1002

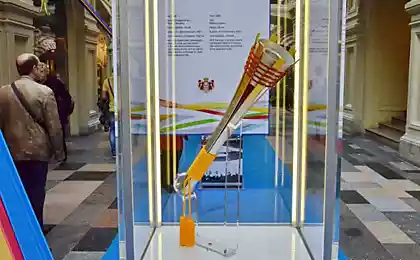

How to make medals for the Olympics in Sochi in 2014 (14 photos)

Production of medals for the Olympic Winter Games in Sochi in 2014 is engaged in a private company "Adamas»

Billets bronze and silver medals at the "Adamas" in Moscow, June 28, 2013. On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Photo: REUTERS / Sergei Karpukhin

Their creation will be spent not less than three kilograms of gold 999-carat, two tons of silver 960-carat and 700 kilos of bronze.

On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Results will be made in 1300 of gold, silver and bronze medals.

Olympic gold medals at the "Adamas" in Moscow, June 28, 2013. On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Photo: REUTERS / Sergei Karpukhin

Olympic gold medals are made of silver 960-carat (525 gram), and then covered with gold (at least 6 grams of 999-th test that sets the standard IOC). Silver consist of silver and weighs 525 grams, bronze - bronze (460 grams)

Work gets gold bullion for making Olympic gold medal at the "Adamas" in Moscow, June 28, 2013. On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Photo: REUTERS / Sergei Karpukhin

All precious metals are used for the needs of the Olympic Games in Russia mined and do sets of awards made only Russian experts

Work on the machine is working on a bronze medal at the "Adamas" in Moscow, 28 June 2013. On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Photo: REUTERS / Sergei Karpukhin

They produce medals in a single shop. There are medals all stages of manufacturing, from cutting round billet to the final polishing. Workflow for every coin consists of 25 stages. Most of them are associated with the processing of the metal strand (20 operations), and the rest - to the processing of polycarbonate / paste made from it as a patchwork quilt - one of the symbols of the Sochi-2014.

Operating working on Olympic silver medal at the "Adamas" in Moscow, June 28, 2013. On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Photo: REUTERS / Sergei Karpukhin

Fabrication starts with medals casting, rolling and cutting the workpiece, whereby the yield of metal squares of silver or bronze (depending on the merits of the coin), measuring 12 by 12 cm and a thickness of 12 mm. Then modern lathe cut from a square round billet 10 cm

Operating working on Olympic silver medal at the "Adamas" in Moscow, June 28, 2013. On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Photo: REUTERS / Sergei Karpukhin

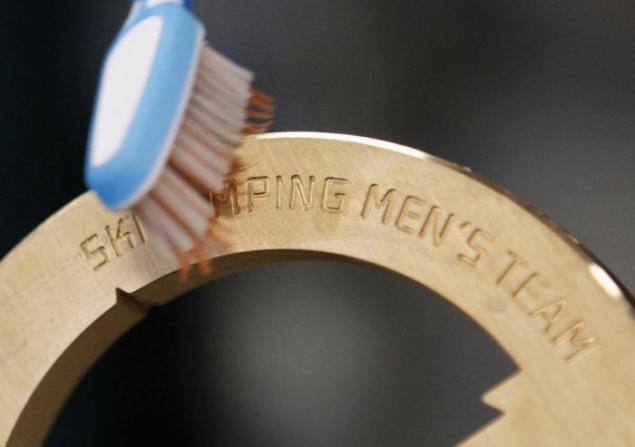

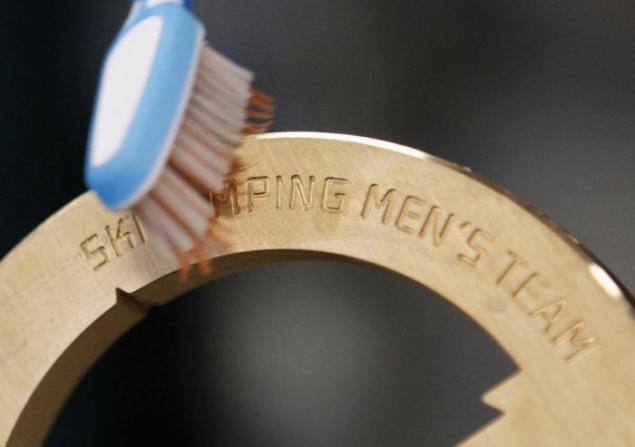

Workers use a brush to clean the bronze medal at the "Adamas" in Moscow, June 28, 2013. On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Photo: REUTERS / Sergei Karpukhin

Then the workpiece is sent to the milling, where the patterns are applied, the symbols of the Olympics, the names of disciplines. Prepared by the method of high-speed milling pocket under mounting tape

Operating working on Olympic silver medal at the "Adamas" in Moscow, June 28, 2013. On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Photo: REUTERS / Sergei Karpukhin

A full cycle of the same coin of any value - 18 hours. Production awards for the Paralympic Games in 20 hours, as there is a process that is not that of a normal coin. For example, the application of Braille is necessary for visually impaired and blind athletes.

Operating working on Olympic silver medal at the "Adamas" in Moscow, June 28, 2013. On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Photo: REUTERS / Sergei Karpukhin

One of the main stages of the manufacture of medals is to insert a metal part of the elements made of polycarbonate, which is a piece of "patchwork of Sochi-2014". They are joined by special precision parts manufacturing. Match the size is measured in hundredths or thousandths of a micron. For this polycarbonate cools and is inserted into the body of the coin. Then it is heated and, due to the temperature drop, there is an expansion of elements and their mutual fixing. That is why the material of polycarbonate insert was chosen rather than glass. The reliability of the polymer is much higher, in addition, it is not necessary to glue.

Operating working on Olympic silver medal at the "Adamas" in Moscow, June 28, 2013. On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Photo: REUTERS / Sergei Karpukhin

Gold (left) and bronze medal at the "Adamas" in Moscow, June 28, 2013. On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Photo: REUTERS / Sergei Karpukhin

Then they cut out the coin box, which will be placed in polycarbonate crystals. After this award several times grind and wash - until the final receipt of the final type.

The factory promise: these medals will survive everything - joy bites winners, bathing in champagne accidentally falling on the asphalt from a great height, and even throws on the wall in the hearts of the award is not the dignity to which athletes expect.

Billets bronze and silver medals at the "Adamas" in Moscow, June 28, 2013. On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Photo: REUTERS / Sergei Karpukhin

Their creation will be spent not less than three kilograms of gold 999-carat, two tons of silver 960-carat and 700 kilos of bronze.

On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Results will be made in 1300 of gold, silver and bronze medals.

Olympic gold medals at the "Adamas" in Moscow, June 28, 2013. On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Photo: REUTERS / Sergei Karpukhin

Olympic gold medals are made of silver 960-carat (525 gram), and then covered with gold (at least 6 grams of 999-th test that sets the standard IOC). Silver consist of silver and weighs 525 grams, bronze - bronze (460 grams)

Work gets gold bullion for making Olympic gold medal at the "Adamas" in Moscow, June 28, 2013. On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Photo: REUTERS / Sergei Karpukhin

All precious metals are used for the needs of the Olympic Games in Russia mined and do sets of awards made only Russian experts

Work on the machine is working on a bronze medal at the "Adamas" in Moscow, 28 June 2013. On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Photo: REUTERS / Sergei Karpukhin

They produce medals in a single shop. There are medals all stages of manufacturing, from cutting round billet to the final polishing. Workflow for every coin consists of 25 stages. Most of them are associated with the processing of the metal strand (20 operations), and the rest - to the processing of polycarbonate / paste made from it as a patchwork quilt - one of the symbols of the Sochi-2014.

Operating working on Olympic silver medal at the "Adamas" in Moscow, June 28, 2013. On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Photo: REUTERS / Sergei Karpukhin

Fabrication starts with medals casting, rolling and cutting the workpiece, whereby the yield of metal squares of silver or bronze (depending on the merits of the coin), measuring 12 by 12 cm and a thickness of 12 mm. Then modern lathe cut from a square round billet 10 cm

Operating working on Olympic silver medal at the "Adamas" in Moscow, June 28, 2013. On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Photo: REUTERS / Sergei Karpukhin

Workers use a brush to clean the bronze medal at the "Adamas" in Moscow, June 28, 2013. On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Photo: REUTERS / Sergei Karpukhin

Then the workpiece is sent to the milling, where the patterns are applied, the symbols of the Olympics, the names of disciplines. Prepared by the method of high-speed milling pocket under mounting tape

Operating working on Olympic silver medal at the "Adamas" in Moscow, June 28, 2013. On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Photo: REUTERS / Sergei Karpukhin

A full cycle of the same coin of any value - 18 hours. Production awards for the Paralympic Games in 20 hours, as there is a process that is not that of a normal coin. For example, the application of Braille is necessary for visually impaired and blind athletes.

Operating working on Olympic silver medal at the "Adamas" in Moscow, June 28, 2013. On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Photo: REUTERS / Sergei Karpukhin

One of the main stages of the manufacture of medals is to insert a metal part of the elements made of polycarbonate, which is a piece of "patchwork of Sochi-2014". They are joined by special precision parts manufacturing. Match the size is measured in hundredths or thousandths of a micron. For this polycarbonate cools and is inserted into the body of the coin. Then it is heated and, due to the temperature drop, there is an expansion of elements and their mutual fixing. That is why the material of polycarbonate insert was chosen rather than glass. The reliability of the polymer is much higher, in addition, it is not necessary to glue.

Operating working on Olympic silver medal at the "Adamas" in Moscow, June 28, 2013. On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Photo: REUTERS / Sergei Karpukhin

Gold (left) and bronze medal at the "Adamas" in Moscow, June 28, 2013. On the jewelry factory "Adamas" in Moscow in full swing production of the medals for the Olympic Games in Sochi in 2014. Photo: REUTERS / Sergei Karpukhin

Then they cut out the coin box, which will be placed in polycarbonate crystals. After this award several times grind and wash - until the final receipt of the final type.

The factory promise: these medals will survive everything - joy bites winners, bathing in champagne accidentally falling on the asphalt from a great height, and even throws on the wall in the hearts of the award is not the dignity to which athletes expect.

False scientific facts (30 photos)

Optical illusion - the impression of a visible object or phenomenon