1069

Moscow Oil Refinery (49 photos)

Excursion in the territory of the Moscow oil refinery - one of the leading enterprises of the domestic oil refining industry and the largest supplier of oil to the market in the capital region. The factory occupies a leading position in the production of high-octane gasoline and clean diesel fuel, as well as among the top five companies on capacity utilization in the deep processing of oil.

Source In the mid 30s of the twentieth century the government decided to build near Moscow refinery to supply the capital and the area of automotive fuel and bitumen.

The production complex plant includes 23 processing plants and produce gasoline brands AI-80; AI-92; AI-95, diesel fuel, jet fuel, bitumen, sulfur, various polymers and so on.

Installation of primary oil refining "CDU-AVT-6". It produces Vakkumnye atmospheric distillation of crude oil, and is intended for separation of oil into its component parts in their boiling points in order to obtain commercial petroleum products or their components.

When the atmospheric distillation of crude oil heated to 360-370 ° C at which distilled fractions boiling away and remains in the residue oil. From oil fractions are obtained different types of fuels (gasoline, jet fuel and diesel engines), raw materials for petrochemical synthesis (benzene, ethylbenzene, xylene, ethylene, propylene, butadiene), solvents and more.

Vacuum Column - the heart of the installation. Further distillation of the oil is carried out under vacuum. The resulting material is used as a raw material for oil, wax, bitumen, cracking or can be used as a liquid fuel oil. The residue (concentrate, tar) after oxidation may be used as road construction and asphalt or as a component of the boiler fuel.

The cylindrical heat exchangers.

Most refining processes carried out at high temperatures and heat exchangers are used for heating and cooling the product.

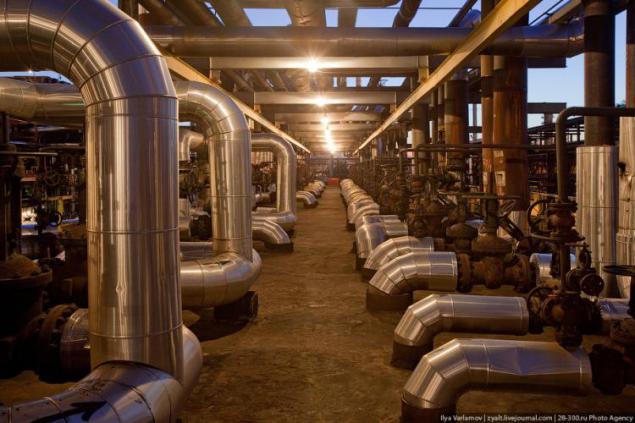

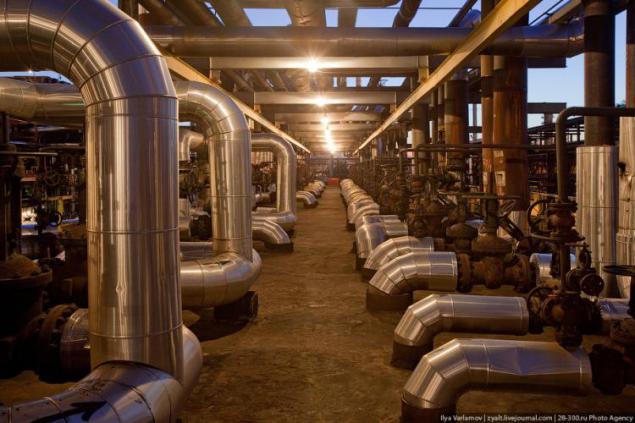

Latches.

Various product pipelines leading to the heat exchanger.

The performance of such a facility - 6 million tons of oil per year.

A significant increase in the consumption of petroleum products and the increasingly stringent quality requirements have caused a need for so-called secondary refining.

As a result, recycling of the oil was prepared starting materials for the production of the major products: synthetic rubber, fibers, plastics, surfactants, detergents, softeners, additives, dyes, and many others.

Catalytic cracking unit G-43-107. Catalytic cracking - one of the most important processes that ensure deep processing of petroleum to produce high-octane gasoline.

Combined installation for the production of MTBE (methyl tert-butyl ether).

Combined installation TAME (tert-amyl ethyl ether).

MTBE and TAME work allows the plant to produce high-octane gasolines in the framework developed by the Moscow Government programs to reduce the harmful effects of transport on the environment in Moscow.

Untrained person it is impossible to understand in the light pipe system, compressors and valves.

One of the points and control the operation of plants for the processing of crude oil.

Approximately look monitors employees of the plant.

Catalytic reforming A-35-11 / 300. With its help produce unleaded gasoline brands AI-AI-92ek and 95ek with improved environmental properties that meet European emission standards Euro-3.

The same night setting.

By order of the Moscow government in 1993 began the construction of Russia's first set of polypropylene production capacity of 100 thousand tons per year.

Technological process of granular polypropylene process is a closed cycle and waste technology in all phases is fully automated.

Polypropylene is used for the production of injection molding, extrusion, blow molding products: pipes, fittings, sheets, tapes, films, packaging, and non-woven fabrics, fibers, filaments, yarns, and other film products for technical, household and medical supplies.

On the left - a catalytic cracking unit G-43-107, and the right - granulation of polypropylene.

Source In the mid 30s of the twentieth century the government decided to build near Moscow refinery to supply the capital and the area of automotive fuel and bitumen.

The production complex plant includes 23 processing plants and produce gasoline brands AI-80; AI-92; AI-95, diesel fuel, jet fuel, bitumen, sulfur, various polymers and so on.

Installation of primary oil refining "CDU-AVT-6". It produces Vakkumnye atmospheric distillation of crude oil, and is intended for separation of oil into its component parts in their boiling points in order to obtain commercial petroleum products or their components.

When the atmospheric distillation of crude oil heated to 360-370 ° C at which distilled fractions boiling away and remains in the residue oil. From oil fractions are obtained different types of fuels (gasoline, jet fuel and diesel engines), raw materials for petrochemical synthesis (benzene, ethylbenzene, xylene, ethylene, propylene, butadiene), solvents and more.

Vacuum Column - the heart of the installation. Further distillation of the oil is carried out under vacuum. The resulting material is used as a raw material for oil, wax, bitumen, cracking or can be used as a liquid fuel oil. The residue (concentrate, tar) after oxidation may be used as road construction and asphalt or as a component of the boiler fuel.

The cylindrical heat exchangers.

Most refining processes carried out at high temperatures and heat exchangers are used for heating and cooling the product.

Latches.

Various product pipelines leading to the heat exchanger.

The performance of such a facility - 6 million tons of oil per year.

A significant increase in the consumption of petroleum products and the increasingly stringent quality requirements have caused a need for so-called secondary refining.

As a result, recycling of the oil was prepared starting materials for the production of the major products: synthetic rubber, fibers, plastics, surfactants, detergents, softeners, additives, dyes, and many others.

Catalytic cracking unit G-43-107. Catalytic cracking - one of the most important processes that ensure deep processing of petroleum to produce high-octane gasoline.

Combined installation for the production of MTBE (methyl tert-butyl ether).

Combined installation TAME (tert-amyl ethyl ether).

MTBE and TAME work allows the plant to produce high-octane gasolines in the framework developed by the Moscow Government programs to reduce the harmful effects of transport on the environment in Moscow.

Untrained person it is impossible to understand in the light pipe system, compressors and valves.

One of the points and control the operation of plants for the processing of crude oil.

Approximately look monitors employees of the plant.

Catalytic reforming A-35-11 / 300. With its help produce unleaded gasoline brands AI-AI-92ek and 95ek with improved environmental properties that meet European emission standards Euro-3.

The same night setting.

By order of the Moscow government in 1993 began the construction of Russia's first set of polypropylene production capacity of 100 thousand tons per year.

Technological process of granular polypropylene process is a closed cycle and waste technology in all phases is fully automated.

Polypropylene is used for the production of injection molding, extrusion, blow molding products: pipes, fittings, sheets, tapes, films, packaging, and non-woven fabrics, fibers, filaments, yarns, and other film products for technical, household and medical supplies.

On the left - a catalytic cracking unit G-43-107, and the right - granulation of polypropylene.