4609

Olympic medals

I suggest you along with the author of this reportage go to a jewelry factory, walk through the shops and see where all the same, and as awards are made to compete in the Winter Olympics "Sochi-2014" Gold medal consists of an average of 525 grams of silver 960 samples and 6 grams of gold 999.

Birth of medals begins in furnaces, where melted bronze and silver. Semi-continuous casting method is cast thick sheet metal. In the process of casting it can form pores and air to avoid this, the sheet metal is rolled on multi-ton mill.

Further, from a rolled sheet metal blank made medals - the square plates, which are placed in a furnace where it is heated with a protective atmosphere to a temperature of 180 degrees Celsius and kept for 2 hours to remove the internal stress in the next coin. She then slowly cooled.

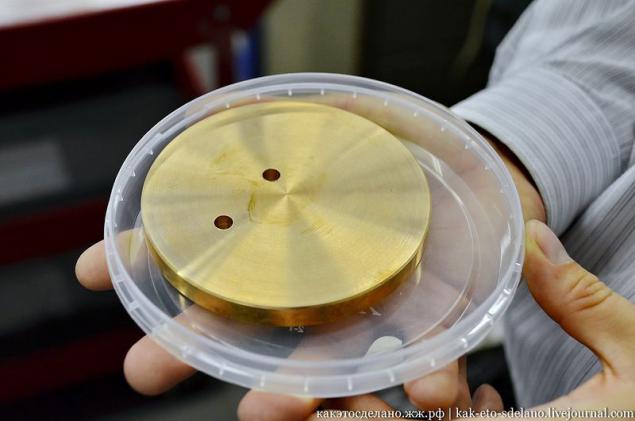

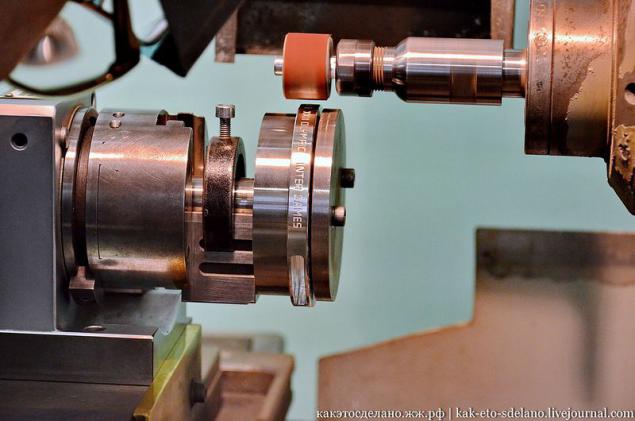

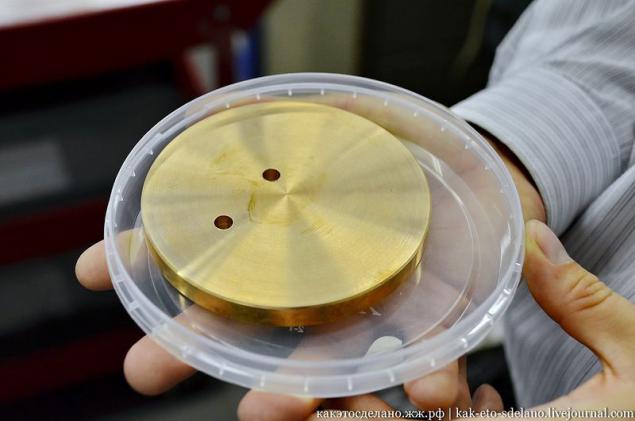

After cooling the workpiece falls first on one lathe, where the cut is such a washer, then a second, higher precision, where the turning of the workpiece. Case Diameter medal after these operations is 100 mm, thickness 10 mm.

After the treatment, nice to look at those shiny roundels.

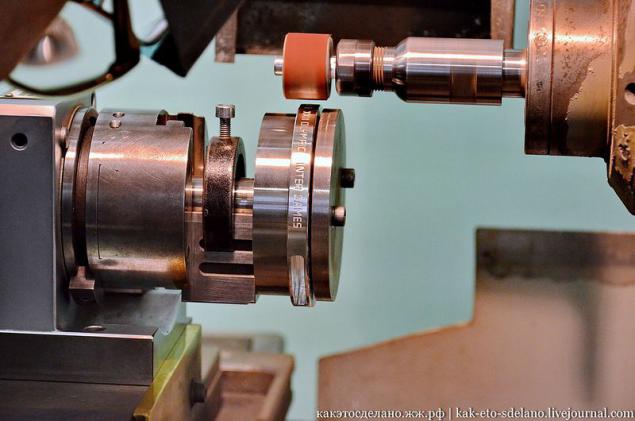

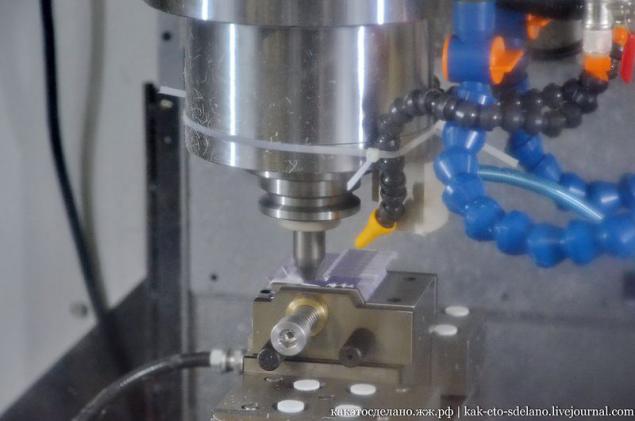

Then the "Puck" is placed in such a device, it is securely fixed in order

to make a preform technological holes for mounting the workpiece housing medals to technological devices.

These are neat hole.

Then the medal is attached through the holes on this device. Pay attention to the inscription.

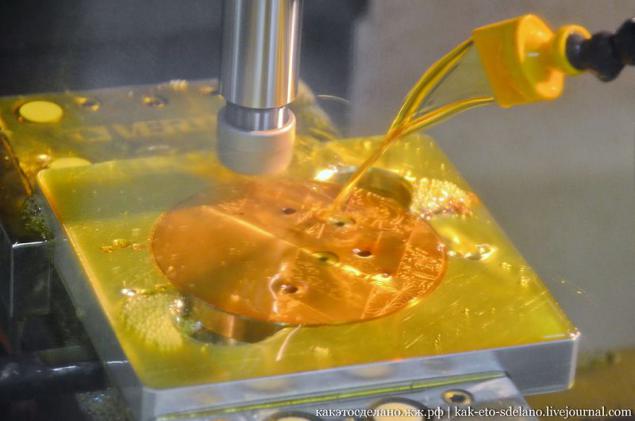

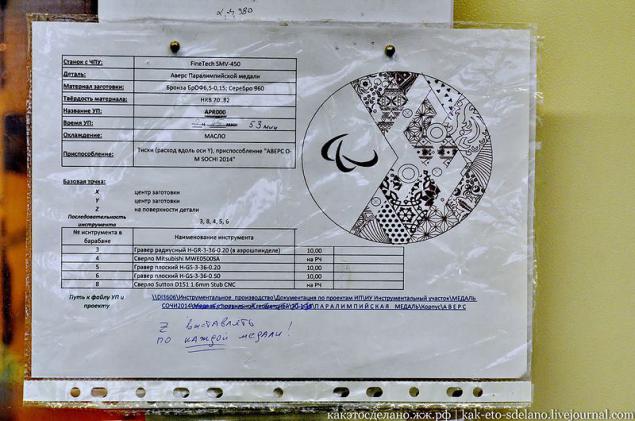

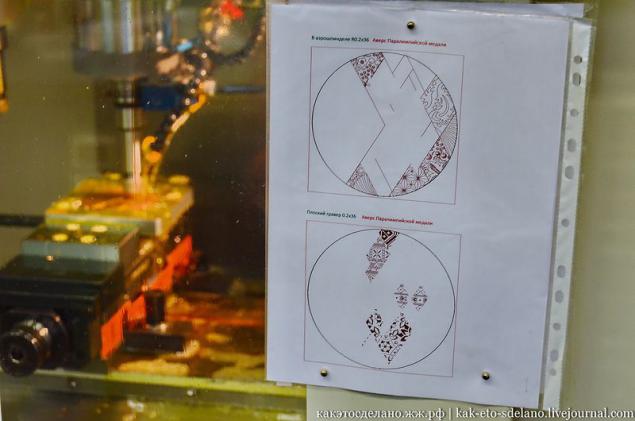

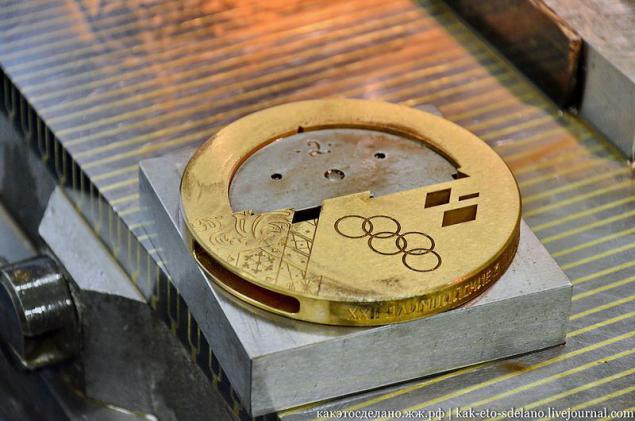

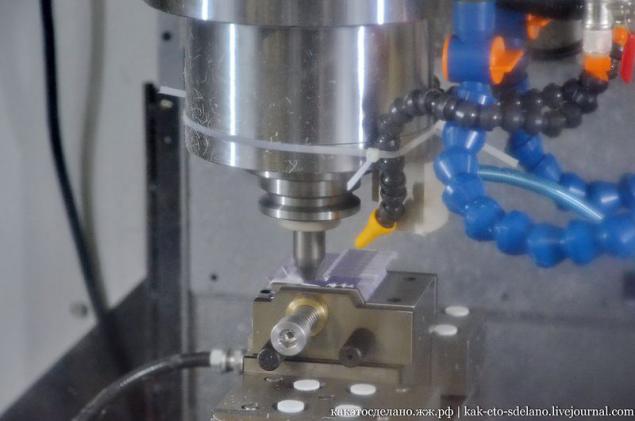

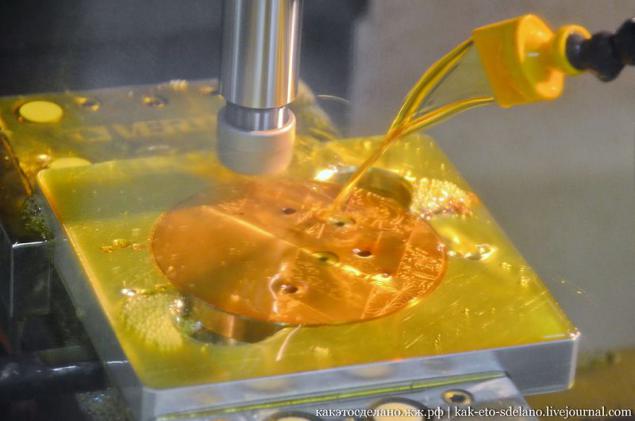

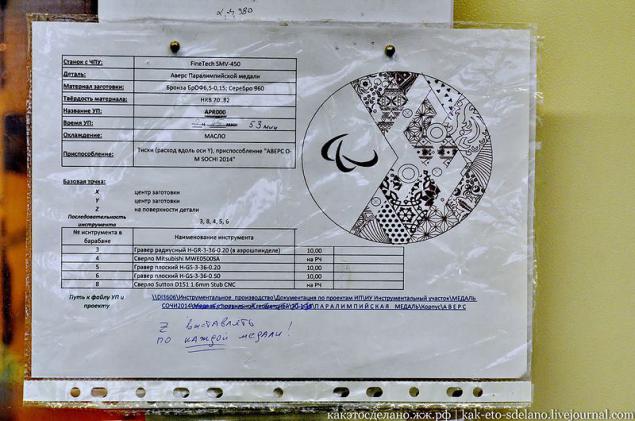

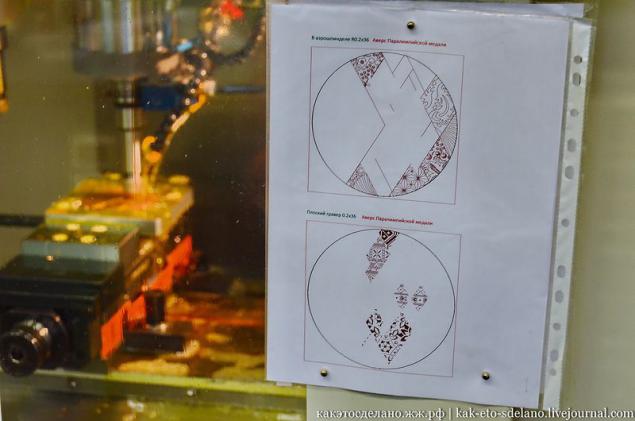

After that, the device enters into the workpiece precision machining centers, CNC, where the method of high-speed milling (Hight Speed Milling) is performed applying patterns and symbols of the Olympic Games - Olympic rings on the obverse of the coin

patterns, logos and names Olympiad Olympic disciplines on the reverse.

Then, on the same machine engraving is performed the official name of the Olympic Games in three languages on the Edge and pocket milling under mounting tape. All snap!

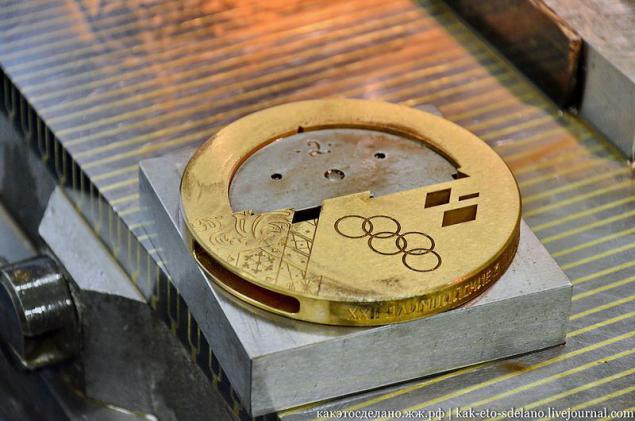

It looks like a bronze medal obverse Sochi Paralympic Games after the end of the milling process.

Then medal gets into the tub precision EDM wire-cut-out of the machine, where the method of electrical erosion of metal cutting is performed 4 crystals under windows.

Then, silver and gold medals applied maker's mark, testing is carried out on a sample of 960 compliance and branding in the state inspection of assay supervision.

After the holes are cut crystals (about them the story below), medal goes to a precision flat grinding machine, which grinds master obverse and reverse body medals, to give the desired texture of the obverse and reverse of the coin.

Resurfacing procedure behind, it's time to take ultrasonic bath, to throw off all the dirt medals.

The next operation - drilling holes for mounting pin fixing tape and Treating edges of the holes, which are held by masters needle files manually.

I went into the next room to see what was going on with the medal, and there leading NTV Kirill Kiknadze with a film crew to shoot the scene transfer about Olympic medals.

After edging the coin hit the tumbling. Very interesting process. Here in vibrogaltovochnom drum filled with stainless steel housing medal is processed, it is necessary to ensure the presentation.

Simply put, the body medals rubs against metal balls of different sizes in the water with detergent.

These are the balls.

Device with medals falls under the stream of water from the tap. But that's not all!

After these tortures medal goes to grinding machine, which produces pre-treatment The edge of the coin - surface preparation for polishing.

After grinding Edge gets a medal in polishing machines, which usually polished gold chains that are produced here, at the "Adamas".

After polishing medal once again gets in an ultrasonic bath.

The last step in the manufacture of olmpiyskih medals - assembly, connection metal part medals and crystals.

But before that, they must lie in the refrigerator at a temperature of -35 degrees to the crystals easily entered the grooves carved into the medals.

And even at room temperature crystal expand and stand so firmly that it would be almost impossible to remove it from the medals.

After the medal is ready, it is packaged in plastic and placed in a safe.

And now tell you about the crystals. They are cut from such a sheet of polycarbonate, which is similar to acrylic, but with properties far superior to him.

Thickness he is the same as a coin.

To cut crystals polycarbonate plant specialists was selected special cutter with a protective coating on the cutting edge.

On CNC cut from a sheet of polycarbonate crystals of different sizes.

When cutting polikarbonart cooled jet of compressed air, to reduce friction and deformation of the workpiece.

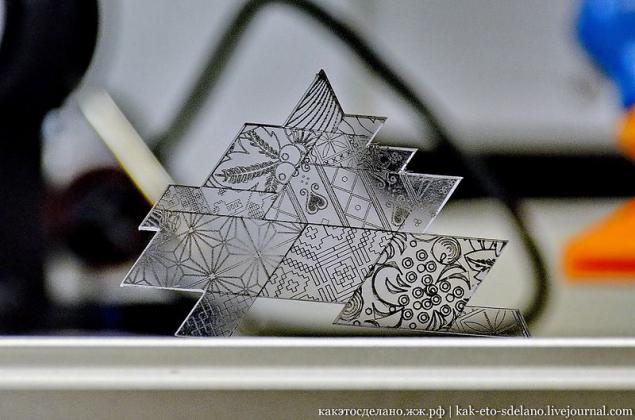

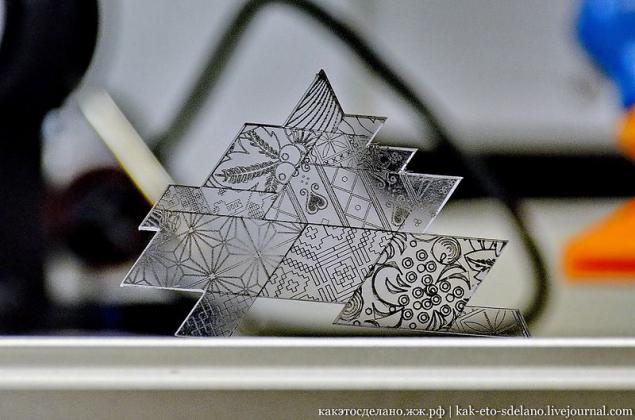

The result here is a carved leaf.

Ready crystals.

All laser crystal is dealt a pattern similar to those that have been engraved on the metal part of the coin.

To see this process take this piece of polycarbonate, climb to the third floor of the plant and go to the secret room through the door.

This equipment, which costs tens of thousands of euros will be processed crystals.

In the computer program is entered, select the desired pattern.

The laser causes pattern exactly in the middle of the crystal.

Yellow contraption - removal of combustion products with laser engraving.

Here's what happens in the end.

Like all processes of production looked Now go to the warehouse of finished products, see some details and go to the place where he designed the coin.

These pins are set to Edge medals and ribbons are used for fastening.

And these pins are set manually on the obverse Paralympic medals and are added to the symbols SOCHI2014 in Braille.

This think-tank plant, where he designed the coin.

Initially, in order to obtain the rights to manufacture the medals competition was held among the different companies. "Adamas" did a better version of the coin in accordance with the terms of reference of the Organizing Committee and won the competition. But prototyping medals were veiled under the anniversary of the plant, so that no one guessed the true purpose of the manufacture of the coin. It is easy to discern the features of the current award, which of course is different from the prototype.

This gold medal, but you have not seen it in the report because it actually - silver!) That is, it is within the silver, and the gold is covered in a plating bath (this stage is not in my reports) and becomes heavier silver medal by only 6 gram. However, it is thicker only a few microns, and to the naked eye did not see.

Gold medal consists of an average of 525 grams of silver 960 samples and 6 grams of gold of 999 tests.

Silver Medal - an average of 525 grams of silver 960 samples.

Bronze medal weighs an average of 460 grams.

Paralympic medals little harder: gold - 680 grams of silver 960 samples and 6 grams of gold of 999 tests. Pay attention to the Braille and the fact that these medals are no gaps, as in the usual Olympic medal in place of a large crystal.

Paralympic silver medal: on average, 680 grams of silver 960 samples

Bronze medal weighs an average of 585 grams.

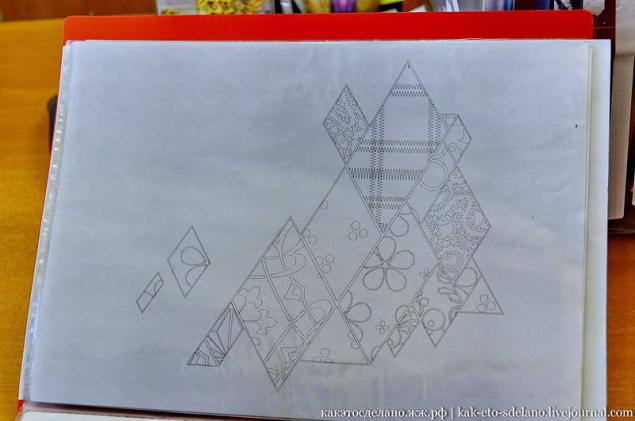

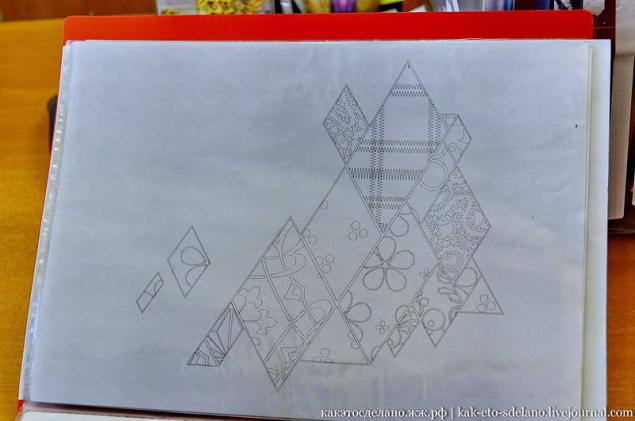

Total for the manufacture of medals will be used for at least 3 kg of gold 999, about 2 tons of silver 960 samples and not less than 700 kg bronze. Total produced about 1300 awards. Over 98 sets of 6,000 athletes will compete in seven Olympic sports. In the manufacture of the same coin takes about 20 hours (as much as I was preparing the material for the community). Here is a sketch of the figure, which is applied to the laser crystal.

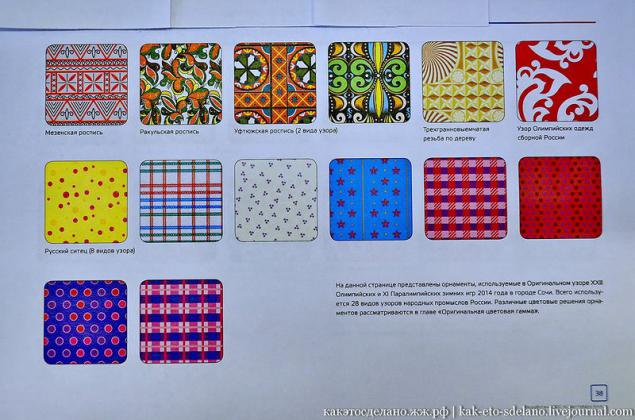

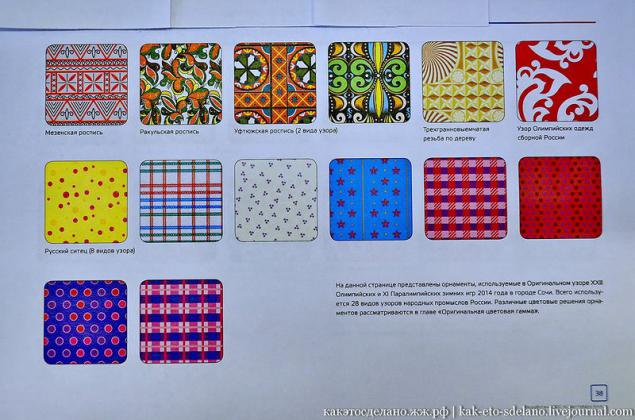

Pattern applied for the award by means of engraving is a mosaic of national patterns of peoples of Russia. Mezenskaya, rakulskaya, uftyuzhskaya painting, Russian chintz patterns.

Gzhel, Khokhloma, Palekh, Zhostovo, drawings pavlopasadskih shawls, Vologda lace, Yakut motives and even patterns Kubachi masters of Dagestan, almost all have these medals.

This options Olympic medals, which have remained sketches, they see the silhouette of Russia in the frame of the patterns or composed of them.

Medals past Olympics. I especially remember the Turin and Vancouver, very original made.

Source: kak-eto-sdelano.livejournal.com

Birth of medals begins in furnaces, where melted bronze and silver. Semi-continuous casting method is cast thick sheet metal. In the process of casting it can form pores and air to avoid this, the sheet metal is rolled on multi-ton mill.

Further, from a rolled sheet metal blank made medals - the square plates, which are placed in a furnace where it is heated with a protective atmosphere to a temperature of 180 degrees Celsius and kept for 2 hours to remove the internal stress in the next coin. She then slowly cooled.

After cooling the workpiece falls first on one lathe, where the cut is such a washer, then a second, higher precision, where the turning of the workpiece. Case Diameter medal after these operations is 100 mm, thickness 10 mm.

After the treatment, nice to look at those shiny roundels.

Then the "Puck" is placed in such a device, it is securely fixed in order

to make a preform technological holes for mounting the workpiece housing medals to technological devices.

These are neat hole.

Then the medal is attached through the holes on this device. Pay attention to the inscription.

After that, the device enters into the workpiece precision machining centers, CNC, where the method of high-speed milling (Hight Speed Milling) is performed applying patterns and symbols of the Olympic Games - Olympic rings on the obverse of the coin

patterns, logos and names Olympiad Olympic disciplines on the reverse.

Then, on the same machine engraving is performed the official name of the Olympic Games in three languages on the Edge and pocket milling under mounting tape. All snap!

It looks like a bronze medal obverse Sochi Paralympic Games after the end of the milling process.

Then medal gets into the tub precision EDM wire-cut-out of the machine, where the method of electrical erosion of metal cutting is performed 4 crystals under windows.

Then, silver and gold medals applied maker's mark, testing is carried out on a sample of 960 compliance and branding in the state inspection of assay supervision.

After the holes are cut crystals (about them the story below), medal goes to a precision flat grinding machine, which grinds master obverse and reverse body medals, to give the desired texture of the obverse and reverse of the coin.

Resurfacing procedure behind, it's time to take ultrasonic bath, to throw off all the dirt medals.

The next operation - drilling holes for mounting pin fixing tape and Treating edges of the holes, which are held by masters needle files manually.

I went into the next room to see what was going on with the medal, and there leading NTV Kirill Kiknadze with a film crew to shoot the scene transfer about Olympic medals.

After edging the coin hit the tumbling. Very interesting process. Here in vibrogaltovochnom drum filled with stainless steel housing medal is processed, it is necessary to ensure the presentation.

Simply put, the body medals rubs against metal balls of different sizes in the water with detergent.

These are the balls.

Device with medals falls under the stream of water from the tap. But that's not all!

After these tortures medal goes to grinding machine, which produces pre-treatment The edge of the coin - surface preparation for polishing.

After grinding Edge gets a medal in polishing machines, which usually polished gold chains that are produced here, at the "Adamas".

After polishing medal once again gets in an ultrasonic bath.

The last step in the manufacture of olmpiyskih medals - assembly, connection metal part medals and crystals.

But before that, they must lie in the refrigerator at a temperature of -35 degrees to the crystals easily entered the grooves carved into the medals.

And even at room temperature crystal expand and stand so firmly that it would be almost impossible to remove it from the medals.

After the medal is ready, it is packaged in plastic and placed in a safe.

And now tell you about the crystals. They are cut from such a sheet of polycarbonate, which is similar to acrylic, but with properties far superior to him.

Thickness he is the same as a coin.

To cut crystals polycarbonate plant specialists was selected special cutter with a protective coating on the cutting edge.

On CNC cut from a sheet of polycarbonate crystals of different sizes.

When cutting polikarbonart cooled jet of compressed air, to reduce friction and deformation of the workpiece.

The result here is a carved leaf.

Ready crystals.

All laser crystal is dealt a pattern similar to those that have been engraved on the metal part of the coin.

To see this process take this piece of polycarbonate, climb to the third floor of the plant and go to the secret room through the door.

This equipment, which costs tens of thousands of euros will be processed crystals.

In the computer program is entered, select the desired pattern.

The laser causes pattern exactly in the middle of the crystal.

Yellow contraption - removal of combustion products with laser engraving.

Here's what happens in the end.

Like all processes of production looked Now go to the warehouse of finished products, see some details and go to the place where he designed the coin.

These pins are set to Edge medals and ribbons are used for fastening.

And these pins are set manually on the obverse Paralympic medals and are added to the symbols SOCHI2014 in Braille.

This think-tank plant, where he designed the coin.

Initially, in order to obtain the rights to manufacture the medals competition was held among the different companies. "Adamas" did a better version of the coin in accordance with the terms of reference of the Organizing Committee and won the competition. But prototyping medals were veiled under the anniversary of the plant, so that no one guessed the true purpose of the manufacture of the coin. It is easy to discern the features of the current award, which of course is different from the prototype.

This gold medal, but you have not seen it in the report because it actually - silver!) That is, it is within the silver, and the gold is covered in a plating bath (this stage is not in my reports) and becomes heavier silver medal by only 6 gram. However, it is thicker only a few microns, and to the naked eye did not see.

Gold medal consists of an average of 525 grams of silver 960 samples and 6 grams of gold of 999 tests.

Silver Medal - an average of 525 grams of silver 960 samples.

Bronze medal weighs an average of 460 grams.

Paralympic medals little harder: gold - 680 grams of silver 960 samples and 6 grams of gold of 999 tests. Pay attention to the Braille and the fact that these medals are no gaps, as in the usual Olympic medal in place of a large crystal.

Paralympic silver medal: on average, 680 grams of silver 960 samples

Bronze medal weighs an average of 585 grams.

Total for the manufacture of medals will be used for at least 3 kg of gold 999, about 2 tons of silver 960 samples and not less than 700 kg bronze. Total produced about 1300 awards. Over 98 sets of 6,000 athletes will compete in seven Olympic sports. In the manufacture of the same coin takes about 20 hours (as much as I was preparing the material for the community). Here is a sketch of the figure, which is applied to the laser crystal.

Pattern applied for the award by means of engraving is a mosaic of national patterns of peoples of Russia. Mezenskaya, rakulskaya, uftyuzhskaya painting, Russian chintz patterns.

Gzhel, Khokhloma, Palekh, Zhostovo, drawings pavlopasadskih shawls, Vologda lace, Yakut motives and even patterns Kubachi masters of Dagestan, almost all have these medals.

This options Olympic medals, which have remained sketches, they see the silhouette of Russia in the frame of the patterns or composed of them.

Medals past Olympics. I especially remember the Turin and Vancouver, very original made.

Source: kak-eto-sdelano.livejournal.com