor, the more that the protection against ionizing radiation in the operation of the icebreaker is much more complicated than, for example, on a coastal nuclear power plant. This is understandable - on a ship for technical reasons it is impossible to install bulky and heavy protective equipment.

The construction of an atomic icebreaker require unique manufacturing power equipment, creating an unprecedented body strength is still full process automation power system management.

Particular attention in the design of the hull has been paid to the shape of the bow, which largely depend on the quality of ice-breaking vessel. Selected for nuclear-powered lines in comparison with existing icebreakers can increase the pressure on the ice. Aft is designed to provide flotation on the ice when reversing and protection of screws and steering from the blows of the ice.

In practice, it was observed that icebreakers sometimes get stuck in the ice not just bow or stern, and sides. To avoid this, it was decided to arrange a special system on the submarine ballast tank. If one side of the tank to pump water into the tank the other side, the vessel rocking from side to side will break the ice and push the sides. The same system of tanks installed in the bow and stern. And if the icebreaker did not break the ice with the course and stuck his nose? Then it is possible to pump water from the aft trim tank in the bow. Pressure will grow on the ice, it will break, and the icebreaker out of ice captivity.

To ensure that such a large ship unsinkable, if the lining is damaged, the body decided to be divided into sections of eleven main transverse watertight bulkheads. In the calculation of the atomic icebreaker designers provided the unsinkable ship by flooding the two largest bays.

These are briefly the main features of the icebreaker, which was to build a team of Admiralty Plant.

Builders housing met with considerable difficulties. It was not easy, for example, stainless steel handle. Previously dominated by machining. This required a lot of time.

Engineers Boris Smirnov, G. Schneider, master A. Golubtsov and cutter Makarov designed and manufactured the original gas-flux cutter. In this way it succeeded in short time efficiently handle a significant portion of parts made of stainless steel. These days, the factory became famous for his work communities welding engineer Bureau B. Smirnov and cutter Makarov. It is about them in the original large-circulation newspaper appeared poems:

Mastered cutting thickness of steel,

Invented Machine,

Engineers and workers - each character,

Inquiring no barriers!

Persistently overcome the first difficulty. But the main difficulties were still ahead; especially a lot of them met on the slipway works and completion of an icebreaker.

Nuclear icebreaker as the most powerful ship in the entire icebreaker fleet designed to fight ice in the toughest conditions; so his body should be particularly strong. The high strength of the body, it was decided to provide the use of a new steel grade. This steel has high toughness. It is well weldable and has a greater resistance to crack propagation at low temperatures.

The housing design nuclear-powered, the system will set it as different from other icebreakers. Bottom, sides, internal deck, platform, and the upper deck in the extremities were recruited by the transverse framing system, and the upper deck in the middle of the ice-breaker - for the longitudinal system.

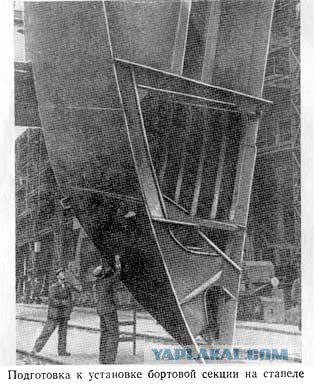

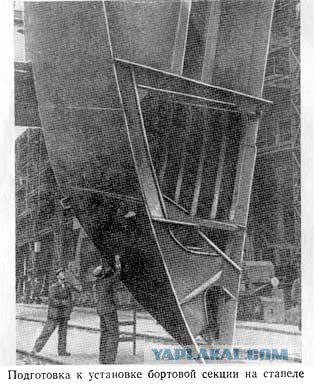

The body height in a good five-story building consists of sections weighing up to 75 tons. Such large sections, there were about two hundred.

Assembly and welding of sections of land led pre-assembly of the body shop.

Before beginning work in the office area of the masters gathered Communists. Everyone worried about one issue: how to better and faster to build nuclear-powered icebreaker?

It was also decided to make three staff development section to finally resolve all issues related to the new technology. These sections are the most sophisticated in design - one of the bottom and two side bow - has gathered a team of Pavel Pimenov, one of the best builders of the plant. Assembling advanced sections allowed us to determine how to collect and welded sections weighing up to 75 tons.

With the pre-assembly area ready section goes directly to the slipway. Collectors checker and immediately set them in place.

In the manufacture of components for the first pilot staff sections revealed that the steel sheets from which they are to be made, weighing 7 tons, and were available at the blank portion of the cranes had a lifting capacity of only up to 6 tons.

Press also had insufficient power. It seemed that there was an insoluble problem.

In discussing this issue it was proposed to establish a more powerful cranes. Some, citing insufficient capacity crane economy and the lack of the necessary presses, offering large-scale processing of thick sheet metal body parts of complex design to transfer to another plant. The latter path was simple and easy, but is related to a waste of public funds. To accept such a proposal would be to carry the metal and templates on the side, and then to carry the items back; I would lose a lot of time and money.

And, indeed, the solution was found. Senior Technologist shop B. Fyodorov, head of the bureau of technological preparation Mikhailov, deputy section chief Mikhail Leonov, master Makarov, gibschiki innovators Rogalev I., V. Ivanov, A. Gvozdev offered treatment and flexible sheet cladding icebreaker produce , without resorting to an increase in capacity of crane equipment, or the replacement of bending presses. Experimental work has shown that the existing factory equipment it is suitable for metal processing. So it was saved about 200 thousand rubles.

Great icebreaker plating thickness required special skills of the workers in the bending parts, as in presses that existed at the plant, so the thickness of the metal cold bending previously exposed. At the initiative of Engineers Gurevich and Nikolai Martynov processing sheet cladding ice belt was mastered in corp soobrabatyvayuschem shop, where heavy manual operations have been completely eliminated.

The amount of welding on the stocks was very high: the icebreaker hull - welded. Someone made a kinda count how many stitches have to make the stocks sector workers? Figured. The result was a considerable figure if all welds to pull in one line, it will stretch from Leningrad to Vladivostok!

The amount of welding forced to think seriously about how to speed up the welding structures. It was decided to implement a wider automatic and semiautomatic welding. Welders set to work on a new method.

It should tell you about one more instructive example of close co-workers, engineers and scientists.

According to the approved design technology of stainless steel welded manually. Here, however, qualified welders to work, but the work went very slowly. How to speed up welding? Only replacing the manual work automatic welding! But the automatic welding of stainless steel have not been applied. However, workers believe that it is possible to cook a gun and "stainless steel". We came to the aid of scientists. Employee Research Institute K. Mladzievsky together with specialists of the plant Zhiltsova K., A. Shvedchikov, M. matzah, N. Stoma and other experienced on steel rails picked up the necessary operating conditions. It conducted more than 200 experiments; Finally, the welding conditions have been fulfilled. Senior

Almost daily production korpusniki held serious examination. A construction time was short. From how to cope with their tasks korpusniki depended term icebreaker descent into the water.

.

There was, for example, such a case. Due to the very large size it can not be delivered by rail to the plant form and stern-post - the main structure of the nose and stern. Massive, heavy, weighing 30 and 80 g, - they do not put on any railway platforms. Engineers and workers decided to make shtevni directly at the plant, boil them parts.

To present the complexity of the assembly and welding of field joints shtevney, suffice it to say that the minimum thickness of the welded part reaches 150 mm.

Welding stem lasted 15 days in 3 shifts !!!

While on the stocks it erected a housing in the different shops of the plant produced and mounted parts, pipelines and appliances. Many of them have dealt with the other businesses. The whole country is generously sent their gifts admiralteytsam -o products for the icebreaker. The main turbine generators were built at the Kharkov Electromechanical Plant, propulsion motors - at the Leningrad plant "Electrosila" Kirov, where to create unique arrangements worked team of engineers and technicians, led by the oldest designer of the plant Kashin. These motors are designed in the Soviet Union for the first time.

In the shops of the famous Kirov factory gathered steam turbines. Above order for the nuclear-powered icebreaker I worked here a great team of designers, led by M. Kozak. In the course of Kirov workers have made a lot of improvements that allow reduction in weight and size of the turbines. Kirov workers coped with the executive order.

At this time, at the Admiralty Works widely developed socialist competition for a worthy meeting of the 40th anniversary of the October Revolution. Most important is the reduction of the period of preparation of the icebreaker to be launched.

The staff of the mechanical assembly shop early for the icebreaker passed all the boring device. In the shop there was a "lightning", "Comrades! Equals at Turner borer Medvedev, made on the three days before the term of the order is responsible for construction of the atomic icebreaker "Lenin"! »

It was an outstanding victory. The fact that the norms were supposed to produce the desired snap two of the workers. However, this work was assigned to one M. Medvedev, as the rest were loaded borer other urgent orders. Medvedev assured his comrades: "Mastering one will not fail!" .. Having prepared the machine, cutters, auxiliary tools and compacted to limit the working day, he labored faithfully for two and completing quests, not only in time, and even earlier.

Such heroes of labor in the factory had many. People did what had seemed impossible. Marker V. Alexandrov and B. Puyto just two days coped with the markings of the rudder. But this "feather" weighs 30 tons !!!

As soon as we handled the rudder on the boring machine lathe I. Anashkin working in the shop 20 years bole bore multi-ton rudder - steering shaft - at the same pace had experienced working with his K. Podgayskiy changer Fomin. Extremely hard work - assembling the steering apparatus drive - prematurely implemented brigade collectors M. and A. Malyushkina Podlazova.

The assembly of the rudder was assigned one of the leading teams of pickers - a brigade of N. Vagina malokorpusnogo shop. Master G. Zubok, the foreman, and all the workers carefully studied the drawings, thought through how best to organize the work.

First they collected and welded frame in an upright position. Then, in the horizontal position, welded thereto trim - thick high-strength steel sheets. After that put into place a loop through which the rudder stock.

Ten of the integrated brigades of fitters were working, competing with one another. Ahead was a brigade of A. Belyakov, only to give up work early and excellent quality !!!

One brigade Smirnov instructed solely responsible job: boring bracket and stern tube propeller shaft. Experienced workers who built a dozen ships, thoughtful: he had never had to handle such large parts. Dispute, ryadili how and where to start. Finally, they decided: a new thing - a new way and it is necessary to initiate and organize the work.

Source:

Many seas surrounding our country, in the winter covered with ice. This makes it difficult and often completely interrupted navigation. Then come to the aid of ships powerful icebreakers. Through the thick ice convoys they spend at the destination port.

Of particular importance acquired icebreakers on the Northern Sea Route, linking the west and east of the Soviet Union. This difficult trail along its entire length covered during the long months of heavy polar ice.

Swimming in the Arctic is limited to the short Arctic summer. It often happens that in the summer and ice prevent the movement of ships. Without icebreakers can not do.

Modern icebreakers - a mighty steel giants, leading a bitter struggle with the ice. But how long is sailing without calling at the ports they can not. Even the best icebreakers with diesel power-plant fuel reserves are not more than 30-40 days. In the harsh conditions of the Arctic, this is clearly not enough: after a struggle with the ice requires a lot of fuel. An hour a powerful icebreaker often burns up to three tons. Although fuel reserves make up almost one third of the weight of the icebreaker in the Arctic during the navigation has to ship several times to enter the base to refuel. There were cases when convoys wintered in polar ice just because fuel supplies ran low on ice breakers ahead of time.

The success of Soviet scientists in the peaceful use of nuclear energy will help in the service of our national economy a new type of fuel. The Soviet people have learned to use the energy of the atom, and water transport. Thus was born the idea of creating an icebreaker, moving with the help of nuclear energy. This idea was realized only after our country was put into operation the world's first nuclear power plant and has accumulated the necessary experience for further work on the establishment of nuclear power plants.

So the world's first nuclear-powered icebreaker "Lenin»

20 ph and text, respectively

Nuclear-powered icebreaker "Lenin»,

the world's first ship civilian nuclear power plant established in the USSR. A. l. "Lenin" was launched on 5 December 1957; He came into operation in late 1959. It is intended for posting cargo ships along the Northern Sea route and diving expedition in the Arctic. Main features: displacement (without ballast) 16 thous. Tonnes, power of main turbine 32, 4 MW (44 thous. Liters. S.), The maximum length of 134, 0 m, width 27, 6 m, depth 16, 1 m, speed in pure water of 18 kt (33 3 km / h). It has good ice passability. A. l. "Lenin" - a flush vessel with an elongated bridge structure and two masts, aft of the available runway platform for helicopter ice reconnaissance. Nuclear steam capacity of the installation of water-water type, located in the central part of the vessel produces steam for the 4 main turbine generators supplying direct current propulsion motors 3, the latter is driven 3 propellers (2 onboard and 1 medium) particularly robust design. There are two stand-alone auxiliary power. Control mechanisms, devices and systems - remote. The crew created good living conditions for the long Arctic navigation. Fully provided radiation safety personnel icebreaker and the environment.

The Communist Party and the Soviet government, to appreciate the achievements of our scientists decided to wide use of nuclear energy in the national economy.

XX Congress of the CPSU aimed at the deployment of works on creation of nuclear power plants for transport purposes, to build a nuclear-powered icebreaker.

It was about the creation of a vessel which can float for very long without calling at ports for fuel.

Scientists estimate that the nuclear-powered icebreaker will consume 45 grams per day of nuclear fuel - as much as will fit in a matchbox. That's why the icebreaker, having virtually unlimited navigation area, will be able to visit in one trip, and in the Arctic, and off the coast of Antarctica. For vessels with nuclear power plant range of distance - not an obstacle.

Honorable and responsible task of construction of the first nuclear-powered icebreaker in the world has been entrusted to the Admiralty Shipyard in Leningrad.

Admiralteytsy had a lot of experience in repair and construction of icebreakers. Back in 1928, they overhauled the "grandfather of the icebreaker fleet" - the famous "Ermak" (pictured below). Its renovation was a good school for admiralteytsev allowed in the future go to the construction of icebreakers.

There was, first of all, the question of how to create a compact nuclear power plant, which would have, and high power, and high survivability under pitching, shock and vibration.

Next, the team was required to ensure the safety of the icebreaker from the harmful effects of radiation associated with the operation of the nuclear reactor, the more that the protection against ionizing radiation in the operation of the icebreaker is much more complicated than, for example, on a coastal nuclear power plant. This is understandable - on a ship for technical reasons it is impossible to install bulky and heavy protective equipment.

The construction of an atomic icebreaker require unique manufacturing power equipment, creating an unprecedented body strength is still full process automation power system management.

Particular attention in the design of the hull has been paid to the shape of the bow, which largely depend on the quality of ice-breaking vessel. Selected for nuclear-powered lines in comparison with existing icebreakers can increase the pressure on the ice. Aft is designed to provide flotation on the ice when reversing and protection of screws and steering from the blows of the ice.

In practice, it was observed that icebreakers sometimes get stuck in the ice not just bow or stern, and sides. To avoid this, it was decided to arrange a special system on the submarine ballast tank. If one side of the tank to pump water into the tank the other side, the vessel rocking from side to side will break the ice and push the sides. The same system of tanks installed in the bow and stern. And if the icebreaker did not break the ice with the course and stuck his nose? Then it is possible to pump water from the aft trim tank in the bow. Pressure will grow on the ice, it will break, and the icebreaker out of ice captivity.

To ensure that such a large ship unsinkable, if the lining is damaged, the body decided to be divided into sections of eleven main transverse watertight bulkheads. In the calculation of the atomic icebreaker designers provided the unsinkable ship by flooding the two largest bays.

These are briefly the main features of the icebreaker, which was to build a team of Admiralty Plant.

Builders housing met with considerable difficulties. It was not easy, for example, stainless steel handle. Previously dominated by machining. This required a lot of time.

Engineers Boris Smirnov, G. Schneider, master A. Golubtsov and cutter Makarov designed and manufactured the original gas-flux cutter. In this way it succeeded in short time efficiently handle a significant portion of parts made of stainless steel. These days, the factory became famous for his work communities welding engineer Bureau B. Smirnov and cutter Makarov. It is about them in the original large-circulation newspaper appeared poems:

Mastered cutting thickness of steel,

Invented Machine,

Engineers and workers - each character,

Inquiring no barriers!

Persistently overcome the first difficulty. But the main difficulties were still ahead; especially a lot of them met on the slipway works and completion of an icebreaker.

Nuclear icebreaker as the most powerful ship in the entire icebreaker fleet designed to fight ice in the toughest conditions; so his body should be particularly strong. The high strength of the body, it was decided to provide the use of a new steel grade. This steel has high toughness. It is well weldable and has a greater resistance to crack propagation at low temperatures.

The housing design nuclear-powered, the system will set it as different from other icebreakers. Bottom, sides, internal deck, platform, and the upper deck in the extremities were recruited by the transverse framing system, and the upper deck in the middle of the ice-breaker - for the longitudinal system.

The body height in a good five-story building consists of sections weighing up to 75 tons. Such large sections, there were about two hundred.

Assembly and welding of sections of land led pre-assembly of the body shop.

Before beginning work in the office area of the masters gathered Communists. Everyone worried about one issue: how to better and faster to build nuclear-powered icebreaker?

It was also decided to make three staff development section to finally resolve all issues related to the new technology. These sections are the most sophisticated in design - one of the bottom and two side bow - has gathered a team of Pavel Pimenov, one of the best builders of the plant. Assembling advanced sections allowed us to determine how to collect and welded sections weighing up to 75 tons.

With the pre-assembly area ready section goes directly to the slipway. Collectors checker and immediately set them in place.

In the manufacture of components for the first pilot staff sections revealed that the steel sheets from which they are to be made, weighing 7 tons, and were available at the blank portion of the cranes had a lifting capacity of only up to 6 tons.

Press also had insufficient power. It seemed that there was an insoluble problem.

In discussing this issue it was proposed to establish a more powerful cranes. Some, citing insufficient capacity crane economy and the lack of the necessary presses, offering large-scale processing of thick sheet metal body parts of complex design to transfer to another plant. The latter path was simple and easy, but is related to a waste of public funds. To accept such a proposal would be to carry the metal and templates on the side, and then to carry the items back; I would lose a lot of time and money.

And, indeed, the solution was found. Senior Technologist shop B. Fyodorov, head of the bureau of technological preparation Mikhailov, deputy section chief Mikhail Leonov, master Makarov, gibschiki innovators Rogalev I., V. Ivanov, A. Gvozdev offered treatment and flexible sheet cladding icebreaker produce , without resorting to an increase in capacity of crane equipment, or the replacement of bending presses. Experimental work has shown that the existing factory equipment it is suitable for metal processing. So it was saved about 200 thousand rubles.

Great icebreaker plating thickness required special skills of the workers in the bending parts, as in presses that existed at the plant, so the thickness of the metal cold bending previously exposed. At the initiative of Engineers Gurevich and Nikolai Martynov processing sheet cladding ice belt was mastered in corp soobrabatyvayuschem shop, where heavy manual operations have been completely eliminated.

The amount of welding on the stocks was very high: the icebreaker hull - welded. Someone made a kinda count how many stitches have to make the stocks sector workers? Figured. The result was a considerable figure if all welds to pull in one line, it will stretch from Leningrad to Vladivostok!

The amount of welding forced to think seriously about how to speed up the welding structures. It was decided to implement a wider automatic and semiautomatic welding. Welders set to work on a new method.

It should tell you about one more instructive example of close co-workers, engineers and scientists.

According to the approved design technology of stainless steel welded manually. Here, however, qualified welders to work, but the work went very slowly. How to speed up welding? Only replacing the manual work automatic welding! But the automatic welding of stainless steel have not been applied. However, workers believe that it is possible to cook a gun and "stainless steel". We came to the aid of scientists. Employee Research Institute K. Mladzievsky together with specialists of the plant Zhiltsova K., A. Shvedchikov, M. matzah, N. Stoma and other experienced on steel rails picked up the necessary operating conditions. It conducted more than 200 experiments; Finally, the welding conditions have been fulfilled. Senior

Almost daily production korpusniki held serious examination. A construction time was short. From how to cope with their tasks korpusniki depended term icebreaker descent into the water.

.

There was, for example, such a case. Due to the very large size it can not be delivered by rail to the plant form and stern-post - the main structure of the nose and stern. Massive, heavy, weighing 30 and 80 g, - they do not put on any railway platforms. Engineers and workers decided to make shtevni directly at the plant, boil them parts.

To present the complexity of the assembly and welding of field joints shtevney, suffice it to say that the minimum thickness of the welded part reaches 150 mm.

Welding stem lasted 15 days in 3 shifts !!!

While on the stocks it erected a housing in the different shops of the plant produced and mounted parts, pipelines and appliances. Many of them have dealt with the other businesses. The whole country is generously sent their gifts admiralteytsam -o products for the icebreaker. The main turbine generators were built at the Kharkov Electromechanical Plant, propulsion motors - at the Leningrad plant "Electrosila" Kirov, where to create unique arrangements worked team of engineers and technicians, led by the oldest designer of the plant Kashin. These motors are designed in the Soviet Union for the first time.

In the shops of the famous Kirov factory gathered steam turbines. Above order for the nuclear-powered icebreaker I worked here a great team of designers, led by M. Kozak. In the course of Kirov workers have made a lot of improvements that allow reduction in weight and size of the turbines. Kirov workers coped with the executive order.

At this time, at the Admiralty Works widely developed socialist competition for a worthy meeting of the 40th anniversary of the October Revolution. Most important is the reduction of the period of preparation of the icebreaker to be launched.

The staff of the mechanical assembly shop early for the icebreaker passed all the boring device. In the shop there was a "lightning", "Comrades! Equals at Turner borer Medvedev, made on the three days before the term of the order is responsible for construction of the atomic icebreaker "Lenin"! »

It was an outstanding victory. The fact that the norms were supposed to produce the desired snap two of the workers. However, this work was assigned to one M. Medvedev, as the rest were loaded borer other urgent orders. Medvedev assured his comrades: "Mastering one will not fail!" .. Having prepared the machine, cutters, auxiliary tools and compacted to limit the working day, he labored faithfully for two and completing quests, not only in time, and even earlier.

Such heroes of labor in the factory had many. People did what had seemed impossible. Marker V. Alexandrov and B. Puyto just two days coped with the markings of the rudder. But this "feather" weighs 30 tons !!!

As soon as we handled the rudder on the boring machine lathe I. Anashkin working in the shop 20 years bole bore multi-ton rudder - steering shaft - at the same pace had experienced working with his K. Podgayskiy changer Fomin. Extremely hard work - assembling the steering apparatus drive - prematurely implemented brigade collectors M. and A. Malyushkina Podlazova.

The assembly of the rudder was assigned one of the leading teams of pickers - a brigade of N. Vagina malokorpusnogo shop. Master G. Zubok, the foreman, and all the workers carefully studied the drawings, thought through how best to organize the work.

First they collected and welded frame in an upright position. Then, in the horizontal position, welded thereto trim - thick high-strength steel sheets. After that put into place a loop through which the rudder stock.

Ten of the integrated brigades of fitters were working, competing with one another. Ahead was a brigade of A. Belyakov, only to give up work early and excellent quality !!!

One brigade Smirnov instructed solely responsible job: boring bracket and stern tube propeller shaft. Experienced workers who built a dozen ships, thoughtful: he had never had to handle such large parts. Dispute, ryadili how and where to start. Finally, they decided: a new thing - a new way and it is necessary to initiate and organize the work.

Source: