714

Polypropylene for heating

In connection with the abundance of those about repairs of varying difficulty, with the participation of plumbing work in me grown rougher.

We'll talk to you today about this wonderful (God forgive me) material, such as polypropylene.

Last time, he got a firm place in the market, due to the strong cheapness and ease of installation.

Himself a sinner, he worked a lot.

I offer you a selection of information on this material. The end will tell.

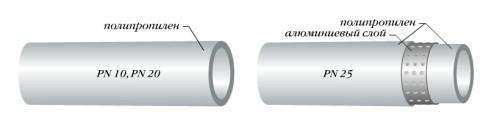

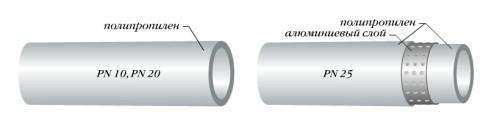

1.Truby are different. Its for operation in cold water, hot water and heating.

The key difference in the wall thickness working pressure (pn), and presence / absence of the reinforcing layer.

cold water pipe is very thin-walled. There is an opinion that it is easiest to work, but it is not. The fact is that the fittings polifuzionnoy welding (here I am only talking about it as the most common), originally universal and thickness and the required warm-up time comparable to the pipe for hot water. Accordingly, overheating of tubes, and as a consequence of poor quality connection is quite common.

For hot water pipe thickness, higher operating pressure, and work with it easier.

in general, the thickness of the pipe there is a significant reduction of linear expansion / contraction, as I will explain below.

Reinforced pipes can be of several types.

Initially substantially all polypropylene reinforced aluminum foil or mesh reinforcement layer being located closer to the outer surface of the pipe. Before welding, this layer is removed using special tools. Plus in reducing oxygen diffusion through the pipe wall, and a significant reduction of the elongation tube feeding fluid.

Later, a reinforcement of aluminum, is located closer to the inner surface of the tube. she immediately became popular because throwing money attachments nobody wanted. the advantages of this type of pipes are the same.

The most "fashionable" Now the tube is reinforced with fiberglass. Manufacturers claim that the extension of her is the same, but from my experience I can say that this is not so.

2. The temperature, pressure and service life.

That's what always held back. The television advertising was about even a guarantee of 50 years. Polypropylene pipes are not recommended for use in central heating systems where water pressure can reach values of 6 or more atmospheres, and the water temperature can rise to 90-95 ° C. For central heating systems may use other pipes made of polymer materials - namely, metal-pipe (see. SP 41-102-98 Design and installation of pipelines of heating systems using metal-pipe).

Lifetime according to the temperature (according to DIN8077 and NIIMosstroy A1)

80 -85 ° C = 10 s

90 - 95 ° C = 5 s

It speaks about the inadmissibility of the use of the pipe in central heating systems. But in private housing construction is the use of polypropylene leads to such things.

3.Lineynoe elongation.

main bolyaka polypropylene. When welding pipes have a temperature, while her other work.

By lowering the temperature of the tube is reduced in length, and vice versa.

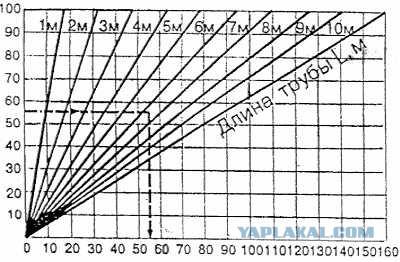

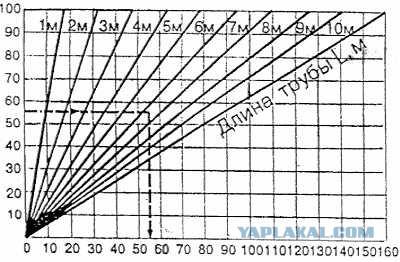

Changing the length of the pipe when the temperature drops is determined according to the formula ΔL = ΔLΔt, where ΔL Changing the length of the pipe, mm;

Δ is the coefficient of linear expansion of the pipe; L - length of the settlement area, m; Δt - the calculated temperature difference, ° C.

For unreinforced pipes linear expansion coefficient of 0, 15 mm / m ° C for reinforced - 0, 03 mm / m ° C.

Example: T1 = 20 ° C, t2 = 75 ° C, L = 6, 5.

According to the formula ΔL = ΔLΔt obtain that, ΔL = 0, 15 x 6, 5 x (75 - 20) = 55 mm, Δt = 75 - 20 = 55 ° C.

On the nomogram ΔL = 55 mm

It appears so:

wherein a very short section truby.Polipropilen has a coefficient of thermal expansion at 12, 5 times greater than that of steel. This fact must be taken into account during installation of polypropylene pipes.

As one friend of mine: the system of polypropylene beautiful welded to the water supply or heating.

4.Primenenie polypropylene pipes for underfloor heating is not recommended, as polypropylene is too high coefficient of thermal expansion that the conditions of underfloor heating is of great importance. This is the first. Secondly, the rotations of polypropylene pipes warm floors can not be performed without welding, and the presence of the compounds in the floor heating is undesirable. Third polypropylene have a fairly low thermal conductivity and thickness of the screed to guess, it is necessary for the health of sex almost nevozmozhno.Polipropilenovye pipes are not recommended for use in underfloor heating. For underfloor heating, as well as for heating systems, it is recommended to use thin metal-pipe, which can be bent over the entire heating zone and not have any connections at the same time.

As a consequence of doing so badly:

5.Zamurovyvat polypropylene pipes in walls and floors in accordance with SNIP 01/31/2003 inadmissible if the building should have a lifespan of over 20 years.

According to the SNIP 2.04.01-85 *, p. 10.1 *, the laying of plastic pipes must be provided mainly hidden in the plinth, cutting grooves, shafts and ducts. This requirement snip justified by the fact that the pipes during the operation must be protected from mechanical impact they are protected from UV radiation and must be free to expand without creating excessive stresses in them.

Even when laying pipe through the wall insulation is recommended.

such as a:

6. I would like to warn you against the use of polypropylene stop valves.

Ball valves stop working is usually 2-3 months. Stocks in them, in order to reduce the cost of construction represent a galvanic couple.

Posted in [mergetime] 1390749215 [/ mergetime]

And finally, remember that buying a welder, and exercise for 20 minutes does not make of you a specialist. )

I understand that a lot of nuances I missed, or simply omitted, but I hope that was helpful.

That's all I wanted to say. All good.

Source:

We'll talk to you today about this wonderful (God forgive me) material, such as polypropylene.

Last time, he got a firm place in the market, due to the strong cheapness and ease of installation.

Himself a sinner, he worked a lot.

I offer you a selection of information on this material. The end will tell.

1.Truby are different. Its for operation in cold water, hot water and heating.

The key difference in the wall thickness working pressure (pn), and presence / absence of the reinforcing layer.

cold water pipe is very thin-walled. There is an opinion that it is easiest to work, but it is not. The fact is that the fittings polifuzionnoy welding (here I am only talking about it as the most common), originally universal and thickness and the required warm-up time comparable to the pipe for hot water. Accordingly, overheating of tubes, and as a consequence of poor quality connection is quite common.

For hot water pipe thickness, higher operating pressure, and work with it easier.

in general, the thickness of the pipe there is a significant reduction of linear expansion / contraction, as I will explain below.

Reinforced pipes can be of several types.

Initially substantially all polypropylene reinforced aluminum foil or mesh reinforcement layer being located closer to the outer surface of the pipe. Before welding, this layer is removed using special tools. Plus in reducing oxygen diffusion through the pipe wall, and a significant reduction of the elongation tube feeding fluid.

Later, a reinforcement of aluminum, is located closer to the inner surface of the tube. she immediately became popular because throwing money attachments nobody wanted. the advantages of this type of pipes are the same.

The most "fashionable" Now the tube is reinforced with fiberglass. Manufacturers claim that the extension of her is the same, but from my experience I can say that this is not so.

2. The temperature, pressure and service life.

That's what always held back. The television advertising was about even a guarantee of 50 years. Polypropylene pipes are not recommended for use in central heating systems where water pressure can reach values of 6 or more atmospheres, and the water temperature can rise to 90-95 ° C. For central heating systems may use other pipes made of polymer materials - namely, metal-pipe (see. SP 41-102-98 Design and installation of pipelines of heating systems using metal-pipe).

Lifetime according to the temperature (according to DIN8077 and NIIMosstroy A1)

80 -85 ° C = 10 s

90 - 95 ° C = 5 s

It speaks about the inadmissibility of the use of the pipe in central heating systems. But in private housing construction is the use of polypropylene leads to such things.

3.Lineynoe elongation.

main bolyaka polypropylene. When welding pipes have a temperature, while her other work.

By lowering the temperature of the tube is reduced in length, and vice versa.

Changing the length of the pipe when the temperature drops is determined according to the formula ΔL = ΔLΔt, where ΔL Changing the length of the pipe, mm;

Δ is the coefficient of linear expansion of the pipe; L - length of the settlement area, m; Δt - the calculated temperature difference, ° C.

For unreinforced pipes linear expansion coefficient of 0, 15 mm / m ° C for reinforced - 0, 03 mm / m ° C.

Example: T1 = 20 ° C, t2 = 75 ° C, L = 6, 5.

According to the formula ΔL = ΔLΔt obtain that, ΔL = 0, 15 x 6, 5 x (75 - 20) = 55 mm, Δt = 75 - 20 = 55 ° C.

On the nomogram ΔL = 55 mm

It appears so:

wherein a very short section truby.Polipropilen has a coefficient of thermal expansion at 12, 5 times greater than that of steel. This fact must be taken into account during installation of polypropylene pipes.

As one friend of mine: the system of polypropylene beautiful welded to the water supply or heating.

4.Primenenie polypropylene pipes for underfloor heating is not recommended, as polypropylene is too high coefficient of thermal expansion that the conditions of underfloor heating is of great importance. This is the first. Secondly, the rotations of polypropylene pipes warm floors can not be performed without welding, and the presence of the compounds in the floor heating is undesirable. Third polypropylene have a fairly low thermal conductivity and thickness of the screed to guess, it is necessary for the health of sex almost nevozmozhno.Polipropilenovye pipes are not recommended for use in underfloor heating. For underfloor heating, as well as for heating systems, it is recommended to use thin metal-pipe, which can be bent over the entire heating zone and not have any connections at the same time.

As a consequence of doing so badly:

5.Zamurovyvat polypropylene pipes in walls and floors in accordance with SNIP 01/31/2003 inadmissible if the building should have a lifespan of over 20 years.

According to the SNIP 2.04.01-85 *, p. 10.1 *, the laying of plastic pipes must be provided mainly hidden in the plinth, cutting grooves, shafts and ducts. This requirement snip justified by the fact that the pipes during the operation must be protected from mechanical impact they are protected from UV radiation and must be free to expand without creating excessive stresses in them.

Even when laying pipe through the wall insulation is recommended.

such as a:

6. I would like to warn you against the use of polypropylene stop valves.

Ball valves stop working is usually 2-3 months. Stocks in them, in order to reduce the cost of construction represent a galvanic couple.

Posted in [mergetime] 1390749215 [/ mergetime]

And finally, remember that buying a welder, and exercise for 20 minutes does not make of you a specialist. )

I understand that a lot of nuances I missed, or simply omitted, but I hope that was helpful.

That's all I wanted to say. All good.

Source: