981

How is the enamelware in Russia

Today, as part of our project "Perm Krai - We have much to be proud of!", We will visit the JSC AK "Lysva Metallurgical Plant" (OJSC "AK LMZ") and look at how to enamelware. In addition to all the facilities of "AK LMZ" also produced household stoves, thermos, enameled sink, etc., but it enamelware factory that is always appreciated in our country. And this choice is not accidental! After all, its very appearance in Russia is obliged Lysvintsam! The idea of release of enamelware in our country has its roots in 1913 and belongs to the owner of the plant Count Paul Shuvalov, who asked for its implementation to the Urals Polish specialists. Specialists were Poles (head Janda) with plants "Lebor" and "Volcano", which brought with them, and skilled workers. Equipment setup and preparation of enamels were kept secret from the Russian.

66 photos, the source

But not everything turned out so smoothly. Turbulent events of 1917, coming in Lysva Kolchak caused enormous harm to the plant and shop. The situation was aggravated by the fact that the Whites fled technical officers Poles, who took with them the secret recipe for making dishes. Only in 1921, Eugene Kuklin, student Dmitri Mendeleev, the remains of enamel on drains able to unravel the secret of its structure ... Since our Lysvensky plant one of the largest players in this market for the production of enamelled products. Of course compete with cheap imports is not easy, but at the expense of impeccable quality, variety and tradition, we can definitely be proud of what we have in the Perm region has a production!

Also Lysvensky plant is a pioneer and a pioneer in the development and implementation of innovations in emalproizvodstve. In the 50's began construction of workshops for the production of emalposudy Novokuznetsk, Magnitogorsk, Novomoskovsk, Zaporozhye, in the '70s - in Cherepovets, Kerch, Bekabad. Lysventsy helped train personnel, improve the organization of labor, sharing new technologies.

3. A little digress from the historical data and let's go through the plant. To enter the factory formed 4-through, we'll go to the factory through the central entrance

4. Administrative building of JSC "AK LMZ" stands at the center of the plant - so to speak residence administering authority.

5. A little wandering on the territory, we come to the shop enamelware. By the way, Lysva Steel Works - a company with a complete production cycle, covering for enamelware - frits are also produced at the plant

Frits designed for enamel coatings to protect the surface of products made of different materials from corrosion in accordance with the functionality of the products.

At the moment the range of more than 50 kinds of silicate and ceramic frits for protective coatings. So all this allows us to speak primarily about the high quality of our products lysvennskih metallurgists.

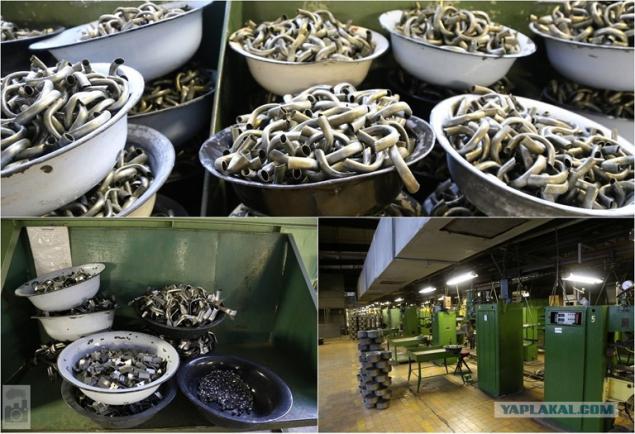

For technical reasons, we did not get on the first few stages, which produces cutting and stamping blanks, extract the shape and configuration. Next comes the form of crop and its stamping silicone matrix. Parallel manufactured pens and other accessories, as well as cutting down the right holes. I think we are not the last time in Lysva on this venture and make sure to separate and report on the matter. Now let's begin our tour of the fascinating emalproizvodstvu, namely, that we have seen with their own eyes, and happy to share with you. So, go ahead!

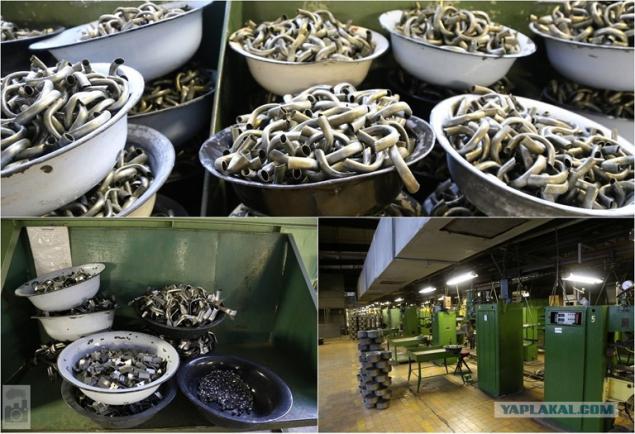

7. And this is, so to speak ...

posudonakopiteli

-

-

-

-

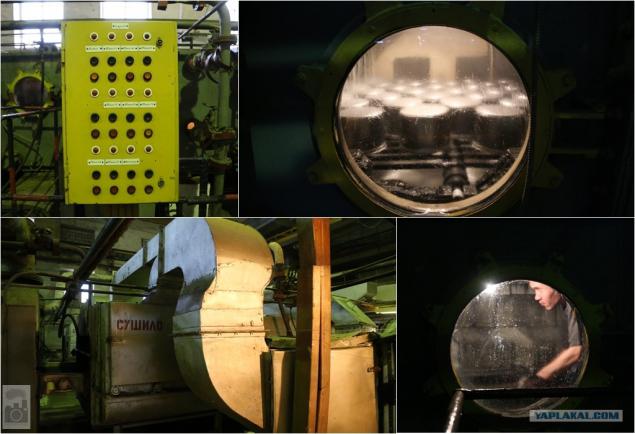

12. The next step, which we will begin our story, this water treatment. Yes, yes, before moving on to the enamel product, to wash off all the emulsion that remains after punching workshop, using a mixture of acid degreasing, and it happens here in such enclosed conveyors.

13. Girls sorted and laid out in the correct sequence ...

-

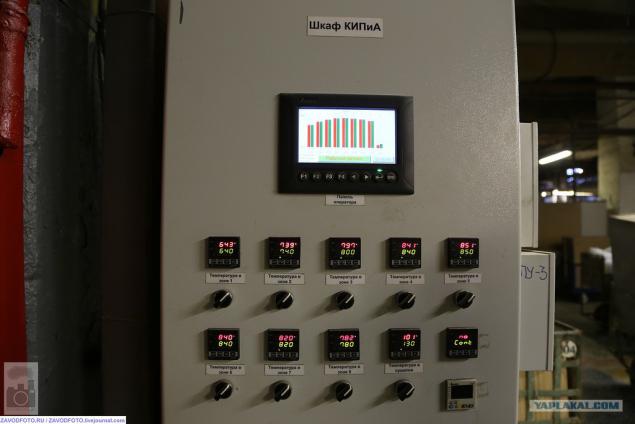

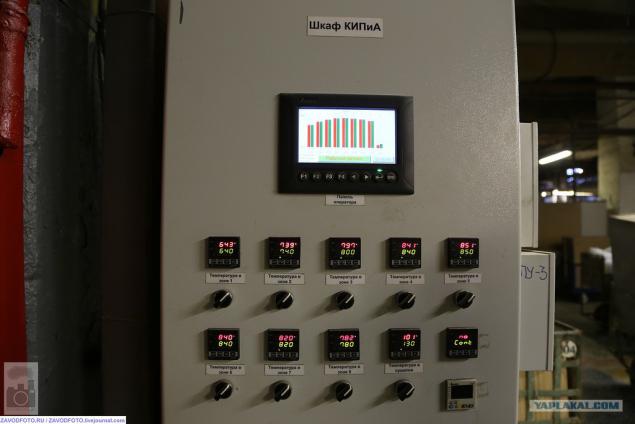

15. This remote control conveyor for cleaning products

16. In the windows you can see the assembly line production, as it moves along the conveyor

17. In addition to tableware and lysventsy make such cleaning enamel.

18. With the help of welding machines, as shown in the photo below, attach the handle to the saucepans and lids to the loops ...

19. Take the characters slightly larger

20. This process is called contact welding

21. And again ladies at the helm ...

-

23. After fitting attached to products, go to the beginning of the process of enamelling and the first stage - a primer

24. In most cases, manual labor, so that each piece of Lysva how to live, with your soul, mood, character ...

-

26. A bit of automation does not hurt.

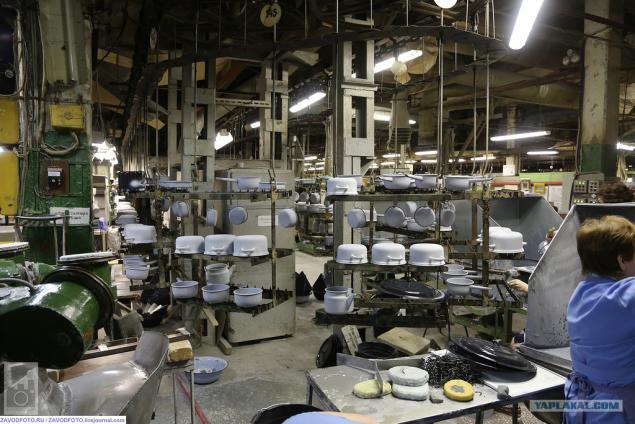

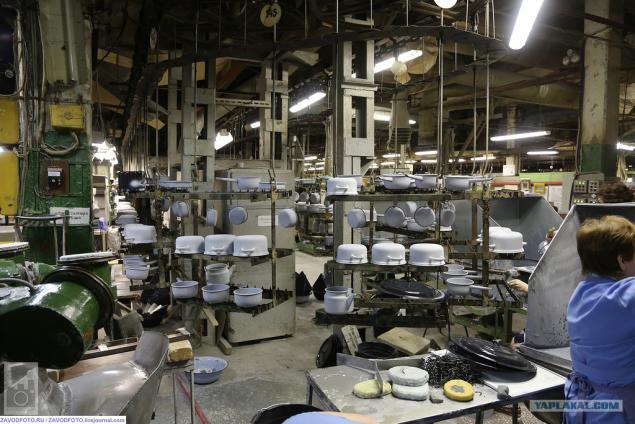

27. That such rotating holders workers inserted untreated pots, kettles ... another couple of laps and the product on the conveyor moves on

28. This process is called enameling dipping

29. Manual enamelling

30. And then the enemy does not slip, the eyes of the controller - the best friend of the buyer ...

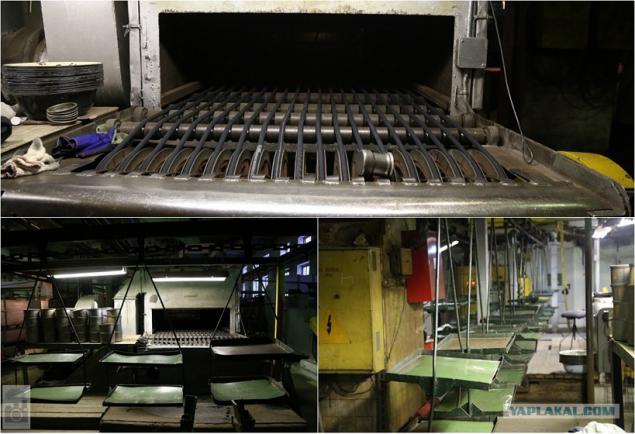

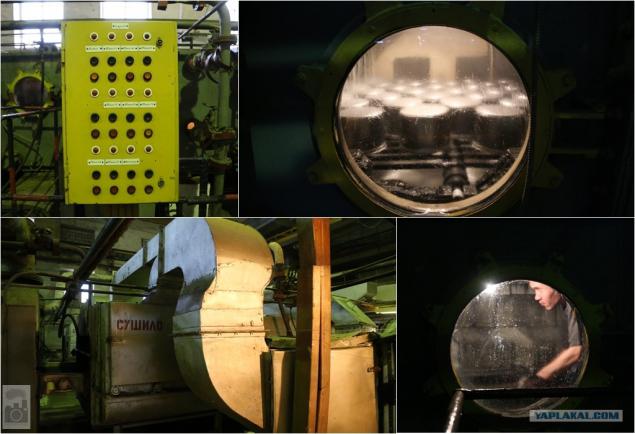

31. The next stage of the production process first firing primer

32. Gray enters and leaves the white ...

-

34. And then the most important - the wardrobe! Here's a hot here on the background of our winter ...

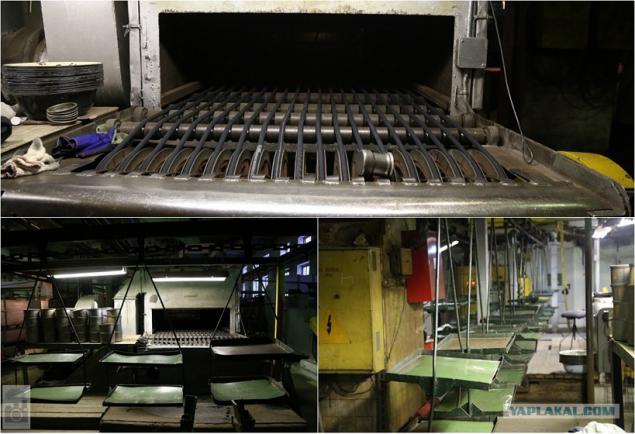

35. Further, after the first coat of enamel coating process is repeated again on the stove to warm up ...

36. These are the love-out of the oven ...

37. but that's not all, we are waiting for the final stage of the outer enamelling, which is done manually

Source:

66 photos, the source

But not everything turned out so smoothly. Turbulent events of 1917, coming in Lysva Kolchak caused enormous harm to the plant and shop. The situation was aggravated by the fact that the Whites fled technical officers Poles, who took with them the secret recipe for making dishes. Only in 1921, Eugene Kuklin, student Dmitri Mendeleev, the remains of enamel on drains able to unravel the secret of its structure ... Since our Lysvensky plant one of the largest players in this market for the production of enamelled products. Of course compete with cheap imports is not easy, but at the expense of impeccable quality, variety and tradition, we can definitely be proud of what we have in the Perm region has a production!

Also Lysvensky plant is a pioneer and a pioneer in the development and implementation of innovations in emalproizvodstve. In the 50's began construction of workshops for the production of emalposudy Novokuznetsk, Magnitogorsk, Novomoskovsk, Zaporozhye, in the '70s - in Cherepovets, Kerch, Bekabad. Lysventsy helped train personnel, improve the organization of labor, sharing new technologies.

3. A little digress from the historical data and let's go through the plant. To enter the factory formed 4-through, we'll go to the factory through the central entrance

4. Administrative building of JSC "AK LMZ" stands at the center of the plant - so to speak residence administering authority.

5. A little wandering on the territory, we come to the shop enamelware. By the way, Lysva Steel Works - a company with a complete production cycle, covering for enamelware - frits are also produced at the plant

Frits designed for enamel coatings to protect the surface of products made of different materials from corrosion in accordance with the functionality of the products.

At the moment the range of more than 50 kinds of silicate and ceramic frits for protective coatings. So all this allows us to speak primarily about the high quality of our products lysvennskih metallurgists.

For technical reasons, we did not get on the first few stages, which produces cutting and stamping blanks, extract the shape and configuration. Next comes the form of crop and its stamping silicone matrix. Parallel manufactured pens and other accessories, as well as cutting down the right holes. I think we are not the last time in Lysva on this venture and make sure to separate and report on the matter. Now let's begin our tour of the fascinating emalproizvodstvu, namely, that we have seen with their own eyes, and happy to share with you. So, go ahead!

7. And this is, so to speak ...

posudonakopiteli

-

-

-

-

12. The next step, which we will begin our story, this water treatment. Yes, yes, before moving on to the enamel product, to wash off all the emulsion that remains after punching workshop, using a mixture of acid degreasing, and it happens here in such enclosed conveyors.

13. Girls sorted and laid out in the correct sequence ...

-

15. This remote control conveyor for cleaning products

16. In the windows you can see the assembly line production, as it moves along the conveyor

17. In addition to tableware and lysventsy make such cleaning enamel.

18. With the help of welding machines, as shown in the photo below, attach the handle to the saucepans and lids to the loops ...

19. Take the characters slightly larger

20. This process is called contact welding

21. And again ladies at the helm ...

-

23. After fitting attached to products, go to the beginning of the process of enamelling and the first stage - a primer

24. In most cases, manual labor, so that each piece of Lysva how to live, with your soul, mood, character ...

-

26. A bit of automation does not hurt.

27. That such rotating holders workers inserted untreated pots, kettles ... another couple of laps and the product on the conveyor moves on

28. This process is called enameling dipping

29. Manual enamelling

30. And then the enemy does not slip, the eyes of the controller - the best friend of the buyer ...

31. The next stage of the production process first firing primer

32. Gray enters and leaves the white ...

-

34. And then the most important - the wardrobe! Here's a hot here on the background of our winter ...

35. Further, after the first coat of enamel coating process is repeated again on the stove to warm up ...

36. These are the love-out of the oven ...

37. but that's not all, we are waiting for the final stage of the outer enamelling, which is done manually

Source: