1814

Reportage. "AvtoVAZ" without cuts (40 pics + text)

A member of the guard at the entrance. Plant fundamentally guarded only by women.

The total area of the factory more than 600 hectares. Workers move through it on buses and taxis.

Workshop 71-1 - one of the newest in the "AvtoVAZ". Here is melted and stained plastic parts. Staffing includes 1,500 workers, but in 2009 the equipment operates at half strength, the equipment was mothballed. As a result, instead of 500 000 items Lada Kalina, Priora and 2110 will be produced only 250 000-260 000 pieces. Details for "dozen" are produced for export to Ukraine.

Assembling the instrument panel for Lada Priora.

This shop workers no longer drop. The line stopped and closed down because of the crisis.

This shop workers no longer drop. The line stopped and closed down because of the crisis.

Assembly shop body Chevrolet-Niva business, the Enterprise GM-AvtoVAZ literally wedged into the center of the body for the production of plastics for Lada Kalina and Priora. It looks like the body Chevrolet Niva before sending it to the conveyor.

Once on the Chevrolet Niva hung doors and trunk, semi-finished serving his back to the factory GM-AvtoVAZ - in his own paint shop.

Employees of GM-AvtoVAZ plant seems to have no intention of strikes.

Shop employees 71-3 hard to forget about the claims to the quality of the assembly with a poster on the ceiling.

One of the workers "AvtoVAZ" engaged in painting plastic bumpers.

"Flowers bring ourselves. They really everything is dying, the smell of it is very pungent, but we work here, I want to make it pokomfortnee. So how are dying, we are bringing this place more »

Despite the "pungent odor", none of the employees of "AvtoVAZ" was not found respirator. Flowers are dying, people are.

Despite the "pungent odor", none of the employees of "AvtoVAZ" was not found respirator. Flowers are dying, people are.

Form appeals to working exploits remained unchanged even after a quarter century after the collapse of the Soviet Union.

Iron foundry located in the most distress. From 8500 about 3,000 workers lost their jobs in their field. These people are engaged in furnishing the vast territory of "AvtoVAZ": care for your lawn, sweeping the sidewalk.

Cast iron plant "AvtoVAZ" bears little resemblance to modern production - before the crisis, it is not even cleaned. "Before, we did not have time for such cleaning, but now it appears" - agrees shop employee 11-5.

Hot iron is poured into sand molds. How old is this equipment, no one dares to say no.

In a cast iron furnace workshop 3: two imported and one Soviet. According to the staff of "AvtoVAZ", their performance is about the same. This oven has arrived in Russia from Sweden 39 years ago.

The efficiency of the iron foundries workshops on "AvtoVAZ" is two times lower than abroad. In Europe, one worker produces 140 tons of pig iron a year, "AvtoVAZ" - only 70 tons.

The last days in the iron shop. "I was forced to retire. Here I leave, "- says the veteran.

Brigade.

Renovation in avtovazovski.

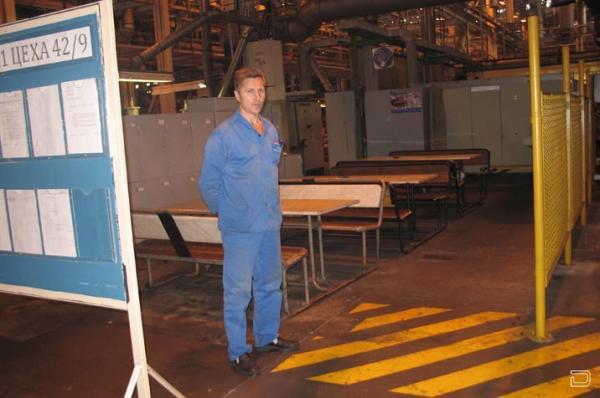

In the assembly and body shop 42-9 and 43-3 layoffs are planned. Lada Kalina are collected 1,500 workers.

The plant has been working in one shift instead of two, on average 2-3 days a week. In fact spent time working workshop receive an average of 5,000 rubles.

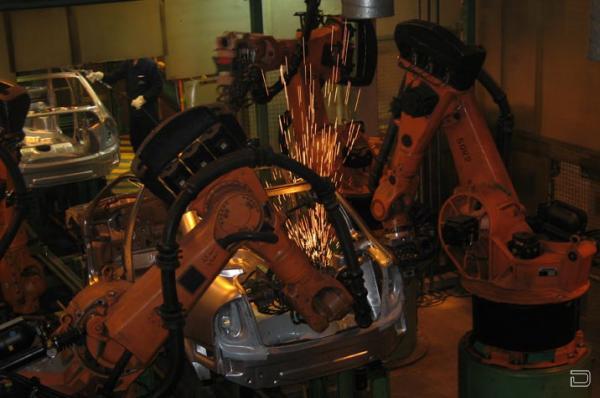

Lada Kalina assembly line looks the most modern. Almost all welding robots doing here Kuka, which are made on the "AvtoVAZ" by a German license. On the day collected exactly 263 machines, each fifth - with marriage. This marriage exhibit at the factory and correct. When fully loaded plant could produce up to 850 cars daily.

Collectors "Kalina" rely modern goggles - working foundries such never dreamed.

Modernization of the assembly line Lada Kalina has its limits. Without hammer "Kalina" is still not collect.

The bear.

Assembled under license robot waits for repairs in the corner shop.

The sign "Stop" version of "AvtoVAZ»

Lada Kalina sedan at the weld line.

Recreation area for workers. Upcoming trade union demonstration here talk a lot, but it does not participate in the plan.

Workers assembly shop Kalina. That they were assigned to eliminate identified marriage.

On the interior Lada Kalina assembly employs another 1,500 workers.

Vehicle equipment indicated on the plate taped to the rear wing. Easy to understand.

The famous "final assembly line»

Shopping, which weighs on the suspension arms, categorically contradicts the safety instructions. But it is very convenient and easier to work fairly. So assembly line workers bypass the rule that they have to go for each item separately

In the assembly hall Lada Kalina specially recruited the youngest - to match the image of the car. Compete with this team can unless the wiring harness assembly shop, which has its own specifics: there are working girls patient with thin fingers

Elena Hodyakova