966

Shop for car production

The idea to get to the place where they produced and produced to this day domestic cars of representative class (by the people "chlenovoz") have matured for a long time, but the right moment just can not. Finally, the stars were formed as it should, and a cold, winter night, we tried to get interested in our shop at the plant Likhachev. Go to it had to be almost the entire plant, which, though sometimes looks abandoned, but still running and protected.

The street was completely calm and deathly silence that we violated the crunch of snow underfoot, at times it seemed that we heard steps per kilometer. This procedure has added nervousness. Surprisingly, despite the cold and late hour, the protection of the plant and did not sleep periodically redirected around the car. But we noticed it was not possible, the car they were noisy, and places where you can lurk in advance at the factory lots. On the entire trip to the shop took almost an hour. Naturally appropriate body did not meet our doors wide open, and with a mind inside was at least one person on duty. But we were not giving up going. And after a while we already were inside and quietly started to take pictures.

40 photo + interesting text

Hence

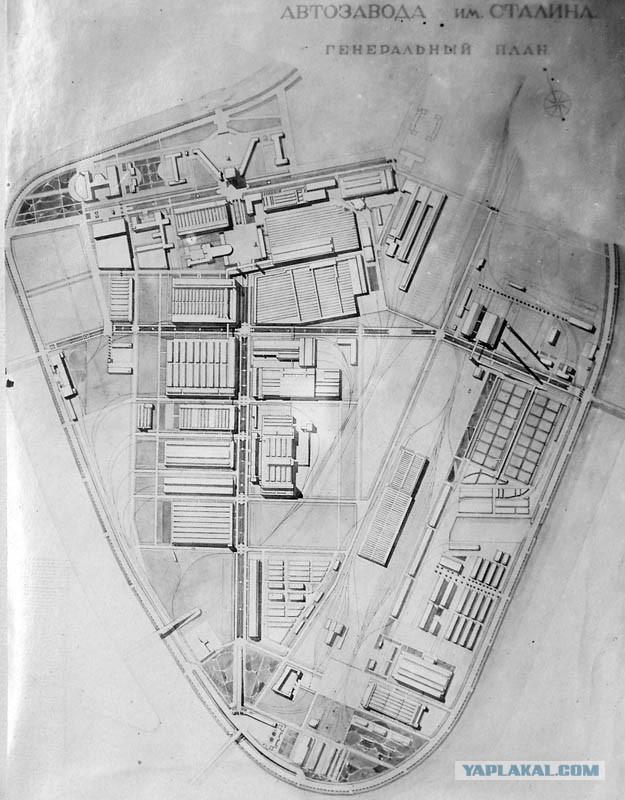

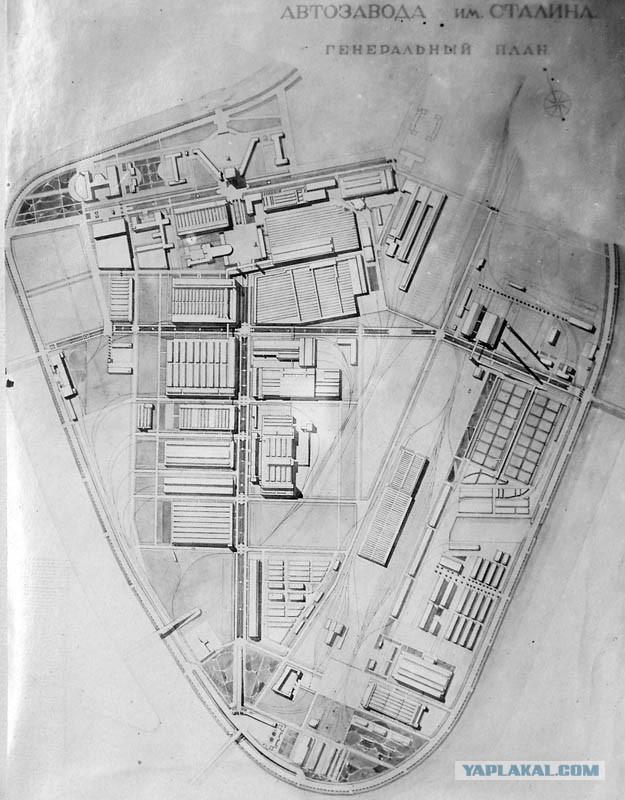

Workshop for production of "chlenovoz" properly called TSLA (shop cars), it is also the 6th machine assembly plant ZIL. It was built in the 30s of the last century, probably during the second reconstruction of the plant, just as there has been in the factory production of passenger cars.

If I had some mysteriously sucked into a temporary funnel a few decades ago, it would be around the exact same situation. The only difference is that I got to be notably off guard, because this plant can be accessed only with a special pass from the KGB and even the management of the plant could not always get into it.

The mention of this workshop in books, magazines as well as on the Internet is very small. Come across the information usually refers to our time, and I, on the contrary, interested in the earliest history of production. So many things had to guess, based on what he saw, so it is likely that there will be mistakes in the description, for which I apologize in advance.

This building has been launched small-scale production of special vehicles and vehicles for senior management. The only exception was the minivan "Youth" about it in more detail, I'll discuss later.

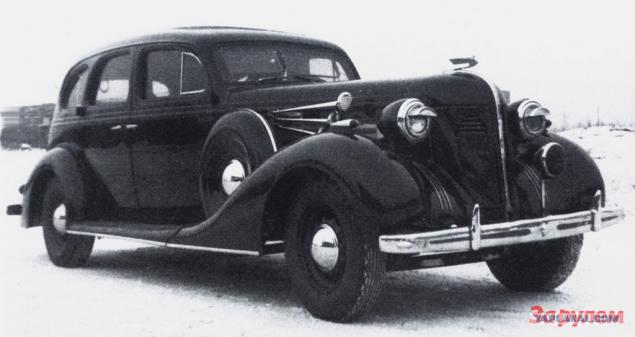

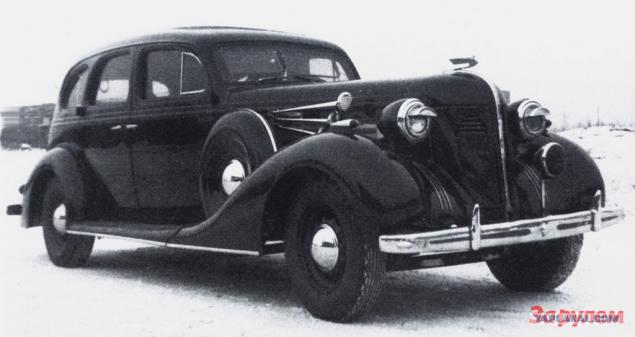

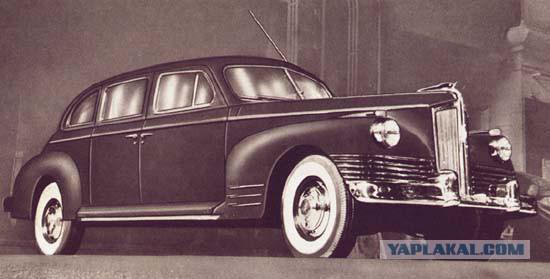

With some models began production in this workshop to find out exactly what I could not. But the first-class car released at the plant was the ZIS-101 (1936 - 1941 YG) was planned to produce not less than 10 000 vehicles per year, which could not possibly be true. For all five years of release, plant and failed even to plan one year (of 8752 was released the car). The reasons for the failure of the plan was a few, but the main mistake was an unfortunate choice of a prototype - "Buick" model in 1934. The American car was difficult to manufacture and, therefore, to establish mass production of high quality not really happened. Therefore, the "Soviet" Buick "" - ZIS-101, did not become a vehicle for senior management. Stalin still prefer American-made cars.

It is worth noting that the body was not an exact copy of the US counterpart, it has designed specifically for American Zisa bodywork company "Ambi-Budd»

The photo of ZIS-101A in the special version for the Kremlin garage. 1940

The next attempt to create a machine for the top management of the USSR, began during the Second World War. September 14, 1942 the People's Commissariat of Medium Machine Building, issued an order on the establishment of the factory named after Stalin (After the death of Likhachev plant was renamed in his honor, and he began to wear a name familiar to us - ZIL) new passenger car class. For me, this decision seems strange country is mobilizing all resources to fight the German army and the elite thinks about limousines. But it is not about that.

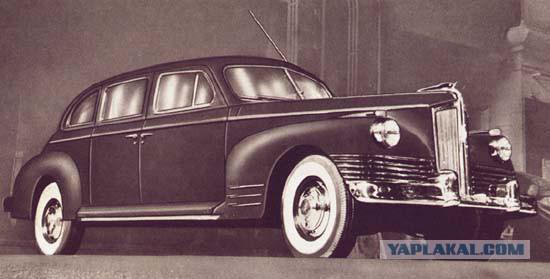

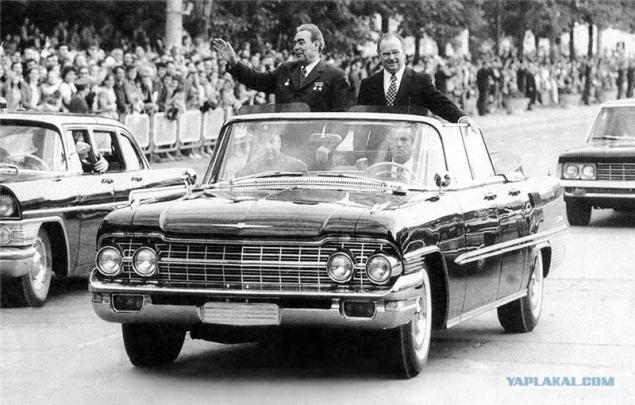

Knowing the love of Stalin to the cars of the brand «Packard», and it took as a basis. Externally, the new machine, called ZIS-110 was almost identical to «Packard 180," but engineers Zisa made a number of changes in the car, such as increasing the distance between the cylinders, thereby improving the cooling of the engine, that they have made the decision "pakkordovskoy" problems of engines - overheating . September 20, 1944 sample ZIS-110 was approved by the State Committee for Defense and, less than a year later, July 20, 1945 began assembling the first batch. Total from 1945 to 1958 were collected in 2072 car.

Marshal GK Zhukov ZIS - 110B

Briefly escape from the history of cars ZIL and see how the car going in TSLA.

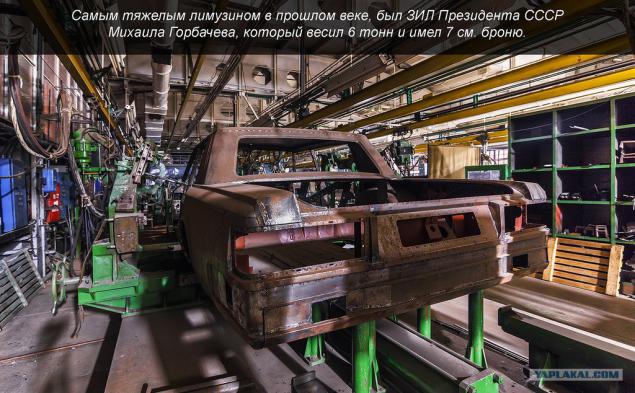

Despite the change in the lineup of cars, production principles in the shop are the same as they were in Soviet times.

To create a body panels used special wooden templates made of oak, in which the metal sheet beaten out, Richt and align with the help of a tin alloy. I think everyone understands that this is done manually.

Such parts manufacturing business laborious, requiring time and specific skills.

As it may be noted that in this production is much easier to make a change in the design of the vehicle than in series.

Obviously, that of making the body parts in this manner, to establish a large car production impossible, but it is not necessary, why in the ordinary Soviet people thousands of limousines.

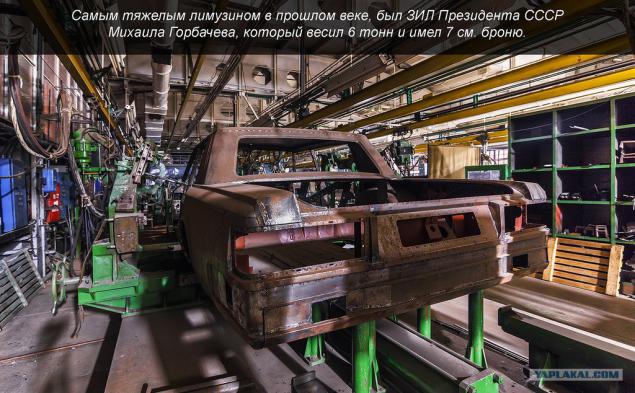

Unlike mass production, where the future car is moving on the conveyor belt and overgrown parts in the shop using the stocks. They are fixed to the vehicle frame her for welded parts.

Body elements are welded from the bottom up. At this stage, it requires maximum precision.

Of course, all the equipment, and the method of assembly machines are already very much out of date, but it does let out cars even more unique.

In the production of one car it takes about six months. In the best years TSLA was producing about 20 cars a year, now this figure is lower - 5-7 cars a year, if not less.

It is noteworthy that this shop was almost complete production cycle of the vehicle.

Coefficient "pure product" was 0, 7, i.e. 70% of machines are manufactured in this place.

For the painting of parts in the shop are special cameras.

Painting is made nitroemalyu, with the application of paint in the 9 - 15 layers. After each layer of color is drying and polishing.

The last layer is applied and polished at the end of run-in testing, which often drove the car more than 1000 kilometers.

In the same workshop produced wood interior trim elements and upholstery.

Sewing, very small and separated by partitions from the shop windows.

Here on these tables that in the photo, cut out the desired elements in leather or fabric.

Let's go back to the history of the lineup of cars ZIL plant.

By the end of 40-ies of the last century, the ZIS-110 was obviously outdated, but despite this the tip of the authorities all arranged. The designers also considered that the time to create a new car, and in 1949 started to develop. Worth remember that the Soviet economy was centrally planned, so that the development of this "sly" learned the scandal, and the project was closed. But all the same design office has continued to work on different nodes, for a new executive car.

There is an opinion that after the Geneva Conference in 1955, Nikita Khrushchev found himself impressed by the luxury car of US President Eisenhower gave the order in the shortest time to develop a new machine class. In 1956 the All-Union Agricultural Exhibition was presented a prototype ZIL-111 "Moscow" made from sketches Valentin sprout.

"Moscow" Khrushchev did not like, because looked pretty outdated compared with American innovations. Therefore, it organized an open competition for a new stylistic decision limousine. The competition won by Lev Eremeev, who at the same time engaged in the design of the car GAZ-13 "Chaika».

Traditionally, for the manufacture of the inner parts of the new car was used the experience of the foreign automobile industry. Therefore Automobile has bought a number of American-made cars to be explored. At the same time it was not complete and mindless copying, but also produced as a result of the car was not entirely domestic development. The design Zil-111 had all the usual attributes of American luxury cars mid-50s: frame chassis with independent spring suspension of front wheels, V-shaped eight, automatic transmission, power steering, brake servo, automatic transmission power windows, antenna, soft top and air conditioning. The first machine was released in 1959, but after 2 years there was a complete modernization of the appearance. This was due to the fact that the new American cars were asked to esterer new fashion, and great similarity with "The Seagull" strained senior management.

The updated car has received index ZIL-111G. This version was produced until 1967. Unlike previous executive class cars are produced at the factory, machines were strictly focused on the needs of the Kremlin. Because of this, on the basis of ZIL-111 were produced only 112 cars in different variations.

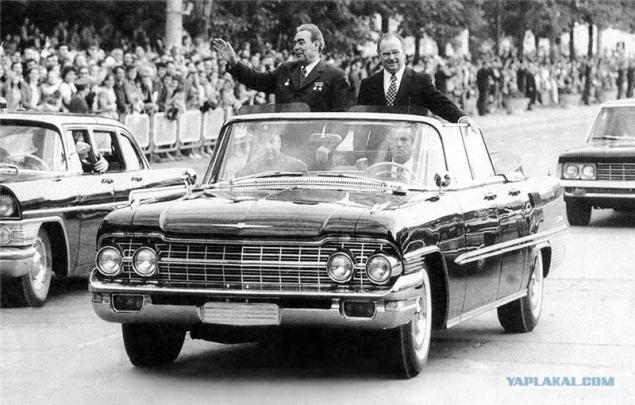

ZIL-111G

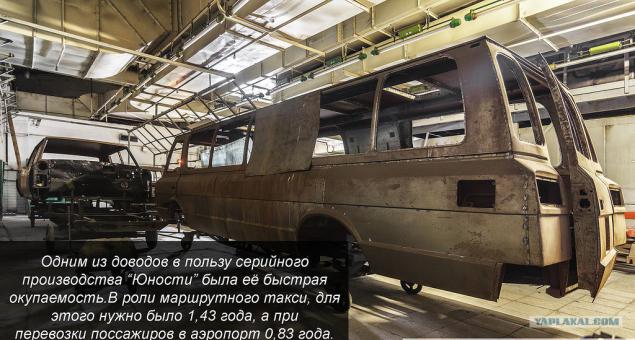

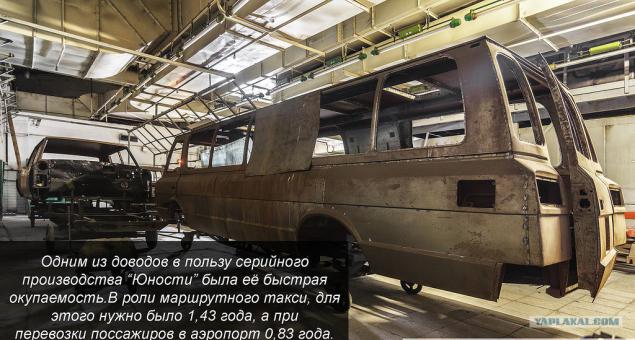

In addition to executive class cars, minibuses TSLA yet released - ZIL-118 "Youth", which, unfortunately, never went to series. First minivan ZIL-118 appeared in 1961, was based on database limousine ZIL-111.

For the first time he saw a minibus "Youth" NS Khrushchev said: "This is a real people's car!". It is not surprising, for the convenience of the passengers were made comfortable seats, individual lighting, radio with four speakers, ashtrays, coat hooks, efficient heating and ventilation systems. For better thermal insulation and sound insulation of interior space between the outer and inner body panels filled with polyurethane foam.

It seems to be the beginning for a new car was more than good, but unfortunately, as I said above, the economy was planned and to get a "good" for manufacturing, it was necessary to notify the USSR State Planning Committee in advance of years so 10 before release. Therefore, a series of these cars did not. During the period 1961-1970 year this workshop has been collected only 20 "Youth".

The biggest achievement of the minibus has been internationally recognized in 1967. "ZIL-118" Youth "has won 12 awards at the International Bus Week in Nice, including the Grand Prize of the President of the French Republic.

Along with the updated line of limousines, minibus and varied. In 1971, at the Exhibition Center was updated "Youth", which, like the first version was highly appreciated and so, unfortunately, there was no place in the State Planning Committee of the new five-year plan. Over the next three years the plant has not released any of the minibus. Suddenly, in the mid-70's, the factory began to receive small orders "Youth", but they were not needed to use them as tourist buses and taxis, as it was intended by designers, and creating uzkospetsilizorovannyh versions. They are used: to the Ministry of Health, as a special ambulance; for the needs of the Ministry of Interior, as the forensic laboratories; for cinematography; and to accommodate the special equipment the KGB. Total from 1971 to 1993 were collected 86 minibuses.

Now the shop is worth a few unfinished bodies of the latest version of "Youth" - ZIL-3207.

Despite the fact that the plant Likhachev is now in decline, the shop is still operating.

It still employs the staff. Many among them, those who have worked all their lives to manufacture a car for senior management.

Nowadays, most of the time TSLA has been repairing cars that are here and have been produced.

Also the staff in the shop found the time and desire to create something new.

But this, as well as the continuation of the history of the lineup of cars ZIL, I will write in the next post. As we descend to the first floor where there is a finished product.

That's all ...

Source:

The street was completely calm and deathly silence that we violated the crunch of snow underfoot, at times it seemed that we heard steps per kilometer. This procedure has added nervousness. Surprisingly, despite the cold and late hour, the protection of the plant and did not sleep periodically redirected around the car. But we noticed it was not possible, the car they were noisy, and places where you can lurk in advance at the factory lots. On the entire trip to the shop took almost an hour. Naturally appropriate body did not meet our doors wide open, and with a mind inside was at least one person on duty. But we were not giving up going. And after a while we already were inside and quietly started to take pictures.

40 photo + interesting text

Hence

Workshop for production of "chlenovoz" properly called TSLA (shop cars), it is also the 6th machine assembly plant ZIL. It was built in the 30s of the last century, probably during the second reconstruction of the plant, just as there has been in the factory production of passenger cars.

If I had some mysteriously sucked into a temporary funnel a few decades ago, it would be around the exact same situation. The only difference is that I got to be notably off guard, because this plant can be accessed only with a special pass from the KGB and even the management of the plant could not always get into it.

The mention of this workshop in books, magazines as well as on the Internet is very small. Come across the information usually refers to our time, and I, on the contrary, interested in the earliest history of production. So many things had to guess, based on what he saw, so it is likely that there will be mistakes in the description, for which I apologize in advance.

This building has been launched small-scale production of special vehicles and vehicles for senior management. The only exception was the minivan "Youth" about it in more detail, I'll discuss later.

With some models began production in this workshop to find out exactly what I could not. But the first-class car released at the plant was the ZIS-101 (1936 - 1941 YG) was planned to produce not less than 10 000 vehicles per year, which could not possibly be true. For all five years of release, plant and failed even to plan one year (of 8752 was released the car). The reasons for the failure of the plan was a few, but the main mistake was an unfortunate choice of a prototype - "Buick" model in 1934. The American car was difficult to manufacture and, therefore, to establish mass production of high quality not really happened. Therefore, the "Soviet" Buick "" - ZIS-101, did not become a vehicle for senior management. Stalin still prefer American-made cars.

It is worth noting that the body was not an exact copy of the US counterpart, it has designed specifically for American Zisa bodywork company "Ambi-Budd»

The photo of ZIS-101A in the special version for the Kremlin garage. 1940

The next attempt to create a machine for the top management of the USSR, began during the Second World War. September 14, 1942 the People's Commissariat of Medium Machine Building, issued an order on the establishment of the factory named after Stalin (After the death of Likhachev plant was renamed in his honor, and he began to wear a name familiar to us - ZIL) new passenger car class. For me, this decision seems strange country is mobilizing all resources to fight the German army and the elite thinks about limousines. But it is not about that.

Knowing the love of Stalin to the cars of the brand «Packard», and it took as a basis. Externally, the new machine, called ZIS-110 was almost identical to «Packard 180," but engineers Zisa made a number of changes in the car, such as increasing the distance between the cylinders, thereby improving the cooling of the engine, that they have made the decision "pakkordovskoy" problems of engines - overheating . September 20, 1944 sample ZIS-110 was approved by the State Committee for Defense and, less than a year later, July 20, 1945 began assembling the first batch. Total from 1945 to 1958 were collected in 2072 car.

Marshal GK Zhukov ZIS - 110B

Briefly escape from the history of cars ZIL and see how the car going in TSLA.

Despite the change in the lineup of cars, production principles in the shop are the same as they were in Soviet times.

To create a body panels used special wooden templates made of oak, in which the metal sheet beaten out, Richt and align with the help of a tin alloy. I think everyone understands that this is done manually.

Such parts manufacturing business laborious, requiring time and specific skills.

As it may be noted that in this production is much easier to make a change in the design of the vehicle than in series.

Obviously, that of making the body parts in this manner, to establish a large car production impossible, but it is not necessary, why in the ordinary Soviet people thousands of limousines.

Unlike mass production, where the future car is moving on the conveyor belt and overgrown parts in the shop using the stocks. They are fixed to the vehicle frame her for welded parts.

Body elements are welded from the bottom up. At this stage, it requires maximum precision.

Of course, all the equipment, and the method of assembly machines are already very much out of date, but it does let out cars even more unique.

In the production of one car it takes about six months. In the best years TSLA was producing about 20 cars a year, now this figure is lower - 5-7 cars a year, if not less.

It is noteworthy that this shop was almost complete production cycle of the vehicle.

Coefficient "pure product" was 0, 7, i.e. 70% of machines are manufactured in this place.

For the painting of parts in the shop are special cameras.

Painting is made nitroemalyu, with the application of paint in the 9 - 15 layers. After each layer of color is drying and polishing.

The last layer is applied and polished at the end of run-in testing, which often drove the car more than 1000 kilometers.

In the same workshop produced wood interior trim elements and upholstery.

Sewing, very small and separated by partitions from the shop windows.

Here on these tables that in the photo, cut out the desired elements in leather or fabric.

Let's go back to the history of the lineup of cars ZIL plant.

By the end of 40-ies of the last century, the ZIS-110 was obviously outdated, but despite this the tip of the authorities all arranged. The designers also considered that the time to create a new car, and in 1949 started to develop. Worth remember that the Soviet economy was centrally planned, so that the development of this "sly" learned the scandal, and the project was closed. But all the same design office has continued to work on different nodes, for a new executive car.

There is an opinion that after the Geneva Conference in 1955, Nikita Khrushchev found himself impressed by the luxury car of US President Eisenhower gave the order in the shortest time to develop a new machine class. In 1956 the All-Union Agricultural Exhibition was presented a prototype ZIL-111 "Moscow" made from sketches Valentin sprout.

"Moscow" Khrushchev did not like, because looked pretty outdated compared with American innovations. Therefore, it organized an open competition for a new stylistic decision limousine. The competition won by Lev Eremeev, who at the same time engaged in the design of the car GAZ-13 "Chaika».

Traditionally, for the manufacture of the inner parts of the new car was used the experience of the foreign automobile industry. Therefore Automobile has bought a number of American-made cars to be explored. At the same time it was not complete and mindless copying, but also produced as a result of the car was not entirely domestic development. The design Zil-111 had all the usual attributes of American luxury cars mid-50s: frame chassis with independent spring suspension of front wheels, V-shaped eight, automatic transmission, power steering, brake servo, automatic transmission power windows, antenna, soft top and air conditioning. The first machine was released in 1959, but after 2 years there was a complete modernization of the appearance. This was due to the fact that the new American cars were asked to esterer new fashion, and great similarity with "The Seagull" strained senior management.

The updated car has received index ZIL-111G. This version was produced until 1967. Unlike previous executive class cars are produced at the factory, machines were strictly focused on the needs of the Kremlin. Because of this, on the basis of ZIL-111 were produced only 112 cars in different variations.

ZIL-111G

In addition to executive class cars, minibuses TSLA yet released - ZIL-118 "Youth", which, unfortunately, never went to series. First minivan ZIL-118 appeared in 1961, was based on database limousine ZIL-111.

For the first time he saw a minibus "Youth" NS Khrushchev said: "This is a real people's car!". It is not surprising, for the convenience of the passengers were made comfortable seats, individual lighting, radio with four speakers, ashtrays, coat hooks, efficient heating and ventilation systems. For better thermal insulation and sound insulation of interior space between the outer and inner body panels filled with polyurethane foam.

It seems to be the beginning for a new car was more than good, but unfortunately, as I said above, the economy was planned and to get a "good" for manufacturing, it was necessary to notify the USSR State Planning Committee in advance of years so 10 before release. Therefore, a series of these cars did not. During the period 1961-1970 year this workshop has been collected only 20 "Youth".

The biggest achievement of the minibus has been internationally recognized in 1967. "ZIL-118" Youth "has won 12 awards at the International Bus Week in Nice, including the Grand Prize of the President of the French Republic.

Along with the updated line of limousines, minibus and varied. In 1971, at the Exhibition Center was updated "Youth", which, like the first version was highly appreciated and so, unfortunately, there was no place in the State Planning Committee of the new five-year plan. Over the next three years the plant has not released any of the minibus. Suddenly, in the mid-70's, the factory began to receive small orders "Youth", but they were not needed to use them as tourist buses and taxis, as it was intended by designers, and creating uzkospetsilizorovannyh versions. They are used: to the Ministry of Health, as a special ambulance; for the needs of the Ministry of Interior, as the forensic laboratories; for cinematography; and to accommodate the special equipment the KGB. Total from 1971 to 1993 were collected 86 minibuses.

Now the shop is worth a few unfinished bodies of the latest version of "Youth" - ZIL-3207.

Despite the fact that the plant Likhachev is now in decline, the shop is still operating.

It still employs the staff. Many among them, those who have worked all their lives to manufacture a car for senior management.

Nowadays, most of the time TSLA has been repairing cars that are here and have been produced.

Also the staff in the shop found the time and desire to create something new.

But this, as well as the continuation of the history of the lineup of cars ZIL, I will write in the next post. As we descend to the first floor where there is a finished product.

That's all ...

Source: