1120

Electric pipe-welding shop

Chelyabinsk Tube Rolling Plant - an industry group of the metallurgical complex of Russia is one of the largest domestic manufacturers of tubular products with a total market share of the ten largest companies in the world pipe. Going into the new factory shop you will at least be surprised, instead of dirt, unpleasant to the touch spets.odezhdy and other attributes of modern plants you will be given a snow-white coat and a white helmet and fireproof shoes and then not required. Let's walk through the shop and find out what he's so good.

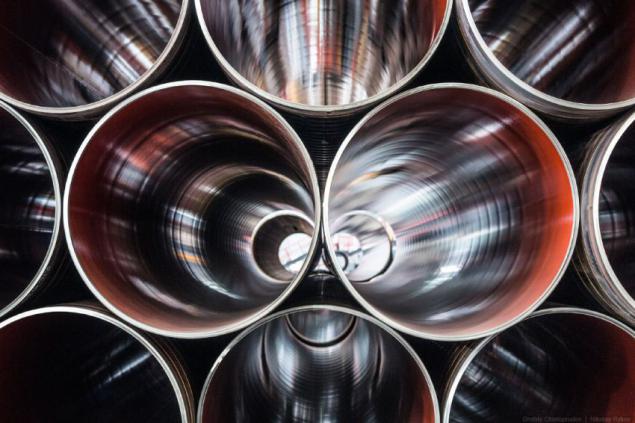

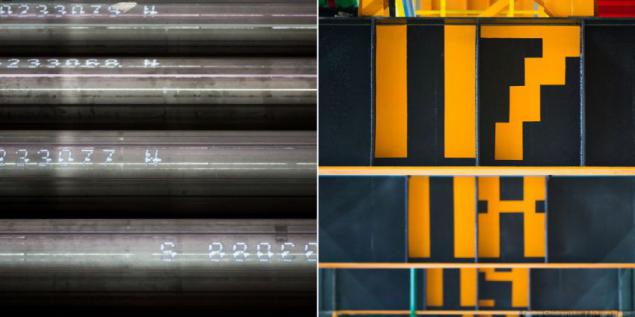

The new equipment allows the plant to produce single-seam welded pipes with diameter up to 1420 mm and wall thickness up to 48 mm and lengths up to 18 meters. With the launch of the new shop Russian fuel and energy industry can fully provide itself with large diameter pipes. There is no need to import such products.

The company ChTPZ confident that the new shop with modern equipment and technology, a fundamentally new accents in the work culture, which is the international quality standards, must have his face. Hence, the sonorous, original, memorable name.

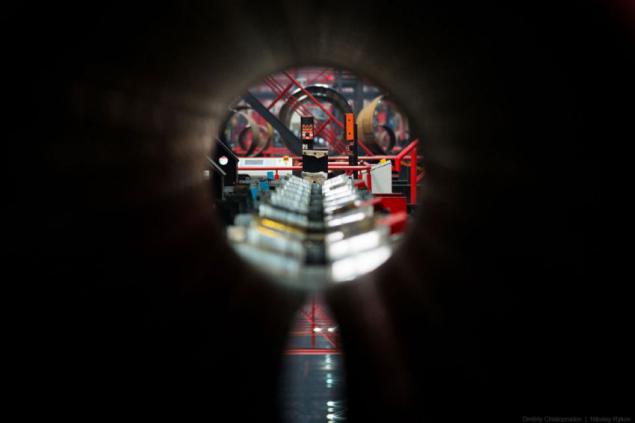

The length of the shop about 720 meters, a width of about 150 meters, and the area - 15 football fields.

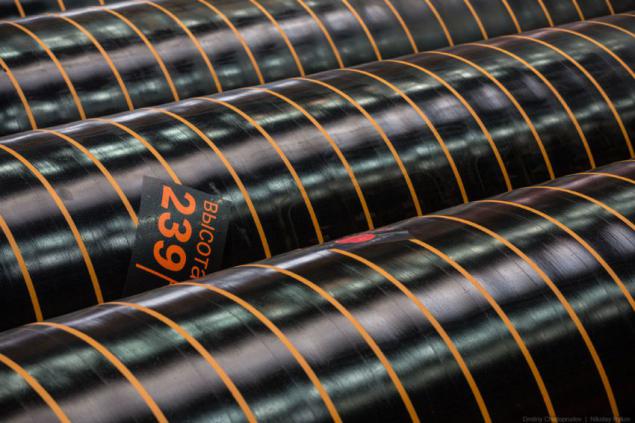

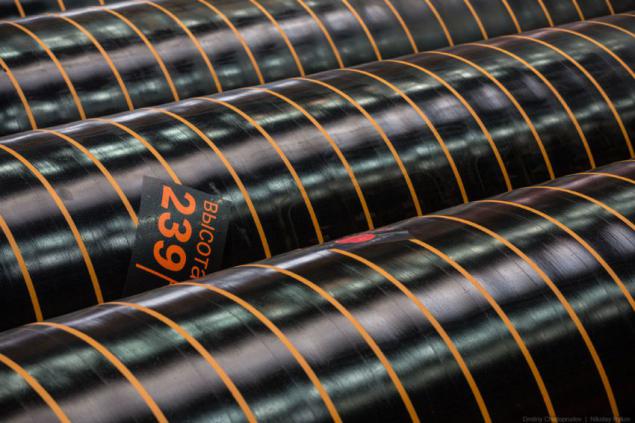

The name "Altitude 239" due to the fact that 239 - is the height of the geographic point where the plant is built, corresponding to the height of the southern part of the Ural Mountains above sea level, and 239 - this is the highest location of this production in the Russian pipe industry.

ChTPZ company is one of the leading industrial groups of the metallurgical complex of Russia. At the end of 2012 the company's share in total shipments of Russian producers accounted for 18%.

The total investment in the project amounted to 21 billion rubles.

Capacities "Altitude 239" include walking areas forming, welding, finishing of internal and external anti-corrosion coatings. It starts from a warehouse of steel sheets - blanks for future pipe.

On manufacture overhead cranes with magnetic suction cups and vacuum traverses.

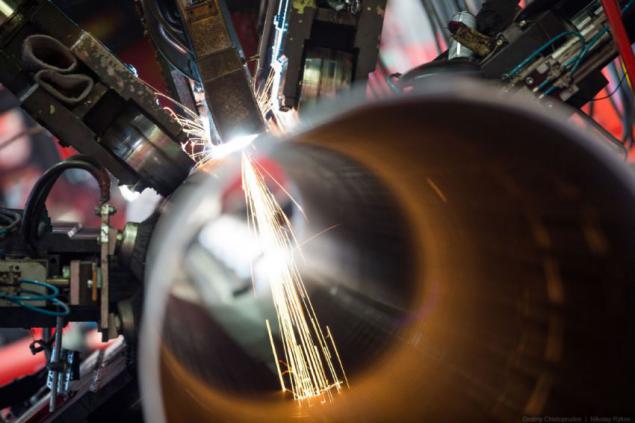

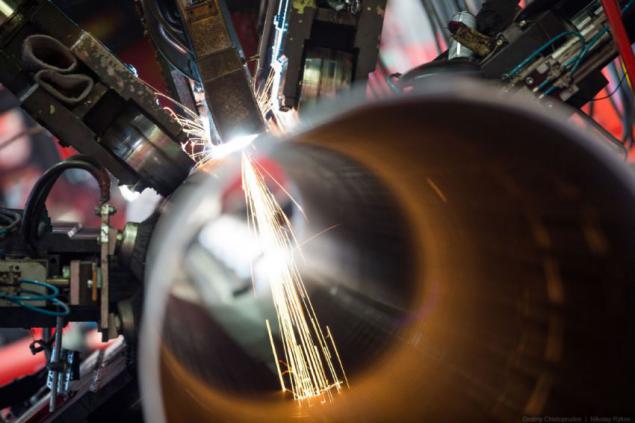

Then come to the work robot manipulators, which are welded to the blank plate technology. It called station welding process plates.

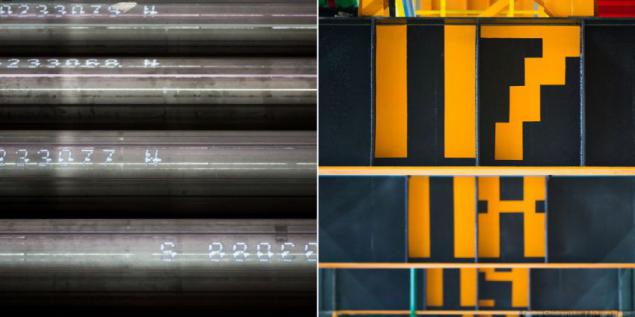

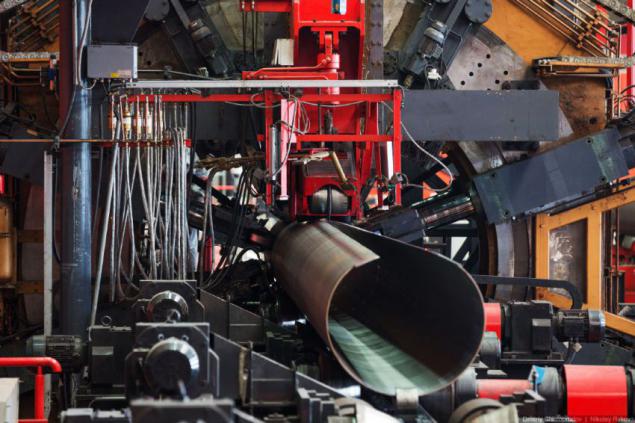

After cutting and marking sheets are sent to the mighty giant shop - two stepwise molding press.

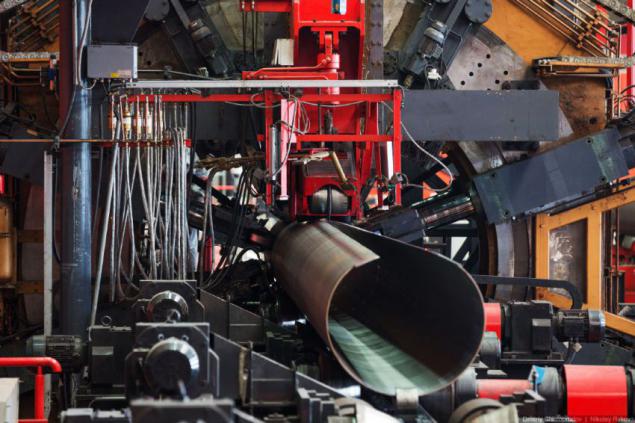

The enormous size of the good press cottage bent steel sheet with a thickness of 2 cm into the pipe for about one minute.

Welded plate required in order to reduce the consumption of the metal. Pipe production is organized in such a way that the beginning and end of the pipe weld is not always wholly different quality. Previously, the pipe at both ends "cut off", ie they cut hoops. Now just cut square plate on the edges of pipes, which account for the beginning and end of the weld.

It was - it became. After a press sheet becomes a cylindrical shape.

The next step in the seamless pipe welded to the cylinder and sent to grinding.

The shop has a garden of stones - a unique "haven of peace". Such an element of decor is not in any industrial enterprise. Garden stones adorned the roof of the drying compartment - that's 30 tons of sand, 12 sakura and 33 stone. Sakura's not real. True - palm trees in the gallery.

I managed to talk with some of the working shop. All men are somehow very satisfied with and proud of their products.

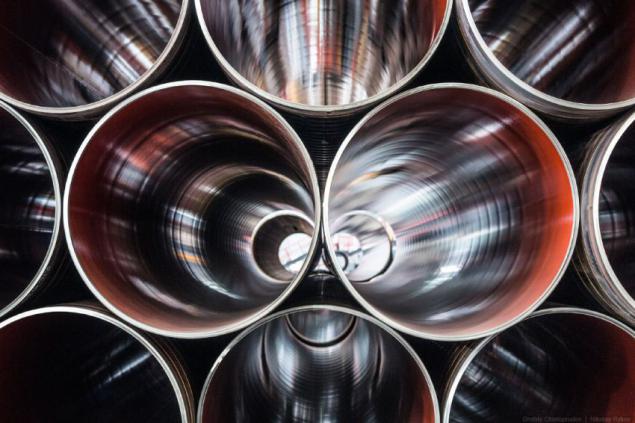

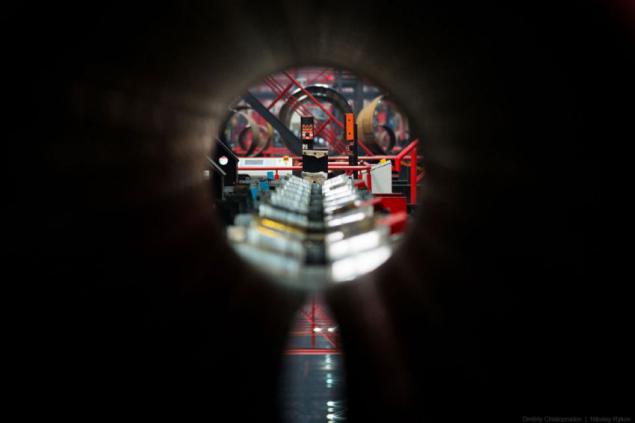

On the "height 239" produced by large-diameter pipes for oil and gas pipelines. They are intended for use in the construction of pipelines in the areas of offshore development, seismically active areas, permafrost areas, difficult terrain, the laying of submarine pipelines and offshore.

A dispatch department.

The new shop CTRP - the first draft of the national "white metal", based on the totality of the production of culture, high product quality, environmental safety and appropriately qualified labor. The term "white metals" is associated with high-tech - medicine, microelectronics, where priority is precision and responsibility, and work clothes personnel are traditionally white robes.

Warehouse of finished goods awaiting shipment to railcars.

Through the use of the latest technologies, "white metals" ChTPZ destroys one of the most stable in the past stereotypes that work with the metal can not be associated with clean clothes and white, traditionally refers to the "black" dirty industries.

Transporting pipes.

Download product in a train, fixing and spacer tubes occupies an entire shift.

Will Chelyabinsk, be sure to take the time to visit this wonderful shop. To get to the tour, you just need to write a letter to the management of the plant.

Oh yeah, I almost forgot. Here is the correct room in the modern Russian factory!

Source: chistoprudov.livejournal.com

The new equipment allows the plant to produce single-seam welded pipes with diameter up to 1420 mm and wall thickness up to 48 mm and lengths up to 18 meters. With the launch of the new shop Russian fuel and energy industry can fully provide itself with large diameter pipes. There is no need to import such products.

The company ChTPZ confident that the new shop with modern equipment and technology, a fundamentally new accents in the work culture, which is the international quality standards, must have his face. Hence, the sonorous, original, memorable name.

The length of the shop about 720 meters, a width of about 150 meters, and the area - 15 football fields.

The name "Altitude 239" due to the fact that 239 - is the height of the geographic point where the plant is built, corresponding to the height of the southern part of the Ural Mountains above sea level, and 239 - this is the highest location of this production in the Russian pipe industry.

ChTPZ company is one of the leading industrial groups of the metallurgical complex of Russia. At the end of 2012 the company's share in total shipments of Russian producers accounted for 18%.

The total investment in the project amounted to 21 billion rubles.

Capacities "Altitude 239" include walking areas forming, welding, finishing of internal and external anti-corrosion coatings. It starts from a warehouse of steel sheets - blanks for future pipe.

On manufacture overhead cranes with magnetic suction cups and vacuum traverses.

Then come to the work robot manipulators, which are welded to the blank plate technology. It called station welding process plates.

After cutting and marking sheets are sent to the mighty giant shop - two stepwise molding press.

The enormous size of the good press cottage bent steel sheet with a thickness of 2 cm into the pipe for about one minute.

Welded plate required in order to reduce the consumption of the metal. Pipe production is organized in such a way that the beginning and end of the pipe weld is not always wholly different quality. Previously, the pipe at both ends "cut off", ie they cut hoops. Now just cut square plate on the edges of pipes, which account for the beginning and end of the weld.

It was - it became. After a press sheet becomes a cylindrical shape.

The next step in the seamless pipe welded to the cylinder and sent to grinding.

The shop has a garden of stones - a unique "haven of peace". Such an element of decor is not in any industrial enterprise. Garden stones adorned the roof of the drying compartment - that's 30 tons of sand, 12 sakura and 33 stone. Sakura's not real. True - palm trees in the gallery.

I managed to talk with some of the working shop. All men are somehow very satisfied with and proud of their products.

On the "height 239" produced by large-diameter pipes for oil and gas pipelines. They are intended for use in the construction of pipelines in the areas of offshore development, seismically active areas, permafrost areas, difficult terrain, the laying of submarine pipelines and offshore.

A dispatch department.

The new shop CTRP - the first draft of the national "white metal", based on the totality of the production of culture, high product quality, environmental safety and appropriately qualified labor. The term "white metals" is associated with high-tech - medicine, microelectronics, where priority is precision and responsibility, and work clothes personnel are traditionally white robes.

Warehouse of finished goods awaiting shipment to railcars.

Through the use of the latest technologies, "white metals" ChTPZ destroys one of the most stable in the past stereotypes that work with the metal can not be associated with clean clothes and white, traditionally refers to the "black" dirty industries.

Transporting pipes.

Download product in a train, fixing and spacer tubes occupies an entire shift.

Will Chelyabinsk, be sure to take the time to visit this wonderful shop. To get to the tour, you just need to write a letter to the management of the plant.

Oh yeah, I almost forgot. Here is the correct room in the modern Russian factory!

Source: chistoprudov.livejournal.com