649

Pipes of polypropylene— a real threat to human health!

At the present time the old pipe heating systems are forcibly changed to tubes made of polypropylene. Harmful if propylene, not many know, but the material is a real threat to human health.

Heating pipes must be of a different material. It is desirable that it was galvanized metal. In order to avoid serious problems later, during overhaul should not agree to pipe of another material.Such works are cheap and they can save considerably.

Propylene is a plastic. Plastic and its fumes contain a number of chemical substances that provoke different diseases. In General, the composition of the plastic mass includes water. Cold is not noticeable, as far as they are harmful. But what happens when the material is exposed temperatures? The release of harmful substances increases. Now imagine that most of the time in a year, the plastic will be hot.

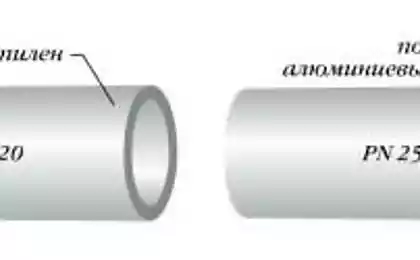

Now of the three most famous materials for the pipeline, which are used in domestic countries, the polypropylene, the first material that does not meet the requirements to use water systems. The material can last 30 years, the maximum allowable temperature acting on it, should not be above 75 degrees. Because the heating is too strong, this becomes a high aspect ratio. This leads to the fact that you need to do the compensation loop. In this case, a possibility of laying flush water. For welding pipes together you will need special tools and skills to work with him.

In second place is the metalloplast "RECH — 1 AND RECH". The material is quite malleable. He maintains a good shape during bending. The use of plastic piping in multi-storey construction and the serial is unacceptable. Pipe metal wall are heterogeneous due to differing coefficients of thermal linear expansion. This leads to the fact that the layers are stratified and for such pipes it is impossible to calculate their service life.

PECs – the material from which made the inner layer of such pipes. Its thickness is not more than 0.8 mm. Though, the position of the estimated load is 2.2 mm. This thickness leads to a decrease in allowable pressure in the 3-4. Aluminum foil in a layer of 0.2 – 0.4 mm can not withstand the pressure of the system. Even if the seams are welded perfectly, and the pipe during installation, are not subjected to multiple bends in the same place. In this case, the foil is drawn, and the integrity is broken before the system start-up.

In any case, should not expose their health to the harmful effects of polypropylene and it is better to give preference to other, more harmless materials. published

Source: vredno-ili-net.ru/texnika/vreden-li-polipropilen.html

Heating pipes must be of a different material. It is desirable that it was galvanized metal. In order to avoid serious problems later, during overhaul should not agree to pipe of another material.Such works are cheap and they can save considerably.

Propylene is a plastic. Plastic and its fumes contain a number of chemical substances that provoke different diseases. In General, the composition of the plastic mass includes water. Cold is not noticeable, as far as they are harmful. But what happens when the material is exposed temperatures? The release of harmful substances increases. Now imagine that most of the time in a year, the plastic will be hot.

Now of the three most famous materials for the pipeline, which are used in domestic countries, the polypropylene, the first material that does not meet the requirements to use water systems. The material can last 30 years, the maximum allowable temperature acting on it, should not be above 75 degrees. Because the heating is too strong, this becomes a high aspect ratio. This leads to the fact that you need to do the compensation loop. In this case, a possibility of laying flush water. For welding pipes together you will need special tools and skills to work with him.

In second place is the metalloplast "RECH — 1 AND RECH". The material is quite malleable. He maintains a good shape during bending. The use of plastic piping in multi-storey construction and the serial is unacceptable. Pipe metal wall are heterogeneous due to differing coefficients of thermal linear expansion. This leads to the fact that the layers are stratified and for such pipes it is impossible to calculate their service life.

PECs – the material from which made the inner layer of such pipes. Its thickness is not more than 0.8 mm. Though, the position of the estimated load is 2.2 mm. This thickness leads to a decrease in allowable pressure in the 3-4. Aluminum foil in a layer of 0.2 – 0.4 mm can not withstand the pressure of the system. Even if the seams are welded perfectly, and the pipe during installation, are not subjected to multiple bends in the same place. In this case, the foil is drawn, and the integrity is broken before the system start-up.

In any case, should not expose their health to the harmful effects of polypropylene and it is better to give preference to other, more harmless materials. published

Source: vredno-ili-net.ru/texnika/vreden-li-polipropilen.html

How wireless technology will change the world in the next 10 years

TRANS-fats are the real culprits of developing diseases of the heart and blood vessels