152

Do heating in a private house, the master begs to put copper pipes instead of plastic, told their terrible cons

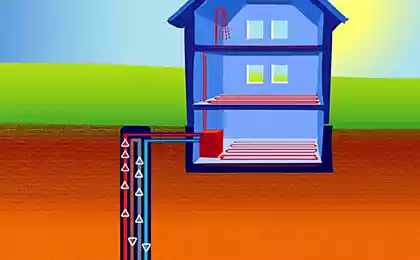

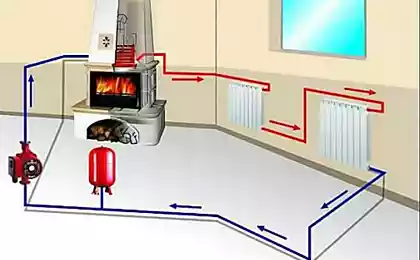

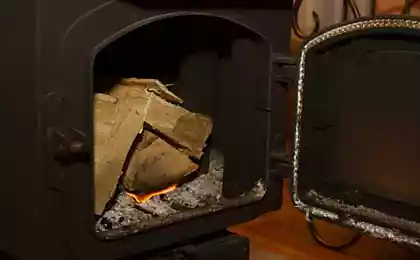

Polypropylene pipes appeared a little less than a hundred years ago. And during this time, a lot has been improved, which allowed them to be used in a variety of areas. But even plastic-pipe They have many shortcomings that many people do not even know.

And today's edition. "Site" It offers to find out why masters are skeptical of those who decide to take polypropylene pipes, for example, for heating in their home. What flaws in this material can become a problem immediately or after a couple of years?

The best plastic pipes

More expensive plastic pipes have aluminum foil as reinforcement. But this material greatly increases the cost of the product, which becomes a problem for many buyers who are looking for something cheaper. Therefore, some manufacturers change aluminum foil to fiberglass. However, the output turns out pipes that are afraid of low temperatures and do not tolerate falls. Although such pipes are stored, as a rule, in cold rooms. And the transportation of products is not always treated appropriately. Therefore, buying plastic pipes with a damaged reinforced layer is quite realistic.

Presence of metallic compounds

Plastic pipes with metal connectors are often disappointing. Plastic and metal react differently to different temperatures and expand differently. So it can easily flow here. To avoid such troubles, you should not save, but buy really the best plastic pipes from reliable manufacturers.

Sellers confidently declare that plastic pipes will last 40 and even 50 years. And there really is some truth to that. After all, if you buy high-quality pipes, entrust their installation to professionals, and even follow all the rules of operation, the products will last for more than a dozen years. If the rules are not followed, then after a couple of years of service, problems may arise.

Perhaps we have forgotten some of the disadvantages of plastic pipes? Share your experience with these products in the comments.

And today's edition. "Site" It offers to find out why masters are skeptical of those who decide to take polypropylene pipes, for example, for heating in their home. What flaws in this material can become a problem immediately or after a couple of years?

The best plastic pipes

- Lots of unreliable joints

By purchasing plastic pipes, the buyer receives many pieces several meters long. And all these pieces have to be joined together. Also, do not forget about different corners and turns, where joints also appear. As a result, after installation, the finished structure has dozens (and sometimes about a hundred) joints. Since most often such pipes are hidden under plaster, the unreliability of any connection becomes a serious problem. After all, the plaster will have to be removed to find a leak. And it is enough for a person who is engaged in soldering pipes to slightly overhold or undermaintain the device to get an unreliable connection. And after a while it will definitely make itself known.

- Diameter reduction at the connection point

With improper welding of two pipes, sometimes the diameter of the joint is brewed. Therefore, if the owners resort to the help of a person who has little experience (or try to do the work themselves), then this problem may arise. In this case, the diameter of the pipe at the connection will decrease, which will worsen the flow of water. And if there are several “brewed” connections, then it will be difficult to talk about the normal functioning of the heating system.

More expensive plastic pipes have aluminum foil as reinforcement. But this material greatly increases the cost of the product, which becomes a problem for many buyers who are looking for something cheaper. Therefore, some manufacturers change aluminum foil to fiberglass. However, the output turns out pipes that are afraid of low temperatures and do not tolerate falls. Although such pipes are stored, as a rule, in cold rooms. And the transportation of products is not always treated appropriately. Therefore, buying plastic pipes with a damaged reinforced layer is quite realistic.

Presence of metallic compounds

Plastic pipes with metal connectors are often disappointing. Plastic and metal react differently to different temperatures and expand differently. So it can easily flow here. To avoid such troubles, you should not save, but buy really the best plastic pipes from reliable manufacturers.

Sellers confidently declare that plastic pipes will last 40 and even 50 years. And there really is some truth to that. After all, if you buy high-quality pipes, entrust their installation to professionals, and even follow all the rules of operation, the products will last for more than a dozen years. If the rules are not followed, then after a couple of years of service, problems may arise.

Perhaps we have forgotten some of the disadvantages of plastic pipes? Share your experience with these products in the comments.

Photographer from the United States changed his mind to eat lobster and put him at home in an aquarium, a new friend on YouTube earns a lot of money

Original version of serving tangerines, so that they look beautiful on the New Year’s table, and guests did not think where to put the peel